金属陶瓷惰性阳极压坯的热脱脂工艺

刘建元,张 雷, 李志友, 周科朝

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:以聚乙烯醇(PVA)和NiFe2O4/Ni型金属陶瓷压坯为对象,采用热重分析(TGA)研究PVA在N2气氛中的热脱脂行为,建立PVA热脱脂速率的数学模型,在此基础上,模拟并计算PVA分解产物气体在多孔粉末压坯内的压力构建情况;结合粉末压坯脱脂强度测试结果,分析粉末压坯在脱脂过程中压坯尺寸、粘结剂含量等因素对升温速率和脱脂时间的影响,获得不同半径尺寸压坯的极限升温速率。运用所得方法和所得极限升温速率结果进行脱脂实验升温制度设计,实现了压坯直径D=0.12 m,压坯厚度e=0.12 m的NiFe2O4/Ni惰性阳极大型压坯的无缺陷热脱脂。

关键词:惰性阳极;PVA;NiFe2O4/Ni;热脱脂;极限升温速率

中图分类号:FT111.522 文献标识码:A 文章编号:1672-7207(2008)05-0980-07

Thermal debinder technology for cermet compacts of inert anode

LIU Jian-yuan, ZHANG Lei, LI Zhi-you, ZHOU Ke-chao

(State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: For developing non-defects large scale NiFe2O4/Ni cermet compacts of inert anode for the primary aluminium industry, the thermo-gravimetric analysis was used to determine the thermal degradation kinetic of poly(vinyl alcohol) which was used as a binder. The kinetic parameters were then used in a coupled transport and kinetic model for evaluating the buildup of the gas pressure within the large scale ceramic green body as a function of variations of the heating rate and the body dimension. The critical heating rate for different body radius was predicted by comparing the gas pressure when the peak degradation rate occurred with the threshold body strength which was determined by the diametric compression test of the green body during thermal debindering. The results show that using these methods to design the thermal debinder process of NiFe2O4/Ni inert anode green body with binder diameter of 0.06 m and binder thickness of 0.12 m, the non-defects debinded and pre-sintered samples are gained after a 2 460 min heating up process.

Key words: inert anode; PVA; NiFe2O4/Ni; thermal debinder; critical heating rate

现代原铝冶炼所用的Hall-Heroult铝电解槽采用消耗式的碳素阳极,存在生产成本高、能耗高、污染严重、劳动强度高等缺点,而高效率、低能耗、低成本、无严重污染的铝电解工艺是现代铝电解工业不断追求的目标,惰性阳极因能解决上述问题而成为铝业界和材料界的研究热点[1-2],人们近年来,对惰性阳极的研究主要集中在尖晶石型复合氧化物阳极方面[1-5]。

金属陶瓷惰性阳极通常采用现代陶瓷工艺制 备,其中加入粘结剂在有效改善粉末的成型性的同时,也增加了脱脂工艺的难度。陶瓷工艺中所使用的有机粘结剂多为水溶性有机物产品,如聚乙烯醇(PVA,polyvinyl alcohol)、聚乙二醇(PEG,polyethylene glycol)等,而热脱脂是最常用的脱脂方法。众多学者对有机物热脱脂行为进行了研究[6-8],研究结果表明热脱脂过程主要包括有机物受热发生降解生成小相对分子质量的降解产物,降解产物通过扩散、渗透等方式由多孔的粉末基体内部传输至基体表面,然后进入炉内气氛。然而,受有机物类型、相对分子质量、含量、脱脂升温速率、粉末坯体外形及尺寸、粉末体特性等因数的影响,在实际工艺中制品往往会出现鼓泡、裂纹、塌陷、变形等各种缺陷,这种情况在制备大尺寸粉末制品时尤为突出。

为了实现大尺寸NiFe2O4/Ni惰性阳极粉末压坯的无缺陷热脱脂,本文作者采用热重分析(TGA)研究PVA在N2气氛中的热脱脂行为,并根据有机物自由分解理论建立PVA热脱脂速率的热力学模型。对以PVA作为粘结剂的NiFe2O4/Ni粉末压坯的压坯强度在脱脂过程中的演变过程进行研究,获得不同温度区间内压坯所能承受的压力值。利用PVA热分解热力学模型,推导了PVA分解产物气体在大尺寸无限长圆柱形压坯内的气体压力构建情况,通过分析粉末压坯在脱脂过程中压坯尺寸、粘结剂含量、升温速率等因素对脱脂行为的影响,获得不同半径尺寸压坯的极限升温速率。利用所得极限升温速率结果对大尺寸NiFe2O4/ Ni惰性阳极粉末压坯的脱脂实验工艺进行优化设计。

