聚丙烯腈基炭纤维的组织结构及力学性能

李丽娅, 黄启忠, 张红波

(中南大学 粉末冶金国家重点实验室, 湖南 长沙 410083 )

摘要: 在不同温度下对聚丙烯腈基炭纤维(PAN-CF)进行张力炭化处理并进行高温石墨化。研究结果表明:在炭化过程中,PAN-CF的拉伸强度在1400℃时达最大值,拉伸模量则随炭化温度的升高而增大;与炭化样品相比,PAN-CF石墨化后的拉伸强度减小,拉伸模量增大;随着炭化温度的升高,微晶c轴方向堆叠厚度Lc增大,层面间距d002减小; 炭化温度为1400℃时,PAN-CF在石墨化后,内部的炭颗粒排列得非常紧密,并且孔洞、裂纹、皮芯结构等缺陷很少;当炭化温度高于1400℃时,石墨化后PAN-CF内部有大量缺陷,使PAN-CF的拉伸强度大大降低。

关键词: 聚丙烯腈基炭纤维; 张力炭化; 石墨化; 组织结构

中图分类号:TQ342.742 文献标识码:A 文章编号: 1672-7207(2005)02-0193-05

Microstructure and Properties of Polyacrylonitrile Carbon Fiber

LI Li-ya, HUANG Qi-zhong, ZHANG Hong-bo

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Polyacrylonitrile carbon fiber (PAN-CF) was tension carbonized at different temperatures and then graphitized. The results show that during the period of carbonization, the tensile strength of PAN-CF reaches the maximum at 1400℃, and the tensile modulus increases with the carbonization temperature increasing. The tensile strength decreases and the tensile modulus increases after the carbonized PAN-CF is graphitized. The larger Lc and lower d002 can be obtained at higher carbonization temperature. When PAN-CF is carbonized at 1400℃ and then graphitized, the inert carbon particles are arranged tightly and the flaws, such as pore, crack and skin-core structure, are very few. But when the carbonization temperature exceeds 1400℃, there are many flaws in the graphitized PAN-CF and the tensile strength decreases rapidly.

Key words:PAN-CF; tension carbonization; graphitization; microstructure

-

聚丙烯腈基炭纤维(PAN-CF)由于具有高的比强度、比模量,而且耐摩擦磨损、耐疲劳、耐腐蚀等优异性能,作为增强材料被广泛应用于C/C复合材料铝基航空材料的制备[1-3]。PAN-CF的性能直接影响基体材料的性能。PAN-CF由粒径仅几纳米、短程有序的六方晶型石墨微晶堆叠而成。石墨微晶的堆叠方向优先与纤维轴向垂直,并决定了纤维模量[4]。纤维强度由纤维内的缺陷、垂直纤维轴向堆叠的微晶百分比决定[5]。另外,PAN-CF的性能与其化学成分和原丝的质量有关[6-8]。在原丝转变成炭纤维的过程中,存在复杂的物理和化学变化,其微观结构也随之改变,从根本上影响炭纤维的性能[9-11]。炭化时,对炭纤维施加一定的张力可显著改善其炭化后的性能[12]。在此,作者研究PAN-CF在张力炭化和石墨化过程中的显微结构与力学性能的变化,用X射线衍射结果表征PAN-CF的微观结构参数;并且利用扫描电子显微镜在高放大倍数下,分析PAN-CF表面和断口在炭化和石墨化过程中的变化。

1 实 验

1.1 材料及实验方法

实验用PAN原丝为上海合成纤维研究所生产的型号为6K的PAN基预氧丝。 首先,在真空炭化炉内将样品进行不同温度下的张力炭化处理,所加张力为每袋8.3×10-4N,9个样品的炭化温度分别为800, 900, 1000, 1100, 1200, 1300,1400,1500,1600℃。然后,于2600℃进行石墨化处理(未加张力)。

1.2 微观结构测试

采用JEOLJSM-35C扫描电镜观察炭纤维的表面形貌和断口组织。

利用日本理学3014 X射线衍射仪测定炭纤维的晶格参数(Lc和d002)。

Lc=Kλ/(βcosθ);(1)

d002=λ/(2sinθ)。(2)

