文章编号:1004-0609(2007)12-2046-08

电解铝液中Al2O3夹杂物的形成机理

贺永东1, 2,张新明1,陈明安1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 金川集团有限公司,金昌 737100)

摘 要:介绍铝电解机制对电解铝液中形成Al2O3夹杂物的影响,分析铝液中Al2O3夹杂物形成的机理,推算CO2对铝液扩散的质量传递方程,描述效应处理过程对铝液中Al2O3夹杂物形成过程的影响。利用Person—Waddington电流效率模型测算电解铝液中可能形成的Al2O3夹杂物最大值。结果表明:电解过程生成的Al2O3夹杂物对铝液的污染,是短流程工艺影响铝熔体冶金质量的主要根源。

关键词:电解铝液;Al2O3夹杂物;CO2;阳极效应;冶金遗传

中图分类号:TG 290; TF 803.25 文献标识码:A

Formation mechanism of Al2O3 inclusion in electrolytic liquid-Al

HE Yong-dong1, 2, ZHANG Xin-ming1, CHEN Ming-an1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Jinchuan Company Limited Group, Jinchang 737100, China)

Abstract: The effect of mechanism of Al electrolyte on the formation of Al2O3 inclusion in electrolytic liquid-Al was introduced. The mechanism of formation of dioxide inclusions in liquid-Al was analyzed. A mass transporting equation of CO2 diffusion into liquid-Al was proposed. The formation of Al2O3 inclusion during manipulating anode effect was described. With Person—Waddington model, the probable maximum dioxide inclusions in electrolytic liquid-Al was quantitative measured. It is suggested that the alumina contained in the electrolytic liquid-Al is the main source of debasing metallurgical quantity.

Key words: electrolytic liquid-Al; Al2O3 inclusion; CO2; anode effect; metallurgical heredity

铝是仅次于钢铁的第二大金属,在国民经济与国防建设中具有极其重要的战略地位[1]。铝熔体质量影响铝制品质量,洁净的液体金属是获得优质铝制品的保证[2]。Al2O3等非金属夹杂物是影响铝熔体冶金质量的关键因素之一[3]。在铸锭中,非金属夹杂物大都以颗粒状或膜状存在,破坏铝基体的连续性,降低基体强度,恶化铝材的塑性加工性能,降低铝材的耐腐蚀性能和抗断裂韧性,为疲劳裂纹的萌生提供核心[4]。在铝熔体中,Al2O3等非金属夹杂物起到气泡形核的作用,间接地促成疏松的形成[5]。由于氢与氧化铝夹杂物是相互寄生的,氧化铝夹杂的存在是气体难以除净的关键限制因素[6]。研究铝熔体中氧化铝夹杂物的形成过程与形成机理对净化铝熔体、提高铝材质量具有重要的意义[7]。铝的化学性质十分活泼,能与环境中的O2、CO2和H2O等发生反应,生成非金属氧化物夹杂[8]。在20世纪70年代以前,由于受当时技术条件的限制,人们不能直接利用高温电解铝液生产铸锭,而是将电解铝液浇铸成重熔铝锭,利用重熔铸造法生产铸锭半成品。从当时的熔铸工艺特点出发,人们对铝-空气中的水蒸气-氧化铝夹杂物之间的作用机理进行系统研究,形成一套适应长流程工艺特点的铝液污染、净化理论[9-10]。随着技术的发展,直接利用高温电解铝液生产铸坯的短流程工艺已经取代重熔铸造法生产铸坯的长流程工艺。电解过程中产生的氢和氧化夹杂物对铝熔体的污染已经取代传统的水汽对铝熔体的污染,成为影响铝熔体冶金质量的主要根源[11]。原有的铝熔体污染理论,无法解释电解铝液中非金属氧化铝夹杂物的形成过程和形成机理,不能适应短流程工艺要求。本文作者从当前铝电解工艺特点出发,介绍了铝电解机制及物质交换过程对电解铝液中Al2O3夹杂物形成的影响。推算CO2对铝液扩散的质量传递方程。利用Person—Waddington模型对电解铝液中可能形成的Al2O3夹杂的最大值进行定量分析。

