DOI: 10.11817/j.issn.1672-7207.2015.10.013

高速大流量阀控液压缸缓冲优化设计

张增磊1,巫世晶1,钟建英2,胡基才1,赖奇暐1

(1. 武汉大学 动力与机械学院,湖北 武汉,430072;

2. 国家电网河南平高电气股份有限公司,河南 平顶山,467001)

摘要:针对用于1 100 kV特高压断路器中的高速大流量液压缸分闸缓冲制动效果不良这一问题,提出采用系统综合建模的方法,在建立缓冲流量连续方程和运动微分方程的基础上,综合考虑油液密度、动力黏度和体积弹性模量随系统状态的变化,并提出运用CFD(computational fluid dynamics)流场分析法判断缓冲不同阶段的过渡点,同时结合试验测试数据对活塞运动的位移、速度、缓冲压力等动态特性进行对比分析。发现理论计算结果与试验数据差异较大;经过修正的阀控液压缸模型得到的结果与试验基本一致,缓冲压力变化剧烈,其峰值压力高达107.0 MPa,缓冲末速度高达1.75 m/s,会对缓冲套和缸体造成严重的冲击。为有效提升缓冲效果,推导出理想缓冲过程的压力和速度变化规律,给出4种不同柱塞结构的间隙变化模型,并在考虑油液黏性阻尼和可压缩性的条件下,运用阀控缸系统的综合计算模型对不同结构柱塞在初始间隙取不同值时的缓冲效果进行对比分析。研究结果表明:在相同条件下,初始间隙为1.4 mm的圆锥型柱塞的缓冲效果最好,使缓冲峰值压力和末速度降低幅度均超过40%;考虑实际参数的动态变化特性后,理论上最优的抛物线型柱塞的缓冲效果不佳,活塞的末速度较高。

关键词:液压缸;缓冲;动态特性;系统仿真;优化设计

中图分类号:TM56 文献标志码:A 文章编号:1672-7207(2015)10-3646-10

Optimal design of cushion system for high-speed and high-flow valve-controlled hydraulic cylinder

ZHANG Zenglei1, WU Shijing1, ZHONG Jianying2, HU Jicai1, LAI Qiwei1

(1. Department of Power and Mechanical Engineering, Wuhan University, Wuhan 430072, China

2. State Grid Henan Pinggao Electric Co. Ltd., Pingdingshan 467001, China)

Abstract: In order to solve the bad cushion performance of high-speed and high-flow valve-controlled hydraulic cylinder used in 1100 kV ultra-high voltage circuit breaker, a method of comprehensive system simulation was put forward. This system simulation considered density, dynamic viscosity and bulk modulus changing with the status of the system and was based on the general flow continuity equation and motion differential equation. Furthermore, a method of flow field analysis using CFD (computational fluid dynamics) was adopted to distinguish transition point of cushion process in different stages. Compared with test data, the system simulation model was applied to analyze displacement, velocity and pressure features. The theoretical computational result shows a big difference from the test data while the modified hydraulic simulation model basically agrees with the test data. In addition, the tremendously changing pressure is up to 107.0 MPa and a high end speeds up to 1.75 m/s, which causes a great damage to the cushion collar and cylinder body. In order to improve the cushion performance, clearance changing models of four different type plungers were given based on the derivation of velocity and pressure changing rule for ideal cushion process. Different schemes were designed to study the cushion features of different plungers using the comprehensive system simulation model. The results show that conical cushion plunger of 1.4 mm initial clearance is the best scheme which reduces both the peaking pressure and end speed by more than 40% under the same conditions. The parabolic cushion plunger which is the best structure in theory, does not have the best performance in consideration of the dynamic changes of the actual parameter characteristics, and its end speed is high.

Key words: hydraulic cylinder; cushion; dynamic characteristics; system simulation; optimal design

