DOI: 10.11817/j.issn.1672-7207.2018.06.010

薄壁注射成型中聚合物与模具间接触热阻研究

蒋礼1,蒋炳炎1,吴旺青1,朱来余1,DRUMMER Dietmar2

(1.中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

2. 埃尔朗根-纽伦堡大学 聚合物技术研究所,德国 埃尔朗根,91058)

摘要:基于薄壁注射成型过程中聚合物熔体与模具之间的热量交换分析,提出一种可用于计算聚合物与模具界面之间接触热阻(RTC)的新算法,通过结合实验研究与理论分析,获得聚碳酸酯(PC)薄壁制件注射成型中聚合物与模具界面之间的平均RTC,研究注射成型工艺参数以及聚合物与模具之间界面环境对RTC的影响规律。研究结果表明:薄壁注射成型中聚合物与模具界面之间的RTC与成型条件密切相关,其影响不可忽略;RTC随着模具温度、熔体温度、保压压力和保压时间的增加而减小,其中模具温度和保压时间的影响最显著;通过更换导热率较高或者型腔表面粗糙度较高的模芯材料,同样可降低RTC。

关键词:薄壁注塑;接触热阻;界面传热;成型条件

中图分类号:TQ320.63 文献标志码:A 文章编号:1672-7207(2018)06-1381-06

Research on thermal contact resistance between polymer and mold during thin-wall injection molding

JIANG Li1, JIANG Bingyan1, WU Wangqing1, ZHU Laiyu1, DRUMMER Dietmar2

(1. State Key Laboratory of High-Performance Complex Manufacturing,Central South University, Changsha 410083, China;

2. Institute of Polymer Technology, University of Erlangen-Nürnberg, Erlangen 91058, Germany)

Abstract: Based on the heat exchange analysis between polymer and mold during thin-wall injection molding, a novel algorithm for calculating thermal contact resistance(RTC) between polymer and mold was proposed. Through combination of experimental and analytical research, the average RTC between polymer and mold during injection molding for a polycarbonate (PC) thin-wall part was obtained, and the influence of the injection molding process parameters and the interface environment between melt and mold on RTC was researched. The results show that RTC between polymer and mold in thin-wall injection molding is not negligible, and it is strongly correlated with the process conditions. RTC decreases with the increase of the melt temperature, mold temperature, dwell pressure and dwell time, and the mold temperature and dwell time have the greatest influence on RTC. Exchanging with higher thermal conductive or higher surface roughness mold core can also reduce RTC.

Key words: thin-wall injection molding; thermal contact resistance; interface heat transfer; process condition

热塑性塑料的注塑成型工艺凭借其低成本、短周期、易操作等诸多优点,在国防、民用等领域中得到广泛应用。一个完整的注塑过程主要分为充填阶段和后充填阶段,每个阶段都包含复杂的热传递过程[1],其显著地影响着制件和模具的温度分布,进而影响制件的力学性能和尺寸精度,对生产效率也有极大影响[2]。在1个注塑成型周期中,首先,精确计量的聚合物被加热至熔融状态,然后迅速通过1个浇口注射到已被预加热到一定温度的模具型腔中;对于热塑性塑料特别是半结晶的热塑性塑料,制件冷却时体积会收缩,因此,需维持一定的保压压力,在浇口凝固之前注入更多的熔体以补偿制件收缩;当熔体充分冷却凝固后,模具开模制件被顶出;最后,模具合模准备好下一次注塑循环过程。在冷却阶段,浇口凝固后,无法继续保压补偿制件体积收缩,型腔压力下降到最小值,聚合物与模具之间由于制件收缩产生气隙,凝固的聚合物与模具型腔之间实际接触面积变小,导致制件与模具界面之间的热传递过程产生急剧变化,聚合物与模具交界面的表面温度存在1个较大温差,而这个温差正是由于聚合物与模具界面间的接触热阻(thermal contact resistance,RTC)产生的,其定义式为

(1)

(1)

