文章编号:1004-0609(2009)04-0601-06

粉末轧制Mg-Al-Zn合金的烧结

黄光胜1, 2,张忠伟1, 2,黄光杰1, 2,汪凌云1, 2

1. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044;

2. 重庆大学 材料科学与工程学院,重庆 400045)

摘 要:研究用粉末轧制方法制备的Mg-3%Al-1%Zn(质量分数)合金生带坯在氩气气氛下的烧结行为,用X射线衍射、差热分析以及金相方法等分析镁合金在烧结过程中的组织变化。结果表明;粉末轧制镁合金生带材可采用“预烧结-冷轧-再烧结”工艺进行烧结,即在氩气气氛下550 ℃预烧结120 min,然后进行大变形量的冷轧,最后在600 ℃下保温60 min实现烧结;通过再结晶、冷变形与烧结的耦合,获得的带材组织均匀,其相对密度达到97.5%。

关键词:Mg-Al-Zn合金;粉末轧制;烧结;显微组织

中图分类号:TF124 文献标识码: A

Sintering of Mg-Al-Zn alloy prepared by powder rolling

HUANG Guang-sheng1, 2, ZHANG Zhong-wei1, 2, HUANG Guang-jie1, 2, WANG Ling-yun1, 2

(1. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 440044, China;

2. College of Material Science and Engineering, Chongqing University, Chongqing 400045, China)

Abstract: The sintering behavior of green strip of Mg-3%Al-1%Zn magnesium alloy prepared by powder rolling was studied in argon atmosphere. The development of microstructure of magnesium alloy was analyzed by using X-ray diffractometry, DSC and metallography. The results show that the magnesium alloy green strip can be sintered through sintering program of presintering, cold rolling and sintering. The green strip suffers presintering at 550 ℃ for 120 min in argon atmosphere, then standing for large amount of cold roll deformation, and at last sintering at 600 ℃ for 60 min. The strips have uniform microstructure and high relative density of 97.5% by coupling of recrystallization, cold deformation and sintering.

Key words: Mg-Al-Zn alloy; powder rolling; sintering; microstructure

镁合金是最轻的金属结构材料,具有比强度高、减振性好等优点。近年来,镁合金压铸件在汽车等交通工具上已经实现批量应用,而变形镁合金的型材和板材发展也很快[1-2]。由于镁及镁合金的化学性质比较活泼,容易氧化,因此,关于镁及镁合金粉末冶金方面的研究较少,而已有研究又主要集中在镁基复合材料和功能材料领域[3-7],关于用粉末冶金方法制备镁合金结构材料的研究则更少[8-9]。

粉末轧制是粉末冶金成形工艺中制造板、带材的主要方法。该工艺具有连续成形、工艺流程短、生产率高等特点。目前粉末轧制工艺可以制造金属、金属与非金属复合材料、甚至非金属材料[10]。由粉末轧制工艺获得的板材几乎没有各向异性,具有良好的冲压性能[11-12]。而目前用铸锭开坯轧制的镁合金板带材,其生产成本高,有极强的基面织构,冲压性能很差。

随着镁粉在炼钢脱硫中的大量应用,镁粉的生产工艺日趋成熟并且安全可靠,为镁合金粉末冶金研究提供了坚实的基础。前期研究表明[13],在普通二辊轧机上通过粉末轧制制备镁合金带材是可行的。本文作者在前期研究基础上,对粉末轧制镁合金生带坯的烧结进行了探索,为镁合金粉末冶金的工艺制定提供依据和参考。

1 实验

1.1 材料的制备

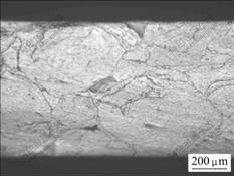

选用180~1 700 mm的Mg粉、180~250 mm的Al粉和48 mm 的Zn粉。用RISE-2006型激光粒度分析仪测得其平均粒径为614、272和9 mm,形貌均为多角形。用漏斗法测量的松装密度分别为0.98、1.38和1.96 g/cm3。按质量分数配制成AZ31(Mg-3%Al-1%Zn)的混合粉末,用轧辊直径为170 mm 的300型二辊板带轧机在室温下轧制成形[13]。轧制速度为0.2 m/s,带坯宽度为90 mm,厚度为0.6~0.8 mm,相对密度为0.83左右。轧制带坯表面光洁度较好,如图1所示。但由于进料漏斗侧壁对金属粉末无侧压,带坯存在较严重的边裂。带坯轧制方向的剖面显微组织如图2所示,粉末颗粒在厚度方向上均有一定程度的压扁,颗粒与颗粒之间接合较紧密,孔洞较少。