液压缸作为工程机械中重要的执行元件,其缓冲性能直接关系到设备整体运行的可靠性[1-3]。液压缸的缓冲方式基本上可分为缸内缓冲和缸外缓冲。液压缸外缓冲须在外部回路上安装节流阀等流量控制元件,结构复杂;而缸内缓冲则是利用活塞端部的缓冲柱塞与缓冲孔之间形成的狭小区域实现节流缓冲,不需在外部回路上添加额外的元件,结构简单,不易发生故障[2-4]。特高压断路器液压操动机构中的用于动力传动的液压缸,具有高速大流量的特点,活塞在很短的时间内(约50 ms)完成动作,最高运行速度可超过10 m/s,同时须拖动接近200 kg的连杆传动机构,因此采用渐变节流缸内缓冲方式。与常用液压缸相比,其高速、重载、大流量的运行特点决定了缓冲结构的复杂性,缓冲柱塞的结构都是阶梯型,其中分闸柱塞有9级阶梯,缓冲柱塞长度和阶梯数量远超过一般液压缸。由于其特定严格的工况和结构的复杂性,因此,各级阶梯的长度和间隙配合是否合理直接关系到缓冲效果的优劣及特高压断路器的运行稳定性,进而影响到特高压电网的可靠性。刘伟等[1]对550 kV高压断路器的液压操动机构的分合闸特性进行了仿真和试验研究,并分析了主要参数对系统特性的影响。李新平等[5]运用Matlab/Simulink对通用液压缸的缓冲性能进行了研究,明确了系统的动态稳定性。江桂云等[6]对液压伺服阀控缸的动态特性进行了研究,分析了不同负载特性时系统的响应。李艳利等[7]对液压缸的缓冲结构和缓冲原理进行了研究,总结设计缸内缓冲装置要考虑的因素。陈登民等[8]对液压缸内部节流缓冲模型进行了研究,分析了常用液压缸内缓冲结构的对比效果。武晓风等[9]设计出一种复合型液压缸缓冲结构,使缓冲冲击小、过程平稳。相关学者虽然已对特定液压缸的缓冲特性进行大量研究[10-18],但将其结合到1 100 kV特高压断路器液压操动机构中还较少见;新型的液压缸内缓冲结构[9-10]被设计出并应用在小型工程机械中,并进行相关的仿真和试验研究,但是在大流量、高功率的特种设备如特高压断路器中的应用还很少;大多分析过程中缓冲峰值压力最高为几十兆帕,且并没有考虑油液的可压缩性等复杂条件;此外,特高压断路器缓冲中的峰值压力超过100 MPa,其大流量、高功率、瞬时动作等特性使对液压缸缓冲的研究具有典型性和复杂性。本文以某1 100 kV特高压断路器液压操动机构中的高速大流量阀控液压缸为研究对象,通过采用系统综合建模方法对其缓冲特性进行设计研究,并提出液压缸的优化方案,以便有效解决液压缸分闸缓冲制动效果不良的问题。

1 数学模型

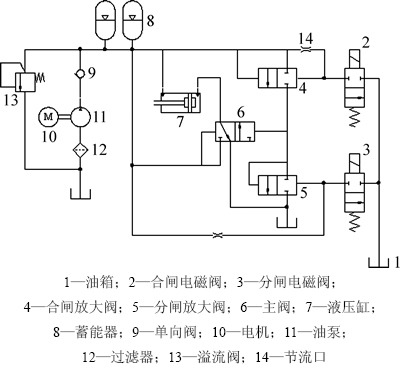

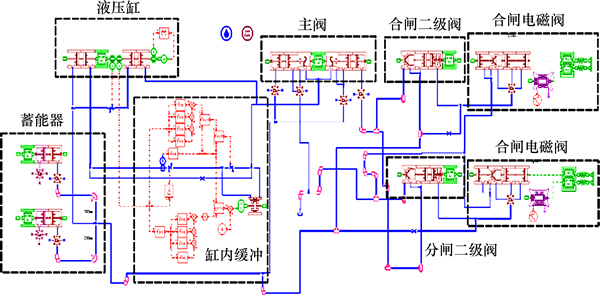

阀控液压缸的工作原理如图1所示,其中,额定压力为32.6 MPa。

当系统检测到蓄能器的压力小于32.6 MPa时,就会启动电机带动液压泵工作,将油箱内的油液通过单向阀打入蓄能器内,给蓄能器储能;当合闸电磁阀收到合闸电压信号时,电磁阀中的电磁铁线圈通电,带动电磁铁铁芯动作,撞击电磁阀阀芯使其开启,由于节流口的作用,合闸放大阀控制腔压力将会降低,从而使放大阀阀口打开,高压油进入主阀的控制腔中,主阀阀芯移动到合闸位置,使液压缸的无杆腔通入高压油,推动活塞杆运动,带动连杆机构及动触头运动,使断路器完成合闸动作。与合闸过程类似,通过电磁阀和放大阀将主阀控制腔内高压油泄去,主阀阀芯移动到分闸位置,液压缸无杆腔与油箱相连从而泄压,液压缸活塞在单侧高压油的推动下移动,带动连杆机构及动触头运动,从而完成分闸动作。

图1 阀控液压缸示意图

Fig. 1 Schematic diagram of valve-controlled hydraulic cylinder

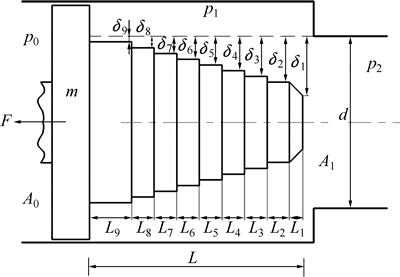

柱塞的9级阶梯形结构如图2所示,其与普通液压缸的不同之处在于液压控制系统和柱塞缓冲结构的精细和复杂。图2中:d为缓冲孔直径;L为缓冲柱塞的总长;L1~L9分别为缓冲柱塞第1~9级台阶的长度;δ1~δ9分别为第1~9级台阶与缓冲孔的配合间隙;p0为系统工作压力;p1为缓冲腔压力;p2为柱塞腔压力;m为包括活塞在内的传动机构的等效质量;F为作用在传动机构端部的负载力;A0和A1分别为左、右两腔的有效承压面积。

