Al-6Mg-0.2Sc合金高应变速率超塑成形性能

陈明和1, 谢优华2, 芮玉龙1, 左敦稳1, 王 珉1

(1. 南京航空航天大学 机电工程学院, 南京 210016;

2. 北京航空材料研究院, 北京 100095)

摘 要: 在温度400~500℃、 初始应变速率为2.0×10-4 ~2.0×10-2s-1的条件下, 对Al-6Mg-0.2Sc合金冷轧板材(初始晶粒尺寸为25μm)进行了相应的超塑性能、 高应变速率超塑性胀形成形实验研究。 结果表明: 在450℃、 初始应变速率为2.0×10-2s-1的实验条件下, Al-6Mg-0.2Sc合金冷轧板材具有高应变速率的超塑性能, 其最大延伸率为421%; 在高应变速率条件下, 胀形成形大端直径为d154mm, 深度h为80mm的锥形零件的成形时间为73s, 成形后零件的壁厚变薄的不均匀率小于8%。 此外, 还对成形零件的微观组织进行了初步的SEM观察分析。 结果表明, 成形零件的微观组织无明显粗化, 其孔洞率小于1.5%。

关键词: Al-6Mg-0.2Sc合金; 高应变速率超塑性; 超塑性胀形; 微观组织 中图分类号: TG146.2

文献标识码: A

High strain rate superplasticity of Al-6Mg-0.2Sc alloy

CHEN Ming-he1, XUE You-huo2, RUI Yu-long1, ZUO Dun-wen1, WANG Min1

(1. College of Mechanical and Electrical Engineering,Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The superplastic properties of a cold-rolled Al-6Mg-0.2Sc alloy were studied in the temperature range of 400-500℃ and strain rates range of 2.0 ×10-4-2.0×10-2s-1 with a maximum elongation-to-failure of 308% recorded at 450℃ and an initial strain rate of 2.0×10-2s-1. At the same time, high strain rate superplastic (HSRS) bulging of a cold-rolled Al-6Mg-0.2Sc alloy sheet was investigated at 450℃and an initial strain rate of 2.0×10-2s-1. The forming time of a cone-shaped part (diameter of 154mm) is 73s and nonuniformity of wall thickness is less than 8%. Besides, fracture microstructure of sample was examined using both optical and scan electron microscope. The results show that the grain is not coarsened and the cavity rate is less than 1.5%.

Key words: Al-6Mg-0.2Sc alloy; high strain rate superplasticity; superplastic bulging; microstructure

近年来, 为了满足飞行器等交通工具轻型化的需要, 人们对开发具有良好的成形性能的Al-Mg基超轻型合金发生了浓厚兴趣[1, 2]。 用微量钪(Sc)元素合金化的铝镁基合金(Al-Mg-Sc合金), 由于微量稀土元素钪的作用, 在铝镁基合金中形成连续的、 热稳定性好的所谓的L12相, 如Al3Sc沉淀相, 可以阻止材料晶粒的粗化, 使该合金具有高的强度和韧性、 良好的耐蚀性和可焊性 , 成为航空航天、 核能和船舰等国防军工尖端领域用新型铝合金结构材料[3, 4]。 虽然Al-Mg-Sc合金的冷成形性能不尽人意, 但许多研究成果表明: Al-Mg-Sc合金具有超塑性, 特别是在高应变速率(≥10-2s-1)条件下显现出优异的超塑性能。 如Musin等[5]利用Al-5.7%Mg-0.32%Sc合金, 在450℃ 、 初始应变速率5.6×10-2的条件下, 获得了2000%的延伸率; Nieh等[6]利用Al-6Mg-0.3Sc 合金, 在温度475~520℃的范围内、 初始应变速率10-4~100s-1 范围内进行了高应变速率超塑性研究, 并获得了1130%的延伸率。 Al-Mg-Sc合金呈现出的优异的高应变速率超塑性能, 使得其成形性能获得了显著的改善。 所以, Al-Mg-Sc合金除了被应用在飞机机身、 飞机薄壁板及增强面板上以外, 还非常适合于在诸如汽车覆盖件、 IT制造业等一般民用工业中广泛应用。 自20世纪90年代以来, Al-Mg-Sc合金的开发及其相应的高应变速率超塑性研究已成为国际材料与加工领域研究的热点。 我国也研发了具有较好性能的Al-6Mg-0.2Sc合金, 但对其高应变塑率超塑性及其成形性的研究还处于起步阶段。