图1 粉末轧制镁合金生带坯

Fig.1 Powder rolling green strip of magnesium alloy

图2 生带坯剖面显微组织

Fig.2 Microstructures of longitudinal section of green strip

1.2 实验方法

生带坯在氩气气氛下烧结,升温速度为10 ℃/min,保温温度分别为400、450、500和550 ℃,保温一定时间后,随炉冷却至200 ℃取出。沿着垂直于轧制方向在每条生带坯中部间隔地取3块试样,用800号砂纸打磨成约3 cm×5 cm的长方形,用游标卡尺测量边长并计算体积,然后在分析天平上称量,取3块试样的平均值计算其相对密度。

用D-Max-1200日本理学X射线衍射仪进行物相分析,使用铜靶和石墨弯晶单色器,管电流和管电压分别为30 mA和40 kV,衍射角为10?~90?,扫描速度为3 (?)/min。取直径为3 mm生带坯小圆片两片,叠放在一起,在STA 449C综合热分析仪上进行差热分析。差热分析从室温加热到550 ℃保温1 h,升温速度为10 ℃/min,用纯度为99.99%的氩气保护。显微组织用10%乙酸水溶液腐蚀,在Olympus 显微镜上 观察。

2 结果与分析

2.1 AZ31生带坯的预烧结

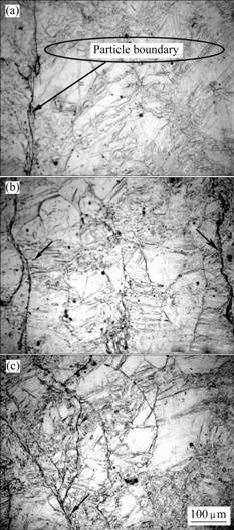

生带坯在400 ℃至500 ℃烧结120 min后,颗粒边界清晰,没有实现烧结。在颗粒内部出现了大小不均匀的再结晶晶粒,位于颗粒破裂处和颗粒边界线之间的再结晶晶粒细小,位于颗粒内部的再结晶晶粒则较粗大。

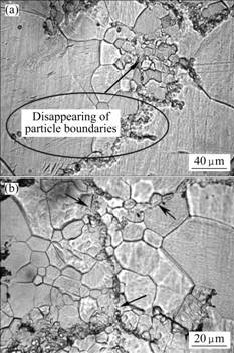

图3所示为生带坯在550 ℃烧结120 min的显微组织。由图可见,粒界开始消失,在图中箭头所示位置,粒界已经被细小的再结晶晶粒取代,这些部位可以认为已经发生了烧结。与400~500 ℃烧结相似,颗粒内部同样出现了大小不均匀的再结晶晶粒。550 ℃烧结120 min能实现局部烧结,但不能完全烧结。

图3 轧制生带材在氩气保护下550 ℃烧结120 min的显微 组织

Fig.3 Microstructures of green strip sintered at 550 ℃ for 120 min in argon atmosphere

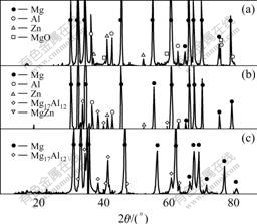

图4所示为生带坯及其在550 ℃烧结60和120 min的XRD谱,烧结前生带坯中存在Mg、Al、Zn和MgO。图4(b)所示为550 ℃烧结60 min后的XRD谱,除了Mg、Al、Zn这3种单质外,还出现了Mg17Al12和MgZn的峰线。图4(c)所示为烧结120 min后的XRD谱,单质Al和单质Zn的峰线消失,Al与Zn已经全部溶入Mg基体或与Mg形成化合物相。MgZn相的峰线也已经消失,表明Zn已经完全以固溶形式存在Mg基体中。

