固溶-时效热处理工艺对近β钛合金显微组织演化与力学性能的影响

来源期刊:中国有色金属学报(英文版)2019年第5期

论文作者:武川 詹梅

文章页码:997 - 1006

关键词:Ti-5Al-5Mo-5V-3Cr-1Zr钛合金;热处理;固溶;时效;显微组织演化;力学性能;断裂机理

Key words:Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy; hot treatment; solution; aging; microstructural evolution; mechanical properties; fracture mechanism

摘 要:研究钛合金Ti-5Al-5Mo-5V-3Cr-1Zr(Ti-55531)在不同固溶(760~820 °C)与时效(580~640 °C)热处理条件下的显微组织演化、力学性能及断裂机理。结果表明,初生α相(αp)的体积分数随固溶温度的升高而降低,而次生α相(αs)的长度随时效温度升高而降低,其宽度则随时效温度升高而增加。Ti-55531合金的屈服强度和抗拉强度随固溶温度升高而降低,但随时效温度的升高而增大。合金在800 °C固溶2 h、640 °C时效8 h的条件下获得的抗拉强度(1434 MPa)与韧性(伸长率7.7%)达到最优匹配。随时效温度和时间的增加,αs相发生粗化,使微观裂纹扩展路径变得曲折、崎岖,从而提高裂纹扩展阻力,最终提高合金的韧性与断裂韧性。

Abstract: The microstructural evolution, mechanical properties and fracture mechanism of a Ti-5Al-5Mo-5V-3Cr-1Zr (Ti-55531) alloy after solution (760-820 °C) plus aging (580-640 °C) treatments were investigated. The results show that the volume fraction of the primary α (αp) phase decreases with the increase of solution temperature, and the length of the secondary α phase (αs) decreases while its width increases with the increase of aging temperature. Yield and tensile strengths decrease with the increase of solution temperature, while increase with the increase of aging temperature. A good balance of tensile strength and ductility of the alloy is obtained under solution of 800 °C for 2 h plus aging of 640 °C for 8 h, in which the tensile strength is 1434 MPa and the elongation is 7.7%. The coarsening αs phase makes crack propagation paths deflected and tortuous, which increases the crack propagation resistance and improves the ductility and fracture toughness.

Trans. Nonferrous Met. Soc. China 29(2019) 997-1006

Chuan WU1,2, Mei ZHAN2

1. National-Local Joint Engineering Laboratory of Intelligent Manufacturing Oriented Automobile Die and Mould, Tianjin University of Technology and Education, Tianjin 300222, China;

2. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 12 June 2018; accepted 8 January 2019

Abstract: The microstructural evolution, mechanical properties and fracture mechanism of a Ti-5Al-5Mo-5V-3Cr-1Zr (Ti-55531) alloy after solution (760-820 °C) plus aging (580-640 °C) treatments were investigated. The results show that the volume fraction of the primary α (αp) phase decreases with the increase of solution temperature, and the length of the secondary α phase (αs) decreases while its width increases with the increase of aging temperature. Yield and tensile strengths decrease with the increase of solution temperature, while increase with the increase of aging temperature. A good balance of tensile strength and ductility of the alloy is obtained under solution of 800 °C for 2 h plus aging of 640 °C for 8 h, in which the tensile strength is 1434 MPa and the elongation is 7.7%. The coarsening αs phase makes crack propagation paths deflected and tortuous, which increases the crack propagation resistance and improves the ductility and fracture toughness.

Key words: Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy; hot treatment; solution; aging; microstructural evolution; mechanical properties; fracture mechanism

1 Introduction

Near-β titanium alloys have been widely used in the fields of aeronautics, astronautics and marine owning to their advantages of high specific strength ratio, excellent fracture toughness and good corrosion/oxidation resistance [1-3]. Compared with other near β titanium alloys, Ti-5Al-5Mo-5V-3Cr-1Zr (Ti-55531) is a relatively new near-β titanium alloy [4,5]. This alloy has some advantages of good hardenability, excellent strength and high fracture toughness, thus it becomes a suitable candidate for manufacturing the high strength airframe forgings [2,3]. In the aerospace industry, proper microstructures, excellent properties and good dimensional stability are required. To meet these requirements, the forgings are subjected to various heat treatments. During the heat treatment processes, the material has a complex microstructural evolution. Moreover, its mechanical properties are sensitive to a minor variation of microstructures. Therefore, it is essential to clarify the relations among heat treatments, microstructures and mechanical properties.