1 实 验

采用热重法(Thermal gravimetric analyzer,TGA),在(TA, SDT-Q600)型热分析仪上对聚乙烯醇(PVA)在氮气中的热分解行为进行研究,测试温度为378~1 000 K;试验气氛为N2,气体流量为100 mL/min;升温速率分别为2,5和10 K/min。

压坯脱脂强度在脱脂工艺中的演变实验采用平均粒径为2 μm的NiFe2O4粉末,选用湖南湘维科技公司的PVA(17-99H)产品作为粘结剂。将PVA与NiFe2O4粉末按质量比1?99配制成含水50%(质量分数)的浆料,在球磨机内球磨(球料质量比为2?1) 4 h,所得料泥于100 ℃干燥24 h。干燥料经过研磨破碎后过100目(即150 μm)筛,得到质量分数为1% PVA、平均粒径为90 μm左右的NiFe2O4团聚粉末。实验用压坯采用直径为17 mm钢制模具于100 MPa制得,所得压坯的平均相对密度为62%。压坯在氮气中进行脱脂,升温速率约为1.7 K/min,每升温100 ℃保温15 min,保温结束立即取出试样,经空气冷却后进行强度测试,压坯机械强度采用压坯径向受压实验测得,加压速率为5 mm/min,所得实验结果为3个试样测试结果的平均值。压坯强度值由下式给出[5, 9]

2 结果及讨论

2.1 升温速率和温度对PVA热分解行为的影响

PVA热分解剩余质量分数w由式(1)给出,

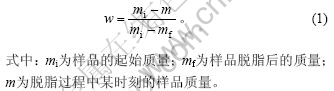

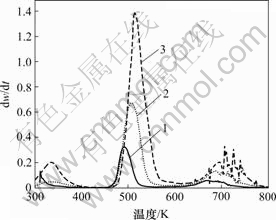

PVA热分解剩余质量分数随温度的变化情况如图1所示。图1表明,w随升温速率的增加而增加。PVA的热分解失重反应表现出明显的三段性。由于PVA是一种吸水性的有机物,因此,第1阶段(400 K以前)的失重主要为PVA内部水汽的蒸发,第2和第3阶段的失重反应分别发生在460~575 K和660~780 K;第2阶段反应的失重率明显比第3阶段的高,说明第2阶段是PVA热分解的主要阶段。

升温速度/(K?s-1): 1—2; 2—5; 3—10

图1 不同升温速率下PVA热分解剩余质量分数

Fig.1 Comparison of residual mass ratio for PVA pyrolysis at different heating rates

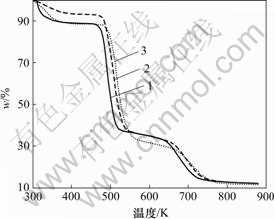

根据自由分解理论[10-13], PVA的分解速率K(即瞬时质量分数的变化量)遵循Arrinious关系:

图2 所示为各升温速率下PVA热分解反应的反应速率随温度的变化情况。PVA在升温速度分别为2,5和10 /min时,出现峰值反应速率的温度分别为492.7,508.1和513.9 K,峰值反应速率分别为0.032 3,0.067 4和0.139 s-1。随着升温速率的提高,峰值反应速率出现的温度也随之升高,而且随升温速率升高反应速率呈倍数增长。而PVA在不同升温速率下的分解反应峰值速率大多发生在460~575 K,说明该温度区间是PVA发生热分解的主要温度区段,因此,该温度范围是采用PVA作为粘结剂的粉末压坯脱脂的关键阶段。

升温速度/(K?s-1): 1—2; 2—5; 3—10

图2 PVA在不同升温速率下的瞬时反应速率

Fig.2 Variations of instantaneous reaction rates dw/dt with temperature at different heating rates for pyrolysis of PVA

上述研究表明,在PVA的热分解过程中,随着升温速率的增加,反应剩余质量分数w也随之增加,而且在相同温度下,升温速率高导致剩余质量分数高,同时,升温速率较高还造成分解反应速率较高,并使峰值反应速率出现在更高的温度下。

