东鞍山含碳酸盐赤铁矿石浮选试验

邵安林

(鞍钢集团矿业公司,辽宁 鞍山,114001)

摘要:针对纯矿物配成的含赤铁矿、菱铁矿、石英的混合矿进行浮选试验。随着铁矿石中菱铁矿质量分数的提高,铁精矿TFe品位、产率和回收率等指标迅速下降,说明现有反浮选流程不能将含有菱铁矿的铁矿石有效分选。提出将菱铁矿预先分离、然后再将赤铁矿和石英分离的分步浮选流程,相比常规反浮选流程,铁精矿TFe质量分数由42.34%上升至59.09%,铁的回收率由53.18%提高到79.84%。而针对东鞍山含菱铁矿的赤铁矿石,采用分步浮选工艺闭路流程,可获得铁精矿TFe质量分数为66.34%,回收率为71.60%。

关键词:假象赤铁矿;菱铁矿;石英;含碳酸盐

中图分类号:TD923 文献标志码:A 文章编号:1672-7207(2013)02-0456-05

Flotation separation of Donganshan carbonates-containing hematite ore

SHAO Anlin

(Mining Company of Anshan Iron & Steel Group Corporation, Anshan 114001, China)

Abstract: For the mixed minerals which were prepared by pure martite, siderite and quartz, the iron grade, yield and recovery decrease rapidly with the increase of siderite content in iron ore, which indicates that the reverse flotation couldn’t concentrate the carbonates-containing hematite ore. Stepped flotation was proposed which separates siderite first and then takes martite apart from quartz. Therefore, the mass fraction of the iron grade increases from 42.34% to 59.09% and iron recovery increases from 53.18% to 79.84% compared with routine reverse flotation. And for Donganshan carbonates-containing hematite ore, the mass fraction of iron grade of 66.34% and recovery of 71.6% are obtained in close-circle experiment of stepped flotation.

Key words: martite; siderite; quartz; carbonates-containing

我国铁矿石资源向“贫、细、杂”的方向发展,选矿难度逐年增大[1-3], 选矿技术也因此得到快速发展[4-8]。东鞍山地区的矿石特点是品位低、嵌布粒度细、结构复杂,按矿石类型划分,可分为假象赤铁矿石英岩、磁铁石英岩、磁铁赤铁石英岩和绿泥假象赤铁石英岩、绿泥假象磁铁石英岩等[9-11]。近几年来,在对东鞍山的铁矿石反浮选实践中发现:随着开采深度的增加,含碳酸盐赤铁矿石质量分数上升,由10%~15%增加到20%~30%,每年含碳酸盐赤铁矿石有1.8×106~2.0×106 t的出矿量,原有阴离子反浮选工艺已不适应处理该部分矿石,选别过程中经常出现“精、尾不分”的严重结果,由于选矿生产能力的提升及含碳酸盐赤铁矿不能入选,东鞍山赤铁矿矿源严重不足,因此,开发含碳酸盐赤铁矿石的分选工艺具有重要的现实意义。东鞍山含碳酸盐赤铁矿石工艺矿物学研究结果表明[12-14]:矿石中铁矿物以假象(半假象)赤铁矿和赤铁矿为主,其次为菱铁矿,还有极少量的磁铁矿,偶尔可见黄铁矿和黄铜矿出现。主要脉石矿物为石英,其它脉石矿物为微晶结构的方解石、少量的铁白云石及其他含铁的硅酸盐矿物等。矿石中主要矿物赤铁矿、石英、菱铁矿质量分数分别为40%,50%和10%。本文作者将假象赤铁矿、石英及菱铁矿纯矿物按照矿石中的质量分数配成混合矿,并利用东鞍山含碳酸盐赤铁矿石原矿,对其进行浮选试验研究,以获得处理东鞍山含碳酸盐赤铁矿石的合理方案,进而为现场的流程改造提供指导。

1 试验原料与试验方法

1.1 试验原料

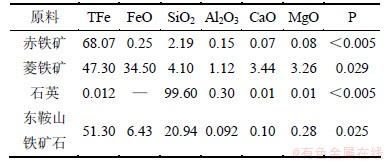

试验采用4种原料,其中:3种为相对较为纯净的矿物,1种为东鞍山现场预选后的铁矿石。将假象赤铁矿、石英纯矿物矿块磨矿处理后,分别选取粒径为0.148~0.050 mm粒级烘干装入磨口瓶备用。菱铁矿纯矿物的粒度较细,粒径小于0.074 mm颗粒质量分数为92.8%,直接使用。4种原料的化学成分见表1。