式中: 为聚合物-模具型腔交界面之间的温差;Q为通过聚合物-模具型腔交界面之间的热流;S为聚合物-模具型腔的接触面积。以往人们对于注塑成型后填充阶段聚合物与模具间传热过程的研究大多是将聚合物与模具间的接触简化为完美的充分接触,不考虑RTC,并假定聚合物-模具界面之间的热传递效率不随时间变化,这样仿真得出的冷却时间不符合实际情况,比实际测出的时间更短。近年来,对于注塑成型制件的质量要求越来越高,关于RTC的研究也逐渐增多。YU等[3]通过简易安装温度和压力传感器测量了不同材料、不同厚度下后填充阶段的RTC,研究了不同厚度下RTC对冷却时间的影响,结果表明,RTC的存在会大幅度增加冷却时间。GOFF等[4-7]利用压力传感器、热流密度计和热电偶搭建了一个测量聚合物-模具内部温度与界面换热系数(等于RTC的倒数)的实验平台,并测量了注塑成型后充填阶段在不同工艺参数下的RTC,根据实验测得结果拟合得到一定粗糙度下计算RTC的经验关系式。RTC主要与保压压力和型腔表面粗糙度有关。BENDADA等[8-9]研究了不同工艺参数对RTC的影响,结果表明,RTC随着保压压力、注射温度和模具温度的升高而减小,并且模具温度对RTC的影响最大。SRIDHAR等[10-11]运用C-MOLD仿真软件,引入气隙建模表征界面换热系数,从数值模拟的角度研究了界面换热系数与气隙厚度、宽度的关系,得出界面换热系数为时间和空间的函数,并认为界面换热系数与制件充填阶段厚度方向的温度场有关联,界面换热系数越大,制件厚度方向温度越高。目前,人们对RTC进行研究得出:1) 在预测薄壁注塑成型温度场分布的过程中,聚合物与模具界面之间的RTC不可忽略,RTC 作为关键参数对整个仿真过程中仿真结果的准确性影响极大[12-17];2) 在整个注塑成型周期中,聚合物与模具界面之间的RTC在时间和空间上呈动态变化[18]。

为聚合物-模具型腔交界面之间的温差;Q为通过聚合物-模具型腔交界面之间的热流;S为聚合物-模具型腔的接触面积。以往人们对于注塑成型后填充阶段聚合物与模具间传热过程的研究大多是将聚合物与模具间的接触简化为完美的充分接触,不考虑RTC,并假定聚合物-模具界面之间的热传递效率不随时间变化,这样仿真得出的冷却时间不符合实际情况,比实际测出的时间更短。近年来,对于注塑成型制件的质量要求越来越高,关于RTC的研究也逐渐增多。YU等[3]通过简易安装温度和压力传感器测量了不同材料、不同厚度下后填充阶段的RTC,研究了不同厚度下RTC对冷却时间的影响,结果表明,RTC的存在会大幅度增加冷却时间。GOFF等[4-7]利用压力传感器、热流密度计和热电偶搭建了一个测量聚合物-模具内部温度与界面换热系数(等于RTC的倒数)的实验平台,并测量了注塑成型后充填阶段在不同工艺参数下的RTC,根据实验测得结果拟合得到一定粗糙度下计算RTC的经验关系式。RTC主要与保压压力和型腔表面粗糙度有关。BENDADA等[8-9]研究了不同工艺参数对RTC的影响,结果表明,RTC随着保压压力、注射温度和模具温度的升高而减小,并且模具温度对RTC的影响最大。SRIDHAR等[10-11]运用C-MOLD仿真软件,引入气隙建模表征界面换热系数,从数值模拟的角度研究了界面换热系数与气隙厚度、宽度的关系,得出界面换热系数为时间和空间的函数,并认为界面换热系数与制件充填阶段厚度方向的温度场有关联,界面换热系数越大,制件厚度方向温度越高。目前,人们对RTC进行研究得出:1) 在预测薄壁注塑成型温度场分布的过程中,聚合物与模具界面之间的RTC不可忽略,RTC 作为关键参数对整个仿真过程中仿真结果的准确性影响极大[12-17];2) 在整个注塑成型周期中,聚合物与模具界面之间的RTC在时间和空间上呈动态变化[18]。

RTC对注塑成型温度场的影响很大,特别是大型薄壁类制件或精细微纳零件等。影响聚合物与模具界面之间RTC的因素很多,主要包括模具型腔压力、熔体和模具温度、聚合物种类、模具材料及其表面粗糙度等[19]。目前,对RTC的测量难度较大,现有研究关于RTC影响因素的结论也不完全一致。为此,本文作者自主搭建聚合物与模具界面之间RTC的测量平台,从注塑成型周期中热量交换平衡的角度出发,得到计算RTC的新算法,并研究注塑成型工艺参数和聚合物与模具间界面环境对RTC的影响规律。

1 实验

1.1 实验原理

在整个注射成型过程中,聚合物熔体与模具之间时刻发生热量交换,根据RTC的定义,可知时间t内,聚合物熔体与模具间热交换的能量Q1为

(2)

