脉冲频率对铁基粉末脉冲电流烧结过程的影响

龙 雁, 李元元, 李小强, 邱 诚, 罗宗强

(华南理工大学 机械工程学院, 广州 510640)

摘 要: 采用脉冲频率为0、 50和100Hz的电流对高能球磨铁基粉末进行脉冲电流烧结, 并研究脉冲频率对粉末的致密化行为、 烧结材料的显微组织和力学性能的影响。 结果表明, 通电烧结初期脉冲电流烧结样品的密度和硬度均高于直流电流烧结的试样, 但通电烧结后期使用脉冲电流与直流电流所烧结样品的密度和硬度差别不大; 相同烧结温度下不同脉冲频率烧结试样的横向断裂强度的相对大小为σ50Hz>σ100Hz>σ0Hz; 当烧结温度为1100℃时, 不同脉冲频率下所获得的烧结材料的显微组织没有显著差别。

关键词: 铁基粉末; 脉冲电流烧结; 脉冲频率; 显微组织; 力学性能 中图分类号: TF124.5

文献标识码: A

Effect of pulse frequency on pulsed electric current sintering process of iron-based powders

LONG Yan, LI Yuan-yuan, LI Xiao-qiang, QIU Cheng, LUO Zong-qiang

(School of Mechanical Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: The iron-based powders prepared by high-energy ball-milling were sintered by means of pulsed electric current sintering (PECS) at various pulse frequencies (0, 50 and 100Hz). The effects of pulse frequency on the densification behavior of powder as well as the microstructure and mechanical properties of as-sintered specimen were investigated. The results show that during the initial sintering stage, the density and hardness of the specimen sintered with pulsed current are higher than those of the specimen sintered with direct current. Whereas, this difference is not obvious during the later sintering stage. When the sintering temperature is the same, the relative transverse rupture strength of the specimens sintered at various pulse frequencies is σ50Hz>σ100Hz>σ0Hz. No obvious difference can be found from the microstructures of specimen sintered at various pulse frequencies under the sintering temperature of 1100℃.

Key words: iron-based powders; pulsed electric current sintering; pulse frequency; microstructure; mechanical property

20世纪80年代以来, 脉冲电流烧结(pulsed electric current sintering, PECS)技术获得了迅速发展。 与常规烧结、 热压和热等静压等烧结方法相比, 脉冲电流烧结具有升温速率快, 烧结温度低, 烧结时间短, 烧结材料密度高等突出特点[1-3], 因此在各种陶瓷、 金属、 复合材料、 纳米材料等新材料的制备和研究中得到了广泛应用[4-9]。

电流的脉冲频率是脉冲电流烧结中的一个重要参数。 一些研究者试图研究脉冲次数(脉冲频率)对烧结材料组织和性能的影响, 并在此基础上分析脉冲电流在烧结过程中所起的特殊作用, 但至今仍未得出一致的结论。 研究表明, 随着脉冲频率的增加, 铜粉坯体的电阻率下降, 从而认为脉冲电流能有效地摧毁铜颗粒表面的氧化膜[10]。 Wang等[11]发现先对铜粉施加脉冲电流可提高随后电阻加热的升温速率。 XIE等[12]认为在致密化后期脉冲频率对铝粉脉冲电流烧结材料的密度、 显微组织、 电阻率和抗拉强度并没有明显影响, 不同脉冲频率下烧结活化能的差异也不大。

为了了解脉冲频率对粉末脉冲电流烧结过程的影响, 本文采用不同脉冲频率(0, 50和100Hz)对球磨铁基粉末进行脉冲电流烧结, 并研究脉冲频率对粉末致密化过程、 烧结材料的显微组织和力学性能的影响规律。