CHEN et al [4] investigated the phase trans- formation between the α and β phases. They established a kinetics model of the α phase growth and dissolution. MANSHAD and DIPPENAAR [6] studied the morphological evolution of α phase in a Ti-5553 alloy. They found that α phase was closely related to the aging temperature and time. CHEN et al [7] found that the finer acicular secondary α (αs) phase can precipitate in β matrix during an aging stage. The size of αs phase increased with the increase of aging temperature, and finally influenced the strength and ductility. According to the researches of ZHU et al [8] and ZHU et al [9], the morphology of αs phase mainly depended on solution temperature. The lath α phase can improve the strength and plasticity, while the acicular α phase can reduce the strength with no loss of ductility. DU et al [10] investigated the microstructural evolution and mechanical properties of a new β titanium alloy during solution plus aging treatment. Their results showed that the size and volume fraction of αs phase were sensitive to temperature. ZHANG et al [11] studied the morphology evolution of the αs phase of a Ti-7Mo-3Al-3Nb-3Cr alloy during isothermal heat treatment. ZHAO et al [12] showed that the phase boundaries of αs phase increased with the increase of annealing temperature, while the volume fraction of primary α (αp) phase decreased. XU et al [13] studied the microstructural evolution and tensile properties of a Ti-5553 alloy during solution plus aging treatment. They showed that the β solution treatment plus aging resulted in high strength, and the α + β solution treatment plus aging resulted in good combination of strength and ductility.

Although there has been some work on the same or similar alloys, the relation among the heat treatments, microstructural evolution and mechanical properties of the Ti-55531 alloy has not been studied exhaustively and systemically. Therefore, in this work, the microstructural evolution of the Ti-55531 alloy during heat treatments was studied, and their morphologies, sizes, volume fraction, precipitation location and growth modes were analyzed. Subsequently, the strength, ductility and fractography were evaluated. Finally, the effect of heat treatment on the mechanical properties and fracture mechanism was discussed.

2 Experimental

The as-received Ti-55531 alloy has a composition (in wt.%) of 5.21 aluminum (Al), 5.06 molybdenum (Mo), 4.96 vanadium (V), 3.01 chromium (Cr), 1.07 zirconium (Zr), 0.25 iron (Fe), 0.12 others, and balanced Ti. The β-transus temperature is 845 °C. The initial microstructure is shown in Fig. 1(a), which consists of a fine, bimodal α+β structure of approximately 45% (volume fraction) equiaxed αp phase (denoted by white arrow) and 55% transformed β phase, where the αp phase has an average grain diameter of 2-3 μm.

To investigate the effects of heat treatment on the microstructural evolution and mechanical properties, cubic (dimensions of 15 mm in length, 13 mm in width and 5 mm in depth) and standard tensile samples (see Fig. 1(b)) were electro-discharged from the received material. These samples were firstly solution-treated at 760, 780, 800 and 820 °C for 0.5, 2 and 4 h, respectively. Then, the samples solution-treated at 800 °C for 2 h were subjected to aging treatment at 580, 600, 620 and 640 °C for 6, 8 and 10 h, followed by air cooling (corresponding to cooling rate of 100 °C/min) [14]. The detailed heat treatment procedures are shown in Table 1.

Fig. 1 Initial microstructure of as-received Ti-55531 alloy (a) and sizes of standard tensile sample (unit: mm) (b)

Table 1 Solution treatment and solution (800 °C, 2 h) plus aging treatment parameters of Ti-55531 alloy

After the heat treatment, the cubic samples were metallographically polished and etched with a solution of 1.5 mL hydrofluoric acid + 3 mL nitric acid + 100 mL water for 10-15 s. The OLYMPUS/PMG3 optical microscope (OM) and Zeiss Sigma 500 scanning electron microscope (SEM) were used to observe the microstructure. Quantitative measurements of grain size and volume fraction of each phase were conducted.

The standard tensile samples were tested using an MTS810 material test system (according to standard GR/T 228-2002). After the tensile tests, the yield strength (Rp0.2), tensile strength (Rm), breaking strength (Rb), uniform elongation (Au) and failure elongation (Af) were measured. The fractography was analyzed by the SEM to identify the fracture mechanism.

