文章编号:1004-0609(2015)04-0945-07

碳含量对金属注射成形17-4PH不锈钢显微组织和力学性能的影响

张 翔1,何 浩1,李益民1,刘 晨2,满露梅2,胡幼华1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 广西冶金研究院,南宁 530023)

摘 要:通过在喂料中添加石墨改变注射成形17-4PH不锈钢组织中的碳含量,研究不同碳含量对MIM 17-4PH显微组织和力学性能的影响。结果表明:在烧结态和固溶时效态试样中,碳含量少于0.16%(质量分数)的相组织主要由马氏体和少量的铁素体构成。随着碳含量的逐渐升高,冷却过程中奥氏体未能完全转变成马氏体,组织中出现奥氏体,在碳含量为0.16%的烧结态和固溶时效态试样中,其显微组织为马氏体和奥氏体共同组成的双相组织,而且奥氏体相含量随着碳含量增加而逐渐增加;在碳含量达到0.25%以上时,试样的显微组织完全转变为奥氏体,导致试样的表观硬度下降,抗拉强度下降,伸长率提高。

关键词:MIM17-4PH不锈钢;碳含量;相转变;力学性能

中图分类号:TF124.3 文献标志码:A

Effect of carbon content on microstructure and mechanical properties of metal injection molded 17-4PH stainless steel

ZHANG Xiang1, HE Hao1, LI Yi-min1, LIU Chen2, MAN Lu-mei2, HU You-hua1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Guangxi Research Institute of Metallurgical, Nanning 530023, China)

Abstract: Graphite was added into the 17-4PH stainless steel to vary the carbon content. The effect of carbon content on the microstructure and mechanical properties of metal injection molded 17-4PH stainless steel was investigated. The results show that the samples by solid solution and aging treatment, mainly consist of martensite and a small amount of ferrite at carbon content less than 0.16%. Austenite fails to completely transform into martensite in the cooling process and the amount of austenite increases gradually with the carbon content increasing. The samples consist of both martensite and austenite at carbon content of 0.16%. Then, the samples mainly consist of austenite when carbon content is more than 0.25%. This leads to a decrease in hardness and tensile strength, while the elongation increases.

Key words: MIM17-4PH stainless steel; carbon content; phase transformation; mechanical property

金属注射成形(Metal injection molding,简称MIM)能够以较低成本制备具有复杂形状的高性能异形金属零部件而越来越受到人们的重视[1]。17-4PH不锈钢是一种应用广泛的沉淀硬化型马氏体不锈钢,通过粉末注射成形工艺制备17-4PH材质零部件,可以较低成本成形复杂形状零件, 具有生产效率高、制品性能好等优势[2]。目前,关于MIM 17-4PH不锈钢的研究主要集中在不同的脱脂工艺、烧结工艺和热处理工艺对产品致密度、显微组织和力学性能的影响[3-7]。但是,在MIM生产过程中,由于粘结剂的添加、脱脂和烧结等过程都会造成产品中碳含量的波动,而碳含量的波动对MIM不锈钢的烧结密度、抗腐蚀性能和显微组织有很大的影响[8]。脱碳对17-4PH不锈钢的影响已有研究。KYOGOKU等[9]研究了发现随着脱脂温度的提高,残余碳含量降低,烧结样从奥氏体和马氏体双相组织变成了马氏体和铁素体双相组织。WU等[10]研究了在较低碳含量时碳和烧结温度对铁素体的形成和试样力学性能的影响,发现较多的碳会使铁素体发生转变,含量减小。刘振宝等[11]发现,15-5PH中碳含量增高,使得钢中逆转变奥氏体组织的体积分数增加,降低了钢的强度。目前,技术条件中规定的C含量<0.07%(质量分数),但是实际生产过程中往往会由于脱脂不完全而残余部分碳[12],从而出现增碳的现象,而目前对增碳现象及其对产品的组织和性能的研究还比较少。在此,本文作者通过在喂料中添加石墨改变试样的碳含量,研究了在增碳条件下,MIM17-4PH不锈钢的烧结性能、显微组织和力学性能。

