Microstructures and properties of cold drawn and

annealed submicron crystalline Cu-5%Cr alloy

HE Wen-xiong(贺文雄), YU Yang(于 洋), WANG Er-de(王尔德),

SUN Hong-fei(孙宏飞), HU Lian-xi(胡连喜), CHEN Hui(陈 晖)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 22 February 2008; accepted 7 July 2008

Abstract: The microstructures and properties after cold drawing and subsequent annealing of submicron crystalline Cu-5%Cr (mass fraction) alloy were investigated. The results show that, the microstructure of submicron crystalline Cu-5%Cr can be further refined by cold drawing. After cold drawing, the grains of Cu-5%Cr alloy with grain size of 400-500 nm can be refined to be cellular structures and subgrains with size of 100-200 nm. Both strength and ductility of Cu-5%Cr alloy can be enhanced by cold drawing, and the optimal mechanical properties can be achieved with drawing deformation increasing. It is suggested that dislocation glide is still the main mechanism in plastic deformation of submicron crystalline Cu-5%Cr, but grain boundary slide and diffusion may play more and more important roles with drawing deformation increasing. When the cold drawn Cu-5%Cr wires are annealed at 550 ℃, fine recrystal grains with grain size of 200-300 nm can be obtained. Furthermore, there are lots of fine Cr particles precipitated during annealing, by which the recrystallization softening temperatures of the cold drawn Cu-5%Cr wires can be increased to 480-560 ℃. Due to the fact that Cr particles have the effect of restricting Cu grains growth, a favorable structural thermal stability of the submicron crystalline Cu-5%Cr can be achieved, and the submicron grained microstructure can be retained at high temperature annealing.

Key words: Cu-5%Cr alloy; submicron crystalline; cold drawing; recrystallization; thermal stability

1 Introduction

Cu-Cr alloys have wide applications due to the combination of high electrical conductivity and high strength[1-2]. Compared with dilute Cu-Cr alloys, the higher Cr content Cu-Cr alloys have relatively higher thermal stability, which is important when they are used as electrode material, such as Cu-5%Cr (mass fraction) [3]. The increased solid solubility allows extensive precipitation and strengthening after ageing, and the primary Cr particles play an important role both in strengthening and in restricting grains coarsening[1]. However, because copper and chromium are immiscible, the Cr content of Cu-Cr alloys prepared by conventional melting and casting processes is usually not more than 1% (mass fraction). Otherwise, it will bring about macro-segregation. Mechanical alloying can improve the solubility of Cr in Cu matrix and a supersaturated solid solution can be formed at room temperature[3-11]. Furthermore, by mechanical alloying, submicron crystalline and even nano-crystalline Cu-Cr composite powders can be prepared[7-11]. By applying appropriate technical methods in the following consolidation, the grain growth can be restricted, and thus, the near fully-densified Cu-Cr billets with submicron grains can be prepared[3, 9-11].

Many studies have been done on severe plastic deformation (SPD) of Cu matrix composite materials to achieve ultrafine grains and superior mechanical properties, such as equal channel angular pressing (ECAP)[12-15] and mult-pass drawing[16-17]. For the existing submicron crystalline materials, relatively little research has been done on the rules of further plastic deformation, recrystallization and thermal stability of submicron crystalline materials. In the present study, based on the fully-densified Cu-5%Cr alloy with submicron grains prepared by mechanical alloying, hot compacting and hot hydrostatic extrusion, cold drawing with heavy deformation and subsequent annealing have been performed. The microstructures and properties of Cu-5%Cr under various drawing deformations and various annealing temperatures have been investigated. The possibilities of further grain refinement and properties improvement of submicron crystalline Cu-5%Cr through plastic deformation have been studied. The recrystallization and structural thermal stability of submicron crystalline Cu-5%Cr have also been studied.

2 Experimental

The submicron crystalline Cu-5%Cr alloy used in the present experiment was prepared by means of mechanical alloying, hot compaction and hot hydrostatic extrusion. Firstly, the mixture of elemental copper and chromium powders (75 μm, 99.9% purity, with a Cu-to- Cr mass ratio of 95?5) was mechanically alloyed under protection of pure argon for 10 h in a homely-made high-energy ball-attritor. The ball to powder mass ratio was 10?1 and the stirring speed of the attritor was 400 r/min, respectively. Then, the mechanically alloyed powders were compacted at 400 ℃ for 0.5 h under vacuum into d 40 mm×40 mm cylindrical billets. The compacted Cu-5%Cr billets were put in graphite-glass cans and extruded at 750 ℃ with extrusion ratio of 81?1 (d 36 mm→d 4 mm), and the submicron crystalline Cu-5%Cr rods with relative density of about 99.5% were obtained.