1.1 流量方程

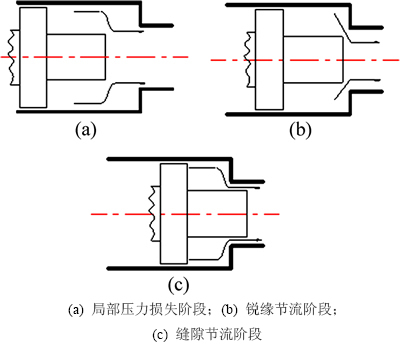

高速液压缸的缓冲基本上可分为3个阶段,如图3所示。图3(a)中,当缓冲柱塞离缓冲孔较远时,缓冲腔的油液通过缓冲孔流出,由于局部流道断面收缩而产生压力损失,可称为局部压力损失阶段,其流量方程为

(1)

(1)

式中:Q1为局部压力损失阶段的流量;d为缓冲孔内径;Cf为流道断面收缩的流量系数;Δp为收缩断面前后的压力差;ρ为油液密度。

图3(b)中,当缓冲柱塞离缓冲孔较近时,柱塞的边缘和排油腔的边缘形成锐缘节流阶段,其流量方程[7,11]为

图2 缓冲柱塞多级台阶结构示意图

Fig. 2 Schematic diagram of multiple steps plunger

图3 缓冲过程的3个阶段

Fig. 3 Three stages of whole cushion process

(2)

(2)

式中:Q2为锐缘节流阶段的流量;Cd为锐缘节流的流量系数;x为活塞位移;δ为柱塞与缓冲孔之间的径向间隙;l0为柱塞与缓冲孔之间的距离。

图3(c)中,当缓冲柱塞进入缓冲孔后,进入缝隙节流阶段,其流量方程[4]为

(3)

(3)

式中:Qf为缝隙节流阶段的流量;μ为油的动力黏度;ε为柱塞的偏心比;v为活塞运动速度。

对于3个阶段中2个过渡点的确定,一种方法是可通过流量进行判断[11]。当锐缘节流的流量小于等于局部断面收缩的流量时,可认为开始进入锐缘节流阶段,即

(4)

(4)

同理,当缝隙节流的流量小于等于锐缘节流的流量即可认为进入缝隙节流阶段,即

(5)

(5)

但由于缓冲过程时间短、液体特性变化剧烈、流场复杂,仅根据上式计算出的过渡点不一定精确。在此提出结合CFD(computational fluid dynamics)流场分析法,计算出活塞在运动过程中的24个不同位置流场,通过流场的流速和压力分布情况,来进一步确定2个过渡点。

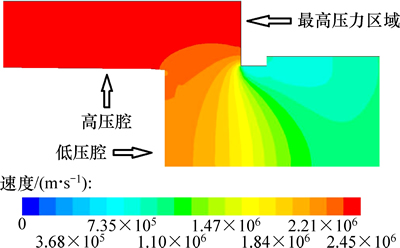

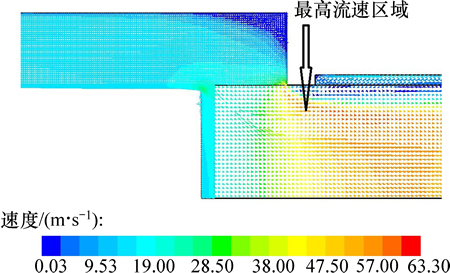

当柱塞距离缓冲孔较远时,缓冲腔和柱塞腔内的压力很低且分布基本一致;柱塞进入缓冲孔后缓冲腔内压力较高并且分布均匀;通过将各个位置的压力场和速度场对比分析,得到第1个过渡点,即从局部压力损失到锐缘节流的过渡点是柱塞距离缓冲孔1.5 mm时的位置,此时的局部压力场和速度矢量图分别如图4和图5所示。由图4和图5可见:在此过渡点开始形成高压腔和低压腔,且在两腔之间油液的速度较高,最高可达26.1 m/s,这在局部压力损失和缝隙节流损失阶段不会出现;通过计算发现第2个过渡点,即锐缘节流到缝隙节流的过渡点,是在柱塞刚好进入缓冲孔时所处的位置。

1.2 流量连续方程

缓冲腔流量连续方程计算如下。

局部压力损失阶段流量Q3为

(6)

(6)

式中:V1为缓冲腔的体积;A2为排油腔的有效水压面积;p1为缓冲腔的压力;βe为油液体积弹性模量。

锐缘节流和缝隙节流阶段流量Q4为

(7)