1 实验

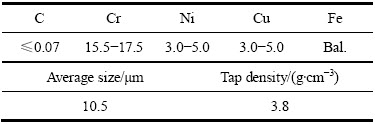

实验采用Osprey公司提供的气雾化17-4PH不锈钢粉末和石墨粉末为原料。其组成和性能如表1所列,粉末形貌如图1所示。在17-4PH粉末中分别加入质量分数为0、0.1%、0.2%、0.3%和0.4%石墨粉末,试样成分及实际测得碳含量情况如表2所列。

注射生坯采用溶剂脱脂+热脱脂两步脱脂法。溶剂脱脂所用的溶剂为二氯甲烷,脱脂温度为36 ℃,拉伸样溶剂脱脂时间为4 h,溶剂脱脂后干燥2 h,在900 ℃下进行热脱脂,之后在1340 ℃烧结,保温90 min;然后在1040 ℃固溶处理30 min,在480 ℃时效处理240 min。

采用阿基米德排水法测定烧结体的密度;采用LECO碳-氧分析仪测量烧结样品的碳含量;采用Instron万能试验机测量抗拉强度和伸长率,拉伸速度为1.0 mm/min。采用HDI-1875型布洛维硬度计上测量烧结样品HRB和HRC硬度;采用Polyvarmet金相显微镜观察腐蚀前后烧结样品的微观结构及测量样品的显微硬度;采用JSM-6360扫描电镜观察试样的拉伸断面形貌。

表1 气雾化17-4PH不锈钢粉末的组成和粉末性能

Table 1 Chemical composition and properties of 17-4PH stain steel powder by gas atomization

图1 17-4PH和石墨粉末的SEM形貌

Fig.1 SEM micrographs of particles 17-4PH(a) and graphite(b) powder

表2 不同石墨添加量试样的实测碳含量

Table 2 Actual carbon content in samples with different additions of graphite

2 结果与讨论

2.1 碳含量对17-4PH不锈钢烧结性能和力学性能的影响

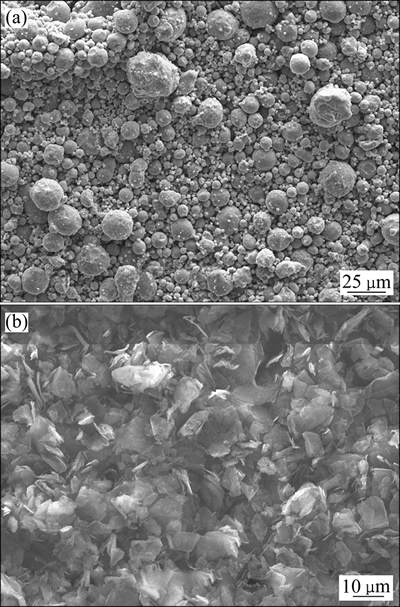

烧结获得的试样密度随碳含量的变化曲线如图2所示。从图2可以看出,随着碳含量从0.07%增加到0.25%,试样致密度随着碳含量的增加逐渐降低,而碳含量为0.25%~0.34%时,试样致密度又有所回升。从试样的显微组织中也可以看出,烧结试样密度的降低主要是由于孔隙率的增加。在碳含量0.07%~0.25%的范围内,随着碳含量的增加,碳和其他元素更易形成碳化物,聚集在晶界处[13-14],如DAVIS等[15]在高铬不锈钢中发现,晶界析出碳化铬Cr23C6,这些晶界碳化物不利于烧结颈的形成。另一方面,在1340℃烧结时,17-4PH不锈钢的组织中存在高温铁素体,高温铁素体的体积密度较小,有利于原子扩散和孔隙的消除[16],而碳含量的增加阻碍了奥氏体向高温铁素体的转变,从而阻碍了烧结致密化过程,导致试样致密度随着碳含量的增加逐渐降低。由于碳含量降低了试样的熔点,碳含量0.34%的试样1340 ℃温度下烧结时,产生了微量过烧,开始出现液相,促进了致密化,试样密度又开始有所回升。