2.2 PVA热分解热力学参数的计算

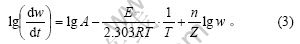

对式(2)求对数得到:

将热分解反应任意两相邻时间点的分解速率的对数相减可得:

。 (4)

。 (4)

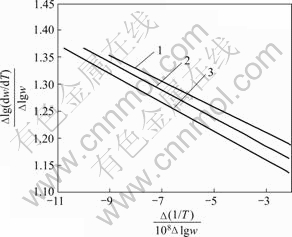

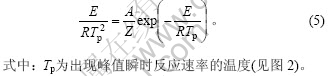

由式(4)可知,lg(dw/dt)/lgw与(1/T)/lgw呈直线关系,对不同升温速率下的PVA热分解反应所得TGA数据按照上式作图(图3),可由所得直线斜率求得E,直线截距为n,计算结果如表1所示。计算结果显示PVA的热分解反应的平均激活能E=127.769 kJ/mol,该值与Yutaka等[14-18]所得数据E=148.35 kJ/mol相比有13.9%的相对误差,但文献[14-18]中并未给出所用PVA的具体相对分子质量,因此,认为所得数据基本合理,可作为所选PVA制品热分解反应的基本热力学参数。另外,计算所得反应平均级数为1.1957,说明PVA的热分解反应并非一级反应,但在其后的模拟计算中为了简化计算过程,假设PVA的热分解反应为一级反应。

升温速度/(K?s-1): 1—2; 2—5; 3—10

图3 不同升温速率下PVA热分解TGA试验数据

Fig.3  vs

vs  from TGA data for pyrolysis of PVA at different heating rates

from TGA data for pyrolysis of PVA at different heating rates

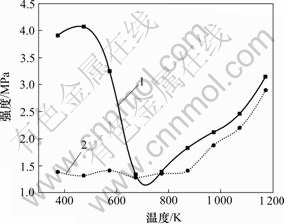

采用式(5)[19-22]对频率因子A进行计算:

不同升温速率下所得的频率因子计算结果如表1所示,取频率因子平均值A=4.712 2×1012。

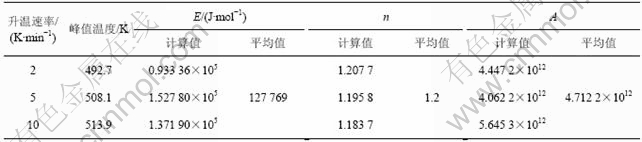

2.3 NiFe2O4/Ni粉末压坯在脱脂过程中的强度演变

以1% PVA作为粘结剂的NiFe2O4/Ni粉末压坯及不含粘结剂的压坯在脱脂过程中的强度变化如图4所示。从图4可以看出,未添加粘结剂的NiFe2O4/Ni粉末压坯在低于900 K时一直保持与室温条件下相同的强度,约为1.5 MPa。粘结剂的加入可以成倍提高压坯的室温强度,含1% PVA的NiFe2O4/Ni粉末压坯的室温强度约为3.8 MPa。在压坯脱脂过程中,随着粘结剂PVA的分解、脱除,压坯强度开始逐渐下降,当温度达到700 K左右时,压坯内的PVA已经基本脱除(见图1),PVA对压坯的粘结作用消失,因而压坯强度也下降到最低点,即与不含粘结剂的压坯强度相同。之后,随着温度的继续升高,当粉末开始发生烧结时,压坯强度又开始上升。图4所示结果表明,压坯强度开始升高的温度在900 K左右,说明在该温度下,已有烧结反应发生。综合图1和图4的结果,发现在PVA发生主要热分解反应的温度区间(400~600 K),压坯强度先升高后降低,并从最高值4.08 MPa降至3.0 MPa左右,而与此同时,PVA正经历主要的分解反应阶段,TGA试验结果表明,在该温度区间内PVA约失重68%,即大部分PVA在该阶段已经分解脱除。由此,可以做出如下推断:在PVA热分解主要阶段中,热分解产物气体在压坯内部所产生的压力只要不大于该阶段最低的压坯强度,压坯内部就不会形成开裂、微裂纹等缺陷,因此,设定在压坯热脱脂过程中,在400~ 600 K,压坯所能承受的极限压力为3.0 MPa;同样,在600~900 K,压坯所能承受的极限压力为1.5 MPa。需要说明的是,压坯的强度由压坯压溃试验获得,其所表现的是压坯承受压应力的能力,而用该值来表征压坯承受内部气体所产生的张应力并不能真实地反映压坯承受张应力的能力,但是,在目前并无有效方法来对压坯张应力的承受能力进行测定的情况下,仅以此值作为参考,待测试方法改进时,再对其进行修订。