(2)

式中:RTC为熔体与模具间的接触热阻; 为熔体-模具型腔交界面间的温差;S为熔体-模具型腔的接触面积。

为熔体-模具型腔交界面间的温差;S为熔体-模具型腔的接触面积。

聚合物熔体在模具型腔流动过程中,在聚合物熔体的流动方向上,不考虑熔体之间的导热,在时间t内,聚合物熔体损失的能量Q2为

(3)

(3)

式中:c为聚合物熔体的比热容;ρ为聚合物熔体密度;ω为聚合物熔体的流动速度(即注射速率); 为聚合物熔体的温度变化。

为聚合物熔体的温度变化。

当注射成型完成若干个制品成型周期后,各项成型工艺参数都趋于稳定,聚合物熔体带来的热量等于冷却剂在冷却管道中带出的热量,模具达到动态热平衡状态。即在注射成型周期中的熔体充填阶段,熔体从浇口处的A点流向制件中心处的B点,在该过程中,Q1=Q2,即

(4)

(4)

式中:t0为熔体从浇口处流到制件中心处的时间。聚合物熔体在浇口处和制件中心处的表层温度分别为TA和TB,模具温度相对于熔体温度变化较小,取模具表面温度为初始模具温度T0,因此,基于聚合物熔体的热损失分析可得到注射成型熔体充填过程中聚合物熔体与模具界面间平均RTC:

(5)

(5)

1.2 成型材料与实验设备

注射成型材料选用德国Bayer MaterialScience公司的PC-2865,该材料的基本属性如下:导热率为0.21 W/(m·K),比热容为2.1 kJ/(kg·℃),成型温度为270~310 ℃,密度为1.2 g/cm3。所有注塑成型实验均采用德国ARBURG 370S型精密注塑机完成,该注塑机螺杆直径为20 mm,锁模力最大为500 kN,最大注射压力为250 MPa。

1.3 注射成型实验设计

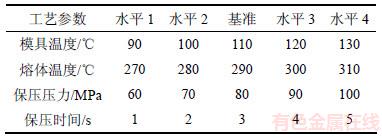

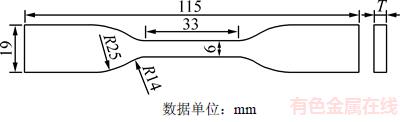

成型制件选用ASTM D638塑料拉伸试验标准中的Ⅳ型试件,如图1所示,厚度H为0.5 mm。为研究模具温度、熔体温度、保压压力和保压时间对聚合物熔体与模具型腔界面之间RTC的影响,选用模具型腔表面材料为镍(Ni),模具型腔表面粗糙度为0.034 μm,进行单因素实验,工艺水平如表1所示。通过更换模具模芯,研究模具型腔表面材料和模具型腔表面粗糙度对RTC的影响,工艺参数选取表1中的基准值,模具型腔表面粗糙度分别为0.034,0.356和1.209 μm,模具型腔材料选用镍,进行单因素实验,研究模具型腔表面粗糙度对RTC的影响。模具型腔材料选取镍(Ni)、模具钢3Mo2Cr和不锈钢0Cr18Ni9Ti,其导热率分别为80.0,33.4和16.6 W/(m·K),模具型腔表面粗糙度为0.034 μm,进行单因素实验,研究模具型腔材料对RTC的影响。

表1 PC工艺参数水平值

Table 1 Reference valve of process parameters of PC

图1 成型制件尺寸

Fig. 1 Dimensional sizes of injection molding part

1.4 聚合物熔体表面温度测量

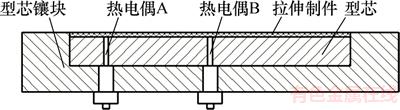

选用OMEGA 5TC-TT-K-40-36型微细热电偶测量聚合物熔体的表面温度,其线径为0.075 mm,探头端面直径为0.100 mm,理论响应时间为50 ms。温度传感器布局位置如图2所示。

图2 传感器布置示意图

Fig. 2 Layout of thermocouples

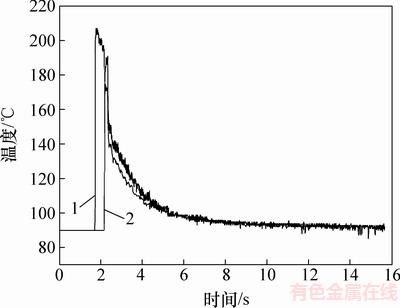

传感器探头与模具型腔表面齐平,传感器A测量熔体入口处的表面温度TA,传感器B测量制件中心处的熔体表面温度TB。在整个注塑实验过程中,聚合物熔体2个不同位置的表面温度均能被准确测量,如图3所示。