(7)

图4 第1个过渡点的局部压力场

Fig. 4 Local pressure field of transition point

图5 第1个过渡点的局部速度矢量图

Fig. 5 Local velocity vector diagram of transition point

柱塞腔流量连续方程计算如下。

局部压力损失阶段流量Q5为

(8)

(8)

锐缘节流和缝隙节流阶段流量Q6为

(9)

(9)

式中:V2为柱塞腔体积;Cdp为柱塞腔后的断面收缩系数;Av为柱塞腔回油的过流面积。

1.3 运动学方程

活塞的运动学方程如下。

局部压力损失阶段为

(10)

(10)

锐缘节流和缝隙节流阶段为

(11)

(11)

式中:B为黏性阻尼系数。

1.4 状态方程的修正

以上建立的流量方程、流量连续方程和运动方程,都是采用集中参数法描述缓冲过程中各状态变量之间的相互关系,可称为状态方程。由于缓冲压力的峰值超过100 MPa,因此,不能忽略压力对现有的状态常量如密度、体积弹性模量和动力黏度的影响。

液体的黏度μ随压力的变化规律一般可按下式进行计算:

(12)

(12)

式中:μp为缓冲压力为p时的黏度,Pa·s;μ0为缓冲压力为1×105 Pa时的黏度,Pa·s;α为黏压系数,取决于液体的物理性质。

液体的体积弹性模量βe也随压力变化而变化,特别是在高压时,体积弹性模量变化可能较大。此外,体积弹性模量还会受到油液中的含气量的影响[4]。此外,油液在管道中流动,当压力变化很大时,油液的压缩性、混入气体的压缩性和管道容器的壁面变形会对系统刚度产生很大的影响,因此,需要计算等效体积弹性模量βE,即

(13)

(13)

式中:βc为管道容器的体积弹性模量;βl为油液的体积弹性模量;βg为混入气体的体积弹性模量;Vo为油液中纯油的体积;Vg为油液中混入空气的体积。

油液的密度随压力的变化可根据其体积的压缩量来计算,但又要引入体积这一新的状态变量,使问题变得复杂。密度ρ、体积弹性模量βe和压力p之间的关系为

(14)

(14)

由式(14)可以看出:若不考虑油液的可压缩性,忽略油液密度、体积弹性模量和黏度的动态变化,仅通过求解状态方程来对缓冲过程进行分析,则得不到与实际相符的计算结果。

2 计算与试验对比分析

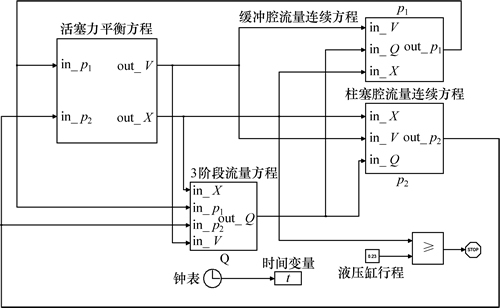

对式(1)~(11)所代表的缓冲状态方程采用MATLAB/Simulink求解,计算模型如图6所示。求解器选择ode15s(stiff/NDF),步长选择为自动变步长(auto-variable-step),数值微分方程的最大阶次为5阶,对方程求解后作为理论结果用于和仿真与试验对比。

理论模型忽略控制阀系统的阀芯运动特性、阀芯液动力、支座弹簧力、阀芯阻尼等,认为控制阀阀口瞬时开启,必然会使系统的响应“快于”实际动作过程。因此,综合考虑三级控制阀、蓄能器和管道系统的动态特性对液压缸缓冲的共同作用,并考虑油液的可压缩性,根据式(1)~(14)运用AMESim液压系统仿真平台建立缓冲的综合仿真模型如图7所示。

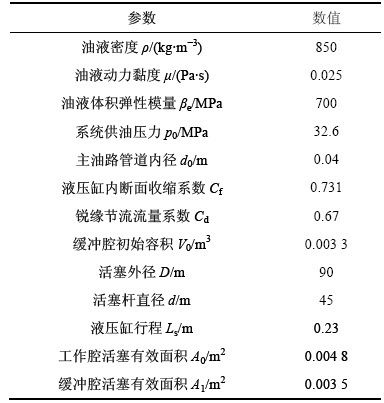

缓冲的主要参数及其取值如表1所示,其中油液密度、动力黏度和体积弹性模量是分闸过程的初始值,在计算过程中会根据系统的实时状态进行动态变化。同时对液压操动机构进行试验测试,通过试验结果、系统仿真和理论计算的对比分析,来对分闸缓冲过程进行系统、综合的研究。

图6 状态方程的MATLAB/Simulink计算模型

Fig. 6 Simulation model of state equations in MATLAB/Simulink

图7 高速液压缸分闸缓冲系统仿真模型

Fig. 7 Simulation model of opening cushion system for high-speed hydraulic cylinder