表1 PVA热分解热力学计算结果数据

Table 1 Calculated results of activity energy, reaction order and frequency factors for PVA pyrolysis

1—含PVA;2—不含PVA

图4 NiFe2O4/Ni粉末压坯在脱脂过程中的强度演变过程

Fig.4 Evolution of strength of compacts with and without PVA during versus temperature treatments

2.4 PVA热分解产物气体在压坯中所构建的气体压力与升温速率的关系

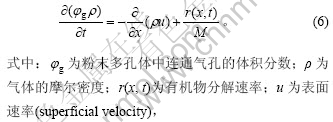

有机物粘结剂热分解产物气体在粉末多孔体内所造成的压力可由下式表达[20-22]:

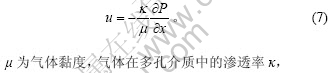

由Darcy公式给出:

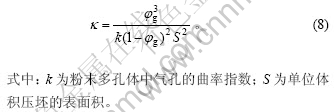

渗透率服从Kozeny-Carman关系:

随着粘结剂在粉末基体内降解的不断进行,粘结剂所占的体积分数 也随之不断减少,对于密度为ρb的有机物,其体积分数的变化正比于其热分解反应速率,并遵循质量守恒原则,因此有:

也随之不断减少,对于密度为ρb的有机物,其体积分数的变化正比于其热分解反应速率,并遵循质量守恒原则,因此有:

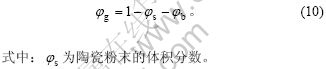

粉末多孔体内气体所占体积 可由下式表达:

可由下式表达:

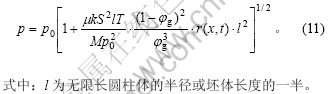

脱脂工艺通常采用较慢的升温速率,因此,在压坯内所形成的温度和粘结剂浓度梯度一般较小,可忽略不计。非稳态情况下(式(6)所定义的条件下),粉末多孔体内部的相对压力分布情况可由式(11)[20-22]来进行计算,

上述方程及关系式(6)~(11)采用有限微分方法进行处理,在线性升温速率Z=dT/dt的条件下,估算有机物热分解产物随温度升高而在压坯内部构建的压力分布状态。方程系数的取值:T0=300 K,p0=0.1 MPa, =0.08,

=0.08, =0.60,ρb=1 000 kg/m3,M=44 g/mol,μ=0.025×10-3 Pa·s,S=6×106 m-1,k=5。

=0.60,ρb=1 000 kg/m3,M=44 g/mol,μ=0.025×10-3 Pa·s,S=6×106 m-1,k=5。

粉末多孔体中的孔隙是由粉末堆垛所造成的具有不规则形状和尺寸分布的、三维联通的、曲折的毛细管管道,而气体分子扩散的驱动力源于气体的浓度梯度而非气体压力梯度,气体分子通过相互碰撞(布朗运动)由高浓度区域向低浓度区传输,因此,气体在粉末多孔体中的传输受到粉末形貌、堆垛特性、孔径、孔隙体积分数以及气体特性等原因的影响。众多学 者[23-26]对物质在多孔介质中的传输过程进行了较为系统的研究,但是,这些研究主要集中在低孔隙度、高粘结剂含量的注射成形坯件方面,而且所得研究结果缺乏实用性,对大尺寸的粉末压坯的研究也较少。因而,本文重点研究在大尺寸、低粘结剂含量粉末坯体中由有机物热分解产物气体所造成的压力与升温制度及坯体尺寸的关系,为了简化计算,模拟过程中采用无限长圆柱体模型,即只考虑一维的情况,并针对D=0.05 和0.1 m进行详细的对比分析。

