DOI: 10.11817/j.issn.1672-7207.2019.09.010

螺纹硬态旋风铣削轴承钢GCr15切屑形貌及特性试验研究

何彦1,白云龙1,李丽2,王禹林3,李育锋1,易力力1

(1. 重庆大学 机械传动国家重点实验室,重庆,400030;

2. 北京机床研究所,北京,100102;

3. 南京理工大学 机械工程学院,江苏 南京,210094)

摘要:为了揭示螺纹硬态旋风铣削的材料去除和切屑微观锯齿成形机理,采用金相显微镜、扫描电镜(SEM)和纳米压痕法硬度测试等对淬硬轴承钢GCr15的旋风铣削切屑的锯齿形貌几何特征、显微结构和纳米硬度进行试验研究,观测并分析其在切屑上的分布及变化规律,并讨论锯齿节在切削力、热作用下的形成机理。研究结果表明:旋风铣削切屑微观锯齿高度、齿距、锯齿化程度、倾斜角和变形系数在长度方向上存在波动;显微结构和纳米硬度在宏观切屑长度上和微观锯齿上分布不均匀;绝热剪切带和第二变形区的材料经历了剧烈的剪切变形和二次淬火,其硬度高于内部基体和未加工工件表面的硬度。这解释了锯齿特征波动的原因,说明单次切削过程中力、热条件的不稳定性。

关键词:螺纹硬态旋风铣削;锯齿形貌;显微结构;纳米硬度;轴承钢GCr15

中图分类号:TG501.1 文献标志码:A 文章编号:1672-7207(2019)09-2138-10

Experimental investigation on chip morphology and properties in thread hard whirlwind milling of bearing steel GCr15

HEYan 1, BAI Yunlong 1, LI Li2, WANG Yulin3, LI Yufeng1, YI Lili1

(1. State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing 400030, China;

2. Beijing Machine Tool Research Institute, Beijing100102, China;

3. School of Mechanical Engineering, Nanjing University of Science and Technology, Nanjing 210094, China)

Abstract: Aiming to reveal the mechanism of material removing and serrated chip forming in thread hard whirlwind milling process, the experimental investigation on the geometrical characteristics of saw-tooth morphology, microstructure and nanohardness of chips obtained from the whirlwind milling of hardened bearing steel GCr15 was conducted by metallographic, scanning electron microscope (SEM) and nanoindentation hardness test, and their distribution and variation were measured and analyzed. The saw-tooth formation mechanism under the effect of cutting force and heat were discussed. The results indicate that there are fluctuations of saw-tooth height, pitch, segmentation degree, inclination angle and deformation coefficient in the length direction of chips. The distributions of microstructure and nanohardness along the chip length and on the micro-sawtooth are not uniform. Materials in the adiabatic shear bands and secondary deformation zones undergo severe shear deformation and secondary quenching, of which the hardness is higher than that of the chip matrices and unmachined workpiece surface. These results explain the cause of the saw-tooth feature fluctuations and illustrate the instability of the force and heat conditions during single cutting.

Key words: thread hard whirlwind milling; saw-tooth morphology; microstructure; nanohardness; bearing steel GCr15