表1 计算模型所需主要参数

Table 1 Main parameters for simulation model

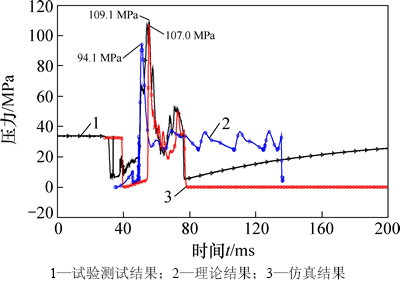

分闸缓冲压力特性如图8所示。由图8可见:压力曲线的变化呈阶段性。在0~38 ms时,无杆腔尚未泄压,压力保持在32.6 MPa;之后无杆腔泄压,在38~60 ms时活塞在单侧高压油作用下运动,压力不断上升,在58 ms时压力最高,由于此时活塞已进入缓冲孔,导致过流面积瞬间减小;在60~80 ms时为9级台阶的渐变节流缓冲阶段,由于过流面积不断变化,因此压力呈现出波动性;在80 ms时分闸结束,缓冲腔油液全部回流到油箱,压力变为0 MPa,缓冲过程结束。对缓冲压力曲线的对比主要是在38~80 ms这段时间内,可以看出系统仿真与试验测试的结果基本一致,试验的最高压力为109.1 MPa,仿真的最高压力为107.0 MPa;而理论计算的最高压力仅为94.1 MPa,最高压力之后的曲线波动与试验不符。这表明所建立的AMESim系统仿真模型考虑油液的可压缩性后,能较精确地反映分闸缓冲压力的动态变化。

图8 分闸缓冲压力特性曲线

Fig. 8 Cushion pressure curves of open action

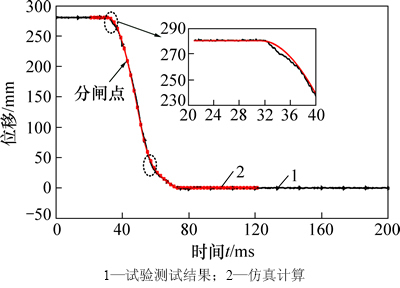

下面进一步对比系统仿真与试验测试得的活塞位移和速度曲线,其中位移曲线如图9所示。由图9可以看出:仿真计算与试验测试的位移基本一致;根据行业标准[2]计算得到的试验分闸时间为20.80 ms,仿真计算为19.86 ms;试验测试的分闸速度为11.68 m/s,仿真计算为11.97 m/s。在动作起始和结束时位移曲线抖动严重,如图9中放大曲线所示,主要是由含间隙的连杆机构引起[2],这在实际动作过程中不可避免。

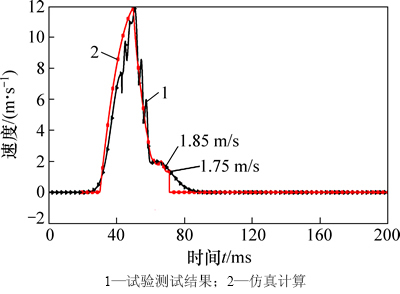

缓冲末速度可从速度曲线中读取,如图10所示。由图10可得:试验测试的分闸末速度为1.85 m/s,仿真计算的分闸末速度为1.75 m/s,两者基本一致。

图9 分闸位移特性曲线

Fig. 9 Displacement curves of open action

图10 分闸缓冲速度特性曲线

Fig. 10 Cushion velocity curves of open action

3 缓冲性能优化设计

通过计算与试验结果的对比分析,表明考虑油液的可压缩性后得到的结果较准确,比一般的只求解缓冲状态方程的方法更精确[5,11]。同时,研究发现现有结构的缓冲最高压力和缓冲末速度都较高,必须进行优化设计。

根据前面建立的流量方程和运动学方程,在固定节流缓冲模式下,若不考虑黏性阻尼和认为油液不可压缩,则按照图2所示的柱塞受力状态可得:

(15)

(15)

(16)

(16)

此方程表达的是柱塞进入缓冲后的运动状态,当t=0 ms时,活塞运动速度v=v0,v0为活塞运动的最高速度。对微分方程进行求解可得速度的表达式为

(17)

(17)

对速度进行求导可得加速度a的表达式为

(18)

(18)

将式(17)代入式(15)中可得缓冲腔压力p1的变化规律为

(19)

(19)

根据式(18)和式(19),在t=0 ms时得到最大负加速度a0和缓冲最高压力p10,即

(20)

(20)

可见固定节流缓冲在缓冲开始就会出现加速度和缓冲压力的峰值,会造成很大的惯性冲击和压力冲击。

理想的缓冲过程是缓冲腔压力p1较低且保持不变,那么缓冲过程一定是等减速过程,速度v和加速度a的变化规律如下式所示:

(21)

(21)

将式(21)代入式(15),可求得间隙随柱塞进入缓冲孔深度的关系为

(22)