1 铝电解机制与物质交换过程对Al2O3夹杂物形成的影响

电解铝生产的基本原理是以冰晶石-氧化铝熔体为电解质,以碳块为阳极,以液体铝为阴极,在直流电流作用下,在阳极析出CO2气体,在阴极析出液体铝。在电解槽中,铝液和电解液(简称两液)受4种力的耦合作用产生运动。铝液和电解液的循环特性、循环强度取决于电解槽的容量、结构和进电方式,并反过来影响电解槽内的物质交换过程。在电解槽工作区间内存在CO2、Al和电解液三相,以及碳-电解液、电解液-铝液两个工作界面,两个界面之间的垂直距离称为极距,高度约为4.3 cm左右。极距上端产物为CO2气体,下端产物为铝液。理论计算表明:每生产1 000 kg铝约可产生1 221 kg CO2气体,在电解工况下CO2的体积约相当于2.806×103 m3,这些气体主要以弥散气泡的形式进入电解液中。由于阳极底掌面积越大,气体排出的阻力越大;电流强度越高、磁场分布越不均匀、槽内两液循环越强烈、铝液的安静性越低,阳极气体随电解液循环进入铝液的可能性越大。特别是阳极气体数量巨大,极距空间狭小,阳极气体与电解液组成的气液两相流在温差、水平电流、强磁场的作用下产生强烈的紊流运动。在极距空间内,溶解的阳极气体能将溶解的金属铝氧化;在紊流流动的电解液循环过程中,也能同铝液接触生成Al2O3污染铝液。在电解铝液中,阳极气体的溶解服从亨利定律:

在高温低压下溶液中气体的浓度可以表示为

Haupin[9]和Bratland[13] 分别测量CO2气体在冰晶石电解液中的溶解度,在1 303 K下分别为0.1和1.17 mol/m3。在两液循环和紊流流动过程中,部分阳极气体随电解液一起向阴极铝液迁移,进入高温铝液中的阳极气体将与高温铝液作用生成Al2O3和CO,这就是电解铝液中Al2O3夹杂物的主要来源:

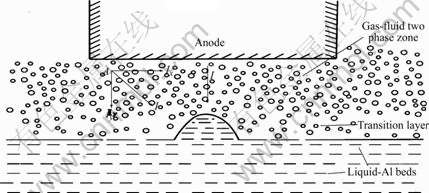

要保证铝电解过程连续进行,必须定时向电解槽中补充Al2O3物料,受电解液溶解能力的限制,加入的Al2O3物料仅一部分迅续溶解进入电解液中,未溶解的Al2O3物料或沉降在电解液-铝液界面上,或沉淀到铝液下的槽底,见图1。用铁棒插入电解槽电解液层和铝液层中保持1 min,然后分析凝固电解质的成分,结果列于表1。由表1可知:电解液-铝液界面上的Al2O3含量远大于电解液层的,因为加料量超过饱和Al2O3浓度,电解液中存在着相当多的未溶Al2O3,过量的Al2O3则沉积在两液界面上。电解液-铝液界面上的Al2O3随两液一起循环,在循环的过程中,大部分Al2O3溶解进入电解液中并参与电解过程,少部分进入铝液中或形成槽底沉淀。加料会在一定程度上污染铝液。槽底沉积的Al2O3易于形成炉底结壳,炉底结壳在电解槽冷热行程的作用下最终发生熔化软化,并呈现出疏松多孔的蜂窝状,蜂窝内为溶有Al2O3的电解液。铝液层内蜂窝状沉淀形成以蜂窝为单位的微型电解槽。微型电解槽以铝为阳极,以炉底碳素材料为阴极,在阳极上发生铝溶解并形成Al2O3,在阴极上生成Al4C3。生成的Al2O3和Al4C3随铝液循环进入铝液中。从炉底取出的蜂窝状沉淀中,常常含有大量的来不及溶解的淡黄色的Al4C3,取出的炉底沉淀具有如下特性:1) Al2O3含量一般为25%~55%;2) 沉淀物中含有0.30%的Al4C3和0.33%的铝;3) 蜂窝周围的铝液和电解液中Al2O3和Al4C3含量明显高于正常值。炉底沉淀及周围的铝液中Al2O3和Al4C3含量分析结果,证明在蜂窝状沉淀中确实存在微型电解槽机制,电解产物Al2O3和Al4C3对电解铝液造成污染。微型电解槽阴、阳两极上所发生的电化学反应为:

图1 电解槽中两液界面上及铝液中沉淀未溶Al2O3示意图

Fig.1 Schematic diagram of solid Al2O3 precipitation bed on interface and inside liquid Al

表1 电解液-铝液界面及槽底沉淀物中的Al2O3含量

Table 1 Content of Al2O3 precipitation on interface and inside liquid Al

2 阳极效应处理对铝液中形成Al2O3夹杂物的影响

阳极效应是一种有害的负反应。其本质是电解液中Al2O3浓度降低,电解液与阳极之间的界面张力增大,润湿性变差,在碳阳极界面上析出的CO2气体不能及时排出并形成一层不导电的气体薄膜,从而导致电流阻塞的过程。向电解液中添加适量Al2O3,使电解液对阳极的润湿性改善,阳极效应即可消除。效应过程本身不导致铝液含杂,但在随后的加料和效应处理过程均在一定程度上影响电解铝液的纯度。受电解液对Al2O3溶解和扩散能力限制,特别是效应期间,电解液停止沸腾,扩散能力严重减弱,依靠电解液自身溶解、富集Al2O3,达到改善阳极润湿性及效应自然熄灭。在实际生产过程中,常依靠人工辅助熄灭效应,往电解液中加入足量的Al2O3后,将湿木条插入铝液、电解液层中,碳水化合物与960 ℃的铝液、电解液发生强烈的脱水反应,生成大量H2O和CO2,并将铝液搅起,铝液穿过气膜阻挡层与阳极底掌接触形成短路。H2O和CO2都能与高温的铝液发生化学反应:

生成的Al2O3污染铝液,产生的CO和H2能在铝液层中产生强烈的沸腾作用,造成铝液短路,效应熄灭。由此可见,熄灭效应的过程实际上是在铝液中造渣的过程,是导致电解铝液中产生氢和氧化夹杂物污染的另一个原因。

3 铝电解槽中多场耦合作用与Al2O3形成

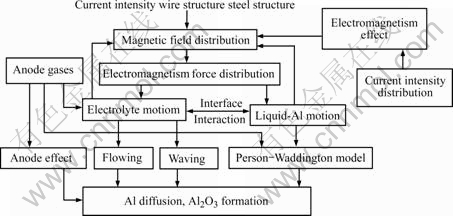

铝电解槽内物质交换以及铝液中生成Al2O3夹杂物的过程受电解槽电场、磁场、热场、浓度场、流场耦合作用的影响。各场当中,电场是电解槽能量运行的基础,是其他各物理场形成的根源。电流产生磁场,电流的热效应产生热场,磁场分布不平衡、热场分布不均匀都会导致铝液、电解液运动产生流速场,流场导致阳极气体向铝液层运动形成浓度场。对电解槽磁场、电场、热场、流速场、浓度场建立解析模型,并利用Ansys综合集成软件系统对所建立的解析模型进行分割和解析,可以求出电解液-铝液界面形状、铝液隆起高度、铝液循环速度、阳极气体逸出速度。根据电解液、铝液相对流动速度,铝液界面形状,极距参数等物理量可以确定CO2对铝液的有效扩散迁移系数,建立阳极气体对铝液扩散的质量传递模型,从而定性地揭示铝液中Al2O3夹杂物的形成规律。铝电解槽物理场耦合关系对形成Al2O3夹杂物的影响见图2。

图2 铝电解槽物理场耦合关系对形成Al2O3夹杂物的影响

Fig.2 Effect of multi-fields linking relationship on formation of Al2O3 inclusion

梅帜等[14]利用解析模型对伊川铝厂五点进电300 kA电解槽进行模拟解析,计算结果表明:电解液中Jx、Jy值存在较大的差异,表明电解槽中A和B两侧间存在较大的水平电流,水平电流是导致电解液、铝液循环,两液界面隆起,促使CO2向铝液层扩散并形成Al2O3夹杂物的主要原因。磁场计算结果表明:槽中心磁场较弱,四角磁场较强,且存在如下关系:|Bx|max>|By|max>|Bz|max>|Bx|max。根据 ,铝液界面在两个大面处的电磁力最大,且Fx、Fy都指向槽中心,在电磁力作用下,铝液在槽中部隆起。由于铝液隆起的区域极距较小通过的电流较强。隆起的铝液尖峰通常是电解槽内导电最活跃的区域,通常比角部区域高出30%~40%[14]。局部电流集中是造成电解液中产生水平电流的原因,水平电流分解示意图如图3所示。由图可知,在气液两相区A点处的电流(I)可以分解为一个水平分量Ix和一个垂直分量Iy。水平电流分量Ix在垂直磁场Bz的作用下,使该区域的电解液产生水平运动。在铝液尖峰处气液两相区内,形成一个围绕尖峰作水平循环运动的两相区,由于局部流体运动强烈,使铝液和电解液之间的迁移扩散增强,铝与CO2作用形成Al2O3夹杂物更趋强烈。流场计算结果表明:铝液流动呈现4个涡,并沿长轴方向排列,两个小面的旋涡较小,偏向B侧;中间两个旋涡较大,偏向A侧。4个漩涡中心分别位于1号~2号、3号~4号、7号~8号、9号~10号阳极导杆对应的短轴处。在A、B两侧端部,铝液和电解液流速较大,由于铝液中部隆起,拱起的高度为2.4 cm,隆起的铝液尖峰插入气-液两相区内与阳极气体直接接触。界面上将有大量的CO2与铝反应。因铝液和电解液处于运动状态,与阳极气体接触的铝液始终是刚运动过来的含Al2O3夹杂物相对较低的铝液;与铝液驻峰接触的阳极气体一旦因消耗而贫化,很快被新运动过来的饱和CO2气泡的电解液取代,反应过程始终十分强烈。因铝液在槽内湍流流动形成4个旋涡。界面上的氧化膜不断形成、不断撕裂,裸露的铝液又经过再氧化、再撕裂过程,铝液-电解液界面上始终不能形成完整的氧化膜。所生成的氧化铝,一部分被界面上的电解液溶解重新进入电解液中,参与电解过程;另一部分随铝液循环进入铝液中。在铝液和电解液接触的界面上,部分CO2气泡通过流体运动和扩散迁移直接进入铝液中,气泡与铝液之间形成一层Al2O3保护膜,能阻止铝液进一步氧化。随着气泡合并、长大、破裂,CO气体随电解液循环排出,Al2O3薄膜则留在铝液中形成铝液中弥散的氧化夹杂。这就是铝液中氧化夹杂的形成过程。