硬态旋风铣削是一种应用于螺纹加工的干式高速硬铣削,它具有高效、精密、低能耗、绿色环保的优势[1-3]。该加工过程中会产生锯齿形切屑,切屑的锯齿形成过程伴随着切削力波动,而这一波动会对刀具的振动和磨损以及工件的表面完整性产生影响[4-7]。切屑的显微结构和硬度的分布反映了其在切削过程中复杂的力、热影响下的塑性变形,更深入地揭示了切屑形成的机理[8-15]。因此,研究旋风铣削锯齿形切屑形貌及其特性十分必要。由于切屑的微观形貌、显微结构和硬度是理解切削加工机理的重要指标,对评估加工性能有重要作用,前人已对传统机加工切屑进行了大量研究。杜劲等[16]在镍基高温合金FGH95和Inconel718的高速铣削加工切屑上观测到明显的锯齿化现象。WAN等[15]对钛合金Ti6Al4V车削锯齿形切屑上绝热剪切带的微观结构展开了试验性研究,结果表明,Ti6Al4V锯齿形切屑形成过程中第一剪切区内的破坏性失效在很大程度上取决于工件材料的绝热剪切敏感性。PU等[17]通过观察高速切削下AISI 1045钢切屑的变形情况,发现了第二剪切区的动态再结晶动态行为,揭示了切屑形貌与平衡剪切角的关系。WANG等[18]在扫描电镜下观察了镍基高温合金Inconel718切屑在正交切削下的变形和断裂情况,发现锯齿形切屑是在结合了韧性断裂的塑性变形机理下产生的。合烨等[19]通过Abaqus/Explicit建立热学-力学正交切削有限元模型,探析了GCr15淬硬轴承钢在硬态车削下锯齿切屑的形成过程及机理,认为绝热剪切机理是形成锯齿状切屑的前提,而微裂纹的出现和扩展源于绝热剪切作用下材料发生的韧性断裂。高延峰等[20-21]从三维形貌特征和微观组织结构方面对近α高温钛合金BTi-6431S的铣削切屑进行了研究,并对比分析了钛合金Ti-6Al-4V和Ti-10V-2Fe-3Al的激光辅助铣削切屑形貌,发现上述切屑在传统铣削条件下均呈现出锯齿状并伴有明显的剪切带,而在激光辅助条件下则呈现出从锯齿型向连续型的过渡,且钛合金Ti-10V-2Fe-3Al切屑的绝热剪切带消失。SUN等[22]测量了钛合金Ti6Al4V端铣加工切屑不同截面上显微硬度的分布:在切屑极顶面上的硬度高于邻近表面的下层硬度;硬度在剪切带处增加;横截面表面不同区域的显微硬度表现出差异。KANANI等[13]通过观察大应变机械加工产生的连续超细晶粒切屑发现:显微硬度和剪切应变随切削速度的变化呈现相反的关系,最小的显微硬度正好出现在最大的剪切应变处和最大接触长度处。虽然在传统切削加工方面,针对切屑形态、显微结构和硬度的研究已十分充分,但是旋风铣削是一种特殊的多刀具断续渐进切削加工方法,通过刀具工件系统的多自由度耦合运动实现螺纹切削,故其切屑形成过程有别于普通车削、铣削切屑,切屑横截面形状是时变且不规则的,且微观形貌规律也可能与之存在较大差异。因此,不同工艺对象的研究结论难以支持硬态旋风铣削切屑形态及特性。在旋风铣削切屑方面,针对加工切屑形貌已有相关试验性文献。朱红雨等[23-24]对旋风铣削切屑的宏、微观形貌展开研究,指出了锯齿状切屑的微观形貌和宏观形貌的本质区别,并分析了微观锯齿形态与工艺参数的关系。但目前的研究都没有考虑由旋铣切屑的时变特性所引发的微观锯齿特征分布的不一致性,也未对切屑显微组织和硬度分布进行深入探讨。为了进一步理解旋铣加工的材料去除及切屑形成机理,本文作者对GCr15的丝杠旋风铣削切屑的微观形态以及力学特性开展试验性研究。分析了切屑形貌、显微结构和纳米硬度的分布情况,以此来探析加工过程中的力、热及材料变形现象。实验结果将为进一步研究这一加工方式的机理提供支持,并为改善实际加工时的加工质量和提高刀具寿命提供指导。

1 基于旋风铣削加工原理的理论未变形切屑形态描述

旋风铣削加工原理如图1所示。多把成型刀具均匀对称地安装在刀盘上,刀盘轴线与工件轴线存在偏心距e,且两轴线夹角θ等于螺纹的螺旋角。加工时,工件低速旋转,转速为nw,刀盘以高转速nt进行同向旋转,工件每旋转1周,刀盘以进给速度f沿工件轴线方向移动1个导程,从而实现整个螺纹滚道的加工。

由于工件被断续切削,形成的切屑也是断续的短屑。根据旋铣加工螺纹滚道渐进成形原理,使用软件UG的布尔运算功能建立的旋铣未变形切屑的3D模型说明了其横截面的演变,如图2(a)和(b)所示。未变形切屑被分成了6段以展示其形成时横截面在不同位置的形状。从图2可以看出,切屑的横截面呈“C”形或类似“新月”形,且形状、厚度沿长度方向不断变化。为了表征未变形切屑厚度,取切屑宽度方向上的二等分的纵截面(中间纵截面)与横截面的交线长度hD来说明未变形切屑厚度的变化规律(图2(c))。以中间纵截面切屑底边长度为切屑长度。

2 实验步骤

2.1 实验设备及方案

实验材料为淬硬轴承钢GCr15(纳米硬度约为7.35 GPa)。实验样件长×宽为6 000 mm×80 mm,样件经过表面低频淬火以保证丝杠的耐磨性和疲劳寿命。GCr15的化学组成和材料性能分别见表1和表2。实验所用刀具如图3所示,其材料为聚晶立方氮化硼(PCBN),切削刃轮廓形状为圆弧,刀具前角γo为 -8°。刀块安装在刀盘上,刀尖的回转直径为90 mm。由于使用高压空气冷却,切削过程不采用切削液。旋铣试验在中国汉江机床有限公司开发的数控旋风铣机床上进行,该机床最大丝杠加工长度为8 m。实验采用顺铣切削方式。切削速度vt、切削深度ap和刀具个数z均选用厂家推荐的常用参数,每组切削条件下的实验重复进行3次。