1 实验

实验采用的原料粉末及其粒径为: 铁粉(〈 150μm)、 铜粉(〈 75μm)、 镍粉(3~5μm)、 钼粉(〈 75μm)和石墨粉(2~3μm)。 将元素粉末按Fe94%、 Cu2%、 Ni2%、 Mo1%、 C1%(质量分数)的成分配比混合后, 放入QM-2SP行星式高能球磨机中球磨 40h, 球料比为 15∶1, 球磨机转速为 226r/min, 球磨介质为高纯氩气。 采用自行研制的脉冲电流烧结装置[13]对球磨铁基粉末进行烧结。 阴模和上下模冲分别采用Al2O3陶瓷和高强石墨制成。 对球磨粉末通以有效电流强度为 1389A的直流电流(脉冲频率为0Hz)和方波脉冲电流(脉冲频率为 50Hz和 100Hz), 其中脉冲电流的峰值电流为 3000A, 基值电流为 120A。 通过嵌入模具的热电偶测量粉末温度, 热电偶测量点距离粉体约2mm。 烧结温度分别为800, 900, 1000, 1050和1100℃, 当测量温度达到指定烧结温度后, 切断电源, 使试样随模空冷至室温。 粉末的测量温度达到1100℃所需的通电时间约为70s。 烧结过程中还施加了27.7MPa的恒定压力。

在JEOL-6460LA扫描电子显微镜上进行粉末试样的形貌分析, XRD分析在D/max-IIIA型日本理学全自动X射线衍射仪上进行, Cu靶, 加速电压50kV。 采用近似函数法, 用衍射峰的半高宽和位置计算出球磨铁粉的晶粒尺寸和晶格畸变。 烧结试样的密度采用阿基米德原理测量, 显微组织用OLYMPUS PME3光学金相显微镜进行分析, 洛式硬度测试和横向断裂强度分别在TIME TH320型硬度计和新三思CMT5105型微机控制万能试验机上进行。

2 结果与讨论

2.1 球磨粉末的性能

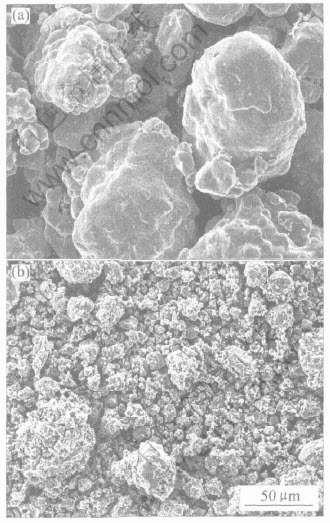

图1所示为球磨前后铁基粉末的SEM像。 由图1可见, 球磨前的雾化铁粉表面较圆滑, 球磨以后粉末经历不断的破碎和焊合过程表面变得凹凸不平, 颗粒的平均直径也比球磨前显著减小, 较细小的颗粒直径仅几微米, 细颗粒有团聚的倾向, 团聚体的直径达到了20~50μm。 图2所示为球磨前后铁基粉末的X射线衍射谱。 从该图可以看出, 粉末

图1 球磨前后铁基粉末的SEM形貌

Fig.1 SEM images of iron-based powders before(a)and after(b)ball-milling

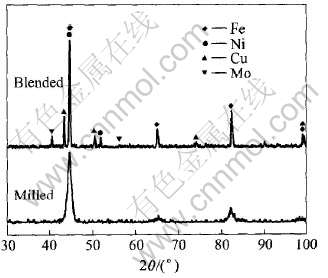

图2 铁基粉末的X射线衍射谱

Fig.2 XRD patterns of iron-based powders

经球磨后既没有新的衍射峰产生, α-Fe的衍射峰也没有发生偏移, 因此球磨过程中未发生明显的反应和固溶。 此外, 经球磨后α-Fe的衍射峰明显宽化, 衍射峰的宽化效应是铁粉在球磨过程中发生晶粒细化和晶格畸变的结果。 近似函数法计算结果表明, 球磨后铁粉的平均晶粒尺寸已下降至10.9nm, 同时晶格畸变达到0.377×10-3。

2.2 脉冲频率对致密化过程的影响

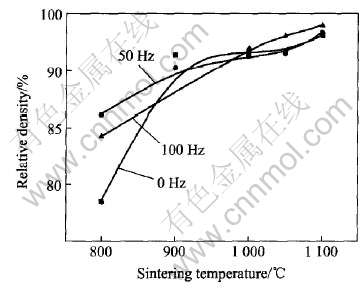

图3所示为脉冲频率分别为 0、 50和100Hz时球磨粉末的烧结致密化曲线。 由该图可见, 在不同的脉冲频率下, 随着烧结温度的上升, 粉末坯体的密度均逐渐提高。 当烧结温度为 800℃时, 采用频率为50Hz和100Hz的脉冲电流所烧结试样的密度高于直流电流烧结的试样。 但当烧结温度继续上升时, 不同脉冲频率烧结试样的密度变得较为接近。 经过高能机械球磨后, 铁基粉末的颗粒和晶粒细化, 晶格畸变增加, 粉末的烧结活性提高, 因此当烧结温度达到1100℃时, 不同脉冲频率下获得的最终烧结试样的相对密度均达到了98.1%~98.9%。