3 Results and discussion

3.1 Microstructural evolution

3.1.1 Effect of solution temperature and time

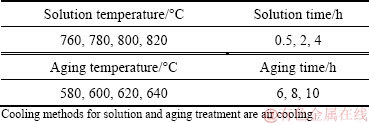

Figures 2(a) to (d) show the SEM micrographs of the Ti-55531 alloy at solution temperatures of 760, 780, 800 and 820 °C for 2 h, respectively. The αp grains are equiaxed and their boundaries are straight. The static coarsening of the αp phase is not apparent. This is because the content of β-stabilizing elements is higher and Mo equivalence of the alloy is about 12.8 [10], which has a significant dragged effect on the grain coarsening [15-17].

Fig. 2 Microstructural evolution of Ti-55531 alloy solution-treated at different temperatures for 2 h followed by air cooling

At 760 °C (see Fig. 2(a)), the volume fraction of the αp is reduced to 35%-40% compared with the initial value of 45% (Fig. 1(a)). At 800 °C, its volume fraction decreases sharply (Fig. 2(c)). Most of the αp phase is dissolved into the matrix. At the solution temperature of 820 °C (Fig. 2(d)), most of the αp phase disappears. The volume fraction of the αp phase is less than 5%.

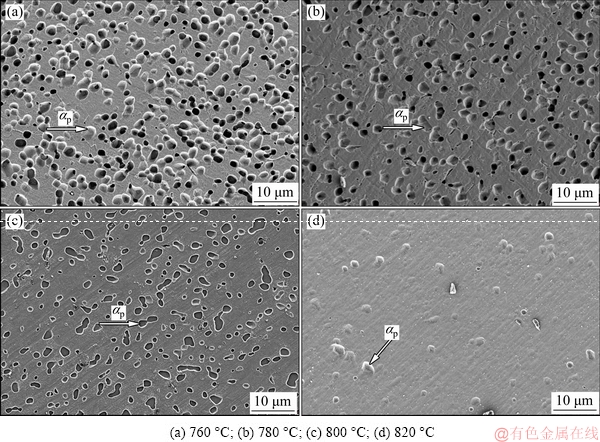

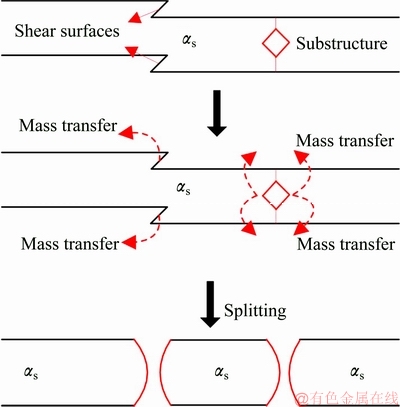

Figure 3 shows the SEM micrographs of the Ti-55531 alloy solution-treated at 780 °C for 0.5-4 h. The αp phase still keeps equiaxed and its grain size has no change. However, the volume fraction of αp phase has a little change with the solution time. The volume fraction is 35%-40% at 0.5 h (Fig. 3(a)). With increasing solution time to 4 h (Fig. 3(c)), this value is reduced to 30%.