Based on the submicron crystalline Cu-5%Cr rods, cold drawing has been performed. After cold drawing with various passes, some of Cu-5%Cr wires were annealed at different temperatures. Then the microhardness was tested with HVS-1000 micro- hardness instrument. Tensile tests of as-drawn Cu-5%Cr wires were carried out with an Instron-5500 material test machine at room temperature, with a gauge span of 25 mm and strain rate of 2.5×10-4 s-1. The microstructures of as-drawn and as-annealed Cu-5%Cr wires were observed by transmission electron microscopy (TEM) (PHILIPS CM12), and bright field images were obtained. At last, some of the as-drawn Cu-5%Cr wires were heated to 800 ℃ to investigate their structural stability.

3 Results and discussion

3.1 Microstructures and properties of cold drawn Cu- 5%Cr alloy

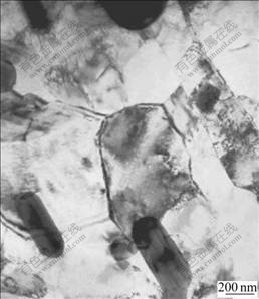

The original Cu-5%Cr rods before drawing were prepared by mechanical alloying, hot compaction and hot hydrostatic extrusion. Their typical microstructure is shown in Fig.1. Because the rods were extruded at 750 ℃, their microstructure was determined mainly by dynamic recrystallization. The grain size is about 400-500 nm. Besides recrystallized grains, there is a part of deformed microstructure.

Fig.1 Microstructure of hot hydrostatic extruded Cu-5%Cr alloy before drawing

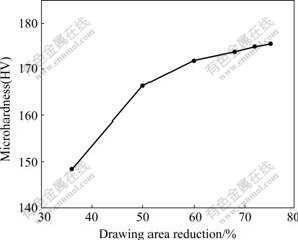

The as-extruded Cu-5%Cr rods were transformed into Cu-5%Cr wires of different diameters by different passes of cold drawing. After cold drawing, the micro- hardness of Cu-5%Cr wires was measured. Fig.2 shows the hardness change of Cu-5%Cr wires with various accumulative drawing area reductions without intermediate annealing. It can be seen that, with accumulative drawing deformation increasing, the microhardness increases obviously. When the drawing deformation is low, the microhardness increases rapidly; on the contrary, when the drawing deformation is high, the microhardness increases slowly, which shows obviously the phenomenon of work-hardening.

Fig.2 Effect of accumulative drawing area reduction on microhardness of Cu-5%Cr wires

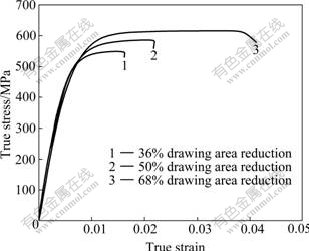

Fig.3 shows the tensile true stress—true strain curves of Cu-5%Cr wires at room temperature with various accumulative drawing area reductions without intermediate annealing. It can be seen in Fig.3 that, with accumulative drawing deformation increasing, both strength and ductility of Cu-5%Cr wires increase. This phenomenon usually does not occur in conventional coarse-grained metal materials. The strain-strengthening resulted by cold drawing is one of the reasons for the strength enhancement. However, the tensile true stress— true strain curves rapidly approach to horizontal line, which demonstrates that the strain-strengthening resulted by tensile test of the as-drawn Cu-5%Cr wires becomes very weak. The enhancement of ductility with drawing deformation increasing is related to the microstructure features and even the deformation mechanism. The further explanation can be obtained from the microstructure features of the as-drawn Cu-5%Cr wires.

Fig.3 Tensile true stress—true strain curves of Cu-5%Cr wires at room temperature with various accumulative drawing area reductions without intermediate annealing

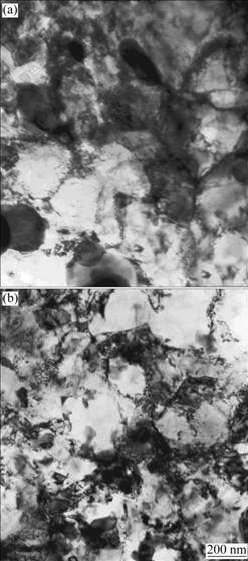

Fig.4 shows TEM images of different-pass cold- drawn Cu-5%Cr wires without intermediate annealing. The accumulative drawing area reductions of Figs.4(a) and (b) are 50% and 68%, respectively. High density dislocation zones, cellular structures and subgrains can be seen on the two images. This indicates that the drawing deformation causes the dislocation density to increase, and causes the cellular structures and subgrains to form. In Fig.4(a) with relatively low drawing deformation, cellular structures with dislocations concentrated on cell walls can be clearly observed. In Fig.4(b) with relatively high drawing deformation, the cellular structures are further refined, and more subgrains are formed.