图1 旋铣加工运动原理图

Fig. 1 Machining kinematic principle in whirlwind milling

图2 未变形切屑横截面的变化

Fig. 2 Evolution of cross sections of undeformed chip

图3 PCBN刀具

Fig. 3 PCBN tool

表1 GCr15轴承钢的化学组成(质量分数)

Table 1 Chemical composition of GCr15 bearing steel%

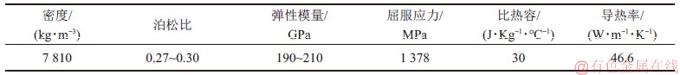

表2 室温下淬硬轴承钢GCr15的材料特性

Table 2 Material properties of GCr15 bearing steel at room temperature

2.2 样品制备与测量

为了研究切屑的形态和力学特性,对每组旋铣实验产生的切屑进行收集。截取特定截面,并冷镶嵌在树脂中,抛光到指定观测位置,然后用体积分数为4%的硝酸酒精溶液腐蚀3 s,最后在无水乙醇中清洗后烘干。在超景深三维系统VHX-1000C下观察切屑的锯齿形貌特征。采用扫描电镜TESCAN VEGA 3 LMH观察切屑金相组织的转变和变形。采用纳米原位力学测试设备Hysitron TI 950测量切屑的纳米硬度,压头为Berkovitch压头,峰值载荷为8 MN。为确保测量结果的可重复性,选取同一加工条件下的3条切屑分别制成样品并观测。在每个切屑上选取数个相邻的锯齿节测量切屑形态特征和硬度,取多次测量的平均值。

3 结果与讨论

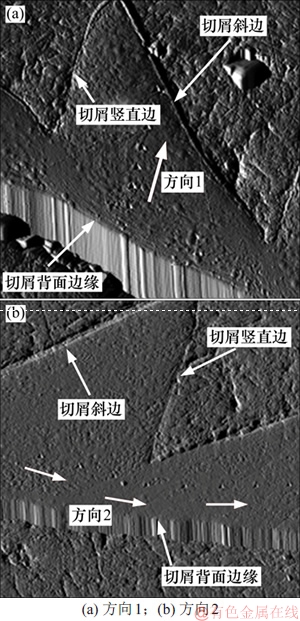

3.1 切屑锯齿形貌特征的分布规律

图4所示为旋铣加工实验得到的切屑。由图4可以发现,分布锯齿的自由表面位于凸面一侧,而光滑的切屑背面位于凹面一侧。切屑被中间截断后,在截面上可以清楚地观察到锯齿形貌,故选择此面为观测面。在测量和分析中以锯齿高度H,齿根高度h、齿距PC、锯齿化程度GS、倾斜角α和切屑厚度变形系数Λh来表征切屑锯齿形貌,这些指标的测量方法如图5所示。锯齿化程度GS可用来表征切屑在不同的成形阶段的锯齿化剧烈水平,其定义为

(1)

(1)

若将切屑厚度从齿根到齿顶的变化近似视为线性增长,则可用H和h的平均值 来表示实验得到的切屑的平均厚度。

来表示实验得到的切屑的平均厚度。

图4 旋铣加工切屑锯齿分布

Fig. 4 Saw-tooth distribution on real chip of whirlwind milling

图5 锯齿几何特征

Fig. 5 Geometrical characteristics of saw-tooth

图6(a)所示为锯齿高度H、齿根高度h以及未变形切屑厚度hD在切屑长度上的分布曲线。其中,xL为测量点距起点的距离与切屑长度之比,未变形切屑厚度基于加工原理采用Mathematica仿真计算得到[25]。在每一刀切削过程中,未变形切屑厚度hD经历了从小到大,再由大变小的演变。从图6(a)可以看出,锯齿高度H在切屑开始形成时迅速增加至最大值,这呈现出与未变形的切屑厚度相似的变化趋势;此后,锯齿高度略有下降,并在到达中部之前一直保持平稳;切屑成形到中部以后H开始逐渐减小。这表明,在切屑长度的前5%部分(xL≤5%)以及后半段,未变形切屑厚度是影响锯齿高度的主导因素,而在xL=5%~50%部分,有其他因素限制了锯齿高度的降低。对比未变形切屑厚度hD和实验切屑锯齿高度H可知,在xL<25%部分,H小于hD,而当xL大于25%后,H一直大于hD;这说明实际切屑的锯齿高度变化不如理论未变形切屑厚度变化剧烈。通过比较实验切屑平均厚度havg与hD可以看出,havg总体上低于hD。经计算,未变形切屑理论长度为37.8 mm,实验切屑的平均长度为43.5 mm。这说明实验切屑在形成过程中由于受到刀具的剪切和挤压作用,切屑等效厚度因锯齿节的产生和滑移而变小。相应地,由体积不变原理可知,切屑长度会被“拉长”。变长的切屑意味着更长的刀-屑接触时间,这会使前刀面积累更多切削热,从而导致切削温度升高,刀具寿命缩短;此外,由于切屑特殊的卷曲形状,较长的切屑更容易引起切屑与刀具、切屑与切屑之间纠缠,不利于排屑,加剧前刀面的磨损,且加工表面容易被残留的切屑划伤,影响工件质量。