本文作者以国产新型Al-Mg-0.2Sc合金冷轧板材(初始晶粒尺寸为25μm)为实验材料, 板料厚度为1.62mm, 对其进行高应变速率超塑性能及其相关的成形性的研究, 以期获得可以用于实际生产应用的性能参数。

1 实验

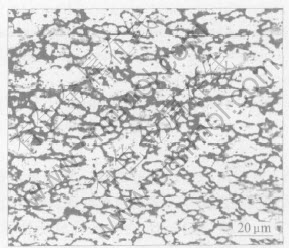

本研究试验板材由中国西南铝业(集团)有限责任公司生产, 板材化学成分为Al-6Mg-0.2Sc(质量分数, %), 冷轧至1.62mm厚, 并经220℃退火; 材料初始晶粒尺寸为25μm左右, 图1 所示为其微观组织。

图1 Al-6Mg-0.2Sc合金的微观组织

Fig.1 Microstructure of cold-rolled Al-6Mg-0.2Sc alloy

本研究包括两方面的内容。 1) 超塑性能试验研究。 实验条件如下: a. 超塑性拉伸试验温度为400~550℃; b. 应变速率为1.5×10-4~2.0×10-1。 试验分别按恒应变速率与恒速率两种方法进行, 试验设备采用带数据采集与处理的微机控制电子万能试验机, 设备型号为CMT5105; 2) 超塑成形性实验研究。 利用第一部分内容的试验优化结果进行盒形件的高应变速率成形性试验研究。 此外, 还进行了初步的相关微观组织观察研究。 研究中先测定材料的工程应力和工程应变曲线, 然后计算出相应的真应力σT 和真应变εT。 超塑性拉伸试样断口和轴剖面上的空洞用JMS6300 扫描电子显微镜进行观察, 并用“现代图像分析”软件进行分析。 金相试样按照铝合金常规制备方法制备, 采用KELLER试剂(HCl 2.5mL+HF 1mL+HNO3 1.5mL)进行腐蚀, 在Neophot-21金相显微镜下进行金相观察。 在扫描电镜JSM-5600LV上进行拉伸试样断口显微观察。