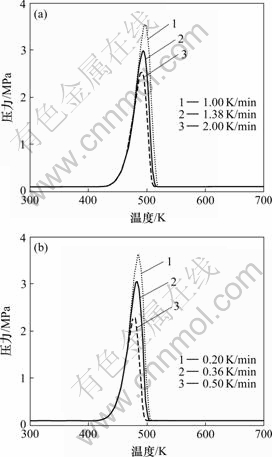

PVA热分解产物气体在粉末压坯内部所造成的压力情况如图5所示。如果将3 MPa作为压坯在400~ 600 K所能承受的极限压力,那么对于D=0.05 m的压坯,其极限升温速率为Z=1.38 K/min;而对于D=0.1 m的情况,其相应的极限升温速率为Z=0.36 K/min, 这2种情况的极限气压出现的温度分别为494 K和484 K。在400~600 K,若使用极限升温速率进行脱脂,则在不考虑保温的情况下,对于D=0.05 m 的压坯,其脱脂时间为115 min,而对于D=0.1 m的压坯,需要 556 min才能将粘结剂脱除,这个时间大约是前一种情况的5倍,由此可见,在相同粘结剂和材料体系以及工艺条件下,制品外形尺寸对脱脂工艺的影响较大。另外,从图5可知,随着升温速率的增加,压力曲线逐渐向高温区移动,出现峰值压力的温度也越高,所得趋势与PVA热分解与升温速率的关系一致。

(a) D=0.05 m;(b) D=0.1 m

图5 热脱脂过程中,压坯内部气体压力与脱脂升温速率和压坯外形尺寸的关系

Fig.5 Relationship among gas pressure inside green body and heating rate and body radius during thermal debinder processing

随着温度的继续升高,当温度达到600 K以后,PVA的热分解反应进入第3阶段,PVA在第2阶段热分解的剩余物质将继续受热分解,分解产物依然为气体。值得注意的是,随着第2阶段反应的结束,约有68% PVA已经被分解、脱除,由此 将随着

将随着 的降低而升高(见方程(10)),这将为气体在粉末基体中的传输提供更大的空间。压坯的脱脂强度试验表明,约在680 K时,压坯的强度达到最低值1.5 MPa,该值与不含PVA的粉末压坯的室温强度基本相同,说明在该温度下,PVA的粘结作用已经消失;随着温度继续上升,当温度达到780 K以后,即当NiFe2O4/Ni 发生烧结反应以后,压坯的强度才开始逐渐上升。若将1.5 MPa作为该温度区间内(600~900 K)压坯的极限强度,则气体压力达到1.5 MPa,D=0.05 m 的压坯所需的极限升温速率为Z=6 K/min,而D=0.1 m压坯所需的极限升温速率为Z=1.2 K/min,出现极限值气压的温度分别为782 K和763 K。

的降低而升高(见方程(10)),这将为气体在粉末基体中的传输提供更大的空间。压坯的脱脂强度试验表明,约在680 K时,压坯的强度达到最低值1.5 MPa,该值与不含PVA的粉末压坯的室温强度基本相同,说明在该温度下,PVA的粘结作用已经消失;随着温度继续上升,当温度达到780 K以后,即当NiFe2O4/Ni 发生烧结反应以后,压坯的强度才开始逐渐上升。若将1.5 MPa作为该温度区间内(600~900 K)压坯的极限强度,则气体压力达到1.5 MPa,D=0.05 m 的压坯所需的极限升温速率为Z=6 K/min,而D=0.1 m压坯所需的极限升温速率为Z=1.2 K/min,出现极限值气压的温度分别为782 K和763 K。

因此,在以PVA作为粘结剂的粉末压坯脱脂工艺中,400~600 K是整个脱脂过程的关键温度,在进行脱脂工艺设计时,必须严格考虑升温速率及适当采取保温,如在峰值压力出现前后的温度点必须要设置保温,具体保温时间可视压坯尺寸而定。