式中:Lc为微晶c轴方向堆叠厚度, nm;λ为入射线Kα1的波长, nm;θ为Bragg角;β为经较正后衍射线的半高宽或积分宽(用弧度表示);K为晶体的形状因子,在计算L002时,K取0.87;d002为层面间距, nm。

1.3 力学性能检测

采用江苏省太仓纺织仪器厂生产的YG-001A型单纤维电子强力仪(附带X-Y记录仪)测试PAN-CF的拉伸强度和拉伸模量。按国家标准GB1871—94测试,试样长为25mm,每种样品测50根,取平均值作为测试结果。

2 结果与分析

2.1 PAN-CF的微观结构参数和力学性能

炭化后试样的微观结构参数如表1所示。由表1可见,张力炭化时,微晶尺寸Lc随热处理温度的升高而增大;在90℃以下时,层面间距d002先随温度的升高而减小,在900~1000℃,d002随温度的升高急剧增大,热处理温度高于1000℃时, d002随温度的升高而减小;在900~1000℃,脱氮反应非常剧烈,体系中所产生的自由基导致层面内缺陷增多,层面间的相互作用力使面间距增大,这与文献[13]中的结果一致。

表 1 2600 ℃炭化样品的微观结构参数

Table 1 Crystallite parameters of PAN-CF carbonized at 2600 ℃

高温石墨化后,PAN-CF的微晶结构参数如表2所示。 由表2可见,与炭化后的结构参数(见表1)相比,Lc有很大的增长,而d002大大减小,更接近于理想石墨晶体的层面间距(0.3354nm);随着炭化温度的升高,PAN-CF石墨化后的Lc和石墨化度增大,d002减小。

表 2 2600℃石墨化后PAN-CF的微晶结构参数

Table 2 Crystallite parameters of graphitized PAN-CF at 2600 ℃

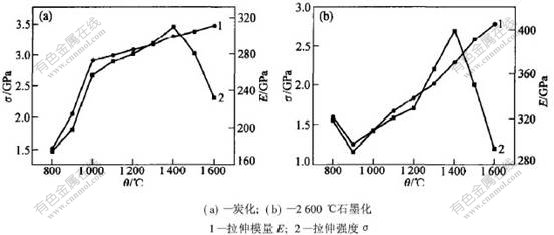

PAN-CF在经张力炭化和无张力石墨化处理后的力学性能如图1所示。由图1(a)可见,热处理温度为800~1600℃时,PAN-CF的拉伸强度先随温度的升高而增大,1400℃时达最大值,然后,随温度的升高而减小;PAN-CF的拉伸模量始终随温度的升高而增大。由图1(b)可见,2600℃石墨化后PAN-CF的性能与其张力炭化处理的温度有很大关系。当张力炭化温度为1400℃时,石墨化后PAN-CF的拉伸强度最大,当温度高于1400℃时,拉伸强度大大降低;而石墨化后PAN-CF的拉伸模量则随张力炭化温度的升高而增大。同时,与炭化后的样品相比,石墨化后PAN-CF的拉伸强度大大降低,而拉伸模量则大大增加。

2.2 PAN-CF的显微组织对力学性能的影响

在800℃和1400℃张力炭化时PAN-CF表面SEM照片如图2所示。由图2可见,在800℃时,PAN-CF表面只有少量的炭颗粒出现且分布较松散,而在1400℃炭化时,PAN-CF的表面存在大量炭颗粒并且密集地交联在一起。在炭化阶段,伴随着非碳原子的驱除,碳原子通过环化、缩聚等反应形成芳环叠面,由于芳环叠面的生长和交联,碳原子之间的结合力提高,Lc增大、d002减小,使拉伸强度和拉伸模量增大[14,15]。

在石墨化处理过程中,随着无定形碳向石墨晶体转化,一方面引起PAN-CF体积收缩,d002减小,使得PAN-CF试样中气孔尺寸增大;另一方面,使得PAN-CF试样中石墨微晶增多、长大,即Lc增大,裂纹扩展易于进行,使拉伸强度显著下降[16]。而PAN-CF的拉伸模量则与石墨微晶的尺寸(Lc)、完善化程度(d002)及其沿纤维轴向的取向度有很大关系。微晶尺寸愈大、完善化程度愈高(d002愈小)、择优取向性愈好,则拉伸模量愈大[17]。PAN-CF在石墨化后,Lc大大增加,同时,d002减小,故其拉伸强度降低而拉伸模量增加。