表1 原料的化学成分质量分数

Table 1 Chemical compositions of materials %

试验所用捕收剂为油酸钠(化学纯)和RA715(工业品)、pH调整剂氢氧化钠(分析纯)、抑制剂淀粉(工业品)、活化剂氧化钙(分析纯),均为市售产品。

1.2 试验方法

当采用纯矿物配成的混合矿进行浮选试验时,在XFG型挂槽式浮选机中进行。每次取4.0 g矿样,采用油酸钠为捕收剂,每次加30 mL去离子水,搅拌2 min后用NaOH调节矿浆pH,再依次加入抑制剂、活化剂、捕收剂,然后进行浮选。加入各种药剂后的搅拌时间均为2 min,浮选时间为4 min。

当采用东鞍山铁矿石进行浮选试验时,在XFD-63型单槽式浮选机里进行。每次取200.0 g矿样,矿浆温度控制在35 ℃左右。泡沫产品和槽内产品分别烘干、称量、化验品位,计算回收率。

2 结果与讨论

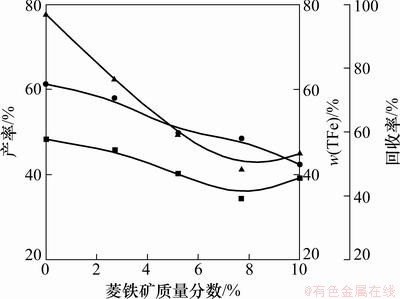

2.1 菱铁矿对反浮选的影响

研究菱铁矿比例对反浮选分离效果的影响,方法是将纯矿物假象赤铁矿与石英按质量比4:5配成混合矿,在混合矿中加入不同质量的菱铁矿,使菱铁矿在混合矿中的质量分数分别为0,2.7%,5.3%,7.7%和10%,并在NaOL质量浓度为160 mg/L、CaO质量浓度为 60 mg/L、淀粉质量浓度为5 mg/L的条件下进行反浮选,结果如图1所示。由图1可见:随着菱铁矿的比例增大,精矿的TFe、产率、回收率都下降,当矿石中含有2.7%的菱铁矿时,浮选精矿的TFe和全铁的回收率就开始明显下降;而当菱铁矿质量分数由0增加到10%时,反浮选铁精矿TFe由61.23%降至42.34%,精矿中铁回收率由96.8%降至53.18%,表明菱铁矿的存在对铁矿物的浮选分选有很大的影响,不利于浮选体系的稳定,大大恶化了矿物的浮选效果。因此,要实现含碳酸盐赤铁矿石的分选,必须消除菱铁矿对浮选的影响。

图1 菱铁矿质量分数对反浮选分离效果的影响

Fig.1 Influence of siderite mass fraction on separation of reverse flotation

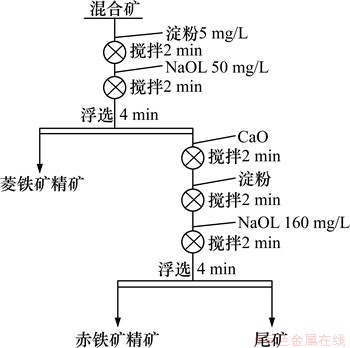

2.2 分步浮选试验研究

由于菱铁矿的存在对浮选效果影响大,本文研究分步浮选分离含碳酸盐的赤铁矿石,首先实现菱铁矿与假象赤铁矿和石英的浮选分离,然后将赤铁矿与石英进行浮选分离。第1步浮选是在油酸钠体系下,以淀粉和CaCl2组合作为调整剂,pH为5~7,此时菱铁矿的可浮性较好,而假象赤铁矿和石英的可浮性较差,因此,可以先将菱铁矿部分分离;第2步浮选是在pH>11的强碱性条件下,以CaO为活化剂,利用石英的可浮性较好而赤铁矿的可浮性差的特点,将石英与赤铁矿等进行反浮选分离。“分步浮选”工艺流程如图2所示。通过前期研究,由于正浮选分离菱铁矿相对容易实现,本研究主要研究第2步反浮选过程中淀粉、CaO质量浓度及pH对浮选效果的影响。试验过程采用的混合矿为赤铁矿与石英质量比为4:5,菱铁矿在混合矿中的质量分数为10%。