With drawing deformation increasing, the disloca- tion density increases, and the misorientation between two adjacent cells increases. Some of the cellular structures transform into subgrains with low-angle grain-boundaries. With drawing deformation further increasing, the number of high-angle grain-boundaries increases, and the refining extent of cellular structures and subgrains increases. In Fig.4, though the sizes of the cells and subgrains are different with drawing deformation changing, the cells and subgrains with size of about 100-200 nm can be obtained when the accumulative drawing area reduction is over 50%. Compared with the microstructure before drawing, the microstructures after drawing are further refined. The cellular structures and subgrains become finer with drawing deformation increasing, which leads to grain refinement strengthening. Grain refinement strengthening is another strengthening mechanism in cold drawn Cu-5%Cr wires.

Fig.4 TEM bright field images of cold drawn Cu-5%Cr wires with accumulative drawing area reductions of 50% (a) and 68% (b) without intermediate annealing

After cold drawing, the increment of dislocation density, the formation of cellular structures, and the occurrence of work-hardening demonstrate that dislocation glide is still the main mechanism in plastic deformation of submicron crystalline Cu-5%Cr. After drawing deformation, the dislocation density is very high. On one hand, in tensile test, the dislocation density attains saturated rapidly, which causes the work-hardening effect to be very weak. On the other hand, with the grains refining, and with the number of high-angle grain-boundaries increasing, other mechanisms such as grain boundary slide and diffusion may play more and more important roles in plastic deformation of Cu-5%Cr, which causes the ductility of Cu-5%Cr to increase. The same result that both strength and ductility increase with plastic deformation increasing in some ultrafine grained materials has also been obtained by other researchers[14-15]. The fact that both strength and ductility of the Cu-5%Cr alloy are enhanced with drawing deformation increasing will lead to the optimal combination of mechanical properties.

3.2 Microstructures and properties of annealed Cu- 5%Cr alloy

After the cold drawn Cu-5%Cr wires were annealed at different temperatures, the microhardness was measured. Based on this, the recrystallization softening temperature can be determined. Fig.5 shows the effects of annealing temperature and drawing area reduction on the hardness of Cu-5%Cr wires (with annealing time of 10 min). It can be seen that, with different drawing deformations, when the annealing temperature is below 480 ℃, the hardness of all as-drawn Cu-5%Cr wires has a little change. In fact, both the recovery of Cu matrix and the precipitation of Cr phase occur when the as-drawn Cu-5%Cr wires are annealed at about 400 ℃. Though recovery causes some extent of softening, the precipitated Cr particles have effects of strengthening and hardening, which can counteract the effect of softening. Furthermore, the fine and dispersedly distributed Cr particles can prevent the recrystallization of Cu matrix and cause the recrystallization temperature to be high[18].

With the annealing temperature increasing further, the hardness of Cu-5%Cr wires decreases greatly. As for the alloys with different drawing deformations, all of the softening temperatures are in the range of 480-560 ℃. That is to say, the recrystallization softening temperatures of the as-drawn Cu-5%Cr wires are in the range of 480-560 ℃, higher than those of pure Cu and dilute Cu-Cr alloys. When the as-drawn Cu-5%Cr wires are annealed in this temperature range, there are also a few Cr particles precipitated, and the softening effect of recrystallization is dominant, thus the hardness is decreased. When the annealing temperature is above 560 ℃, the hardness of all as-drawn Cu-5%Cr wires with different drawing deformations tends to be stable. This is because that, the recrystallization is finished, and the amount of Cr dissolving in Cu matrix is decreased greatly, which causes the precipitation of Cr to decrease greatly, thus the hardness of Cu-5%Cr wires tends to be stable.

Fig.5 Effects of annealing temperature and drawing area reduction on microhardness of Cu-5%Cr wires

The recrystallization softening temperatures of the as-drawn Cu-5%Cr wires fluctuate to some extent with drawing deformation changing. Usually, with drawing deformation increasing, the lattice distortion energy increases, and the driving force of recrystallization increases, which causes the recrystallization softening temperature to descend. However, the results in Fig.5 do not follow this rule completely. This is because that the existence of Cr phase has much influence on the recrystallization of Cu matrix. As mentioned above, fine and dispersedly distributed Cr particles will prevent the recrystallization of Cu matrix and cause the softening temperature to be high. Therefore, the specific recrystallization softening temperatures of the as-drawn Cu-5%Cr wires are determined by multiplicate factors, such as the deformation extent, the size and the distribution of Cr phase.