图6 锯齿特征分布(vt=200 m/min, ap=0.08 mm, z=3)

Fig.6 Distribution of saw-tooth features (vt=200 m/min, ap=0.08 mm, z=3)

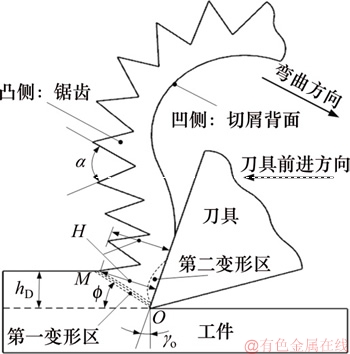

图6(b)所示为齿距PC、锯齿化程度GS、倾斜角α和变形系数Λh在切屑上的分布曲线。由图6(b)可知:PC和GS也呈现出与H相似的变化趋势,说明切屑在成形之初锯齿化的剧烈程度迅速增大,随后保持较高水平,进入后半段才逐渐下降。锯齿的形成本身就伴随着切削力和切削热的波动,而H,PC和GS的变化又意味着切削力和温度波动的幅值与周期在切屑形成的过程中也在不断变化。这就使刀具面临着更加复杂多变的力、热冲击,降低刀具寿命。特别地,H,PC和GS在切屑形成初期的振荡反映了切削力的剧烈波动,这一波动又会造成刀具和工件的振动,降低加工稳定性,降低刀具切入处的工件表面质量。图7所示为切屑锯齿形成过程。从图7可以看出,锯齿节的形成是由被挤压的切屑节块沿着剪切面OM滑移出切屑自由表面而形成的。因此,剪切面与切削速度方向的夹角(剪切角φ)决定了相邻锯齿节斜边与竖直边的夹角(倾斜角α),即φ越大,α越大。因此,倾斜角α与切屑形成时的剪切角φ具有一一对应的关系,可以一定程度上近似表征φ。根据图7可以推导出切屑厚度压缩比(变形系数)Λh与GS,φ之间的关系为:

(2)

(2)

式中:l为第一变形区剪切线OM的长度,μm。

图7 切屑成形示意图

Fig. 7 Picture of chip forming

由式(2)可知,由于刀具前角γo固定不变,则Λh仅与GS,φ呈负相关,即Λh随着GS和φ的增大而减小。这说明锯齿形切屑的变形程度是剪切变形和锯齿化双重影响的结果。从图6(b)可以看出:Λh与α曲线近似呈对称分布,由此可判断剪切角φ在对切屑变形的影响中占主导地位。在切屑形成初期,α存在巨大的波动,α从小于40°迅速跃升至大于50°。其中,小于45°的倾斜角出现在切屑始端,该区域弯曲曲率远大于切屑其他部分的弯曲曲率。这表明此处的切屑在开始形成锯齿前,受刀具挤压而产生的剪切角φ较小,导致Λh较大,即切屑的变形量较大。紧接着,α达到峰值,Λh随之下滑至最低点,此时切屑变形程度最小。进入到切屑中段,GS和α经历过下降后渐趋平稳,α接近45°,Λh有所回升,切屑有变厚的趋势,但由于未变形切屑厚度hD的下降,因此,havg保持相对稳定,没有快速变薄。进入末段,α依然保持平稳,但GS出现下滑,使Λh继续攀升,变形加剧。

此外,剪切角的波动进一步揭示了切削力和切削热情况的改变。根据“切应力与主应力方向呈45°”的剪切理论,由Lee and Shaffer公式[26]可得出剪切角φ与刀具前刀面的摩擦角β满足如下关系:

(3)

(3)

由式(3)可知,导致剪切角波动的原因来自摩擦角β。当刀具刚切入工件时,切屑厚度迅速增大到最大值,对刀具的切削抗力瞬间增大。作为相互作用力,刀具对切屑的挤压和摩擦力也相对很大,但此时刀-屑接触面刚刚产生切削热,温度较低,第二变形区的软化效应不显著,故导致前刀面上的内摩擦区的摩擦因数μ较大,从而令摩擦角β较大,φ较小。随着刀具向前推进,切屑厚度较大时,切屑受到的挤压力和摩擦力增大,产生的大量的切削热,在使刀-屑接触区域温度升高的同时也软化了切屑材料,减小了内摩擦区的摩擦因数μ,从而使摩擦角β变小,φ增大。值得注意的是,剪切角峰值出现的位置与锯齿高度相比稍有延后,这是因为热量的积累需要过程,切削温度在经历最大切削深度后仍有提升。随后,切屑形成进入中后部,切削深度持续下降,挤压和摩擦力减小,生成的切削热也减少,软化作用的减弱导致φ下降。然而,前刀面由于先前不断积累的热量使切削温度在较高水平达到平衡,对切屑背面起到一定软化作用,抑制了φ的进一步下降,故φ在45°维持稳定。由此可知,摩擦条件的变化使刀具面临的切削条件更加恶劣。