图2 分步浮选流程图

Fig.2 Flowsheet of stepped-fotation

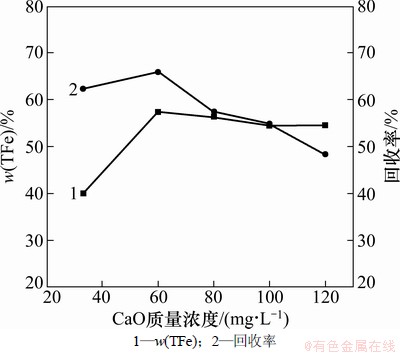

图3所示为CaO质量浓度对石英与赤铁矿浮选分离的影响。由图3可见:随着CaO质量浓度的提高,铁精矿的TFe的质量分数和回收率都是先增加后降低,当CaO质量浓度为60 mg/L时,w(TFe)和回收率都达到最大值,可以获得铁精矿w(TFe)为57.37%、回收率为65.89%的赤铁矿精矿。

图3 石灰质量浓度对反浮选分离效果的影响

Fig.3 Influence of CaO dosage on separation of reverse flotation

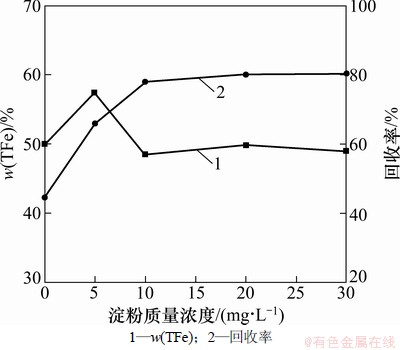

在CaO质量浓度为60 mg/L的条件下,研究淀粉质量浓度对第2步浮选分离的影响,结果如图4所示。由图4可见:随着淀粉质量浓度的增加,铁精矿TFe的质量分数先增加后降低,当淀粉质量浓度为5 mg/L时,w(TFe)达到最大值,而回收率先增加后变化不大,当淀粉质量浓度达到10 mg/L以后,回收率维持在80%左右。综合考虑w(TFe)和回收率,淀粉的适宜质量浓度为5 mg/L。

图4 淀粉质量浓度对反浮选分离效果的影响

Fig.4 Influence of starch dosage on separation of reverse flotation

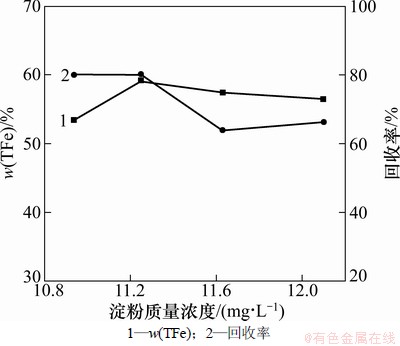

在CaO质量浓度为60 mg/L、淀粉质量浓度为5 mg/L的条件下,研究pH对第2步浮选分离的影响,结果如图5所示。从图5可见:铁精矿的TFe的质量分数及回收率先增加后降低,在pH为11.25时达到最高,分别为59.94%及79.84%。在第2步反浮选过程中,Ca2+对石英的可浮性产生较大影响,在碱性条件下石英被活化,由Ca2+的溶液化学得知[15],在强碱性条件下石英被活化时正是溶液中Ca(OH)+大量生成的时候,Ca(OH)+的生成对石英的浮选起重要作用,钙离子羟基络合物与石英表面裸露的羟基化的硅原子通过氢键或脱除水的方式键合,石英表面裸露的氧原子也以氢键或脱除水的方式与Ca(OH)+作用。但当pH太高时,矿浆中的OH-浓度急剧增加,OH-和RCOO-在石英表面发生竞争吸附,减少了RCOO-与Ca(OH)+结合的机会,同时由于生成易于在矿物表面脱落的Ca(OH)2沉淀,石英的回收率有所下降,导致铁精矿的品位及回收率也随之下降。因此,第2步反浮选适宜的pH为11.25。

图5 pH值对反浮选分离效果的影响

Fig.5 Influence of pH on the separation of reverse flotation

因此,根据上述研究,初步得出分步浮选工艺可以作为处理东鞍山含碳酸盐赤铁矿石的选别方法。适宜的条件为:第1步浮选淀粉质量浓度5 mg/L、NaOL质量浓度50 mg/L、pH值中性;第2步反浮选淀粉质量浓度为5 mg/L,CaO质量浓度为60 mg/L,NaOL质量浓度为160 mg/L,pH为11.25。采用分步浮选方法,与常规反浮选相比,铁精矿的品位可由42.34%上升至59.09%,铁的回收率由53.18%上升至79.84%。