图2 烧结态试样密度随碳含量的变化曲线

Fig. 2 Changing curves of sintered specimen density with carbon contents

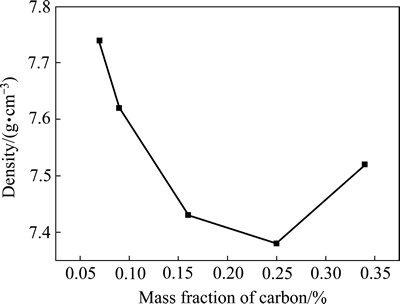

试样的力学性能主要取决于孔隙率和显微组织,MIM17-4PH的显微组织是由马氏体、铁素体以及残留奥氏体组成。WU等[10]通过实验证明,孔隙率的增加会降低试样的抗拉强度。从图3可以看出,随着碳含量的增加,烧结态和固溶时效态下MIM17-4PH抗拉强度在碳含量为0.07%~0.09%范围内缓慢增加。在碳含量>0.09%后,MIM17-4PH抗拉强度明显下降,且在碳含量0.1%~0.3%范围内变化时抗拉强度下降幅度最大。在这个碳含量范围内,孔隙率一直在增加,试样的密度下降。密度下降会导致强度下降,因此可能是试样的显微组织的变化导致了抗拉强度的增加。孔隙率的增加也会降低试样的伸长率,但实验结果发现,伸长率先略微降低后升高到25%左右,超出了17-4PH技术规范伸长率范围(10%~16%)。这从另一个方面说明试样显微组织产生了较大的变化。

表3所列为烧结态、固溶时效态试样的硬度。从表3可以看出,碳含量在0.07%~0.25%范围内变化时,随着碳含量的升高,烧结态和固溶时效态试样的硬度均下降,这主要是试样致密度的降低以及显微组织变化导致的,碳含量0.34%的试样致密化程度提高,其硬度也有所升高。

图3 烧结态(a)和固溶时效(b)试样伸长率和抗拉强度随实际碳含量的变化曲线

Fig. 3 Changing curves of tensile strength and elongation of specimens with carbon contents

表3 不同碳含量试样在不同状态下的硬度值

Table 3 Hardness of specimens with different carbon contents after sintering and solution and aging

2.2 碳含量对17-4PH不锈钢相转变的影响

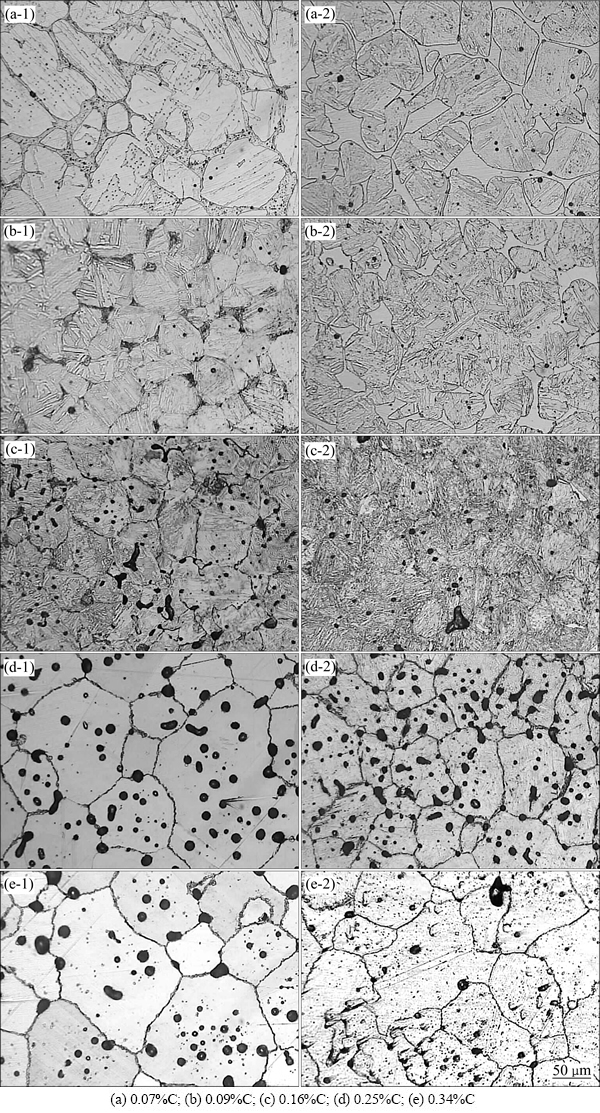

从图4金相图可以看出,在碳含量为0.07%和0.09%试样中,烧结态基体主要是以马氏体为主,在试样固溶时效后的组织中,基体是由马氏体和铁素体组成,且随着碳含量的升高,高温铁素体的转变温度点提高,组织中铁素体的含量减少直至消失,马氏体的量随之增加。随着碳含量的进一步增加,冷却过程中奥氏体未能完全转变成马氏体,开始出现奥氏体组织。在碳含量0.16%烧结态和固溶时效态试样中,都是马氏体和奥氏体共同组成的双相组织,且可以看到板条状的马氏体形成在原奥氏体晶粒的内部。碳含量为0.25%试样中,残留奥氏体进一步增加,而碳含量为0.34%试样基本由奥氏体构成。