值得指出的是,由于切屑中部锯齿高度H,齿距PC和锯齿化程度GS趋于平稳,便于进行不同加工参数下切屑锯齿特征的比较,故选择此处为测量位置。

3.2 切屑锯齿截面上的显微结构分布

GUO等[27]通过XRD实验发现:在经过旋铣加工的螺纹工件表面下存在淬火马氏体、回火马氏体、球状渗碳体以及残余奥氏体,实验结果还显示了从奥氏体到马氏体的金相转变;另外,通过使用红外摄像机测量工件温度,他们验证了旋铣加工中工件的最高温度高于相变温度,而且工件通过空气冷却快速淬火。为了研究切屑锯齿在复杂热、力作用下的形成机理,识别切屑不同部位的显微组织分布并分析其变形情况是非常重要的手段。

在扫描电子显微镜下观察经过腐蚀后的切屑形貌,结果如图8所示。从图8可以看到,锯齿内部基体上分布着细小的粒状碳化物,碳化物颗粒周围的区域颜色较深;而位于第一和第二变形区的条带纤维状组织颜色较亮,且碳化物颗粒消失。这些变形区域因具有较高的抗腐蚀性而显现,故其组织不同于切屑基体。2个区域的组织在锯齿节连接处交汇。

图8 切屑中间纵截面显微结构(vt=180 m/min, ap=0.06 mm, z=3)

Fig. 8 Microstructure in intermediate longitudinal section of chip (vt=180 m/min, ap=0.06 mm, z=3)

位于第一变形区(剪切滑移变形区)的浅色纤维状组织即为绝热剪切带(ASBs),该组织在锯齿节之间周期性地出现。在高速切削条件下,切屑第一变形区的材料在极短的时间内发生剧烈的剪切滑移塑性变形,同时产生大量来不及扩散的切削热。这导致区域局部温度急剧升高,材料被软化,进而又加剧了滑移变形,生成锯齿形切屑。该区域随后又受到来自压缩空气的快速冷却,其组织必然发生变化。从图8可以看出,锯齿斜面上的组织存在“倒伏”现象,晶粒在向锯齿齿根倾斜的方向上被拉长。这是剪切带在斜面上的延伸,验证了锯齿节的滑移。将这一倒伏层的厚度定义为H1。

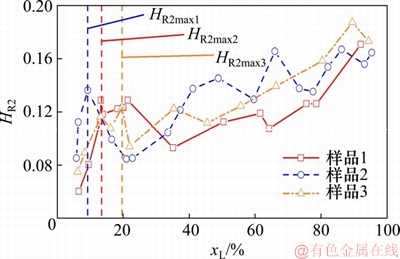

图9 HR2沿切屑长度的变化(vt=200 m/min, ap=0.08 mm, z=3)

Fig. 9 Variation of HR2 along chip length (vt=200 m/min, ap=0.08 mm, z=3)

当切屑以很快的速度从刀具前刀面滑过时,由于非常大的法向应力和剪切应力,摩擦能量在短时间内几乎全部转换为热能。切屑靠近背面(第二变形区)的材料发生严重变形,并且经受了瞬时高温以及在空气中的快速急冷。在这个过程中,工件表面原淬火马氏体先经历了奥氏体化,同时原碳化物颗粒在高温下溶解到奥氏体中,使淬火前的奥氏体中C和Cr元素含量增高。在高压空气中经历二次淬火后,奥氏体转变为淬火马氏体。淬火马氏体因含有较多的Cr元素,因而较耐腐蚀,凸显为颜色较亮(浅)的“白层”,如图8所示。当切削热传递至切屑内部,温度有所下降,这使得基体的原淬火马氏体在较低的高温下回火。回火组织表面上有大量碳化物析出,多相结构有利于电化学腐蚀,而且Cr元素含量下降。这导致回火马氏体较淬火马氏体易受腐蚀液侵蚀,所以凹陷且颜色较暗。