(22)

这是1个抛物线方程,即在不考虑黏性阻尼和油液的可压缩性的条件下,要想实现等减速缓冲,缓冲柱塞是1个抛物线椎体。

圆柱型、圆锥型和台阶型柱塞的间隙随其进入缓冲孔距离的关系为

(23)

(23)

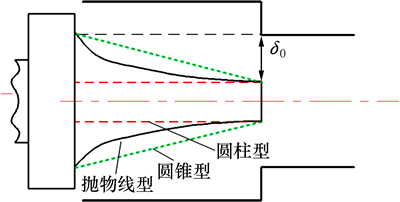

其中:δ0为柱塞的端部和缓冲孔的配合间隙,如图11所示;Li为已经进入缓冲孔的台阶的总长度。

通过推导得抛物线型柱塞理想渐变节流缓冲以及圆柱型、圆锥型和阶梯型的柱塞侧面与缓冲孔的间隙变化规律,下面通过AMESim中建立的系统模型,综合考虑控制阀阻尼和油液可压缩性等在理论推导中难以考虑的因素,对几种柱塞缓冲效果进行对比分析。

3种柱塞的结构和初始间隙如图11所示。将式(22)和式(23)所示的缓冲柱塞与缓冲孔的初始间隙δ0按照等值递增,变化范围为1~4,经过多次计算结果对比分析,在3种柱塞结构中得到效果较好的对比方案,方案选择原则是缓冲峰值压力低,缓冲结束时间不能过长,缓冲末速度小及不能出现反向冲击。

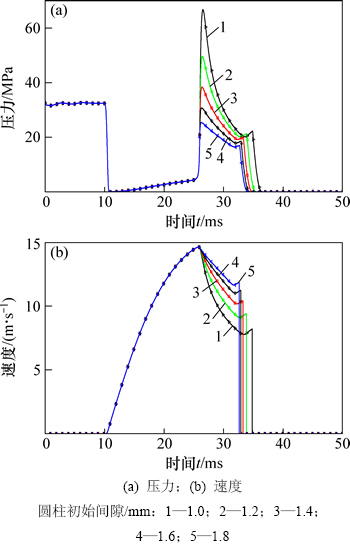

不同结构柱塞在不同初始间隙时的计算结果如图12~14所示。由图12~14可以看出:增大圆柱形柱塞的初始间隙能降低缓冲峰值压力,如图12(a)所示;但缓冲末速度很高,超过7 m/s。若如图12(b)所示,则会对缸体造成巨大的冲击。

图11 不同结构柱塞结构示意图

Fig. 11 Schematic diagram of different plungers

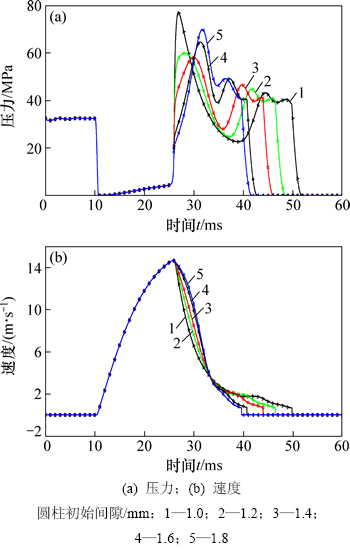

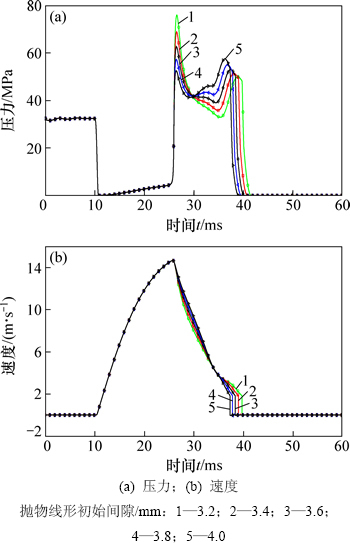

圆锥形柱塞的初始间隙改变能达到较低的缓冲峰值压力和缓冲末速度,其中初始间隙为1.4 mm的圆锥形柱塞的缓冲效果最佳,与原阶梯型设计方案相比,峰值压力从107.0 MPa降低到58.0 MPa,降低幅度为45.8%,如图13(a)所示;末速度从1.75 m/s降低到 0.70 m/s,降低幅度高达60.0%,如图13(b)所示。抛物线形柱塞的初始间隙也能对缓冲峰值压力造成很大的影响,其中当初始间隙取为3.8 mm时,缓冲峰值压力为57.3 MPa,如图14(a)所示;但不同间隙的缓冲末速度都在2 m/s左右,如图14(b)所示,会对缓冲套造成较大的冲击。