图4 不同碳含量试样烧结态和固溶时效后的显微组织

Fig. 4 Microstructures of specimens with different carbon contents after sintering and solution and aging (1—As sintered; 2—After solution and aging)

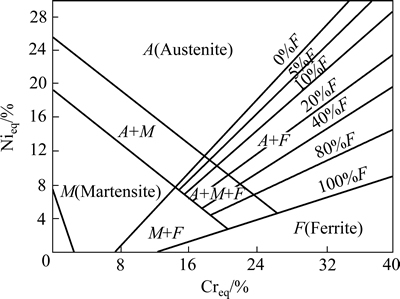

在碳含量较低的(0.07%和0.09%)试样中,高温烧结时组织是奥氏体相和少量高温铁素体,冷却下来形成马氏体和铁素体。根据舍夫勒组织图[17]可知(见图5),铁素体的含量取决于镍当量(Nieq)和铬当量(Creq)的值。在17-4PH不锈钢中,碳含量是镍当量中最大的组成。从舍夫勒组织图中可以得到,随着碳含量的升高,铁素体含量逐渐降低。17%Cr、0.16%C试样的镍当量达到了8.8%,此时相组成主要是马氏体,从舍夫勒组织图看出铁素体含量在5%以下。碳含量再升高,铁素体消失,出现部分残留奥氏体。

图5 舍夫勒组织图[17]

Fig. 5 Schaeffler’s diagram[17]

由于碳是最主要的奥氏体稳定元素,随着碳含量的增加,扩大了γ相区,降低了马氏体相变温度点Ms和Mf[18]。高温下的奥氏体在冷却过程中未能完全完成马氏体转变,试样组织奥氏体相增多。镍和铜等元素也会促进奥氏体相(A)的形成。参考文献[19]根据大量试验结果得到的奥氏体钢马氏体相变点Ms定量经验计算式,可得到碳含量0.25%试样的碳当量在4.08%,Ms为45.3 ℃,马氏体转变量很少,碳含量0.34%的试样的Ms点为20.28 ℃,当马氏体转变温度点Ms小于常温时,γ相区延伸到常温区域,奥氏体在常温下稳定,不再发生马氏体转变,使得高碳含量0.34%试样成为单相奥氏体不锈钢。

因此,当碳含量从0.07%增加到0.09%时,试样中铁素体含量减少,马氏体含量增加,马氏体是硬质相,从而提高了试样的抗拉强度和淬火态硬度,略微降低了伸长率,而当碳含量较高时,残留奥氏体含量逐渐增多,与密度降低的共同作用下造成抗拉强度的明显下降。对于试样的伸长率,残留奥氏体相逐渐增多,由于奥氏体是塑性相,伸长率又大幅提高。碳含量0.34%试样烧结态出现了过烧现象,晶粒长大,晶粒间结合力减弱,试样的伸长率相比0.25%试样的下降。固溶处理使得合金元素溶入到奥氏体中,时效后奥氏体发生转变,使得试样的抗拉强度相比烧结态的有提高,而伸长率的增长变缓。

2.3 试样的断口形貌

图6 不同碳含量烧结样品的断面形貌

Fig. 6 Fracture morphologies of specimens with different carbon contents after sintering

图7 不同碳含量固溶时效态样品的断面形貌

Fig. 7 Fracture morphologies of specimens with different carbon contents after solution and aging

图6所示为5种碳含量烧结态试样的断口形貌。由图6可以看出,碳含量0.07%~0.16%试样的断口形貌均出现典型的韧窝。这些韧窝大小均匀,反映出试样都具有比较好的延性,随着碳含量的增加,韧窝逐渐变浅,且延性逐渐变差。这主要是由于组织中铁素体的含量逐渐减少,马氏体增多。0.25%C试样的断口形貌如图6(d)所示,基本呈韧窝状,且韧窝较深,说明其延性较好。这与相组织中的残余奥氏体含量增加对应,由于奥氏体延性较好,延性增加。0.34%C的试样烧结过程中由于出现过烧,图中端口形貌也呈现出过烧的特征,晶界变宽,延性下降。