在切屑的不同部位白层厚度H2与锯齿高度H的比值HR2并不一致,但依然存在规律。HR2沿切屑长度的变化如图9所示。从图9可以看出,HR2在切屑形成初期达到一个小的极值,这与切屑锯齿高度的峰值有关,HR2极值出现的位置恰好紧随锯齿高度最大值Hmax对应的位置之后。这说明随着切屑瞬时厚度增大至最大值,变形及摩擦产生的热量升高,导致热影响层区域变大,组织变化区域厚度变宽。考虑到切屑瞬时厚度在达到峰值Hmax后开始下降,而热量的积累会使温度继续上升,温度的极值点在时间上稍有延后对材料的影响有一定时间延迟,故HR2极大值位置与Hmax位置存在一定距离。这也印证了倾斜角峰值延后出现的机理。随后,HR2下降,这与切屑瞬时厚度变薄有关。接着,HR2逐渐上升,直至切削完成。虽然此阶段的切屑瞬时厚度和锯齿高度持续下降,但刀-屑接触区域的切削热因摩擦作用而不断积累,导致前刀面的温度持续上升。因此,相对于切屑厚度,热影响区域不断增大。由此可见,在切削周期中,刀-屑接触区域的温度并不是持续升高的,切削初期的温度波动会给切削稳定性带来不利影响。

图10 纳米硬度测量点布置

Fig. 10 Nanohardness measuring points arrangement

图11 中间纵截面上的纳米硬度分布

Fig. 11 Nanohardness distribution in intermediate longitudinal section

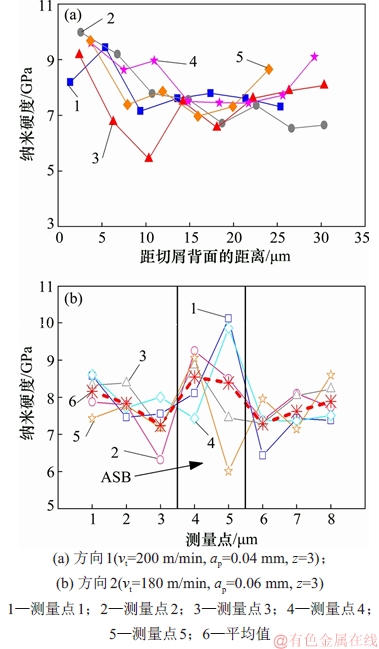

3.3 切屑锯齿截面上的纳米硬度分布

切屑的纳米硬度测量在其锯齿截面上进行。由该截面上显微结构分布差异可以推测,不同位置的硬度可能不一致。因此,选取锯齿节上不同的部位进行测量,测量点布置如图10所示。在垂直于切屑底边方向(方向1)测量一系列点,跨越锯齿厚度,压痕间隔4 μm;又在横穿锯齿连接处的绝热剪切带(方向2)测量一系列点,压痕间隔8 μm。所有纳米压痕测试在同一切屑相同区域的相邻锯齿节上重复3次。

中间纵截面方向1上的纳米硬度分布如图11(a)所示。从图11(a)可见:切屑锯齿截面上沿锯齿高度方向的纳米硬度呈现出“两边高,中间低”的分布趋势,最大硬度出现在最靠近切屑背面一侧的区域;从切屑边缘到切屑内部,硬度明显下降,在达到切屑基体中部后趋于平稳;最后,在抵达切屑斜边时,硬度又有些回升。该分布规律表明:在旋铣加工中,刀-屑接触面因摩擦产生的大量切削热被传导至切屑。具有极高温度的切屑背面附近的材料因受到周围空气的快速冷却,温度急剧下降,过程相当于淬火,使组织发生了变化。另外,该区域材料的严重变形起到了加工硬化作用,而表面氧化也可能是硬度增大的原因之一。该区域恰好对应显微结构观测结果中的“白层”。内部基体的硬度低于“白层”的硬度,但平均纳米硬度依然保持在7.06 GPa左右,这与工件未加工的淬火表面1 mm深度内的平均纳米硬度7.08 GPa 处于同一水平。这说明此处组织并没有转变为较软的回火索氏体或托氏体,根据其硬度推测为回火隐针马氏体。切屑斜边附近的硬度有所上升的原因可能与切屑背面附近的材料硬化的原因相似:绝热剪切带形成演化过程使周围材料经历大变形、高温、“淬火”和氧化,导致硬度增大。

中间纵截面方向2上的纳米硬度分布如图11(b)所示。由图11(b)可见:剪切带附近材料的平均纳米硬度呈现“W”形分布。绝热剪切带上的纳米硬度高于紧邻带两侧的硬度。而远离剪切带的地方,即锯齿内部的基体,其硬度又高于带两侧的硬度。这一现象与前述的锯齿高度方向的硬度分布同理,剪切带处的组织因在短时间内经历了大变形、高温和快速冷却,材料被硬化;而带两侧的位置由于相对较低的变形和温度,加之较缓的降温过程,材料软化效应显著,故硬度下降且低于基体回火马氏体的硬度20%左右。剪切带附近材料硬度的不均匀性说明了切屑长度方向上的材料变形和力热条件不均匀性,验证了旋风铣削加工切屑锯齿形成周期内的不稳定性。