图12 不同初始间隙的圆柱形柱塞缓冲效果

Fig. 12 Cushion effects of cylindrical plunger at different initial clearances

图13 不同初始间隙的圆锥形柱塞缓冲效果

Fig. 13 Cushion effects of conical plunger at different initial clearances

缓冲过程的实质是活塞运动的动能Ek、缓冲腔的压力势能Ep以及活塞与缓冲套撞击后的能量损耗Ew之间的转化,而转化过程中的总能量Econst保持不变,其转化关系为

(24)

(24)

式中:m1和m2分别为活塞及其连杆机构等效到活塞上的当量质量和缓冲腔高压油液的质量;v(t)为活塞随时间变化的速度;p(t)为活塞随时间变化的缓冲腔压力;Ew与碰撞的剧烈程度相关。

综合对比分析,理论上最优的抛物线形柱塞虽然能使缓冲压力波动幅度小、峰值压力低,但是缓冲末

速度较高,且加工制造困难,因此,不适合特高压断路器液压操动机构中的高速液压缸缓冲;圆锥型柱塞缓冲效果良好、设计方便且较容易加工,属于较好的缓冲结构,对现有缓冲结构的改进推荐采用长度为 85 mm、初始间隙为1.4 mm的圆锥形柱塞代替阶梯形柱塞。

4 结论

1) 液压缸缓冲过程分为不同的阶段,仅通过理论推导很难精确判断各阶段的过渡点,提出结合CFD流场分析辅助理论建模的方案,并指出要考虑液压控制系统的综合作用。

2) 通过直接求解状态方程得到的缓冲结果与试验测试不符,其原因是未考虑油液的密度、体积弹性模量和动力黏度随系统状态的动态变化,也未考虑其他液压元件对缓冲的综合影响。

3) 考虑油液的可压缩性和系统中各元件的共同作用后建立的AMESim仿真模型,修正理论模型,得到的结果与试验测试基本一致;并指出现有缓冲结构的缓冲效果不理想,缓冲最高压力高达107.0 MPa,缓冲末速度高达1.75 m/s,不利于系统运行的稳定性。

图14 不同初始间隙的抛物线形柱塞缓冲效果

Fig. 14 Cushion effects of parabolic plunger at different initial clearances

4) 建立不同结构型式柱塞节流缝隙的数学模型,对比分析不同柱塞的缓冲效果,发现考虑油液的可压缩性等因素后,理论上最优的抛物线型柱塞缓冲效果一般,推荐采用初始间隙为1.4 mm圆锥形柱塞作为高速液压缸的缓冲结构,可降低缓冲峰值压力和末速度的幅度在40%以上。可见高速液压缸缓冲制动效果不良主要是由于缓冲柱塞结构参数不合理。研究方法和结论对实际特种高速大流量液压缸的优化设计具有参考价值。

参考文献:

[1] 刘伟, 徐兵, 杨华勇. 高压断路器液压操动机构特性分析[J]. 机械工程学报, 2010, 46(10): 148-155.

LIU Wei, XU Bing, YANG Huayong. Characteristic analysis of high voltage circuit breaker with hydraulic operating mechanism[J]. Chinese Journal of Mechanical Engineering, 2010, 46(10): 148-155.

[2] 陈杰. 特高压断路器传动机构非线性特性研究[D]. 武汉: 武汉大学, 动力与机械学院, 2012: 2-3.

CHEN Jie. Research on nonlinear characteristics of ultra-high voltage circuit breaker drive mechanism[D]. Wuhan: Wuhan University. School of Power and Mechanical Engineering, 2012: 2-3.

[3] 苑舜. 高压断路器液压操动机构[M]. 北京: 机械工业出版社, 1999: 1-3.

YUAN Shun. Hydraulic operating mechanism for high voltage circuit breaker[M]. Beijing: China Machine Press, 1999: 1-3.

[4] 金朝明. 液压流体力学[M]. 北京: 国防工业出版社, 1994: 10-15.

JIN Chaoming. Hydraulic fluid mechanics[M]. Beijing: National Defence Industry Press, 1994: 10-15.

[5] 李新平, 霍族亮, 于仁萍. 基Matlab/Simulink的液压缸建模与仿真[J]. 煤矿机械, 2005, 26(7): 49-51.

LI Xinping, HUO Zuliang, YU Renping. Modeling and simulation of hydraulic cylinder based on Matlab/Simulink[J]. Coal Mine Machinery, 2005, 26(7): 49-51.

[6] 江桂云, 王勇勤, 严兴春. 液压伺服阀控缸动态特性数学建模及仿真分析[J]. 四川大学学报(工程科学版), 2008, 40(5): 195-198.

JIANG Guiyun, WANG Yongqin, YAN Xingchun. Mathematics modeling and simulation analysis of dynamic characteristics for hydraulic cylinder controlled by servo-valve[J]. Journal of Sichuan University (Engineering Science Edition), 2008, 40(5): 195-198.