图7所示为5种不同碳含量试样固溶时效态的断口形貌。由图7可知,0.07%C试样的断口形貌出现典型的韧窝。这些韧窝大小均匀,反映出此试样具有较好的延性。0.09%C试样由于铁素体含量减少,马氏体含量增多,延性略微下降,其断口形貌为少部分韧窝和大部分河流花纹状的解理形貌。0.16%C~0.34%C试样中,随着碳含量的提高,试样中残余奥氏体含量增多,且经过时效处理后,试样的延性逐渐提高,韧窝逐渐变多变深。

3 结论

1) 碳含量对MIM17-4PH的组织和性能有很大的影响。随着碳含量的增加,组织中铁素体含量减少直至消失,烧结致密度减小,马氏体相变温度点Ms 和Mf降低。

2) 当碳含量低于0.16%,仍然能够达到MIM17- 4PH不锈钢的力学性能要求,但当碳含量超过0.16%时,由于残留奥氏体含量升高,甚至出现单相奥氏体相,导致试样强度降低,塑性增加,耐腐蚀能力大幅下降,完全偏离了17-4PH不锈钢的使用要求。因此,MIM制备17-4PH不锈钢时应控制碳含量不超过0.16%。

REFERENCES

[1] 李益民, 刘剑敏, 何 浩. 中国金属注射成形产业和技术现状: 机遇与挑战[J]. 有色金属科学与工程, 2013(2): 1-7.

LI Yi-min, LIU Jian-min, HE Hao. Industrial and technical state of MIM in China: Opportunities and challenges[J]. Nonferrous Metals Science and Engineering, 2013(2): 1-7.

[2] 杨忠臣. 17-4PH不锈钢粉末注射成形工艺研究[D]. 长沙: 中南大学, 2013.

YANG Zhong-chen. Research on powder injection molding of 17-4PH stainless steel[D]. Changsha: Central South University, 2013.

[3] 李益民, KHALIL K A, 黄伯云. 金属注射成形17-4PH不锈钢脱脂保形性研究[J]. 稀有金属材料与工程, 2005, 34(1): 22-27.

LI Yi-min, KHALI K A, HUANG Bai-yun. Compact shape retention for metal injection molding 17-4PH stainless steel[J]. Rare Metal Materials and Engineering, 2005, 34(1): 22-27.

[4] WANG Jun, LIN Yuan-hua, ZENG De-zhi. Effects of the process parameters on the micro-structure and properties of nitrided 17-4PH stainless steel[J]. Metallurgical and Materials Transactions B, 2013, 44(2): 414-422.

[5] 杜大明, 汪 洋, 白小波. 热处理对17-4PH不锈钢组织和性能的影响[J]. 热处理技术与装备, 2012, 33(1): 30-32.

DU Da-ming, WANG Yang, BAI Xiao-bo. Effect of heat treatment on microstructure and property of 17-4PH stainless steel[J]. Heat Treatment Technology and Equipment, 2012, 33(1): 30-32.

[6] 邓德伟, 陈 蕊, 田 鑫, 王冬颖. 热处理对17-4PH马氏体不锈钢显微组织及性能的影响[J]. 金属热处理, 2013, 38(4): 32-36.

DENG De-wei, CHEN Rui, TIAN Xin, WANG Dong-ying. Influence of heat treatment on microstructure and properties of 17-4PH martensitic stainless steel[J]. Heat Treatment of Metals, 2013, 38(4): 32-36.

[7] LI Yi-min, KHALIL K A, HUANG Bai-yun. Rheological, mechanical and corrosive properties of injection molded 17-4PH stainless steel[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(5): 934-939.

[8] 杨 钢, 刘军和, 冯贞伟, 李许明, 方 波, 宋玺玉. 合金元素对0Cr17Ni4Cu4Nb不锈钢组织与力学性能的影响——碳(1)[J]. 特钢技术, 2010, 16(3): 5-9, 17.

YANG Gang, LIU Jun-he, FENG Zhen-wei, LI Xu-ming, FANG Bo, SONG Xi-yu. Effect of alloy element on microstructure and mechanical properties of 0Cr17Ni4Cu4Nb stainless steel carbon (1)[J]. Special Steel Technology, 2010, 16(3): 5-9, 17.