,铝液界面在两个大面处的电磁力最大,且Fx、Fy都指向槽中心,在电磁力作用下,铝液在槽中部隆起。由于铝液隆起的区域极距较小通过的电流较强。隆起的铝液尖峰通常是电解槽内导电最活跃的区域,通常比角部区域高出30%~40%[14]。局部电流集中是造成电解液中产生水平电流的原因,水平电流分解示意图如图3所示。由图可知,在气液两相区A点处的电流(I)可以分解为一个水平分量Ix和一个垂直分量Iy。水平电流分量Ix在垂直磁场Bz的作用下,使该区域的电解液产生水平运动。在铝液尖峰处气液两相区内,形成一个围绕尖峰作水平循环运动的两相区,由于局部流体运动强烈,使铝液和电解液之间的迁移扩散增强,铝与CO2作用形成Al2O3夹杂物更趋强烈。流场计算结果表明:铝液流动呈现4个涡,并沿长轴方向排列,两个小面的旋涡较小,偏向B侧;中间两个旋涡较大,偏向A侧。4个漩涡中心分别位于1号~2号、3号~4号、7号~8号、9号~10号阳极导杆对应的短轴处。在A、B两侧端部,铝液和电解液流速较大,由于铝液中部隆起,拱起的高度为2.4 cm,隆起的铝液尖峰插入气-液两相区内与阳极气体直接接触。界面上将有大量的CO2与铝反应。因铝液和电解液处于运动状态,与阳极气体接触的铝液始终是刚运动过来的含Al2O3夹杂物相对较低的铝液;与铝液驻峰接触的阳极气体一旦因消耗而贫化,很快被新运动过来的饱和CO2气泡的电解液取代,反应过程始终十分强烈。因铝液在槽内湍流流动形成4个旋涡。界面上的氧化膜不断形成、不断撕裂,裸露的铝液又经过再氧化、再撕裂过程,铝液-电解液界面上始终不能形成完整的氧化膜。所生成的氧化铝,一部分被界面上的电解液溶解重新进入电解液中,参与电解过程;另一部分随铝液循环进入铝液中。在铝液和电解液接触的界面上,部分CO2气泡通过流体运动和扩散迁移直接进入铝液中,气泡与铝液之间形成一层Al2O3保护膜,能阻止铝液进一步氧化。随着气泡合并、长大、破裂,CO气体随电解液循环排出,Al2O3薄膜则留在铝液中形成铝液中弥散的氧化夹杂。这就是铝液中氧化夹杂的形成过程。

图3 水平电流分解示意图

Fig.3 Schematic diagram of horizontal current density component

3.1 电解铝液与二氧化碳作用的热力学分析

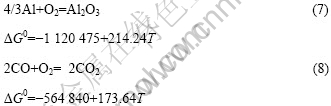

电解铝液与CO2作用的热力学过程如下:

电解铝液与CO2作用的化学反应为

在电解工况下,T=1 233.5 K,ΔG=-505 554.9 J,按质量作用定律,lnKp = -ΔG/(RT) = 49.32,反应的平衡常数为: =2.63×1021。可见,在电解铝液中,即使CO2分压很小,在平衡系统中CO分压也能达到较值,表明反应过程十分完全。根据热力学计算只能确定CO2气体与电解铝液作用的限度和方向,而要研究电解铝液中生成Al2O3夹杂的速度和最终结果,必须分析CO2与电解铝液作用的动力学过程。影响电解铝液中生成Al2O3夹杂的动力学过程可分解为以下几个环节:1) CO2分子向电解铝液界面扩散;2) CO2分子撞击铝液表面并生成Al2O3和CO;3) 生成的Al2O3夹杂通过循环扩散进入铝液。第一步扩散过程是整个过程的限制环节,关于扩散传质的有效扩散系数确定方法参见3.2节。

=2.63×1021。可见,在电解铝液中,即使CO2分压很小,在平衡系统中CO分压也能达到较值,表明反应过程十分完全。根据热力学计算只能确定CO2气体与电解铝液作用的限度和方向,而要研究电解铝液中生成Al2O3夹杂的速度和最终结果,必须分析CO2与电解铝液作用的动力学过程。影响电解铝液中生成Al2O3夹杂的动力学过程可分解为以下几个环节:1) CO2分子向电解铝液界面扩散;2) CO2分子撞击铝液表面并生成Al2O3和CO;3) 生成的Al2O3夹杂通过循环扩散进入铝液。第一步扩散过程是整个过程的限制环节,关于扩散传质的有效扩散系数确定方法参见3.2节。