图3 脉冲频率对烧结试样密度的影响

Fig.3 Effect of pulse frequency on density of sintered specimen

当烧结温度为 800℃时, 脉冲电流烧结试样的密度高于直流电流烧结的试样。 其原因主要是: 通电烧结初期, 粉末坯体的密度较低, 当电流流经粉末时, 粉末颗粒接触区域的电流密度较高, 该区域的局部温度将高于粉末整体的平均温度。 这必然导致颗粒界面微区的金属强度降低, 塑性变形加剧, 甚至局部熔化, 颗粒界面区域物质的粘塑性流动增强, 颗粒间发生相对运动的阻力减小, 从而促进粉末在外加压力下发生相对滑移和颗粒重排。 尽管本实验中采用了有效电流相同的脉冲电流和直流电流进行烧结, 但脉冲电流的峰值(3000A)远高于直流电流的电流强度(1389A), 因此与直流电流烧结相比, 脉冲电流烧结初期粉末颗粒界面区域的瞬时局部温度较高, 粉末的颗粒重排和致密化更迅速, 故其坯体的密度较高。

当烧结温度继续升高时, 粉末坯体的密度增加, 粉末颗粒之间的接触面积增大, 部分颗粒界面消失, 颗粒界面电阻减小, 颗粒内部与颗粒界面区域的温度差减小, 电流对粉末的加热方式由局部集中加热逐步转变为整体均匀加热, 粉末在温度场和应力场的共同作用下发生整体的塑性变形, 密度逐渐上升。 在有效电流强度相同的条件下, 脉冲电流与直流电流在粉末中所产生的温度场较为接近, 因此, 在烧结后期脉冲电流和直流电流烧结试样的密度并没有明显差异。

2.3 脉冲频率对烧结材料强度的影响

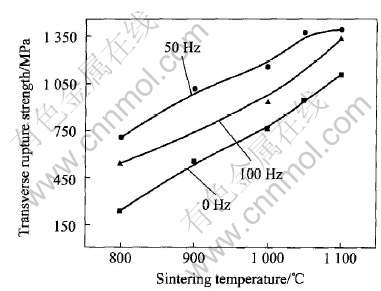

图4所示为采用不同脉冲频率烧结时烧结材料的横向断裂强度随烧结温度的变化曲线。 从该图可以发现, 在不同脉冲频率下, 随着烧结温度的升高, 烧结材料的强度均逐渐升高。 在 800~1100℃的温度区间, 脉冲电流烧结材料的强度均高于同样温度下直流电流烧结的材料, 并且 50Hz的脉冲电流所烧结材料的强度要高于 100Hz脉冲电流所烧结的材料。

本实验中所采用的通电烧结时间极短, 烧结试样的横向断裂强度不仅与其坯体密度有关, 更重要

图4 脉冲频率对烧结试样横向断裂强度的影响

Fig.4 Effect of pulse frequency on transverse rupture strength of sintered specimen

的是与粉末的烧结状况即颗粒间的界面结合强度有关。 当烧结温度为 800℃时, 脉冲电流烧结试样的密度高于直流电流烧结的试样, 因此在该温度下烧结材料的强度也表现出相应的规律。 当烧结温度在 900~1100℃之间时, 脉冲电流和直流电流烧结材料的密度相差不大, 但前者的强度却明显高于后者, 表明脉冲电流烧结试样中粉末颗粒之间的界面结合强度较高。 其原因在于: 1) 烧结初期脉冲电流可能在粉末颗粒间隙和颗粒接触界面诱发放电等离子体, 去除、 破坏粉末颗粒表面的氧化膜和其它杂质, 使粉末表面原子的活性增加, 经净化、 活化后的粉末在此后的烧结过程中更容易发生粘结, 形成烧结颈[14]; 2) 与直流电流烧结相比, 脉冲电流烧结初期粉末颗粒界面区域的局部瞬时温度较高, 将促进颗粒接触区域附近的原子扩散, 加快烧结颈的长大进程, 使粉末间的烧结更迅速、 更充分, 粉末间的结合强度更高。