2.3 东鞍山含碳酸盐赤铁矿分步浮选试验研究

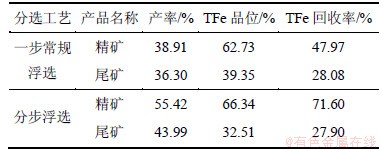

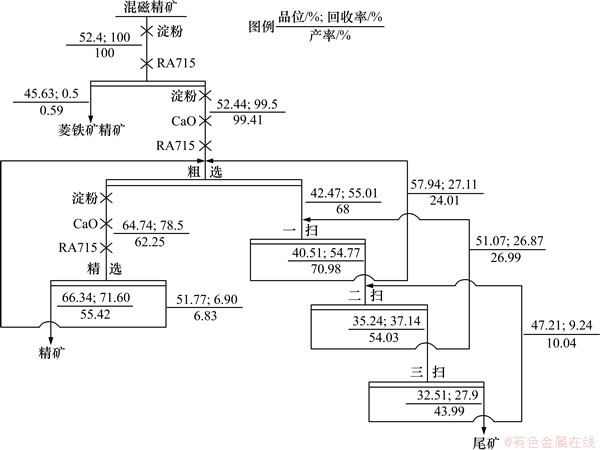

针对东鞍山含碳酸盐赤铁矿石原矿预选后得到TFe的质量分数为51.3%,主要矿物为假象赤铁矿、石英、菱铁矿的矿石,研究分步浮选闭路流程对铁矿石分离的影响,并与常规的一步反浮选进行对比。分步浮选闭路工艺流程如图6所示,试验结果如表2所示。

依据分步浮选中确定的适宜参数,确定分步浮选闭路工艺流程第1步淀粉用量为800 g/t,RA715用量为l 00 g/t;第2步淀粉用量为500 g/t,CaO用量为800 g/t,RA715用量为700 g/t;精选时淀粉用量为100 g/t,CaO用量为200 g/t,RA715用量为300 g/t;3次扫选均不添加淀粉;最终可获得铁精矿TFe的质量分数为66.34%、回收率为71.60%的指标。与一步常规浮选的精矿指标相比,TFe质量分数和回收率分别提高3.61%和23.63%。可见,采用分步浮选工艺,可消除菱铁矿对赤铁矿浮选的影响,是解决含碳酸盐铁矿石浮选分离难题的方法之一。

表2 分选工艺对产品指标的影响

Table 2 Effect of processing flotation on indexes of production

图6 分步浮选闭路数质量流程

Fig.6 Closed-circle flowsheet for indexes mass flow

3 结论

(1) 当菱铁矿质量分数由0增加到10%时,反浮选铁精矿品位由61.23%降至42.34%,精矿中铁回收率由96.8%降至53.18%,菱铁矿的存在大大恶化了赤铁矿的分选,因此,要实现含碳酸盐赤铁矿石的分选,必须先消除菱铁矿对浮选的影响。

(2) 针对纯矿物赤铁矿、石英、菱铁矿配成的混合矿,采用分步浮选工艺,与常规反浮选相比,铁精矿的品位由42.34%上升至59.09%,铁回收率由53.18%上升至79.84%。

(3) 对于东鞍山含碳酸盐赤铁矿石,采用分步浮选闭路工艺流程,可获得TFe质量分数为66.34%、回收率为71.60%的铁精矿,与一步常规浮选的精矿指标相比,w(TFe)和回收率分别提高了3.61%和23.63%。

(4) 采用分步浮选流程基本消除菱铁矿对赤铁矿浮选的不利影响,可以作为处理东鞍山含碳酸盐赤铁矿石的分选方法。

参考文献:

[1] 张久铭, 王贵成, 何亚丽. 我国铁矿资源的秉赋特征与可持续开发利用研究[J]. 中国矿业, 2007, 16(7): 36-39.

ZHANG Jiuming, WANG Guicheng, HE Yali. Nature of Chinese iron mine resource and the research of its sustainable development and utilization[J]. Chinese Mineral Process, 2007, 16(7): 36-39.

[2] 袁致涛, 高太, 印万忠, 等. 我国难选铁矿石资源利用的现状及发展方向[J]. 金属矿山, 2007(1): 1-6.

YUAN Zhitao, GAO Tai, YIN Wanzhong, et al. Utilization status and development direction of refractory ore resource in China[J]. Metal & Mine, 2007(1): 1-6.