[7] 李艳利, 刘志奇, 董朋. 液压缸缓冲结构和缓冲原理的研究[J]. 流体传动与控制, 2013(6): 5-8.

LI Yanli, LIU Zhiqi, DONG Peng. Research on cushioning structure and principal of hydraulic cylinder[J]. Fluid Power Transmission and Control, 2013(6): 5-8.

[8] 陈登民, 李永奇, 张孝元. 液压缸内部节流缓冲模型的研究[J]. 液压气动与密封, 2013(9): 66-69.

CHEN Dengmin, LI Yongqi, ZHANG Xiaoyuan. Research on internal cushioning modeling of the hydraulic cylinder[J]. Hydraulics Pneumatics and Seals, 2013(9): 66-69.

[9] 武晓凤, 赵秋霞, 姚平喜. 液压缸复合缓冲结构及缓冲过程的分析[J]. 液压与气动, 2013(3): 23-26.

WU Xiaofeng, ZHAO Qiuxia, YAO Pingxi. The analysis of composite buffer structure of the hydraulic cylinder and buffering process[J]. Chinese Hydraulics and Pneumatics, 2013(3): 23-26.

[10] 赵伟, 阮健, 李胜. 液压弹射机构动力系统研究[J]. 兵工学报, 2013, 34(4): 459-464.

ZHAO Wei, RUAN Jian, LI Sheng. Research on power system of hydraulic catapult mechanism[J]. Acta Armamentaria, 2013, 34(4): 459-464.

[11] 陈召国, 丁凡. 基于CFD的高速液压缸缓冲过程研究[J]. 机床与液压, 2008, 36(11): 45-47.

CHEN Zhaoguo, DING Fan. Study on buffering process of high speed hydraulic cylinder based on CFD[J]. Machine Tool and Hydraulics, 2008, 36(11): 45-47.

[12] 李松柏, 刘义伦, 刘伟涛. 螺旋摆动液压缸间隙的优化设计[J]. 中南大学学报(自然科学版), 2012, 43(5): 1710-1716.

LI Songbai, LIU Yilun, LIU Weitao. Optimal design for screw rotary cylinder’s radial clearance[J]. Journal of Central South University (Science and Technology), 2012, 43(5): 1710-1716.

[13] LI Ke, Mannan M A, XU Mingqian, et al. Electro-hydraulic proportional control of twin-cylinder hydraulic elevators[J]. Control Engineering Practice, 2001, 9(4): 367-373.

[14] Teng C K, Hsiao C Y, Wang C S. The effect of the guiding directions of the guiding cylinders of an area ratio modified machine cushion on the capability of suppressing impact and vibration[J]. Advances in Engineering Software, 2009, 40(10): 991-999.

[15] 杨武, 荣命哲, 王小华, 等. 考虑电动力效应的高压断路器动力学特性仿真分析[J]. 中国电机工程学报, 2003, 23(5): 103-107.

YANG Wu, RONG Mingzhe, WANG Xiaohua, et al. Dynamic simulation of high-voltage circuit breaker concerning electrodynamic force[J]. Proceedings the Chinese Society for Electrical Engineering, 2003, 23(5): 103-107.

[16] 孙艳玲, 王永良, 雷琴, 等. 特高压断路器液压操动机构仿真研究[J]. 高压电器, 2014, 50(10): 15-19.

SUN Yanling, WANG Yongliang, LEI Qin, et al. Simulation study on ultra-high voltage circuit breaker with hydraulic operating mechanism[J]. High Voltage Apparatus, 2014, 50(10):15-19.

[17] 刘金榕, 易文颖, 夏魁. 新型高速液压缸内缓冲装置及其特性的研究[J]. 机电工程, 2010, 27(3): 33-37.

LIU Jinrong, YI Wenying, XIA Kui. Study on a novel buffering device of high-speed hydraulic cylinder and its characteristics[J]. Journal of Mechanical & Electrical Engineering, 2010, 27(3): 33-37.

[18] 魏忠永, 赵鸿飞, 刘伟, 等. 高压断路器液压操动机构油缸缓冲过程仿真与试验[J]. 农业机械学报, 2010, 41(6): 216-221.

WEI Zhongyong, ZHAO Hongfei, LIU Wei, et al. Cushion process of the hydraulic cylinder of hydraulic operating mechanism for high voltage circuit breaker[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(6): 216-221.

(编辑 刘锦伟)

收稿日期:2014-10-10;修回日期:2014-12-24

基金项目(Foundation item):国家自然科学基金资助项目(51375350);湖北省科技厅重点项目(2011132094);国家电网公司科技项目(208239881)(Project (51374035) supported by the National Natural Science Foundation of China; Project (2011132094) supported by the Technology Department of Hubei Province; Project (208239881) supported by the State Grid)

通信作者:巫世晶,教授,博士生导师,从事机电液混合传动、机械动力学等研究;E-mail:wsj@whu.edu.cn