图3 注射成型周期中聚合物表面温度典型测量结果

Fig. 3 Typical measured results of polymer surface temperature during injection molding

2 结果与讨论

2.1 工艺参数对RTC的影响

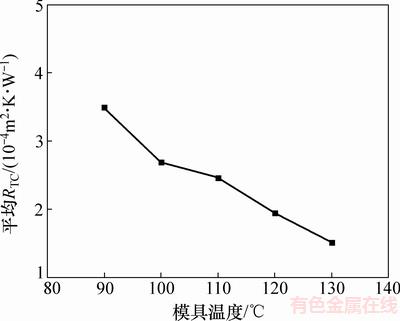

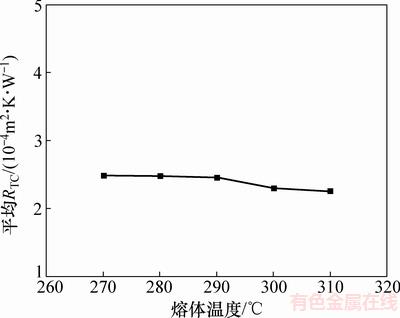

2.1.1 模具温度和熔体温度对RTC的影响

模具温度和熔体温度对平均RTC的影响分别如图4和图5所示。由图4和图5可知:平均RTC随着模具温度和熔体温度升高而降低。这是因为当模具温度和熔体温度增加时,聚合物熔体的黏度降低,聚合物熔体流过喷嘴、流道和浇口等浇注系统的压力降会减小,因此,在较高的模具温度和熔体温度条件下,更多的聚合物熔体能被充填到模具型腔内,制件的体积收缩得到更多补偿,聚合物熔体与模具界面间的气隙减少,因而RTC减小。同时,对比图4和图5可知:模具温度对RTC的影响比熔体温度的影响更显著,当模具温度从90 ℃升高到130 ℃时,平均RTC由3.496×10-4 m2·K/W降低到1.513×10-4 m2·K/W,下降幅度达56.72%;当熔体温度由270 ℃升高到310 ℃时,平均RTC由2.498×10-4 m2·K/W降低到2.269×10-4 m2·K/W,下降幅度仅为9.17%,远小于模具温度的影响程度。这是由于模具温度对聚合物熔体与模具界面间气隙的形成的影响比熔体温度的影响更显著,相对于较高的熔体温度,在较高模具温度条件下,浇口冻结时间延长,冷却速率较慢,聚合物分子链或链段能充分松弛,制件内应力减小,收缩减小;同时,延长浇口冻结时间更容易使得保压压力充分发挥作用,体积补缩更充分,因而,较高的模具温度比较高的熔体温度更容易使得聚合物熔体与模具界面间的气隙减小,模具温度对RTC的影响比熔体温度的影响更显著。