图4 550 ℃烧结0、60和120 min的试样XRD谱

Fig.4 XRD patterns of samples sintered at 550 ℃ under different holding times: (a) Before sintering; (b) 60 min; (c) 120 min

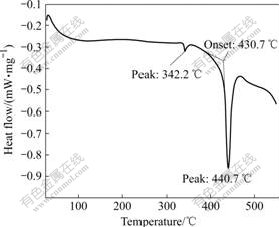

图5所示为生带坯在烧结升温过程中的差热分析曲线。当温度升至342.2和440.7 ℃时各有一个吸热峰,在这两个温度均有相变发生。由于试样为Mg、Al、Zn这3种单质粉末按Mg-3%Al-1%Zn配比混合轧制而成,Al和Zn粉相对于Mg粉的数目很少,粉末之间可认为只发生Mg与Al和Mg与Zn之间的机

图5 Mg-3%Al-1%Zn生带坯烧结升温过程差热分析曲线(DSC)

Fig.5 DSC curve of Mg-3%Al-1%Zn green strip in process of heating

械咬合,忽略Al与Zn之间的反应,从而把三元问题简化成两个二元问题进行分析。

由Mg- Zn二元平相图[14]可知,温度在340和342 ℃均有相变发生,而Mg-Al二元平衡相图中没有出现在该温度附近的相变,因此,第一个吸热峰是Mg粉与Zn粉反应时出现的。对于第二个吸热峰,温度在440.7 ℃。对照Mg-Al二元相图[15],在437 ℃发生共晶反应,生成液相。

2.2 AZ31带坯预烧结后的冷轧变形

经550 ℃预烧结后的带材,具有一定的强度,能承受较大的冷变形量,其冷轧后的显微组织如图6所示。在室温下镁合金的主要滑移面是基面,其滑移系较少,变形需要更多地依赖孪晶,因此,可以观察到大量的孪晶从颗粒边界向颗粒内部延伸。经过50.0%变形后,颗粒间咬合随变形量的增加而变得更加紧密。经过大变形之后的组织中仍然残留有部分比较宽的粒界。当变形量再增加到73.3%时,带材表面则出现龟裂。

图6 生带材550 ℃烧结120 min后的冷轧组织

Fig.6 Microstructures of strips after sintering at 550 ℃ for 120 min and cold rolling with reduce of 20.0% (a), 33.3% (b), and 50.0% (c)

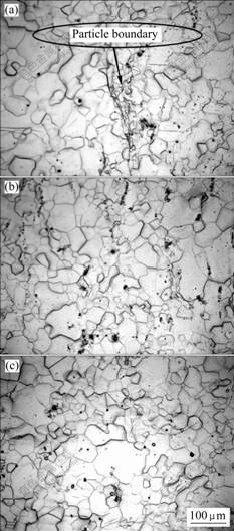

2.3 AZ31带坯经预烧结与冷轧处理后的再烧结

冷轧后在氩气气氛下600 ℃烧结60 min的带材显微组织如图7所示,变形量分别为20.0%、33.3%和50.0%。由图可见,在相同烧结温度和保温时间条件下,增大塑性变形量有利于粒界的消失。在变形量为20.0%时,烧结组织内残留有许多原始的粒界。在残留粒界处存在许多非常细小的再结晶晶粒;当变形量增加到33.3%时,残留的粒界仅在个别地方出现。当冷变形为50.0%时,粒界完全消失。虽然变形量不同,但是再结晶晶粒大小几乎相同。一方面储存的变形能大部分消耗在减小颗粒间隙和烧结孔洞上面了,而用于再结晶驱动的变形能三者相差不大;另一方面是由于粉末表面的氧化物阻碍了再结晶晶粒的长大[15]。

图7 生带材变形后600 ℃烧结60 min的显微组织.