6号试样石墨化前、后和2号、9号试样石墨化后的断口显微组织形貌如图3所示。由图3可见,PAN-CF的断裂为脆性断裂,在边部有断裂台阶,断裂面上有凸起,这是原始纤维结构断裂时形成的。石墨化前(见图3(a)),PAN-CF试样的断口颗粒较粗大,大小相近,排列较稀松。石墨化后,其颗粒变得细小,颗粒之间排列得较为紧密。说明PAN-CF在石墨化的过程中体积收缩较大。石墨化后,2号试样的断口表面有较多的微小气孔和裂纹,而且皮芯结构较明显,即芯部的晶粒细小,皮部的晶粒粗大;6号试样的断口表面炭颗粒排列得非常紧密,而且缺陷较少,皮芯结构没有2号试样的明显;9号试样的断口则明显存在较多的缺陷,断口表面有大量孔洞和裂纹,断口纹理粗大而疏松,横向交联非常弱。PAN-CF体积收缩所产生的缺陷和皮芯结构都会使其性能降低[18]。

图 1 PAN-CF张力炭化和石墨化后的性能

Fig. 1 Properties of PAN-CF after carbonization and graphitization

图 2 在800 ℃和1400 ℃炭化后PAN-CF的SEM照片

Fig. 2 SEM images of PAN-CF carbonized at 800℃ and 1400℃

图 3 石墨化前、后试样断口组织形貌

Fig. 3 SEM images of tensile fracture surface of carbonized and graphitized samples

张力炭化温度较高时,由于在炭化过程中张力的作用,使PAN-CF结合较紧密,择优取向性较好。对于炭纤维,a轴应变与c轴应变之间的泊松比大约为-2;施加张力时,微晶在a向伸长,c向收缩,使微晶彼此结合紧密,沿纤维轴向择优取向,从而使纤维致密化,避免大量孔隙产生,得到结构均匀的高性能炭纤维[19]。但是,当张力炭化温度超过1400℃时,PAN-CF内部的缺陷增多,导致石墨化后PAN-CF内部存在大量缺陷,使拉伸强度降低。

3 结 论

a. 炭化阶段,PAN-CF的拉伸强度随炭化温度的升高而增大,在1400℃时达最大值,随后随温度的上升而减小;拉伸模量则随炭化温度的升高而增大。

b. 2600℃石墨化时,PAN-CF的拉伸强度与炭化处理的温度有很大关系,炭化温度为1400℃时,拉伸性能达最大值;而拉伸模量则随PAN-CF炭化处理温度的升高而增大。

c. 经不同温度张力炭化后的PAN-CF在石墨化后,Lc和石墨化度随张力炭化温度的升高而增大,d002随张力炭化温度的升高而减小。

d. 张力炭化温度为1400℃时,石墨化后PAN-CF内部的炭颗粒排列得非常紧密,并且孔洞、裂纹、皮芯结构等缺陷很少;当炭化温度高于1400℃时,石墨化后PAN-CF内部有大量缺陷,使PAN-CF的拉伸强度大大降低。

参考文献:

[1]MOHAMED S, ALY H, HATTA H, et al. Comparison of 2D and 3D Carbon/Carbon Composites with Respect to Damage and Fracture Resistance[J]. Carbon, 2003,41 (6): 1069-1078.

[2]DHAKATE S R, BAHL O P. Effect of Carbon Fiber Surface Functional Groups on the Mechanical Properties of Carbon-Carbon Composites with HTT[J]. Carbon, 2003,41 (7): 1193-1203.

[3]LANICIN M, MARHIC C. TEM Study of Carbon Fibre Reinforced Aluminium Matrix Composites: Influence of Brittle Phases and Interface on Mechanical Properties[J]. Journal of the European Ceramic Society, 2000, 20(10):1493-1503.

[4]MATHUR R B, GUPTA V, BAHL O P, et al. Improvement in the Mechanical Properties of Polyacrylonitrile/PAN-based Carbon Fibers after Fluorination[J]. Synthetic Metals, 2000,114(2): 197-200.