2.5 脱脂极限升温速率推测方法在D=0.12 m,e=0.12 m的NiFe2O4/Ni惰性阳极压坯脱脂预烧工艺中的应用

通过上述方法,对压坯直径D=0.12 m,压坯厚度e=0.12 m的NiFe2O4/Ni惰性阳极压坯脱脂预烧工艺中的升温速率进行推算,并按照推算值制定试样的脱脂升温工艺制度。计算结果表明,400~600 K的极限升温速率为0.24 K/min,采用该值作为该温度区间试验工艺中的升温速率,该温度区间升温需833 min,为避免压坯在峰值压力在温度480 K时出现缺陷,特在该温度点附近的设置多段保温时间。因此,该区间总共用时1 320 min。在600~900 K内采用0.4 K/min作为升温速率,在900~1 200 K的预烧的温度区间采用的升温速率为0.5 K/min,因此,在大尺寸惰性阳极压坯的脱脂预烧工艺中升温阶段总用时约为2 460 min。从图6可以看出,脱脂预烧实验所得样品质量好,没有明显的裂纹、开裂、分层、龟裂等缺陷产生,说明采用上述大型粉末压坯脱脂极限升温速率推算方法来制定以PVA作为粘结剂的粉末压坯的脱脂工艺现实可行,所制定工艺能够较好地应用于生产实践。

图6 压坯直径D=0.12 m和压坯厚度e=0.12 m时的NiFe2O4/Ni惰性阳极压坯脱脂预烧样品

Fig.6 Photo of non-defects debinded and pre-sintered NiFe2O4/Ni inert anode green body when D=0.12 m and e=0.12 m

3 结 论

a. 采用TGA方法研究并分析了PVA制品的热分解特性,计算所得PVA热分解激活能和频率因子分别为127.769 kJ/mol和4.712 2×1012;此外,构建了PVA热分解的热力学模型,模拟了PVA热分解产物气体在大尺寸粉末压坯内所造成的压力。研究表明,在400~600 K的PVA热分解及热分解产物气体在粉末基体中的扩散是整个脱脂过程的控制步骤。

b. 通过对采用PVA作为粘结剂的粉末压坯在脱脂过程中的强度演变过程的测试,获得了在不同温度区间内压坯所能承受的极限压力,并将该值与相同温度区间的气体压力进行比较,最终获得不同尺寸压坯脱脂的极限升温速率。

c. 采用所得压坯脱脂极限升温速率推算方法,对D=0.12 m,e=0.12 m的NiFe2O4/Ni惰性阳极压坯的脱脂过程进行推算,并采用所得极限升温速率设计试验工艺制度。实验结果表明,所设计的脱脂工艺制度可以成功实现大尺寸粉末压坯的无缺陷脱脂。

参考文献:

[1] Sadoway D R. Inert anodes for the hall heroult cell: The ultimate materials challenge[J]. JOM, 2001, 53(5): 34-35.

[2] Pawlek R P. Inert anodes: an update[C]//Light Metals. 2008, Warrendale: TMS, 2008: 1039-1045.

[3] 张 雷, 周科朝, 李志友, 等. 气氛对NiFe2O4陶瓷烧结致密化的影响[J]. 中国有色金属学报, 2004, 14(6): 1002-1006.

ZHANG Lei, ZHOU Ke-chao, LI Zhi-you, et al. Effect of atmosphere on densification in sintering nickel ferrite ceramic for aluminum electrolysis[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 1002-1006.

[4] 张 雷, 周科朝. 铝电解用NiFe2O4型金属陶瓷惰性阳极的研究进展[J]. 材料导报, 2005, 19(6): 48-51.

ZHANG Lei, ZHOU Ke-Chao. Progress in studies on the NiFe2O4 spinel based cermet inert anodes[J]. Materials Review, 2005, 19(6): 48-51.

[5] 张 雷, 李志友, 周科朝, 等. 聚乙烯醇在镍氧体压坯中的脱脂行为[J]. 粉末冶金材料科学与工程, 2005, 10(6): 340-343.

ZHANG Lei, LI Zhi-you, ZHOU Ke-chao, et al. Degreasing behavior of ployvinyl alcohol in NiFe2O4 compacts[J]. Materials Science and Engineering of Powder Metallurgy, 2005, 10(6): 340-343.

[6] German R M. Theory of thermal debinding[J]. Inter J Powder Metall, 1987, 24(3): 237-245.

[7] Stangle G C, Aksay I A. Simultaneous momentum, heat, and mass transfer with chemical reaction in a disordered porous medium: Application to binder removal from a ceramic green body[J]. Chem Eng Sci, 1990, 45(7): 1719-1731.

[8] Calvert P, Cima M. Theoretical models for binder burnout[J]. Journal of the American Ceramic Society, 1990, 73(3): 575-79.