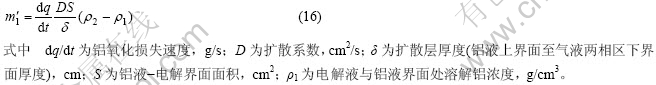

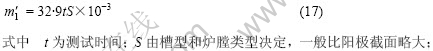

3.2 阳极气体对铝液扩散的质量传递方程

阳极气体逸出速度测算:游离于高温电解液中的单个阳极气体气泡可以看作是理想气体,则

η为电流效率,取η为100%,ρ1 = 2 100 kg/m3,ρ2 = 2 300 kg/m3,g = 9.8l m/s2,h1 = 4.5 cm,h2 = 0,因此可得:V = 6.864×10-4 t。将V对t求导,得到阳极底掌1 cm2区域产生阳极气体的体积流量为: ;考虑阳极底掌下阳极气体与电解液形成的气液两相区厚度为2~4 cm,阳极气体从底掌下六面体区域(宽1 cm,高3 cm)的4个侧面及底面均速排出。气液两相区中气体体积分数为φ,则排气面积S = 0.013 m2;Q = vSφ,v = 5.26 φ;取φ = 30%,则阳极气体逸出速度为v = 17.6 m/s。根据阳极气体逸出速度及多场耦合计算结果,可以计算出两相区与铝液之间的质量迁移系数,得出阳极气体与铝液之间的质量传递方程。以某铝厂300 kA电解槽为例:取电解液温度为960 ℃,电解槽定性尺寸为L = 4.5+21 = 258.5 cm,工况下阳极气体密度为439 kg/m3,电解液粘度γ = 3.31 g/(cm?s);电解液温度较铝液温度高5~10 ℃,电解液循环受阳极气体的冲击作用,循环较强烈。实测电解液平均速度约为铝液循环速度的0.85~0.95倍。取电解液平均循环速度为u = 0.9uAl = 6.804 cm/s;则雷诺准数:Re = puL/γ = 232.49;贝克勤准数:Pe = μL/α = 625.2;施米特准数:Se = γ/Deff = Re/Pe = 2.689;电解液层气液两相区对铝液的有效扩散系数为:Deff = 1.231 m2/s;在两极之间,CO2对铝液的物质交换系数取值为:

;考虑阳极底掌下阳极气体与电解液形成的气液两相区厚度为2~4 cm,阳极气体从底掌下六面体区域(宽1 cm,高3 cm)的4个侧面及底面均速排出。气液两相区中气体体积分数为φ,则排气面积S = 0.013 m2;Q = vSφ,v = 5.26 φ;取φ = 30%,则阳极气体逸出速度为v = 17.6 m/s。根据阳极气体逸出速度及多场耦合计算结果,可以计算出两相区与铝液之间的质量迁移系数,得出阳极气体与铝液之间的质量传递方程。以某铝厂300 kA电解槽为例:取电解液温度为960 ℃,电解槽定性尺寸为L = 4.5+21 = 258.5 cm,工况下阳极气体密度为439 kg/m3,电解液粘度γ = 3.31 g/(cm?s);电解液温度较铝液温度高5~10 ℃,电解液循环受阳极气体的冲击作用,循环较强烈。实测电解液平均速度约为铝液循环速度的0.85~0.95倍。取电解液平均循环速度为u = 0.9uAl = 6.804 cm/s;则雷诺准数:Re = puL/γ = 232.49;贝克勤准数:Pe = μL/α = 625.2;施米特准数:Se = γ/Deff = Re/Pe = 2.689;电解液层气液两相区对铝液的有效扩散系数为:Deff = 1.231 m2/s;在两极之间,CO2对铝液的物质交换系数取值为:

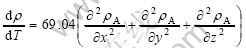

则:β = 69.04 cm2/s;由菲克定律所确定的CO2对铝液扩散的质量传递方程为

4 利用Person—Waddington电流效率模型测算Al2O3生成量

4.1 阳极气体组分与电解铝液中Al2O3夹杂的关系

从理论上讲,阳极气体的组成应该是100%纯CO2。实际生产中,阳极气体成份中约有30%的CO,CO气体主要来源于下述2个副反应:3CO2+2Al = (α-Al2O3)+3CO,为电解槽中铝损失及电解铝液中生成Al2O3夹杂的主要反应;CO2+C = 2CO2 ,为阳极气体气泡与悬浮于电解液中的碳粒之间发生的布达反应。研究表明:阳极气体中产生的CO主要与3CO2+2Al = (α-Al2O3)+3CO反应有关。为了更好地分析电解铝液中氧化夹杂与电解阳极气体成分之间的关系,引入电流效率概念,用实际产铝量占同期理论产铝量的质量分数表示:

由上式可知,电流效率η与金属铝的氧化损失有关,而电解槽中铝的氧化损失与阳极气体的成分有密切关系,Person和Waddington两位学者提出了电流效率的Person—Waddingtion公式:

上式的基本出发点是,直接电解产物阳极气体是100%的CO2,而二次气体中的CO是由阴极铝液与阳极一次产物CO2发生氧化反应后生成的。为方便计算忽略布氏反应(CO2+C=2CO),在此条件下,电解过程中析出的铝的损失,一种是铝重新突破铝液-电解液界面,重新溶解进入电解液中,并与电解液中的CO2气体反应生成Al2O3;一种是阳极气体直接进入铝液,生成Al2O3并形成夹杂,对后续工艺过程产生冶金遗传影响。

设生成氧化铝的金属铝总损失量m0由铝的溶解损失 (电解液中氧化损失),铝液中的氧化损失

(电解液中氧化损失),铝液中的氧化损失 (铝液中氧化反应形成氧化夹杂物)两部分构成,同期实际产铝量与理论产铝量分别为m1、m2。阳极气体的组分为CO和CO2气体,两种组分的体积分数依次为x和y,且x+y = 1,则产生1个单位阳极气体的铝的总损失量可按下述反应计算:2Al+3CO2 = Al2O3+3CO;铝的总氧化损失:mT = 27/41x。根据铝的溶解公式(9),铝向电解液中溶解扩散总量为

(铝液中氧化反应形成氧化夹杂物)两部分构成,同期实际产铝量与理论产铝量分别为m1、m2。阳极气体的组分为CO和CO2气体,两种组分的体积分数依次为x和y,且x+y = 1,则产生1个单位阳极气体的铝的总损失量可按下述反应计算:2Al+3CO2 = Al2O3+3CO;铝的总氧化损失:mT = 27/41x。根据铝的溶解公式(9),铝向电解液中溶解扩散总量为

铁军和邱竹贤等[8],在工业电解槽上测出的铝的溶解损失为

根据电流效率定义、法拉第定律和Person—Waddington模型,对时间t作如下推导:反应的电流效率为:η = 1-0.5x,根据电流效率定义和Person—Waddington模型: ;将m0=27x/41代入得,产生1个单位阳极气体析出铝的理论产量为:m2 = 54/41,析出铝的实际产量为:m1 = m2-m0 = 27(1+y)/41。根据理论产量和法拉第定律,得出反应所需时间为:t = 3.925/I,I为系列电流,将t代入

;将m0=27x/41代入得,产生1个单位阳极气体析出铝的理论产量为:m2 = 54/41,析出铝的实际产量为:m1 = m2-m0 = 27(1+y)/41。根据理论产量和法拉第定律,得出反应所需时间为:t = 3.925/I,I为系列电流,将t代入 =32.9tS×10-3,可得铝的溶解损失为:m′ = 0.129 S/I;铝的氧化损失为:

=32.9tS×10-3,可得铝的溶解损失为:m′ = 0.129 S/I;铝的氧化损失为: = m0-

= m0- = 27x/41- 0.129S/I;设由

= 27x/41- 0.129S/I;设由 克铝氧化生成的Al2O3夹杂量为A,则有:

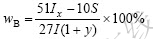

克铝氧化生成的Al2O3夹杂量为A,则有: ;生成的Al2O3夹杂物占铝总量(实际产量)的质量分数(wB)为

;生成的Al2O3夹杂物占铝总量(实际产量)的质量分数(wB)为

。

。

由上式可知,铝液中生成的Al2O3夹杂物总量随阳极气体中CO含量升高而增大,随电流强度的增加而增大,随铝液与电解液界面积增大而减小。

4.2 利用奥氏气体分析法测算电解铝液中形成的Al2O3夹杂量

在铝工业上,用于测量阳极气体组份的方法有3种:红外线气体分析仪,热导法和奥氏气体分析法,3种测量方法均能较好地满足实际生产要求。本处采用奥氏气体分析法,奥氏气体分析法是利用化学吸收的原理,按容积单位来测定阳极气体的组分。2004年5月、6月和7月连续对某公司300 kA大型预焙槽进行阳极气体组份分析,分析结果列于表5。累计测试1 329槽次,阳极气体总平均成分为:w(CO2) = 73.29%,w(CO) = 26.71%;测算电解液-铝液界面积S = 406 325 cm2,测试期间平均电流为:302.5 kA。按测试组分比例,产出一个单位的阳极气体实际析出的铝量为:m1 = 1.141 2 g;生成的Al2O3夹杂量为:A = 5.606×10-3 g;生成Al2O3夹杂占铝总量的质量分数:(A/m1)×100% = 0.49%。