[5]KIM J, LEE W I, LAFDI K. Numerical Modeling of the Carbonization Process in the Manufacture of Carbon/Carbon Composites[J]. Carbon,2003, 41 (13):2625-2634.

[6]EDIE D D. The Effect of Processing on the Structure and Properties of Carbon Fibers[J]. Carbon, 1998, 36(4):345-362.

[7]MIN B G, SREEDUMAR T V, UCHIDA T, et al. Oxidative Stabilization of PAN/SWNT Composite Fiber[J]. Carbon, 2005,43(3): 599-604.

[8]CHEN J C, HARRISON I R. Modification of Polyacrylonitrile (PAN) Carbon Fiber Precursor via Post-spinning Plasticization and Stretching in Dimethyl Formamide (DMF)[J]. Carbon, 2002, 40(1): 25-45.

[9]ZHANG Wang-xi, LIU Jie, WU Gang. Evolution of Structure and Properties of PAN Precursors during Their Conversion to Carbon Fibers[J]. Carbon, 2003, 41(14): 2805-2812.

[10]TOYODA M, SHIMIZU A, IWATA H. Exfoliation of Carbon Fibers Through Intercalation Compounds Synthesized Electrochemically[J]. Carbon, 2001,39(11): 1697-1707.

[11]华中,王月梅,赵萍,等. 应用Raman光谱方法研究PAN基炭纤维中sp2杂化的C—C原子键距与碳化温度的关系[J]. 吉林师范大学学报, 2003, (1):77-79.

HUANG Zhong, WANG Yue-mei, ZHAO Ping, et al. Study of Relation Between Bond Length of C—C Atoms with sp2 Hybridization and Carbonization Temperature in PAN-based Carbon Fiber by Raman Spectroscopy[J]. Journal of Jilin Normal University, 2003, (1):77-79.

[12]SUNG M G, SASSA K, TAGAWA T, et al. Application of a High Magnetic Field in the Carbonization Process to Increase the Strength of Carbon Fibers[J]. Carbon, 2002, 40(11): 2013-2020.

[13]赵根祥,金允正,王健. 硝酸法PAN基预氧丝在炭化期间分子结构的变化[J].高分子材料科学与工程,1995,11(1):46-49.

ZHAO Gen-xiang, JIN Yun-zheng, WANG Jian. The Chang of Molecular Constitution of PAN-based Preoxidative Fiber with Nitric Acid Wet-spun Method during the Carbonization[J]. Polymer Materials Science and Engineering, 1995, 11(1):46-49.

[14]YAN J, REY A D. Theory and Simulation of Texture Formation in Mesophase Carbon Fibers[J]. Carbon, 2002,40(14): 2647-2660.

[15]冀克俭, 张银生, 张以河, 等.聚丙烯腈纤维炭化过程中纤维表面的XPS研究[J]. 高分子材料科学与工程, 2003,19(1):205-211.

JI Ke-jian, ZHANG Yin-sheng, ZHANG Yi-he, et al. XPS Study of Fiber Surface for PAN Fiber in Carbonization[J]. Polymer Materials Science and Engineering, 2003,19(1):205-211.

[16]PARIS O, LOIDL D, PETERLIK H. Texture of PAN-and Pitch-based Carbon Fibers[J]. Carbon, 2002, 40(3): 551-555.

[17]常维璞,沈曾民,王理.高模量炭纤维的研制[J]. 新型炭材料, 1998, 13(1):28-32.

CHANG Wei-pu, SHEN Zeng-min, WANG Li. Manufacture of High Modulus Graphitized Carbon Fibers[J]. New Carbon Materials, 1998, 13(1):28-32.

[18]KOA T H, KUOB W S, TZENGC S S, et al. The microstructural Changes of Carbon Fiber Pores in Carbon-Carbon Composites during Pyrolysis[J]. Composites Science and Technology, 2003,63 (12): 1965–1969.

[19]SAVAGE G. Carbon-Carbon Composites[M]. London: Chapmen &Hall, 1992.

收稿日期:2004-11-24

基金项目:国家重点工业性实验项目([1998]1817)

作者简介:李丽娅(1973-),女,湖南郴州人,讲师,博士,从事C/C复合材料、磁性材料研究

论文联系人: 李丽娅,女,讲师,博士;电话:0731-8877328(O)