[9] Baklouti S, Bouaziz J, Chartier T, et al. Binder burnout and evolution of the mechanical strength of dry-presssed ceramics containing poly(vinyl alcohol)[J]. Journal of the European Ceramic Society, 2001, 21(8): 1087-1092.

[10] Oliveira A A M, Kaciany M, Hrdina K E, et al. Mass diffusion controlled bubbling and optimum schedule of thermal degradation of polymeric binders in molded powders[J]. International Journal of Heat and Mass Transfer, 1999, 42(17): 3307-3329.

[11] Song J H, Evans J R G, Ediringhe M J, et al. Determination of gas transport coefficients in ceramic bodies during thermolysis of organic additives[J]. Interational Materials Reviews, 1996, 41(3): 116-128.

[12] Shi Z, Guo Z X, Song J H. A Diffusion-controlled kinetic model for binder burnout in a powder compact[J]. Acta Materialia, 2002, 50(8): 1937-1950.

[13] Shi Z, Guo Z X. Kinetic modelling for binder removal in a powder-based compacts[J]. Materials Science and Engineering, 2004, A365(1/2): 129-135.

[14] Yutaka S, Junichi N, YAO Zhang, et al. Kinetics of property change associated with atmospheric humidity changes in alumina powder granules with PVA binder[J]. Journal of European Ceramic Society, 2002, 22(16): 2835-2840.

[15] Vijayalaxmi R, Latha P, Ashokan P V. Thermal degradation of poly (N-vinylpyrrolidone)-poly (vinyl alcohol) blends[J]. Polymer Journal, 1999, 31(10): 887-889.

[16] Freeman E S, Carroll B. The application of thermoanalytical techniques to reaction kinetics. Thermo-gravimetric evaluation of the kinetics of the decomposition of calcium oxalate monohydrate[J]. J Phys Chem, 1958, 62(4): 394.

[17] Mishra R, Rao K J. Thermal and morphological studies of binary and ternary composites of poly(vinyl alcohol) with alumina and zirconia[J]. Ceramics International, 2000, 26(2): 371-378.

[18] Shie J L, Chen Y H, Chang C Y, et al. Thermal pyrolysis of poly(vinyl alcohol) and its major products[J]. Energy Fuels, 2002, 16(1): 109-118.

[19] Shende R V, Lombardo S J. Determination of binder decomposition kinetics for specifying heating parameters in binder burnout cycles[J]. Journal of the American Ceramic Society, 2002, 85(4): 780-786.

[20] Shivashankar T S, German R M. Effective length scale for predicting solvent-debinding times of components produced by powder injection molding[J]. Journal of the American Ceramic Society, 1999, 82(5): 1146-1152.

[21] Liau L C K, Peters B, Krueger D S, et al. Role of length scale on pressure increase and yield of poly(vinyl butyral)-barium titanate-platinum multilayer ceramic capacitors during binder burnout[J]. Journal of the American Ceramic Society, 2000, 83(11): 2645-2653.

[22] Feng K, Stephen J L. Modeling for the pressure distribution in three-dimensional porous green bodies during binder removal[J]. J Am Cerma Soc, 2003, 86(2): 234-240.

[23] Ying S J, Lam Y C, Chai J C, et al. Simulation of thermal debinding: Effects of mass transport on equivalent stress[J]. Computational Materials Science, 2004, 30(3/4): 496-503.

[24] Matar S A, Edirisinghe M J, Evans J R G, et al. Diffusion of degradation products in ceramic moldings during pyrolysis: Effect of geometry[J]. Journal of the American Ceramic Society, 1996, 79(3): 749-755.

[25] West A C, Lombardo S J. The role of thermal and transport properties on the binder burnout of injection-molded ceramic components[J]. Chemical Engineering Journal, 1998, 71(3): 243-252.

[26] Dong C, Bowen H K. Hot-stage of bubble formation during binder burnout[J]. Journal of the American Ceramic Society, 1989, 72(6): 1082-1087.

收稿日期:2007-12-20;修回日期:2008-03-04

基金项目:国家重点基础研究发展规划资助项目(2005CB623703);湖南省科技计划资助项目(2007GK3096);中南大学博士后科学基金资助项目 (2007年)

通信作者:张 雷(1975-),男,辽宁锦州人,博士后,从事粉末冶金功能材料研究;电话:0731-8836264;E-mail: fgmzhang@163.com