Figs.6(a) and (b) show the TEM images of Cu-5%Cr with accumulative drawing area reduction of 72% annealed at 500 and 550 ℃ respectively for 10 min. It can be seen in Fig.6(a) that, besides a few Cu recrystal grains and lots of fine precipitated Cr particles, there are still subgrains with some dislocations, which reveals that it is the initial stage of recrystallization. In Fig.6(b), it can be seen that recrystallization has almost finished, and almost all of Cu matrix consists of Cu recrystal grains with grain size of about 200-300 nm. Compared with the grains before drawing, the recrystal grains are finer.

Furthermore, in two images, lots of Cr particles can be observed. It should be pointed out that, the biggish Cr particles and the deformed Cr particles are undissolved Cr particles in mechanical alloying or precipitated Cr particles in previous process; only the smallish and non- deformed Cr particles are precipitates in annealing. The diffusive tunnels of solute atoms increase after cold drawing due to crystal defects increasing, which can accelerate the precipitation of Cr particles during annealing, so as to affect the microstructure and properties of Cu-5%Cr wires after annealing. The precipitated fine Cr particles have important precipitation strengthening effect in Cu-5%Cr alloy.

Fig.6 TEM bright field images of Cu-5%Cr with accumulative drawing area reduction of 72% annealed at 500 ℃ (a) and 550 ℃ (b) for 10 min

3.3 Structural thermal stability of Cu-5%Cr alloy

The structural stability of cold drawn Cu-5%Cr wires at high temperature was investigated. Fig.7 shows the microstructure of Cu-5%Cr wire with drawing area reduction of 72% annealed at 800 ℃ for 10 min. It can be seen that recrystallization has finished and equiaxed Cu grains are obtained. Compared with those annealed at 550 ℃, the grains annealed at 800 ℃ have grown up to some extent. But they are still very fine, with grain size of about 500-600 nm, and no abnormal growth occurs. That is to say, the grains of Cu matrix have a favorable thermal stability.

Fig.7 TEM bright field image of Cu-5%Cr wire with drawing area reduction of 72% annealed at 800 ℃ for 10 min

In Fig.7, the Cr particles with particle size of about 10-100 nm can be seen. When the Cr particles precipitate along Cu grain boundaries, especially at trifurcate grain boundaries (can be seen in Fig.7), they have strong effect of pining up the grain boundaries, preventing the grain boundaries from moving, and preventing Cu grains from growing up effectively.

Cu and Cr are immiscible, so the grain growth can be restricted by each other. Mechanical alloying as a nonequilibrium method can be utilized to synthesize metastable Cu-Cr supersaturated solid solution at first, then the Cu-Cr supersaturated solid solution decomposes during subsequent processing and heat treatment, and lots of finely dispersedly distributed Cr particles emerge. Besides the precipitation strengthening effect, the Cr particles can restrict grains growth of Cu matrix, thus the favorable structural thermal stability of submicron crystalline Cu-5%Cr can be achieved at last.

4 Conclusions

1) Both strength and ductility of the submicron crystalline Cu-5%Cr alloy can be enhanced by cold drawing, and the optimal mechanical properties can be achieved with drawing deformation increasing. The microstructure of submicron crystalline Cu-5%Cr can be further refined by cold drawing. After cold drawing, the submicron crystalline Cu-5%Cr with grain size of 400-500 nm can be further refined to be cellular structures and subgrains with size of 100-200 nm. After annealing at 550 ℃ for 10 min, recrystal grains with grain size of 200-300 nm can be obtained.

2) After cold drawing, the increment of dislocation density, the formation of cellular structures, and the occurrence of work-hardening demonstrate that dislocation glide is still the main mechanism in plastic deformation of submicron crystalline Cu-5%Cr. However, with drawing deformation increasing, grain boundary slide and diffusion may play more and more important roles.

3) When the cold drawn Cu-5%Cr wires are annealed, besides recovery and recrystallization of Cu matrix, there are lots of fine Cr particles precipitated, by which the recrystallization softening temperatures of the cold drawn Cu-5%Cr wires can be increased to the range of 480-560 ℃, higher than those of pure Cu and dilute Cu-Cr alloys. Due to the fact that Cr particles have the effect of restricting Cu grains growth, a favorable structural thermal stability of the submicron crystalline Cu-5%Cr can be achieved, and the submicron grained microstructure can be retained at high temperature annealing.