2 实验结果

2.1 Al-6Mg-0.2Sc合金的超塑性能

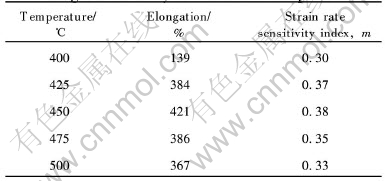

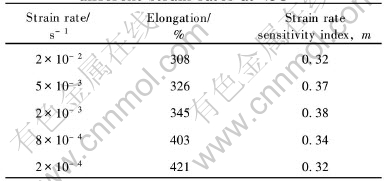

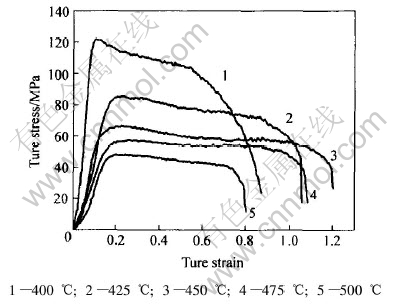

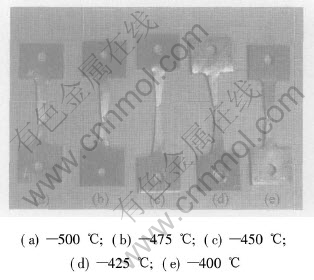

在温度为 400~500℃和应变速率为2.0×10-4~2.0×10-2s-1的范围内, 分别进行400、 425、 450、 475、 500℃与2×10-2、 5×10-3、 2×10-3、 8×10-4、 2×10-4s-1等5个实验条件相互组合的等应变速率超塑性能实验。 实验结果表明, Al-6Mg-0.2Sc合金的最佳超塑性温度为450℃, 应变速率为2×10-4s-1, 获得的最大延伸率为421%; 在温度450℃、 应变速率2.0×10-2s-1时, 获得的最大延伸率为308%。 根据日本标准协会为高应变速率超塑变形制订的标准, 即规定应变速率大于10-2s-1 的超塑变形行为为高应变速率超塑变形[7, 8], 故该实验研究用合金呈现出高应变超塑性能。 温度超过500℃时, 该材料的超塑性能随应变速率的适当提高出现延伸率增加的现象。 表1所列为不同温度下的延伸率和m值(应变速率敏感系数), 表2所列为450℃时不同应变速率下的延伸率和m值。 图2所示为不同温度下的等应变速率拉伸的真实应力—应变曲线。 图3所示为450℃时不同应变速率下的应力—应变曲线。 图4所示为部分超塑性拉伸试件照片。

2.2 Al-6Mg-0.2Sc合金的超塑性胀形

在完成以上的高应变速率超塑性性能试验研究的基础上, 进行高应变速率超塑性胀形实验。 超塑性胀形先用有限元软件MARC建立模型来仿真, 求解胀形压力及贴模时间。 定义材料本构方程σe=

表1 Al-6Mg-0.2Sc合金在不同温度下的延伸率和m值

Table 1 Elongation and m value of Al-6Mg-0.2Sc alloy at different temperatures

表2 Al-6Mg-0.2Sc合金在450℃不同应变速率下的延伸率和m值

Table2 Elongation and m value of Al-6Mg-0.2Sc alloy under different strain rates at 450℃

图2 Al-6Mg-0.2Sc合金在初始应变速率为2.0×10-2s-1时不同温度下的真应力—真应变曲线

Fig.2 True stress—true strain curves for Al-6Mg-0.2Sc alloy tested under initial strain rate of 2.0×10-2s-1 at different temperatures

图3 450℃时Al-6Mg-0.2Sc合金在不同初始应变速率下的真应力—真应变曲线

Fig.3 True stress—true strain curves for Al-6Mg-0.2Sc alloy tested at 450℃ under different initial strain rates

图4 初始应变速率为2×10-2s-1时不同温度下Al-6Mg-0.2Sc合金的超塑性拉伸试件照片

Fig.4 Photos of Al-6Mg-0.2Sc samples tested under initial strain rate of 2.0×10-2s-1 at different temperatures

, 按照超塑性能试验获得的最佳变形参数, 取

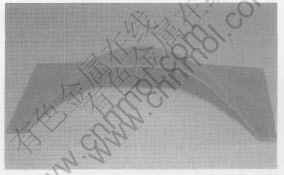

, 按照超塑性能试验获得的最佳变形参数, 取 为665、 m为0.387, 初始应变速率为2×10-2s-1, 温度为450℃。 成形零件的形状为锥形, 最大直径为154mm, 深度h为80mm, 板料厚度为1.62mm。 通过有限元模拟计算出压力—时间加载曲线, 得出成形时间约为65s, 实际试验成形时间为73s。 图5所示为高应变速率超塑胀形成形零件, 图6所示为成形零件的剖切断面。 经测量, 成形件的壁厚的不均匀率小于15%。

为665、 m为0.387, 初始应变速率为2×10-2s-1, 温度为450℃。 成形零件的形状为锥形, 最大直径为154mm, 深度h为80mm, 板料厚度为1.62mm。 通过有限元模拟计算出压力—时间加载曲线, 得出成形时间约为65s, 实际试验成形时间为73s。 图5所示为高应变速率超塑胀形成形零件, 图6所示为成形零件的剖切断面。 经测量, 成形件的壁厚的不均匀率小于15%。