4 结论

1) 在切屑形成初期,锯齿高度H,齿距PC、锯齿化程度GS和倾斜角α都先迅速增加至峰值,然后下降,最后在中部趋于平稳。在切屑长度的起始段以及后半段,影响锯齿高度的主导因素是未变形切屑厚度。

2) 切屑厚度变形系数Λh受到GS和φ的双重影响,其中,剪切角φ对切屑变形的影响占主导地位。在中部,α降低导致了切屑变形量的增加,从而限制了H和havg的急速下降。切屑末段GS下降导致Λh上升,变形加剧。α的变化与刀具前刀面的摩擦情况有关。切削热对工件材料的软化作用会减小摩擦角β,进而增大φ。

3) 锯齿截面显微结构不均匀分布。绝热剪切带和第二变形区的材料经历了剧烈的剪切变形和二次淬火。观测结果印证了锯齿倾斜角峰值的出现相对于锯齿高度峰值有所延迟的机理:热量的积累导致切削温度的极值点在时间上有所延后,进而对材料的影响存在延迟。

4) 在加工硬化、切削热引发的软化作用、周围空气的快速冷却的综合影响下,切屑锯齿截面上沿锯齿高度方向的纳米硬度呈现出“两边高,中间低”分布趋势。

5) 锯齿特征在切屑长度方向上的波动变化说明了每次旋铣切削过程中切削力和切削温度的宏观波动;显微结构和纳米在锯齿节内的不均匀性表明了锯齿形成周期内力、热的微观波动,进一步验证了旋风铣削加工切屑锯齿形成周期内的不稳定性。

参考文献:

[1] MOHAN L V, SHUNMUGAM M S. Simulation of whirling process and tool profiling for machining of worms[J]. Journal of Materials Processing Technology, 2007, 185(1/2/3): 191-197.

[2] LEE M, KANG D, SON S, et al. Investigation of cutting characteristics for worm machining on automatic lathe: comparison of planetary milling and side milling[J]. Journal of Mechanical Science and Technology, 2008, 22(12): 2454-2463.

[3] SONG Shuquan, ZUO Dunwen. Modelling and simulation of whirling process based on equivalent cutting volume[J]. Simulation Modelling Practice and Theory, 2014, 42: 98-106.

[4] KOUADRI S, NECIB K, ATLATI S, et al. Quantification of the chip segmentation in metal machining: application to machining the aeronautical aluminium alloy AA2024-T351 with cemented carbide tools WC-Co[J]. International Journal of Machine Tools and Manufacture, 2013, 64: 102-113.

[5] BARTARYA G, CHOUDHURY S K. State of the art in hard turning[J]. International Journal of Machine Tools and Manufacture, 2012, 53(1): 1-14.

[6] RECHT R F. A dynamic analysis of high-speed machining[J]. Journal of Engineering for Industry, 1985, 107(4): 309.

[7] COTTERELL M, BYRNE G. Characterization of chip formation during orthogonal cutting of titanium alloy Ti-6Al-4V[J]. CIRP Journal of Manufacturing Science and Technology, 2008, 1(2): 81-85.

[8] ZHU Lida, JIN Xiaoliang, LIU Changfu. Experimental investigation on 3D chip morphology properties of rotary surface during orthogonal turn-milling of aluminum alloy[J]. The International Journal of Advanced Manufacturing Technology, 2016, 84(5/6/7/8): 1253-1268.

[9] BEJJANI R, BALAZINSKI M, ATTIA H, et al. Chip formation and microstructure evolution in the adiabatic shear band when machining titanium metal matrix composites[J]. International Journal of Machine Tools and Manufacture, 2016, 109: 137-146.

[10] ZHAO Yanhua, SUN Jie, LI Jianfeng. Study on chip morphology and milling characteristics of laser cladding layer[J]. The International Journal of Advanced Manufacturing Technology, 2015, 77(5/6/7/8): 783-796.

[11] ZHU Lida, WU Jijiang, LI Zhaobin, et al. Investigating chip morphology and its characteristics in the high-speed milling of a Ti-6Al-4V thin plate[J]. Journal of Mechanical Science and Technology, 2015, 29(10): 4359-4366.

[12] NOMANI J, PRAMANIK A, HILDITCH T, et al. Chip formation mechanism and machinability of wrought duplex stainless steel alloys[J]. The International Journal of Advanced Manufacturing Technology, 2015, 80(5/6/7/8): 1127-1135.

[13] KANANI M, SOHRABI S, EBRAHIMI R, et al. Continuous and ultra-fine grained chip production with large strain machining[J]. Journal of Materials Processing Technology, 2014, 214(8): 1777-1786.

[14] LI Anhai, ZHAO Jun, ZHOU Yonghui, et al. Experimental investigation on chip morphologies in high-speed dry milling of titanium alloy Ti-6Al-4V[J]. The International Journal of Advanced Manufacturing Technology, 2012, 62(9/10/11/12): 933-942.