3.1.2 Effect of aging temperature and time

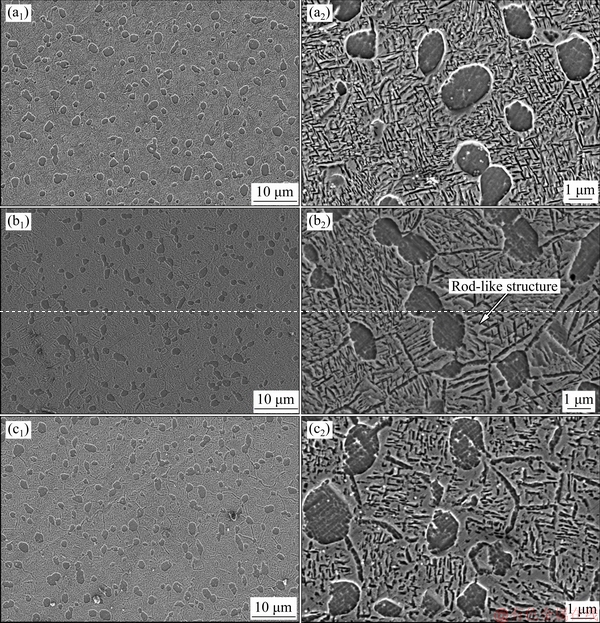

The Ti-55531 alloy was solution-treated at 800 °C for 2 h, followed by aging at 580-640 °C (20 °C interval) for 6-10 h (2 h interval). Figures 4(a1, a2) display the microstructures aging-treated at 580 °C for 8 h. It is seen that the equiaxed αp phase is around the original grain boundaries. The lamellar αs phase precipitates inside the β grains. The αs phase is cross-distributed irregularly and the orientation is random, thus the orientation is different from one to other. The precipitation process usually consists of two stages, nucleation and growth. When the cooling rate is less than 100 °C/min, the αs phase preferentially nucleates at the β/β grain boundaries (GB) or the α/β interface (PI), because these zones have high energy for the αs nucleation [11]. In this study, the samples were cooled in air, which produced a high driving force for the αs nucleation. At aging temperature of 600 °C (Figs. 4(b1, b2)), the αp phase still has no change, but the αs/βr (retained beta phase) interface becomes clearer, obvious coarsening of αs lamella takes place. At 620 °C (Figs. 4(c1, c2)) and 640 °C (Figs. 4(d1, d2)), the coarsening phenomenon is more pronounced, the width of αs phase increases while the interlamellar spacing decreases.

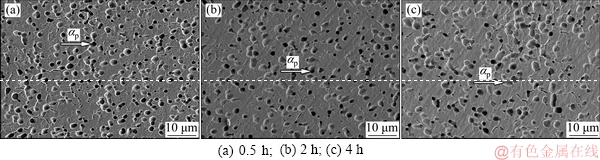

The coarsening of lamellar αs phase is a thermally activated process, and the coarsening rate depends on the diffusivity of solute atoms. Therefore, the coarsening of the αs phase is more pronounced at higher temperatures. Two mechanisms, namely boundary splitting and termination migration, can interpret the coarsening, which are graphically illustrated in Figs. 5 and 6 [15], respectively. During the initial stage, the boundary splitting mechanism is dominant. Some defect zones such as shear surfaces and substructures are produced inside the αs phase. The mass transfers from these zones to adjacent flat surfaces to reduce surface energy. Therefore, the nature of the boundary splitting is the fade away of inside boundary of α phase and incuneation of β phase [15,17]. Then, the lamellar αs phase is split and begins to coarsen.

Fig. 3 Microstructural evolution of Ti-55531 alloy solution-treated at 780 °C for different time followed by air cooling

Fig. 4 Microstructural evolution of Ti-55531 alloy aging treated at 580 °C (a1, a2), 600 °C (b1, b2), 620 °C (c1, c2) and 640 °C (d1, d2) for 8 h followed by air cooling

Fig. 5 Illustration of boundary splitting mechanism [15]

The termination migration is another important mechanism to explain the coarsening. This theory was firstly proposed for the coarsening behavior of pearlite in steels [18,19], which has been successfully applied to explaining the coarsening of lamellar αs phase in titanium alloys [20,21]. For the lamellar αs phase, the curvature in the termination location is higher than that in other flat locations, which results in a higher potential energy at these positions. In this case, a chemical potential curvature can be formed between the termination and other flat position, which drives the solute atoms to migrate from the termination to other place, finally resulting in the dissolution of termination tips and the coarsening of the lamellar microstructure [15].

Figure 7 shows the microstructural evolution of the Ti-55531 alloy at different aging time. The αs phase displays the boundary splitting and subsequent coarsening behavior. At 6 h (Figs. 7(a1, a2)), the equiaxed αp phase precipitates around the β grain boundaries, the lamellar αs phase is arranged randomly inside the β grains, and the αs phase boundaries are not clear. At the aging time of 8 h (Figs. 7(b1, b2)), the lamellar αs phase evolves into a short rod-like structure. The length and width of the short rod-like αs phase decrease and increase, respectively, compared with the initial values. At 10 h, the coarsening phenomenon is more pronounced, which is displayed in Figs. 7(c1, c2).