图4 模具温度对平均RTC的影响

Fig. 4 Effect of mold temperature on average of RTC

图5 熔体温度对平均RTC的影响

Fig. 5 Effect of melt temperature on average of RTC

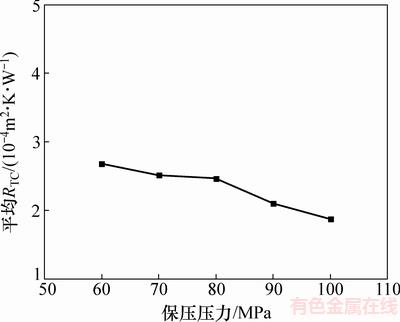

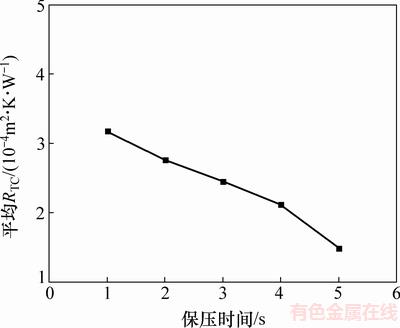

2.1.2 保压压力和保压时间对RTC的影响

保压压力和保压时间对平均RTC的影响分别如图6和图7所示。从图6和图7可见:平均RTC随着保压压力增大和保压时间延长而减小。这是由于保压压力和保压时间增大,补偿制件收缩的熔体增加,型腔内熔体的密度增大,熔体冷却收缩变形小,熔体与模具型腔表面的接触面积增大,熔体与模具型腔之间传热速率加快,因而熔体与模具界面之间的RTC减小。同时,对比图6和图7可知:保压时间对RTC的影响比保压压力的影响更显著;当保压时间由1 s增加到5 s时,RTC由3.189×10-4 m2·K/W降低到1.502×10-4 m2·K/W,下降幅度为52.9%;当保压压力由60 MPa升高到100 MPa时,RTC由2.678×10-4 m2·K/W降低到1.869×10-4 m2·K/W,下降幅度为30.21%,比保压时间的影响程度小。这是由于保压时间对制件保压阶段的体积收缩补偿作用更大,随着保压时间延长,体积补偿量更多。

图6 保压压力对平均RTC的影响

Fig. 6 Effect of dwell pressure on average of RTC

图7 保压时间对平均RTC的影响

Fig. 7 Effect of dwell time on average of RTC

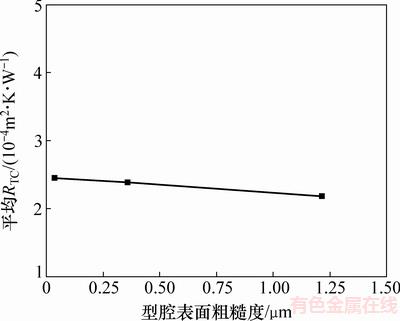

2.2 模具型腔表面粗糙度对RTC的影响

模具型腔表面粗糙度对平均RTC的影响规律如图8所示。从图8可知:随着模具型腔表面粗糙度增大,RTC减小。这是由于聚合物熔体与模具型腔表面的实际接触面积增大,在单位时间内,由高温聚合物熔体传递到模具型腔表面的热量更多,因而聚合物熔体与模具型腔之间的RTC减小。

图8 型腔表面粗糙度对平均RTC的影响

Fig. 8 Effect of cavity surface roughness on average of RTC

2.3 模具型腔表面材料对RTC的影响

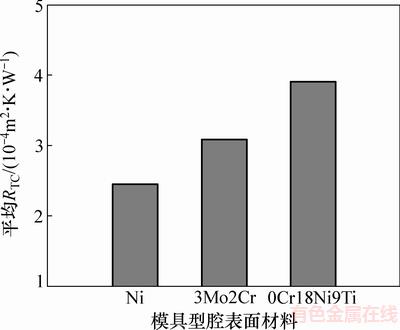

模具型腔表面材料对平均RTC的影响规律如图9所示。从图9可知:当模具材料为0Cr18Ni9Ti时,RTC最大为3.921×10-4 m2·K/W;当模具材料为3Mo2Cr时,RTC为3.597×10-4 m2·K/W;当模具材料为Ni时,RTC最小,为2.679×10-4 m2·K/W。这是因为0Cr18Ni9Ti的导热率为16.6 W/(m·K),3Mo2Cr的导热率为33.4 W/(m·K) ,Ni的导热率为80.0 W/(m·K),随着模具材料导热率增加,热量在模具内部的传递更快,热散失更快,因而,聚合物熔体与模具界面之间的传热加快,RTC减小。

图9 模具型腔表面材料对平均RTC的影响

Fig. 9 Effect of mold surface material on average of RTC

3 结论

1) 在实际注塑成型过程中,制件由于冷却收缩,聚合物熔体与模具界面之间产生气隙,熔体与模具之间的接触不是完全接触,两者之间形成界面接触热阻,对制件与模具界面之间的热传递过程影响极大。

2) 注射成型工艺参数是影响聚合物与模具界面之间RTC的关键因素。随着模具温度、熔体温度、保压时间、保压压力升高,制件得到更多的体积收缩补偿,熔体与模具界面间的气隙减小,因此,熔体与模具间RTC减小,且其中模具温度和保压时间的影响作用较显著。

3) 通过更换表面粗糙度更高、导热率更高的模芯材料,在单位时间内,高温聚合物熔体传递到模具的热量更多,同样可获得较小的RTC。

参考文献:

[1] BAI Y, YIN B, FU X, et al. Heat transfer in injection molding of crystalline plastics[J]. Journal of Applied Polymer Science, 2006, 102(3): 2249-2253.

[2] LIU S J, SU P C. Novel three-dimensional in-cavity transient temperature measurements in injection molding and fluid-assisted injection molding[J]. Polymer Testing, 2009, 28(1): 66-74.