根据Al-O平衡相图,在铝熔点660.452 ℃时,氧在铝液中的平衡溶解度为2.0 10-10(质量分数),所占的摩尔分数为3.0

10-10(质量分数),所占的摩尔分数为3.0 10-10,换算为氧化铝的质量分数为4.25

10-10,换算为氧化铝的质量分数为4.25 10-10。在氧化铝熔点为2 050 ℃左右时,氧在铝液中的平衡溶解度为0.1%,换算为氧化铝的质量百分数为0.212 5%。铝电解温度一般在960 ℃左右, 在平衡条件下,铝液中可溶的氧化铝量略大于4.25

10-10。在氧化铝熔点为2 050 ℃左右时,氧在铝液中的平衡溶解度为0.1%,换算为氧化铝的质量百分数为0.212 5%。铝电解温度一般在960 ℃左右, 在平衡条件下,铝液中可溶的氧化铝量略大于4.25 10-10,但远小于0.212 5%。因生成的Al2O3是致密的,密度为3.97 g/cm3,较铝液的密度(2.3 g/cm3)。因此,进入铝液中的氧化膜大部分沉入槽底形成槽底Al2O3沉淀,少部分Al2O3薄膜则悬浮于铝液中形成铝液中最初的氧化铝夹杂物。 经实验测定,电解铝液由电解车间转运至铸造车间,经过捞渣、炉内精炼、炉外在线处理后,铸成半成品,炉内总的渣量为0.6%~0.8%,炉渣的组成包括抽铝时混入铝液中的电解液、铝液中分离出的氧化夹杂物以及铝液转运、倒炉过程形成的氧化损失。综合上述分析可知,电解过程中所生成的氧化铝夹杂物主要形成了炉底沉淀,小部分溶入电解铝液中,对后续的工艺过程造成冶金遗传影响。值得注意的是:Person—Waddington电流效率模型是在忽略布氏反应、假设铝损失仅与铝的二次反应有关推导出来的,说明的是一种理想情况。Back教授、科斯丘科夫教授以及邱竹贤教授先后对Person—Waddington电流效率模型进行文献修正[8],修正后的模型给出因布氏反应造成阳极气体组份发生改变的修正系数,考虑了电解析出氢、析出钠、电流空耗、铝离子不完全放电等影响电流效率的因素。根据Person—Waddington模型推导出的氧化铝夹杂公式,不能说明有多少Al2O3最终变成炉底沉淀,及多少Al2O3仍保留在电解铝液中,最终成为影响冶金遗传的因素。它说明可能生成铝液夹杂的最大值。用于定性分析铝液中生成Al2O3夹 杂的机理。使用该式须满足Person—Waddington模型条件,同时符合铁军和邱竹贤导出的铝液溶解损失条件。

10-10,但远小于0.212 5%。因生成的Al2O3是致密的,密度为3.97 g/cm3,较铝液的密度(2.3 g/cm3)。因此,进入铝液中的氧化膜大部分沉入槽底形成槽底Al2O3沉淀,少部分Al2O3薄膜则悬浮于铝液中形成铝液中最初的氧化铝夹杂物。 经实验测定,电解铝液由电解车间转运至铸造车间,经过捞渣、炉内精炼、炉外在线处理后,铸成半成品,炉内总的渣量为0.6%~0.8%,炉渣的组成包括抽铝时混入铝液中的电解液、铝液中分离出的氧化夹杂物以及铝液转运、倒炉过程形成的氧化损失。综合上述分析可知,电解过程中所生成的氧化铝夹杂物主要形成了炉底沉淀,小部分溶入电解铝液中,对后续的工艺过程造成冶金遗传影响。值得注意的是:Person—Waddington电流效率模型是在忽略布氏反应、假设铝损失仅与铝的二次反应有关推导出来的,说明的是一种理想情况。Back教授、科斯丘科夫教授以及邱竹贤教授先后对Person—Waddington电流效率模型进行文献修正[8],修正后的模型给出因布氏反应造成阳极气体组份发生改变的修正系数,考虑了电解析出氢、析出钠、电流空耗、铝离子不完全放电等影响电流效率的因素。根据Person—Waddington模型推导出的氧化铝夹杂公式,不能说明有多少Al2O3最终变成炉底沉淀,及多少Al2O3仍保留在电解铝液中,最终成为影响冶金遗传的因素。它说明可能生成铝液夹杂的最大值。用于定性分析铝液中生成Al2O3夹 杂的机理。使用该式须满足Person—Waddington模型条件,同时符合铁军和邱竹贤导出的铝液溶解损失条件。

5 结论

1) 随着利用铝锭重熔为铝液生产铸锭的长流程工艺被直接利用高温电解铝液铸造各种半成品的短流程工艺所取代,电解过程中生成的氧化夹杂物对铝熔体的污染成为影响铝熔体纯净度的主要根源。

2) 电解铝液中形成的Al2O3夹杂物是由霍耳-埃鲁法特有的电解机制特点决定的。加料过程、效应处理、炉底形成的微型电解槽均能在一定程度上污染铝熔体。多场耦合作用导致铝液界面隆起,隆起的尖峰插入气液两相区;气液两相区内存在CO2向铝液层的扩散过程;处于循环状态的铝液表面不能形成完整的Al2O3保护膜,局部电流集中导致温度升高,使铝液、阳极气体之间的迁移扩散增强,两相之间的质量传递方程为

3) 根据Person—Waddington理想电流效率模型,铝液中形成的Al2O3夹杂量,与阳极气体组份中CO含量、铝液向电解液中溶解、扩散过程存在一定的关系,产生的氧化铝夹杂物占铝的质量分数(wB)为

REFERENCES

[1] 王建华. 我国铝加工业现状及发展趋势[J]. 世界有色金属, 2003, 243: 24-27.