3.2 Mechanical properties

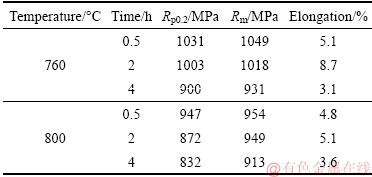

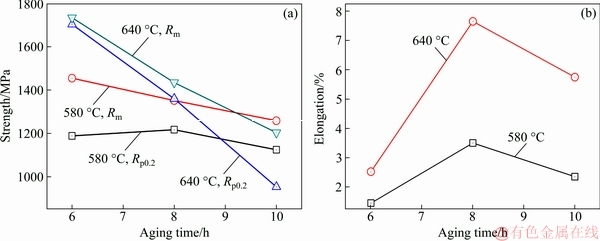

The mechanical properties of the Ti-55531 alloy under different heat treatments are listed in Tables 2 and 3. It is seen that the mechanical properties are sensitive to temperature and time. The variation of yield strength (Rp0.2), tensile strength (Rm) and elongation with temperature and time is graphically illustrated in Figs. 8 and 9, respectively. The yield strength Rp0.2 and tensile strength Rm increase with the decrease of solution temperature, as shown in Fig. 8(a), while these values decrease with the solution time. This phenomenon may be related to the αp dissolution and to the β phase coarsening during the solution treatment [22]. The volume fraction of the αp phase decreases with the increase of solution temperature. The αp phase with a HCP (hexagonal close packed) structure has a higher deformation resistance than β phase with BCC (body-centered cubic) structure, thus the strength of the alloy decreases with increasing temperature. In addition, the grain boundary area decreases with the growth of β phase grains, which can largely reduce the deformation resistance. The variation of the elongation with solution temperature and time is depicted in Fig. 8(b). The elongation increases with increasing solution time at the initial stage; however, it decreases with further increasing solution time. This may be caused by static coarsening. During the initial stage, the microstructure gradually becomes uniform, thus the material displays a good ductility. However, the sizes of grains begin to increase dramatically with the increase of solution time, which can reduce the ductility of material.

Fig. 6 Graphical illustration of termination migration mechanism [15]

Fig. 7 Microstructural evolution of Ti-55531 alloy aging-treated at 600 °C for 6 h (a1, a2), 8 h (b1, b2) and 10 h (c1, c2) followed by air cooling

Table 2 Tensile properties of Ti-55531 alloy under different solution conditions

Table 3 Tensile properties of Ti-55531 alloy solution-treated at 800 °C for 2 h under different aging conditions

The variation of strength and ductility of the alloy with aging conditions is shown in Fig. 9(a). The strength can be greatly improved after the aging treatment. For instance, the values of Rp0.2 and Rm reach 1704 and 1734 MPa, respectively, after being aging-treated at 640 °C for 6 h. Generally, the strength increases with increasing aging temperature and decreasing aging time. It has been reported that the αs phase is an important factor influencing the strength and ductility of titanium alloys [23]. Although the volume fraction of the αs phase decreases slightly with increasing aging temperature, its sizes including length and width increase largely, which can increase the interface area of α/β. The α/β interface acts as an effective dislocation barrier during the plastic deformation. Additionally, the space of the αs phase is another factor determining the strength of the alloy. The strength of titanium alloy is inversely proportional to the space, which can be expressed as S=a+bl -1, where S is the strength of a alloy, a and b are constants, l is the space between two neighboring lamellar αs phases. The size of the αs phase increases, while the space decreases with the increase of the aging temperature, thus the strength of the alloy increases as well.

αs phase also influences the elongation of the alloy. The elongation increases with the increase of aging temperature, as shown in Fig. 9(b). This is because the size of αs phase increases, whereas its volume fraction decreases with the increase of the aging temperature. At the beginning of deformation, the stress and strain are distributed uniformly in the matrix. However, the strain localization takes place with further deformation. In particular, small αs phase is harder to deform plastically, so that strain localization is extreme, which can lead to the macroscopic brittleness. Thus, the elongation of the alloy is improved by the sacrifice of its strength. The elongation increases firstly and then decreases with the increase of aging time. The variation trend is similar to that with solution treatment.

Fig. 8 Variation of strength (a) and ductility (b) of Ti-55531 alloy with solution temperature and time

Fig. 9 Variation of strength (a) and ductility (b) of Ti-55531 with aging temperature and time