[15] WAN Zhenping, ZHU Yuen, LIU Hongwei, et al. Microstructure evolution of adiabatic shear bands and mechanisms of saw-tooth chip formation in machining Ti6Al4V[J]. Materials Science & Engineering: A, 2012, 531:155-163.

[16] 杜劲, 刘战强, 张入仁, 等. 镍基高温合金高速铣削加工表面完整性[J]. 中南大学学报(自然科学版), 2012, 43(7): 2593-2600.

DU Jin, LIU Zhanqiang, ZHANG Ruren, et al. Surface integrity on high speed milling Ni-based superalloy[J]. Journal of Central South University(Science and Technology), 2012, 43(7): 2593-2600.

[17] PU Chunlei, ZHU Guohui, YANG Shubao, et al. Effect of microstructure softening events on the chip morphology of AISI 1045 steel during high speed machining[J]. International Journal of Advanced Manufacturing Technology,2016,82(9/10/11/12):2149-2155.

[18] WANG Bing, LIU Zhanqiang, HOU Xin, et al. Influences of cutting speed and material mechanical properties on chip deformation and fracture during high-speed cutting of inconel 718[J]. Materials, 2018, 11(4): 461.

[19] 合烨, 王昌赢, 陈小安, 等. 硬态车削轴承钢GCr15切屑形成机理分析[J]. 上海交通大学学报, 2013, 47(5): 800-805.

HE Ye, WANG Changying, CHEN Xiaoan, et al. Finite element simulation of chip formation mechanism in hard turning GCr15 steel[J]. Journal of Shanghai Jiao Tong University, 2013, 47(5): 800-805.

[20] 高延峰, 刘彬彬, 胡翱. BTi-6431S高温钛合金铣削加工切屑的微观形貌研究[J]. 机械设计与制造, 2016(1): 126-129.

GAO Yanfeng, LIU Binbin, HU Ao. Chip morphology and properties research in milling high temperature titanium alloy BTi-6431S[J]. Machinery Design & Manufacture, 2016(1): 126-129.

[21] 高延峰, 肖建华. Ti-6Al-4V和Ti-10V-2Fe-3Al钛合金激光辅助铣削切屑形貌研究[J]. 组合机床与自动化加工技术, 2016(10): 29-31.

GAO Yanfeng, XIAO Jianhua. Chip morphologies during laser assisted machining of Ti-10V-2Fe-3Al and Ti-6Al-4V alloys[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2016(10): 29-31.

[22] SUN J, GUO Y B. A new multi-view approach to characterize 3D chip morphology and properties in end milling titanium Ti-6Al-4V[J]. International Journal of Machine Tools and Manufacture, 2008, 48(12/13): 1486-1494.

[23] 朱红雨, 李迎. PCBN刀具硬态旋风铣削切屑宏观形貌研究[J]. 制造技术与机床, 2011(9): 101-104.

ZHU Hongyu, LI Ying. Study on macro-morphology of hard whirling chips with PCBN tools[J]. Manufacturing Technology & Machine Tool, 2011(9): 101-104.

[24] 朱红雨, 李迎. 基于微观锯齿状切屑的旋风硬铣削加工机理研究[J]. 组合机床与自动化加工技术, 2014(6): 118-120.

ZHU Hongyu, LI Ying. Study on machining mechanism for hard whirling based on micro-serrated chips[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2014(6): 118-120.

[25] 王立祥. 丝杠旋风铣削时变切削力的切削比能评估方法[D]. 重庆: 重庆大学机械工程学院, 2016: 1-66.

WANGLixiang. Evaluation method of specific cutting energy consumption based on instantaneous variation cutting force of whirlwind milling for lead screw[D]. Chongqing: Chongqing University. College of Mechanical Engineering, 2016: 1-66.

[26] BOOTHROYD G. Fundamentals of metal machining and machine tools[M]. Auckland:McGraw-Hill International Book Co., 1975: 79-81.

[27] GUO Qin, CHANG Li, YE Lin, et al. Residual stress, nanohardness, and microstructure changes in whirlwind milling of GCr15 steel[J]. Materials and Manufacturing Processes, 2013, 28(10): 1047-1052.

(编辑 赵俊)

收稿日期: 2018 -12 -24; 修回日期: 2019 -03 -26

基金项目:国家自然科学基金资助项目(51575072,51605058);重庆市研究生科研创新项目(CYB18022)

Foundation:(Projects(51575072, 51605058) supported by the National Natural Science Foundation of China; Project(CYB18022) supported by the Graduate Research and Innovation Foundation of Chongqing of China)

通信作者:王禹林,博士,教授,从事旋风铣削硬态切削技术、先进制造技术、智能装备与机器人、精密测控技术等研究;E-mail:wyl_sjtu@126.com