然而, 当脉冲频率从50Hz增加到100Hz时, 在同样温度下铁基烧结材料的强度反而下降。 表明脉冲电流的活化烧结效果并未随着脉冲频率的增加而增加; 相反, 随着脉冲频率的上升, 脉冲周期缩短, 单次脉冲周期中峰值电流持续的时间减少, 反而使通电初期颗粒界面的瞬时局部温度下降, 不利于粉末间的烧结, 故粉末颗粒间的界面结合强度有所下降, 烧结材料的整体强度也随之下降。

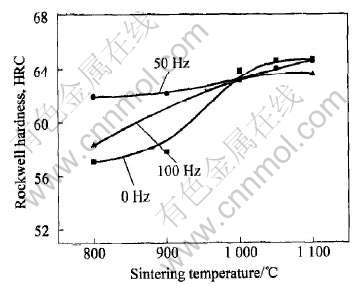

2.4 脉冲频率对烧结材料硬度的影响

图5所示为采用不同脉冲频率烧结时烧结材料的硬度随烧结温度的变化曲线。 从图中可见, 当烧结温度较低时, 不同脉冲频率烧结材料的硬度相对

图5 脉冲频率对烧结试样洛氏硬度的影响

Fig.5 Effect of pulse frequency on Rockwell hardness of sintered specimen

大小为HRC50Hz>HRC100Hz>HRC0Hz; 而在较高温度区间, 不同脉冲频率对烧结材料硬度的影响并不明显, 这一变化规律与图3中烧结材料密度的变化规律较为相似。 粉末烧结材料的宏观硬度主要与材料的密度和粉末颗粒本身的硬度(抗压强度)有关, 对颗粒界面的结合状况则并不像横向断裂强度那么敏感[15], 因此在烧结过程中烧结材料的硬度表现出与密度相似的变化规律。

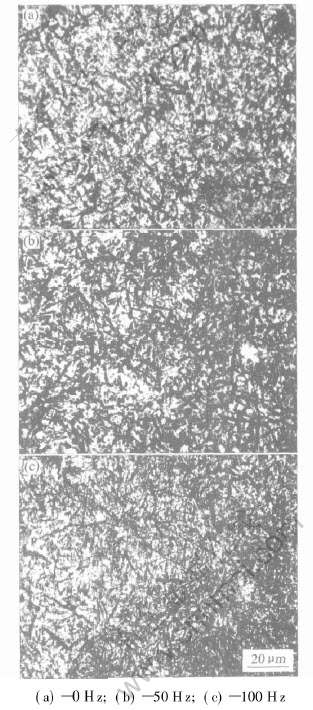

2.5 脉冲频率对烧结材料显微组织的影响

图6所示为脉冲频率对烧结材料显微组织的影响(最终烧结温度为1100℃)。 从图中可见, 在该

图6 脉冲频率对1100℃温度下烧结试样显微组织的影响

Fig.6 Effect of pulse frequency on microstructure of specimen sintered under 1100℃

温度下, 各烧结试样的显微组织都十分均匀、 致密, 看不到明显的孔隙, 在铁基体中密布着一些细长的针状贝氏体, 较长的达到10~20μm。

经过高能机械球磨以后, 铁基粉末的颗粒细化, 合金化元素在铁基粉末中弥散均匀分布, 不同成分的粉末颗粒间界面增多, 相互扩散距离缩短, 界面结合更紧密, 因此尽管通电烧结过程很短, 合金化元素已向奥氏体中迅速扩散, 合金化元素固溶于奥氏体中使奥氏体的稳定性增加, C-曲线右移, 从而使烧结材料在冷却过程中发生了贝氏体转变。 从针状贝氏体的长度来看, 各试样在高温下均发生了显著的晶粒长大, 烧结材料的组织已经从烧结前的纳米级长大至微米级。 在1100℃温度下不同脉冲频率烧结试样的显微组织并没有明显的差别。

3 结论

1) 脉冲频率对粉末坯体密度的影响主要表现在通电烧结初期, 与直流电流相比, 脉冲电流可提高粉末在烧结初期的致密化速率; 通电烧结后期采用不同脉冲频率的电流所烧结的试样密度差别不大。

2) 在各烧结温度下, 脉冲电流烧结材料的强度均高于直流电流所烧结的材料, 且 50Hz脉冲电流所烧结材料的强度要高于 100Hz脉冲电流所烧结的材料。 在测量温度相同的条件下, 脉冲电流比直流电流更能促进烧结颈的生成与长大, 提高颗粒的界面结合强度, 但脉冲频率并不是越高越好。