3.3 Fracture mechanism

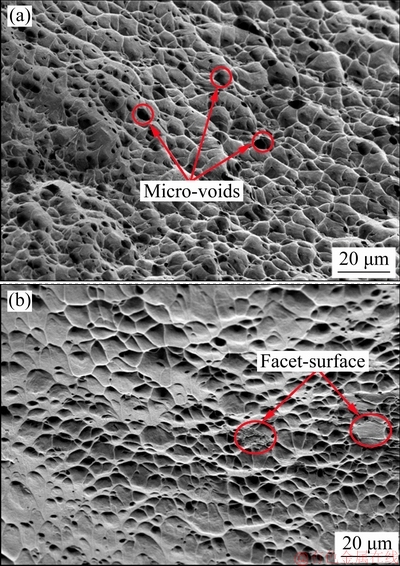

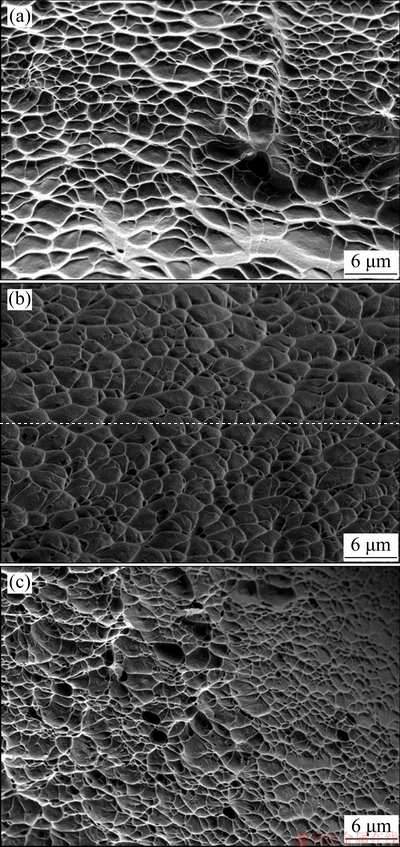

The fractographs of the alloy solution-treated at 760 °C for different time are shown in Fig. 10(a). In Fig. 10(a), the fracture surface can be identified as a typical dimpled region, where the dimples become elongated, but the morphologies of these dimples are more uniform and the average diameter of the dimples is about 5 mm. Some micro-voids can also be found, as remarked by red arrows. These characteristics represent a typical ductile fracture mode and indicate good ductility of the alloy.

The fractograph at solution temperature of 800 °C is shown in Fig. 10(b). The fracture surface includes many deep dimples and some micro-voids, which shows that the ductile failure mode is still dominant. The average diameter of the dimples is about 10 mm. Moreover, some facet surfaces can be observed, which demonstrates that the fracture mode of the alloy under this condition may be a combination of ductile and brittle modes. This may be caused by some brittle or second phases in the β matrix. The stress and strain localization between the brittle phases and β matrix induce some brittle fractures during tensile process.

Fig. 10 Fractographs of alloy solution-treated at 760 °C (a) and 800 °C (b) for 0.5 h

Figure 11 shows the fractographs of the alloy aging- treated at 580 °C for 6-10 h. The fracture surfaces include many deep dimples and some micro-voids. This indicates that the ductile fracture is still a dominant mechanism. However, there are still some differences among these fractographs. After being aging-treated at 580 °C for 6 h, the fracture surface is relatively flat, as shown in Fig. 11(a). With the increase of aging time, the fracture surface shows some obvious ups and downs, even a big fracture step (see Fig. 11(c)). Moreover, the dimples are not uniform, and their sizes around the fracture step are smaller than those in other regions.

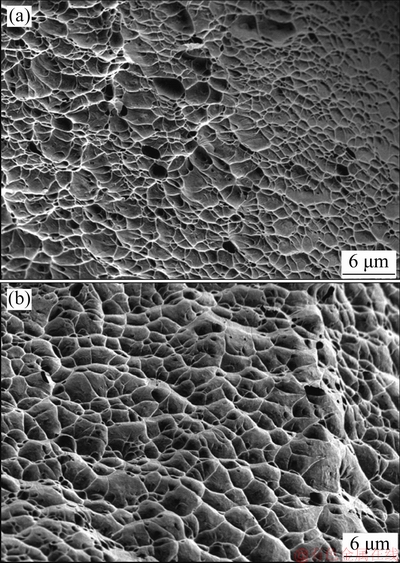

The effect of aging temperature on the fractograph is investigated, and the results are shown in Fig. 12. The fracture surfaces are covered with many deep and dense dimples and some micro-voids. In Fig. 12(a), where the aging condition is 580 °C for 10 h, the fracture surface shows relatively flat, but there are still some smaller ups and downs. At aging temperature of 640 °C (Fig. 12(b)), the ups and downs become more obvious, even a big fracture step can be observed, and the dimples become more uniform and deep than those at 580 °C. This indicates that the crack propagation is difficult and more energy is required for cracks to bypass the αs phase. The crack propagation is controlled by the αs phase. The coarsening of αs phase takes place easily at higher aging temperatures. The alloy containing a coarser αs phase usually has a rougher crack front profile, which can lead to a higher crack propagation resistance, and finally the increase of the ductility and fracture toughness.