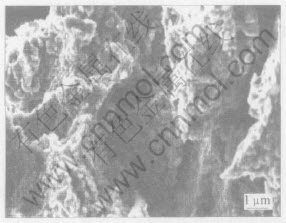

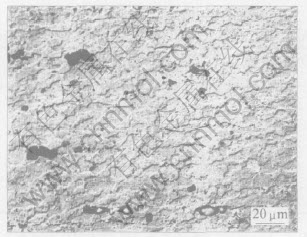

2.3 Al-6Mg-0.2Sc合金超塑性变形区的微观观察

本研究还对超塑性拉伸试件的断口及超塑性胀形零件的最大变形区进行了SEM初步观察。 图7所示为在450℃、 初始应变速率2.0×10-2s-1下的高应变速率超塑拉伸试件的断口形貌, 图8所示为锥形高应变速率超塑性成形件最大变形处孔洞的低

图5 Al-6Mg-0.2Sc合金的高应变超塑性胀形零件照片

Fig.5 Photo of workpiece of Al-6Mg-0.2Sc alloy by high strain rate superplastic bulging tested under initial strain rate of 2×10-2s-1

图6 Al-6Mg-0.2Sc合金的高应变超塑性胀形零件剖面厚度的变化

Fig.6 Thickness distribution of workpiece for Al-6Mg-0.2Sc alloy by high strain rate superplastic bulging

图7 Al-6Mg-0.2Sc合金高应变速率超塑拉伸试件的断口形貌

Fig.7 Fractograph of stretched sample for Al-6Mg-0.2Sc alloy by high strain rate superplastic bulging tested under initial strain rate of 2.0×10-2s-1 at 450℃

图8 Al-6Mg-0.2Sc合金高应变速率胀形零件的孔洞的SEM像

Fig.8 SEM image of cavity of workpiece for Al-6Mg-0.2Sc alloy by high strain rate superplastic bulging

倍SEM形貌, 经过图像处理软件处理得出其孔洞率在1.4%左右。

3 讨论

一般超塑性材料具有较好的超塑性性能的基本条件为: 稳定的细小晶粒, 一般小于10μm; 合适的变形温度, 许多细晶粒材料的超塑性变形一般发生在0. 5Tm(Tm是绝对温度熔点)附近; 较低的初始应变速率, 一般在10-4~10-3s-1之间[9, 10]。

本研究所用Al-6Mg-0.2Sc合金材料的原始晶粒尺寸在25μm左右, 其通常的超塑性温度应该在370℃左右, 但本试验研究结果表明其超塑性开始温度在400℃左右, 而且有很宽的超塑性温度范围(400~500℃)。 这与文献[11]作者研究得到的粗晶的Fe3Al基合金材料的超塑性温度的情况很相似, 可能是由于粗晶材料的超塑性温度要比细晶材料的超塑性温度要高的缘故, 但具体的原因还不十分清楚。 Al-6Mg-0.2Sc合金中由于Sc的存在, 形成了细小的分布均匀的连续的Al3Sc沉淀相, 对材料塑性变形时的动态及静态再结晶的晶界与亚晶界起到钉扎作用, 从而有效地抑制晶粒的长大, 有助于小角度晶粒与大角度晶粒之间的转换以及随后的晶粒滑移[12, 13], 这也是该合金具有高应变速率超塑性的原因。 在高应变速率下变形, 在晶粒间的相互挤压和转动作用下, 晶粒很容易细化并趋于等轴化, 晶界上液相物质产生得较少, 晶粒的细化会使晶界滑移更易进行, 且变形过程中不易于产生孔洞, 等轴性较好的细小晶粒不仅能促进晶界滑动, 而且能加速原子扩散, 孔洞相容性较好, 超塑性能力较强。 粗晶材料的超塑性变形与细晶材料超塑性变形有根本的不同, 高应变速率下粗晶材料超塑性变形会导致晶粒细化, 而细晶材料的超塑性变形细化晶粒是前提条件, 且变形过程中晶粒会发生粗化[14, 15]。 从图7可以看出, 高应变速率超塑性变形后的断口处粗大的纤维状组织也是由细小的等轴晶粒组成的, 断裂处韧窝基本消失, 形成了典型的冰糖状沿晶断裂形貌, 这也可为材料的高应变速率性能提供条件。 从图8的经过高应变超塑性胀形变形后的空洞SEM观察可以看出, 变形后的微观组织中的空洞率很小, 因而胀形零件有好的室温性能。