[9] KYOGOKU H, KOMATSU S, NAKAYAMA H. Advances in powder metallurgy and particulate materials (Vol. 3)[M]. Princeton, New Jersey: Metal Powder Industries Federation, 1997: 18.

[10] WU Yun-xin, GERMAN R M, BLAINE D. Effects of residual carbon content on sintering shrinkage, microstructure and mechanical properties of injection molded 17-4 PH stainless steel[J]. Journal of Materials Science 2002, 37(17): 3573-3583.

[11] 刘振宝, 梁剑雄, 杨志勇, 古立新, 张秀丽, 孙常亮. 碳含量对15-5PH沉淀硬化不锈钢板材的组织与性能的影响[J]. 航空材料学报, 2011, 31(1): 7-12.

LIU Zhen-bao, LIANG Jian-xiong, YANG Zhi-yong, GU Li-xin, SUN Chang-liang. Effect of carbon content on microstructure and mechanical properties of type 15-5PH precipitation hardened stainless steel[J]. Journal of Aeronautical Materials, 2011, 31(1): 7-12.

[12] 韩 波, 史庆南, 王效琪, 起华荣, 李 伟, 刘 捷. 粉末注射成形工艺及其特点[J]. 南方金属, 2009(3): 18-21.

HAN Bo, SHI Qing-nan, WANG Xiao-qi, QI Hua-rong, LI Wei, LIU Jie. Powder injection molding process and its features[J]. Southern Metals, 2009(3): 18-21.

[13] 刘志勇, 方晓英, 郭 红, 王卫国. 初始碳化物对冷轧退火奥氏体不锈钢晶界特征分布的影响[J]. 电子显微学报, 2011, 30(4): 340-344.

LIU Zhi-yong, FANG Xiao-ying, GUO Hong, WANG Wei-guo. The effect of initial carbide on grain boundary character distribution of the cold rolled and annealed 304 austenitic stainless steel[J]. Journal of Chinese Electron Microscopy Society, 2011, 30(4): 340-344.

[14] 郭富强, 程世长, 刘正东, 包汉生, 张代明. 碳、铌对ASME S30432奥氏体耐热钢晶间腐蚀性能的影响[J]. 机械工程材料, 2007, 31(8): 11-14.

GUO Fu-qiang, CHEGN Shi-chang, LIU Zheng-dong, BAO Han-sheng, ZHANG Dai-ming. Effect of carbon and niobium on intergranular corrosion of ASME S30432 austenitic heat resistant steel[J]. Materials for Mechanical Engineering, 2007, 31(8): 11-14.

[15] DAVIS J R. Stainless steels[M]. Ohio: ASM International, Materials Park, 1994: 13.

[16] WU Yun-xin, BLAINE D, SCHLAEFER C, MARX B, GERMAN R M. Sintering densification and microstructural evolution of injection molding grade 17-4 PH stainless steel powder[J]. Metallurgical and Materials Transactions A, 2002, 33(7): 2185-2194.

[17] SCHAEFFL A L. Constitution diagram for stainless-steel weld metal (2): Schaeffler diagram[J]. Metal Progress, 1974, 106(1): 227-227.

[18] 范洪涛, 石 伟. 中碳低合金钢马氏体转变开始点的预测[C]// 第九次全国热处理大会论文汇编. 大连: 中国机械工程学院, 2007: 229-234.

FAN Hong-tao, SHI Wei. Prediction of martensitic transformation start points of several medium carbon low alloy steels[C]// The Ninth National Conference on Heat Treatment. Dalian: Chinese Mechanical Engineering Society, 2007: 229-234.

[19] 戴起勋. 奥氏体钢马氏体相变点Ms, Mεs[J]. 钢铁, 1995(8): 52-58.

DAI Qi-xun. Martensite transformation point Ms and Mεs of austenitic steel[J]. Iron and Steel, 1995(8): 52-58.

(编辑 龙怀中)

基金项目:湖南省自然科学基金资助项目(2015JJ3147);总装备部项目(303001042);广西科技攻关项目(14122007-22)

收稿日期:2014-07-13;修订日期:2014-11-14

通信作者:何 浩,助理研究员,博士;电话:0731-88836310;E-mail: he_hao555@csu.edu.cn