Fig. 11 Fractographs of alloy solution-treated at 800 °C for 2 h plus aging-treated at 580 °C for 6 h (a), 8 h (b) and 10 h (c)

Fig. 12 Fractographs of alloy solution-treated at 800 °C for 2 h plus aging-treated at 580 °C (a) and 640 °C (b) for 10 h

4 Conclusions

(1) The volume fraction of the αp phase decreases with the increase of solution temperature, while the size and morphology are insensitive to the solution temperature.

(2) The αs phase nucleates at the β grain boundaries and α/β phase interface and within β grains during the aging treatment. The coarsening of lamellar αs phase can take place during the aging treatment, the length decreases and width increases with the increase of aging temperature.

(3) The yield and tensile strengths increase with increasing aging temperature. A good balance of strength and ductility is reached after the solution treatment at 800 °C for 2 h plus aging at 640 for 8 h, in which the tensile strength is 1434 MPa and the elongation is 7.5%.

(4) The coarsening lamellar αs phase makes the crack propagation paths more deflected and tortuous, which increases the crack propagation resistance and finally improves the ductility and fracture toughness.

References

[1] SHI Zhi-feng, GUO Hong-zeng, LIU Rui, WANG Xiao-chen, YAO Ze-kun. Microstructure and mechanical properties of TC21 titanium alloy by near-isothermal forging [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 72-79.

[2] DIKOVITS M, POLETTI C, WARCHOMICKA F. Deformation mechanisms in the near-β titanium alloy Ti-55531 [J]. Metallurgical and Materials Transactions A, 2014, 45: 1586-1596.

[3] WARCHOMICKA F, POLETTI C, STOCKINGER M. Study of the hot deformation behavior in Ti-5Al-5Mo-5V-3Cr-1Zr [J]. Materials Science and Engineering A, 2011, 528: 8277-8285.

[4] CHEN Fu-wen, XU Guang-long, ZHANG Xiao-yong, ZHOU Ke-chao, CUI Yu-wen. Effect of α morphology on the diffusional β to α transformation in Ti-55531 during continuous heating: Dissection by dilatometer test, microstructure observation and calculation [J]. Journal of Alloys and Compounds, 2017, 702: 352-365.

[5] FAN Xiao-guang, ZHANG Yan, GAO Peng-fei, LEI Zhen-ni, ZHAN Mei. Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field [J]. Materials Science and Engineering A, 2017, 694: 24-32.

[6] MANSHAD A D, DIPPENAAR R J. Development of α-phase morphologies during low temperature isothermal heat treatment of a Ti-5Al-5Mo-5V-3Cr alloy [J]. Materials Science and Engineering A, 2011, 528: 1833-1839.

[7] CHEN Yu-yong, DU Zhao-xin, XIAO Shu-long, XU Li-juan, TIAN Jing. Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy [J]. Journal of Alloys and Compounds, 2014, 586: 588-592.

[8] ZHU Yan-yan, CHEN Bo, TANG Hai-bo, CHANG Xu, WANG Hua-ming, LI Jia. Influence of heat treatments on microstructure and mechanical properties of laser additive manufacturing Ti-5Al-2Sn-2Zr-4Mo-4Cr titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 36-46.

[9] ZHU Yan-chun, HUANG Qing-xue, SHI Xiao-hui, SHUAI Mei-rong, ZENG Wei-dong, ZHAO Yong-qing, HUANG Zhi-quan, MA Li-feng. Precipitation location of secondary phase and microstructural evolution during static recrystallization of as-cast Ti-25V- 15Cr-0.3Si titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 1521-1529.

[10] DU Zhao-xin, XIAO Shu-long, XU Li-juan, TIAN Jing, KONG Fan-tao, CHEN Yu-yong. Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy [J]. Materials and Design, 2014, 55: 183-190.

[11] ZHANG Xue, KOU Hong-chao, LI Jin-shan, ZHANG Feng-shou, ZHOU Lian. Evolution of the secondary α phase morphologies during isothermal heat treatment in Ti-7333 alloy [J]. Journal of Alloys and Compounds, 2013, 577: 516-522.

[12] ZHAO Hui-jun, WANG Bao-yu, LIU Gang, YANG Lei, XIAO Wen-chao. Effect of vacuum annealing on microstructure and mechanical properties of TA15 titanium alloy sheets [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1881-1888.

[13] XU Sheng-hang, LIU Yong, LIU Bin, WANG Xin, CHEN Zhi-xing. Microstructural evolution and mechanical properties of Ti-5Al- 5Mo-5V-3Cr alloy by heat treatment with continuous temperature gradient [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 273-281.