[3] YU C J, SUNDERLAND J E, POLI C. Thermal contact resistance in injection moulding[J]. Polymer Engineering and Science, 1990, 30(24): 1599-1606.

[4] GOFF R L, POUTOT G, DELAUNAY D, et al. Study and modeling of heat transfer during the solidification of semi-crystalline polymers[J]. International Journal of Heat and Mass Transfer, 2005, 48(25): 5417-5430.

[5] GOFF R L, DELAUNAY D, BOYARD N, et al. On-line temperature measurements for polymer thermal conductivity estimation under injection molding conditions[J]. International Journal of Heat and Mass Transfer, 2009, 52(5): 1443-1450.

[6] DELAUNAY D, BOT P L, FULCHIRON R, et al. Nature of contact between polymer and mold in injection molding, Part I:influence of a non-perfect thermal contact[J]. Polymer Engineering & Science, 2000, 40(7): 1682-1691.

[7] MASSE H, ARQUIS E, DELAUNAY D, et al. Heat transfer with mechanically driven thermal contact resistance at the polymer-mold interface in injection molding of polymers[J]. International Journal of Heat and Mass Transfer, 2004, 47(8): 2015-2027.

[8] BENDADA A, et al. Analysis of thermal contact resistance between polymer and mold in injection molding[J]. Applied Thermal Engineering, 2004, 24(14): 2029-2040.

[9] BENDADA A, et al. Investigation of thermal contact resistance in injection molding using a hollow waveguide pyrometer and a two-thermocouple probe[J]. Review of Scientific Instruments, 2003, 74(12): 5282-5284.

[10] SRIDHAR L, SEDLAK B M, NARH K A. Parametric study of heat transfer in injection molding-effect of thermal contact resistance[J]. Journal of Manufacturing Science and Engineering, 2000, 122(4): 698-705.

[11] SRIDHAR L, NARH A. Finite size gap effects on the modeling of thermal contact conductance at polymer-mold wall interface in injection molding[J]. Journal of Applied Polymer Science, 2000, 75(14): 1776-1782.

[12] NGUYEN-CHUNG T, JUETTNER G, LOESER C, et al. Determination of the heat transfer coefficient from short-shots studies and precise simulation of microinjection molding[J]. Polymer Engineering & Science, 2010, 50(1): 165-173.

[13] EL OTMANI R, ZINET M, BENHADID H. Numerical simulation and thermal analysis of the filling stage in the injection molding process: Role of the mold-polymer interface[J]. Journal of Applied Polymer Science, 2011, 121(3): 1579-1592.

[14] SOBOTKA V, AGAZZI A, BOYARD N, et al. Parametric model for the analytical determination of the solidification and cooling times of semi-crystalline polymers[J]. Applied Thermal Engineering, 2013, 50(1): 416-421.

[15] BRANCIFORTI M C, CORREA M C S, POLLET E, et al. Crystallinity study of nano-biocomposites based on plasticized poly (hydroxybutyrate-co-hydroxyvalerate) with organo- modified montmorillonite[J]. Polymer Testing, 2013, 32(7): 1253-1260.

[16] SOME S C, DELAUNAY D, FARAJ J, et al. Modeling of the thermal contact resistance time evolution at polymer–mold interface during injection molding: Effect of polymers’ solidification[J]. Applied Thermal Engineering, 2015, 84: 150-157.

[17] LIU Y, GEHDE M. Evaluation of heat transfer coefficient between polymer and cavity wall for improving cooling and crystallinity results in injection molding simulation[J]. Applied Thermal Engineering, 2015, 80: 238-246.

[18] HONG S, KANG J, YOON K. Correlation between thermal contact resistance and filling behavior of a polymer melt into multiscale cavities in injection molding[J]. International Journal of Heat and Mass Transfer, 2015, 87: 222-236.

[19] LIU Y, GEHDE M. Effects of surface roughness and processing parameters on heat transfer coefficient between polymer and cavity wall during injection molding[J]. The International Journal of Advanced Manufacturing Technology, 2016, 84(5/6/7/8): 1325-1333.

(编辑 陈灿华)

收稿日期:2017-06-10;修回日期:2017-08-12

基金项目(Foundation item):国家重点基础研究发展计划(“973”计划)项目(2012CB025905);国家自然科学基金面上项目(51575540) (Project(2012CB025905) supported by the National Basic Research Development Program(973 Program) of China; Project(51575540) supported by the National Natural Science Foundation of China)

通信作者:蒋炳炎,博士,教授,从事高分子材料精密成型技术研究;E-mail:jby@csu.edu.cn