Fig.7 Microstructures of strips after sintering at 660 ℃ for 60 min with deformations of 20% (a), 33.3% (b) and 50% (c)

3 讨论

在粉末轧制过程中,颗粒发生了塑性变形。如果轧制压力很大,颗粒还会破裂。分别测量生带坯纵向、横向和垂直板面上的粉末颗粒长度,得出平均颗粒长度分别为672、631和540 mm。与原始粉末平均直径614 mm相比,3个方向上颗粒的平均变形量分别为9.5%、2.8%和12.1%,室温下如此大的冷变形量足够导致镁粒破裂,并且也为预烧中镁发生再结晶贮存了能量。

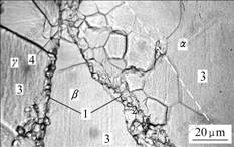

图8所示为生带坯550 ℃烧结120 min后的显微组织,主要由粉末颗粒边界、沿着颗粒边界向颗粒内部生长的细小再结晶晶粒群、较大的再结晶晶粒和穿过颗粒界限生长的再结晶晶粒等几部分组成。在α颗粒内,边界处晶粒最小,在3 mm以下;由外向里颗粒内部晶粒逐渐增大,到达图中白色虚线位置时,晶粒大小约为12 mm;再向里面,再结晶晶粒变得非常粗大。对于β颗粒情况则完全不同,其边部几乎没有细晶区,内部也只有几个晶粒。由于镁粉是通过铸锭切削获得,而铸锭的晶粒直径往往在几百个微米,甚至几个毫米大。因此,单个粉末颗粒内部的晶界几乎可以忽略,在烧结后观察到的所有晶粒几乎都应该是再结晶晶粒。γ颗粒的情况和β颗粒类似,只是在靠近β的边界处存在大量细小的再结晶晶粒群。

图8 氩气保护下550 ℃烧结120 min生坯带的显微组织

Fig.8 Microstructure of strip sintered in argon at 550 ℃ for 120 min: 1—Initial powder boundaries; 2—Recrystal grain group growing towards center in particle α; 3—Large recrystal grains; 4—Small grains growing cross over particles β and γ being phagocytized by large recrystal grain nearby

通常晶粒的长大方式是大晶粒吞噬周围的小晶粒。图8中较大的晶粒就是通过吞噬周围晶粒长大的,其中β颗粒内部的大晶粒几乎吞噬了颗粒内部的全部晶粒,而γ颗粒内部也仅剩下几个较大的晶粒,并且这些大晶粒正在吞噬旁边的小晶粒。只有α颗粒内部还残留有比较多的细小再结晶晶粒,随着时间的延长,这些细小的再结晶晶粒也将被大晶粒吞噬掉,最后颗粒内部只留有几个大的晶粒。

在550 ℃保温120 min后,大部分颗粒边界清晰可见,只有少量的粒界被细小的再结晶晶粒取代,局部实现烧结,使得镁合金带材具有一定的强度,能承受较大冷轧变形量,最大可达到50%。与传统铸锭轧制获得的板材相比具有更大的承受冷变形能力,这由于预烧结后的带材是多孔结构。在冷轧过程中,由于物质的流动,以及未烧结部位粒界的进一步破碎,产生新生表面,为最后的烧结提供了更有利的条件。由于带材较薄,在预烧后的冷轧过程中可以认为在厚度方向的变形是均匀的,最后的烧结中就得到了较均匀的再结晶组织。

在550 ℃烧结120 min后带材密度有微重增加,从0.83变为0.845;对550 ℃烧结120 min后的带材进行冷变形后烧结,有利于带材密度的提高。经过20.0%压下变形的生带坯相对密度可以达到0.883,在600 ℃烧结60 min后带材密度可以达到理论密度的94.1%;经过33.3%的冷变形,600 ℃烧结60 min后可以达到理论密度的95.3%;经过50.0%冷变形,600 ℃烧结60 min后可以达到理论密度的97.5%,已经非常接近合金的理论密度,可以认为已经实现完全烧结。

4 结论

1) 镁合金生带坯在粉末轧制过程中产生了较大的塑性变形,在氩气气氛下烧结时发生再结晶,在颗粒边界处再结晶晶粒细小,颗粒内部的再结晶晶粒粗大。通过颗粒边界处再结晶晶粒的长大实现局部烧 结,镁合金带坯具有一定的强度与塑性。

2) 粉末轧制镁合金生带材可采用“预烧结-冷轧-再烧结”工艺进行烧结,即在氩气气氛下550 ℃预烧结,然后进行大变形量的冷轧,最后在600 ℃下保温60 min可以实现烧结,可获得均匀细小的再结晶组织,并具有较高的相对密度。

REFERENCES

[1] FRIEDRICH H E, MORDIKE B L. Magnesium technology: Metallurgy, design data, applications[M]. Springer-Verlag, 2006.