[14] LUTJERING G, WILLIAMS J C. Titanium [M]. 2nd ed. Berlin: Springer, 2007.

[15] XU Jian-wei, ZENG Wei-dong, MA Hao-yuan, ZHOU Da-di. Static globularization mechanism of Ti-17 alloy during heat treatment [J]. Journal of Alloys and Compounds, 2018, 736: 99-107.

[16] WU Chuan, YANG He, LI Hong-wei, YANG Guo-bao. Primary alpha grain coarsening behavior of Ti-6Al-2Zr-1Mo-1V alloy in the alpha + beta two-phase field [J]. Journal of Materials Engineering and Performance, 2013, 22: 2557-2566.

[17] MENG Miao, FAN Xiao-guang, YANG He, GUO Liang-gang, ZHAN Mei, GAO Peng-fei. Precipitation of secondary alpha in competition with epitaxial growth of primary alpha in two-phase titanium alloys [J]. Journal of Alloys and Compounds, 2017, 714: 294-302.

[18] TIAN Yong-lai, KRAFT R W. Mechanisms of pearlite spheroidization [J]. Metallurgical and Materials Transactions A, 1987, 18: 1403-1414.

[19] TIAN Yong-lai, KRAFT R W. Kinetics of pearlite spheroidizations [J]. Metallurgical and Materials Transactions A, 1987 18: 1359-1369.

[20] SEMIATIN S L, CORBETT M W, FAGIN P N, SALISHCHEV G A, LEE C S. Dynamic-coarsening behavior of an α/β titanium alloy [J]. Metallurgical and Materials Transactions A, 2006, 37: 1125-1136.

[21] SEMIATIN S L, KIRBY B C, SALISHCHEV G A. Coarsening behavior of an alpha-beta titanium alloy [J]. Metallurgical and Materials Transactions A, 2004, 35: 2809-2819.

[22] FAN Jian-kuan, LI Jin-shan, KOU Hong-chao, HUA Ke, TANG Bing. Influence of solution treatment on microstructure and mechanical properties of a near β titanium alloy Ti-7333 [J]. Materials and Design, 2015, 83: 499-507.

[23] SHI Xiao-hui, ZENG Wei-dong, SHI Chun-ling, WANG Hao-jun, JIA Zhi-qiang. The fracture toughness and its prediction model for Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy with basket-weave microstructure [J]. Journal of Alloys and Compounds, 2015, 632: 748-755.

武 川1,2,詹 梅2

1. 天津职业技术师范大学 汽车模具智能制造技术国家地方联合工程实验室,天津 300222;

2. 西北工业大学 凝固技术国家重点实验室,西安 710072

摘 要:研究钛合金Ti-5Al-5Mo-5V-3Cr-1Zr(Ti-55531)在不同固溶(760~820 °C)与时效(580~640 °C)热处理条件下的显微组织演化、力学性能及断裂机理。结果表明,初生α相(αp)的体积分数随固溶温度的升高而降低,而次生α相(αs)的长度随时效温度升高而降低,其宽度则随时效温度升高而增加。Ti-55531合金的屈服强度和抗拉强度随固溶温度升高而降低,但随时效温度的升高而增大。合金在800 °C固溶2 h、640 °C时效8 h的条件下获得的抗拉强度(1434 MPa)与韧性(伸长率7.7%)达到最优匹配。随时效温度和时间的增加,αs相发生粗化,使微观裂纹扩展路径变得曲折、崎岖,从而提高裂纹扩展阻力,最终提高合金的韧性与断裂韧性。

关键词:Ti-5Al-5Mo-5V-3Cr-1Zr钛合金;热处理;固溶;时效;显微组织演化;力学性能;断裂机理

(Edited by Wei-ping CHEN)

Foundation item: Project (SKLSP201853) supported by the Fund of the State Key Laboratory of Solidification Processing in NWPU, China; Project (51625505) supported by the National Science Fund for Distinguished Young Scholars of China; Project (U1537203) supported by the Key Program Project of the Joint Fund of Astronomy and National Natural Science Foundation of China; Project (KYQD1801) supported by the Scientific Research Foundation of Tianjin University of Technology and Education, China

Corresponding author: Chuan WU; Tel: +86-18526404293; E-mail: zjkwuchuan@126.com

DOI: 10.1016/S1003-6326(19)65008-9