[3] 王运敏, 田嘉印, 王化军, 等. 中国黑色金属矿选矿实践[M]. 北京: 科学出版社, 2008: 1479-1480.

WANG Yunmin, TIAN Jiayin, WANG Huajun, et al. Mineral processing practice of ferrous metal ore in China[M]. Beijing: Science Press, 2008: 1479-1480.

[4] Pavlovic S, Brandao P R G. Adsorption of starch, amylase, amylopectin and glucose monomer and their effect on the flotation of hematite and quartz[J]. Minerals Engineering, 2003, 16(11): 1117-1122.

[5] 毛钜凡, 张勇. 多价金属离子对菱锰矿可浮性的影响[J]. 中国锰业, 1994, 12(6): 23-28.

MAO Jufan, ZHANG Yong. Effects of polyvalent metal ions on rhodochrosite flotation[J]. China’s Manganese Industry, 1994, 12(6): 23-28.

[6] Weissenbom P K. Behaviour of amylopectin and amylase components of starch in the selective flotation of ultraflne iron ore[J]. Int J Miner Process, 1996, 47(3): 197-21l.

[7] 刘亚川, 龚焕高, 张克仁. 金属离子对浮选药剂作用的影响[J]. 金属矿山, 1994(2): 45-48.

LIU Yachuan, GONG Huangao, ZHANG Keren. Effect of metal ions on the flotation reagent functions[J]. Metal Mine, 1994(2): 45-48.

[8] Leal Filho L S, Seidl P R, Correia J C G, et al. Molecular modeling of reagents for flotation processes[J]. Minerals Engineering, 2000, 113(14): 1495-1503.

[9] 张兆元, 吕振福, 印万忠. 东鞍山铁矿石中菱铁矿对反浮选的影响[J]. 金属矿山, 2008(10): 52-55.

ZHANG Zhaoyuan, LV Zhenfu, YIN Wangzhong. Effect of siderite on reverse flotation of Dong’an shan iron ore[J]. Metal&Mine, 2008(10): 52-55.

[10] 张泾生, 阙煊兰. 矿用药剂[M]. 北京: 冶金工业出版社, 2008: 635-636.

ZHANG Jingsheng, QUE Xuanlan. Mineral reagents[M]. Beijing: Metallurgical Industry Press, 2008: 635-636.

[11] 闫志为, 刘辉利, 张志卫. 温度及CO2对方解石、白云石溶解度影响特征分析[J]. 中国岩溶, 2009, 28(1): 7-10.

YAN Zhiwei, LIU Huili, ZHANG Zhiwei. Influences of temperature and CO2 on the solubility of calcite and dolomite[J]. Carsologica Sinica, 2009, 28(1): 7-10.

[12] 吴大清, 刁桂仪, 彭金莲. 矿物对金属离子的竞争吸附实验研究[J]. 地球化学, 1997, 26(6): 25-32.

WU Daqing, DIAO Guiyi, PENG Jinlian. Experiment on the competition adsorptions of metal ions onto minerals[J]. Geochimica, 1997, 26(6): 25-32.

[13] 熊大和. SLon磁选机分选东鞍山氧化铁矿石的应用[J]. 金属矿山, 2003(6): 21-24.

XIONG Dahe. Application of Magnetic separator to separate Dong’an shan iron ore[J]. Metal & Mine, 2003(6): 21-24.

[14] 刘再华, Dreybrodt W, 韩军, 等. CaCO3-CO2-H2O 岩溶系统的平衡化学及其分析[J]. 中国岩溶, 2005, 24(1): 1-14.

LIU Zaihua, Dreybrodt W, HAN Jun, et al. Equilibrium chemistry of the CaCO3-CO2-H2O system and discussion[J]. Carsologica Sinica, 2005, 24(1): 1-14.

[15] 王淀佐, 胡岳华. 浮选溶液化学[M]. 长沙: 湖南科学技术出版社, 1998: 134-135.

WANG Dianzuo, HU Yuehua. Solution chemistry flotation[M]. Changsha: Hunan Science and Technology Press, 1998: 134-135.

(编辑 邓履翔)

收稿日期:2012-04-30;修回日期:2012-06-29

基金项目:国家“十二五”支撑项目(2012BAB141305)

通信作者:邵安林(1963-),男,黑龙江肇东人,博士,教授级高级工程师,从事铁矿资源的开发及利用研究;电话:0412-5612563;E-mail:alshao@163.com