References

[1] MORRIS M A, MORRIS D G. Microstructures and mechanical properties of rapidly solidified Cu-Cr alloys [J]. Acta Metall, 1987, 35: 2511-2522.

[2] LI Hua-qing, XIE Shui-sheng, WU Peng-yue, MI Xu-jun. Study on improvement of conductivity of Cu-Cr-Zr alloys [J]. Rare Metals, 2007, 26: 124-130.

[3] HU L X, WANG E D. Fabrication of high strength conductivity submicron crystalline Cu-5%Cr alloy by mechanical alloying [J]. Trans Nonferrous Met Soc China, 2000, 10(2): 209-212.

[4] BOTCHAROVA E, HEILMAIER M, FREUDENBERGER J, DREW G, KUDASHOW D, MARTIN U, SCHULTZ L. Supersaturated solid solution of niobium in copper by mechanical alloying [J]. J Alloys Comp, 2003, 351: 119-125.

[5] MARTINEZ V de P, AGUILAR C, MARIN J, ORDONEZ S, CASTRO F. Mechanical alloying of Cu-Mo powder mixtures and thermodynamic study of solubility [J]. Mater Lett, 2007, 61: 929-933.

[6] MORRIS D G, MORRIS M A. Rapid solidification and mechanical alloying techniques applied to Cu-Cr alloys [J]. Mater Sci Eng A, 1988, A104: 201-213.

[7] MORRIS M A, MORRIS D G. Microstructural refinement and associated strength of copper alloys obtained by mechanical alloying [J]. Mater Sci Eng A, 1989, A111: 115-127.

[8] RAGHU T, SUNDARESAN R, RAMAKRISHNAN P, RAMA MOHAN T R. Synthesis of nanocrystalline copper-tungsten alloys by mechanical alloying [J]. Mater Sci Eng A, 2001, A304: 438-441.

[9] LIU J L, LIU Z Y, WANG E D. Structures, properties and responses to heat treatment of deformation processed Cu-15%Cr composite powders prepared by mechanical milling [J]. Trans Nonferrous Met Soc China, 2002, 12(6): 837-840.

[10] LIU J L, WANG E D, LIU Z Y. Phases interface in deformation processed Cu-15wt.%Cr composite prepared by elemental powders [J]. Mater Sci Eng A, 2004, A382: 301-304.

[11] HE W X, WANG E D, CHEN H, YU Y, LIU J L. Effects of deformation on microstructures and properties of submicron crystalline Cu-5%Cr alloy [J]. Trans Nonferrous Met Soc China, 2007, 17(2): 384-388.

[12] VINOGRADOV A, PATLAN V, SUZUKI Y, KITAGAWA K, KOPYLOV V I. Structure and properties of ultra-fine grain Cu-Cr-Zr alloy produced by equal-channel angular pressing [J]. Acta Materialia, 2002, 50: 1639-1651.

[13] HUANG C X, WANG K, WU S D, ZHANG Z F, LI G Y, LI S X. Deformation twinning in polycrystalline copper at room temperature and low strain rate [J]. Acta Materialia, 2006, 54: 655-665.

[14] XU C Z, WANG Q J, ZHENG M S, ZHU J W, LI J D, HUANG M Q, JIA Q M, DU Z Z. Microstructure and properties of ultra-fine grain Cu-Cr alloy prepared by equal-channel angular pressing [J]. Mater Sci Eng A, 2007, A459: 303-308.

[15] VALIEV R Z, ALEXANDROV I V, ZHU Y T, LOWE T C. Paradox of strength and ductility in metals processed by severe plastic deformation [J]. Journal of Materials Research, 2002, 17: 5-8.

[16] BOTCHAROVA E, FREUDENBERGER J, GAGANOV A, KHLOPKOV K, SCHULTZ L. Novel Cu-Nb-wires: Processing and characterization [J]. Mater Sci Eng A, 2006, A416: 261-268.

[17] LIU J B, MENG L, ZENG Y W. Microstructure evolution and properties of Cu-Ag microcomposites with different Ag content [J]. Mater Sci Eng A, 2006, A435/436: 237-244.

[18] MORRIS M A., LEBOEUF M, MORRIS D G. Recrystallization mechanisms in a Cu-Cr-Zr alloy with a bimodal distribution of particles [J]. Mater Sci Eng A, 1994, A188: 255-265.

Corresponding author: HE Wen-xiong; Tel: +86-631-5687267; E-mail: hewell@sina.com

DOI: 10.1016/S1003-6326(08)60234-4

(Edited by YANG Bing)