3) 当烧结温度较低时, 不同脉冲频率烧结材料的洛氏硬度的相对大小为HRC50Hz>HRC100Hz>HRC0Hz; 而在较高温度区间, 脉冲频率对烧结材料硬度的影响并不明显。

4) 当最终烧结温度为1100℃时, 不同脉冲频率下获得的烧结材料的显微组织没有显著差别。

REFERENCES

[1]Groza J R. Field activation provides improved sintering[J]. Metal Powder Report, 2000, 4: 16-18.

[2]Omori M. Sintering, consolidation, reaction and crystal growth by the spark plasma system(SPS)[J]. Mater Sci Eng A, 2000, A287: 183-188.

[3]Perera D S, Tokita M, Moricca S. Comparative study of fabrication of Si3N4/SiC composites by spark plasma sintering and hot isostatic pressing[J]. Journal of European Ceramic Society, 1998, 18: 401-404.

[4]张久兴, 刘科高, 周美玲. 放电等离子烧结技术的发展和应用[J]. 粉末冶金技术, 2002, 20(3): 129-134.

ZHANG Jiu-xing, LIU Ke-gao, ZHOU Mei-ling. Development and application of spark plasma sintering technology[J]. Powder Metallurgy Technology, 2002, 20(3): 129-134.

[5]张东明, 傅正义. 放电等离子加压烧结(SPS)技术特点及应用[J]. 武汉工业大学学报, 1999, 21(6): 15-32.

ZHANG Dong-ming, FU Zheng-yi. Characteristics and application of spark plasma sintering(SPS) technology[J]. Journal of Wuhan University of Technology, 1999, 21(6): 15-32.

[6]Srivatsan T S, Ravi B G, Naruka A S, et al. A study of microstructure and hardness of bulk copper sample obtained by consolidating nanocrystalline powders using plasma pressure compaction[J]. Mater Sci Tech A, 2001, A311: 22-27.

[7]Murakami T, Kitahara A, Koga Y M, et al. Microstructure of Nb-Al powders consolidated by spark plasma sintering process[J]. Mater Sci Eng A, 1997, 239-240: 672-679.

[8]ZHAN Guo-dong, Kuntz J, WAN Ju-lin, et al. Alumina-based nanocomposites consolidated by spark plasma sintering[J]. Scripta Materialia, 2002, 47: 737-741.

[9]Jung Y G, Ha C G, Shin J H, et al. Fabrication of functionally graded ZrO2/NiCrAlY composites by plasma activated sintering using tape casting and its thermal barrier property[J]. Mater Sci Eng A, 2002, A323: 110-118.

[10]陈立东, 王士维. 脉冲电流烧结的现状与展望[J]. 陶瓷学报, 2001, 22(3): 204-207.

CHEN Li-dong, WANG Shi-wei. Status and prospect of pulsed electric current sintering[J]. Journal of Ceramics, 2001, 22(3): 204-207.

[11]Wang S W, Chen L D, Kang Y S, et al. Effect of plasma activated sintering parameters on the densification of copper powder[J]. Materials Research Bulletin, 2000, 35: 619-628.

[12]XIE Guo-qiang, Ohashi O, Chiba K, et al. Frequency effect on pulse electric current sintering process of pure aluminum powder[J]. Mater Sci Eng A, 2003, A359: 384-390.

[13]LI Yuan-yuan, LONG Yan, LI Xiao-qiang, et al. Fast consolidation of iron powders by pulse electric current sintering[J]. Materials Science Forum, 2004, 471: 225-229.

[14]Groza J R, Zavaliangos A. Sintering activation by external electrical field[J]. Mater Sci Eng A, 2000, A287: 171-177.

[15]Livne Z, Munitz A, Rawers J C, et al. Consolidation of nanoscale iron powders[J]. Nanostructured Materials, 1998, 10(4): 503-522.

(编辑李向群)

基金项目: 国家杰出青年科学基金资助项目(50325516); 广东省科技攻关资助项目(2003A1070302)

收稿日期: 2006-07-12; 修订日期: 2006-11-17

通讯作者: 龙 雁, 博士; 电话: 020-87113832; E-mail: ylong1@scut.edu.cn