WANG Jian-hua. Present state and perspectives on aluminium working industry of our country[J]. World Nonferrous Metal, 2003, 243: 24-27.

[2] 贺永东, 张新民. 微量Cr、Mn、Ti、Zr对Al-Zn-Mg-Cu合金组织性能的影响[J]. 中国有色金属学报, 2005, 15(10): 1594-1601.

HE Yong-dong, ZHANG Xin-ming. Effect of minor Cr and Mn and Ti and Zr on the microstructure and mechanical properties of Al-Zn-Mg-Cu based alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(10): 1594-1601.

[3] 文 江, 孙宝德. 铝熔体纯净化技术研究进展[C]//铝—21世纪基础研究技术发展研讨会论文集. 北京: 国家“973”计划项目组, 2002.

WEN Jiang, SUN Bao-de. The advance of study on purifying technology of liquid-Al[C]//Al-symposium of Base Research Technology for the 21th at the Meeting of Advancing and Learning. The group of Planning Item of National “973” Program, 2002.

[4] 吴秀铭. 中国铝工业50年[J]. 世界有色金属, 2004, 246: 19-23.

WU Xiu-ming. Fifty years about aluminium industry of China[J]. World Nonferrous Metal, 2004, 246: 19-23.

[5] 章宗和. 铝合金熔体的除气[J]. 特种铸造及有色合金, 2003, (6): 6-11.

ZHANG Cong-he. Degassing of liquid aluminium alloy[J]. Special Foundary and Nonferrous Metal Alloy, 2003, (6): 6-11.

[6] 傅高升, 康积行, 陈文哲, 钱匡武. 高效排杂熔剂过滤净化工业纯铝[J]. 中国有色金属学报, 2001, l1(3): 433-439.

FU Gao-sheng, KANG Ji-xing, CHEN Wen-zhe, Qian Kuang-wu. Purification of commercial aluminium by filtrating with high-efficient flux for removing inclusions[J]. The Chinese Journal of Nonferrous Metal, 2001, 11(3): 433-439.

[7] 傅高升, 康积行. 提高铝熔体净化效果的理论途径[J].轻合金加工技术, 2002(6): 34-41.

FU Gao-sheng, KANG Ji-xing. The theory path of improvement effect on purification liquid aluminum[J]. Light Alloy Fabrication Technology, 2002(6): 34-41.

[8] 田应甫. 大型预焙电解槽生产实践[M]. 长沙: 中南大学出版社, 2004. 121-165

TIAN Ying-pu. Productive practice of large scale electrolytic cell with roasting anode[M]. Changsha: Central South of University Publisher, 2004. 121-165.

[9] 贺永东. 铝及铝合金中氢和氧化夹杂的冶金遗传[D]. 武汉: 武汉理工大学, 2004, 5.

HE Yong-dong. Metallurgical heredity of hydrogen and oxide in the Aluminum and Aluminum alloy[D]. Wuhan: Wuhan Institute of University, 2004.

[10] Grjotheimk B D, International seminar on refining liquid aluminium and aluminum alloys[J]. 1997, 1937-1941.

[11] Buchhol E A. Investigation of the effect of different metal feeding system on cast structures using a water model[J]. Light Metal, 2001: 1043-1049.

[12] 贺永东. 低熔损特深熔铝炉[J]. 轻合金加工技术, 2000(3): 15-21.

HE Yong-dong. Melting aluminum furnace with low burning loss and large depth molten pool[J]. Light Alloy Fabrication Technology, 2000(3): 15-21.

[13] 姜昌伟, 梅 炽. 用标量电位与双标量磁位法计算铝电解槽三维磁场[J]. 中国有色金属学报, 2003, 13(4): 1021-1025.

JIANG Chang-wei, MEI Chi. Computation of 3D magnetic field in prebaked cells using scalar voltage potential method and two scalar magnetic potentials method[J]. The Chinese Journal of Nonferrous Metal, 2003, 13(4): 1021-1025.

基金项目:国家重大基础研究发展规划资助项目(2005CB623706)

收稿日期:2007-10-17;修订日期:2007-09-25

通讯作者:贺永东,高级工程师,博士;电话:13884516363; E-mail: hydongq@126.com

(编辑 龙怀中)