4 结论

1) Al-6Mg-0.2Sc合金具有较好的高应变速率(10-2s-1)超塑性能, 在450℃、 初始应变2×10-2s-1时, 单向拉伸的延伸率为421%。

2) Al-6Mg-0.2Sc合金在较宽的温度范围内(425~500℃)都具有较好的超塑性能。

3) Al-6Mg-0.2Sc合金在较高的超塑性变形温度时(>500℃), 高的应变速率比低的应变速率呈现出更好的超塑性能(初始应变速率为5×10-3s-1时的延伸率为367%, 初始应变速率为2×10-4s-1时的延伸率为289%)。

4) 高应变速率(2×10-2s-1)条件下成形的零件的壁厚的不均匀变薄率小于8%, 其微观组织的孔洞率在1.5%左右。

REFERENCES

[1]Xing H L, Wang C W, Zhang K F, et al. Recent development in the mechanics of superplasticity and its applications[J].Journal of Materials Processing Technology, 2004, 151(1-3): 196-202.

[2]Tsunemichi I, Mao J, Shang L D, et al. High strain rate superplasticity of TiC particulate reinforced 2014 aluminum alloy composites[J]. Materials Science and Engineering A, 2004, 364(1-2): 281-286.

[3]姜锋, 白兰, 尹志民, 等. Al-Mg-Sc 中间合金的制备[J]. 中国有色金属学报, 2003, 13(3): 584-587.

JIANG Feng, BAI Lan, YIN Zhi-min, et al. Preparation of Al-Mg-Sc master alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 584-587.

[4]Maeng D Y, Lee J H, Hong S I. The effect of transition elements on the superplastic behavior of Al-Mg alloys[J]. Mater Sci and Eng A, 2003, 357(1-2): 188-195.

[5]Musin F, Kaibyshev R, Motohashi Y, et al. High strain rate superplasticity in a commercial Al–Mg–Sc alloy[J]. Scripta Materialia, 2004, 50(3): 511-516.

[6]Nieh T G, Hsiung L M, Wadsworth J, et al. High strain rate superplsticity in a continuously recrystallized Al-6%Mg-0.3%Sc alloy[J]. Acta Mater, 1998, 46(8): 2789-2800.

[7]Sakuma T, Higashi K. Summary in the project towards innovation in superplasticity[J] . Materials Transactions JIM, 1999, 40(8): 702-715.

[8]Higashi K. High strain rate superplasticity and its applications[A]. Proceedings of IMMM'99[C]. London, 1999. 237-244.

[9]Sherby, Wadsworth J. Superplasticity and its applications[J]. J Prog Mater Sci, 1989, 33: 166-172.

[10]林兆荣. 金属超塑性成型原理及应用[M]. 北京: 航空工业出版社, 1990.

LIN Zhao-rong. Theory and Application of Superplastic Forming in Metals[M]. Beijing: Aeronautical Industry Press, 1990.

[11]Gao D C, Yangw Y, Huang X, et al. Superplastic deformation in a coarse grained Fe3Al based alloy[J].Scripta Mater, 2001, 44(3): 501-505.

[12]Filatov Y A, Yelagin V I, Zakharov V. New Al-Mg-Sc alloys[J]. Mater Sci Eng, 2000, 280A(1): 97-101.

[13]吴艳青, 张克实, 耿晓亮, 等. LY12 合金粗晶材料的超塑性变形机制[J]. 中国有色金属学报, 2003, 12(5): 986-990.

WU Yan-qing, ZHANG Ke-shi, GENG Xiao-liang, et al. Superplastic deformation mechanisms of coarse-grained LY12[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 986-990.

[14]Carrino L, Giuliano G, Ucciardello N. Analysis of void growth in superplastic materials[J]. Journal of Materials Processing Technology, 2004, 155-156(3) : 1273-1279.

[15]LIN Dong-liang, SUN Feng. Superplasticity in a large-grained TiAl alloy[J]. Intermetallics, 2004, 12(2): 875-883.

(编辑陈爱华)

基金项目: “十五”国防预研项目(41312020303)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 陈明和(1962-), 男, 博士, 副教授

通讯作者: 陈明和, 副教授; 电话: 025-84892508; E-mail: meemhchen@nuaa.edu.cn