[2] MORDIKE B L, EBERT T. Magnesium properties-applications- potential[J]. Mater Sci Eng A, 2001, 302: 37-45.

[3] TUN K S, GUPTA M. Improving mechanical properties of magnesium using nano-yttria reinforcement and microwave assisted powder metallurgy method[J]. Composites Science and Technology,2007, 67(13): 2657-2664.

[4] 岳云龙, 苏 通, 陶文宏, 尹海燕. 粉末冶金法制备SiC颗粒增强AZ81镁基复合材料性能研究[J]. 稀有金属材料与工程, 2007, 36(3): 533-536.

YUE Yun-long, SU Tong, TAO Wen-hong, YIN Hai-yan. Mechanics properties of SiC particulate reinforced AZ81 magnesium matrix composites by powder metallurgy[J]. Rare Metal Materials and Engineering, 2007, 36(3): 533-536.

[5] WONG W L E, GUPTA M. Development of Mg/Cu nanocomposites using microwave assisted rapid sintering[J]. Composites Science and Technology, 2007, 67: 1541-1552.

[6] GARC?ES G, DOM?INGUEZ F, P?EREZ P, CARUANA G, ADEVA P. Effect of extrusion temperature on the microstructure and plastic deformation of PM-AZ92[J]. Journal of Alloys and Compounds, 2006, 422: 293-298.

[7] XIE Wen, LIU Yue, LI De-song, ZHANG Jian, ZHANG Zhen-wei, BI Jing. Influence of sintering routes to the mechanical properties of magnesium alloy and its composites produced by PM technique[J]. Journal of Alloys and Compounds, 2007, 431(1/2): 162-166.

[8] NAKASHIMA K, IWASAKI H, MORI T, MABUCHI M, NAKAMURA M, ASAHINA T. Mechanical properties of a powder metallurgically processed Mg-5Y-6Re alloy[J]. Mater Sci Eng, 2000, A293: 15-18.

[9] DUBE R K. Metal strip via roll compaction and related powder metallurgy routs[J]. International Materials Reviews, 1990, 35(5): 253-291.

[10] JIANG Hai, HE Xin-bo, QU Xuan-hui, HUMAIL I S, WANG Xi-tao. Preparation of AZ91 alloy by powder metallurgy method[J]. Trans Nonferrous Met Soc China, 2006, 16, s1855-s1858.

[11] GU Jin-hai, ZHANG Xiao-nong, QIU Yong-fu, GU Ming-yuan. Damping behaviors of magnesium matrix composites reinforced with Cu-coated and uncoated SiC particulates[J]. Composites Science and Technology, 2005, 65: 1736-1742.

[12] NISHIYAMA K, MATSUI R, IKEDA Y, NIWA S, SAKAGUCHI T. Damping properties of a sintered Mg-Cu-Mn alloy[J]. Journal of Alloys and Compounds, 2003, 355: 22-25.

[13] HUANG Guang-sheng, WANG Ling-yun, ZHANG Zhong-wei, HUANG Guang-jie, PAN Fu-sheng. Manufacturing technique of magnesium alloy sheets by powder rolling[J]. Materials Science Forum, 2005, 488/489: 445-448.

[14] BUSK R S. Magnesium products design[M]. New York, Marcel Dekker, Inc, 1987.

[15] XI Y L, CHAI D L, ZHANG W X, ZHOU J E. Titanium alloy reinforced magnesium matrix composite with improved mechanical properties[J]. Scripta Materialia, 2006, 54: 19-23.

收稿日期:2008-02-27;修订日期:2008-12-25

通讯作者:黄光胜,副教授,博士;电话:023-65112239;E-mail: gshuang@cqu.edu.cn

(编辑 何学锋)