文章编号: 1004-0609(2005)05-0675-05

退火过程中AA3003铝合金的析出行为

张新明, 吴文祥, 蹇 雄, 周卓平

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 通过硬度、 电阻检测以及光学显微镜、 透射电镜观察, 研究了AA3003铝合金在退火过程中的析出行为以及对合金显微组织的影响。 结果表明: 低温阶段(〈450℃), 大的冷轧变形量将导致更多的析出; 在高温阶段(>450℃)时的析出与冷轧变形量无关; 在300℃退火时, 析出发生在再结晶之前, 导致晶粒粗大; 而在500℃退火时, 再结晶发生在析出之前, 可获得细小的等轴晶。 对于铝电解电容器用AA3003铝合金阴极箔的生产, 宜采用500℃, 30min中间退火制度, 这样既可以保证大量弥散相的析出, 又可以获得细晶组织, 有利于提高阴极箔比的电容。

关键词: AA3003铝合金; 阴极箔; 析出; 再结晶 中图分类号: TG335; TG146.2

文献标识码: A

Precipitation behavior of AA3003 aluminium alloy during annealing

ZHANG Xin-ming, WU Wen-xiang, JIAN Xiong, ZHOU Zhuo-ping

(School of Materials Science and Engineering, Central South University,

Changsha 410083, China)

Abstract: The precipitation behavior of AA3003 aluminum alloy during annealing as well as its effect on the microstructures of alloys was investigated by means of hardness, electrical resistivity measurements, optical microscopy and transmission electric microscopy. The results show that in the low temperature region(〈450℃)higher cold reduction results in larger amount of precipitates. However, the precipitation at about 500℃ is independent on the cold deformation reduction. On annealing at 300℃, precipitation is prior to recrystallization, the grains become coarse. But on annealing at 500℃, recrystallization is prior to precipitation, and fine grains are obtained. As for the production of AA3003 aluminium foil for cathode of aluminium electrolytic capacitor, the intermediate annealing process of 500℃, 30min is suitable, because a large amount of precipitates occurs and fine grains are obtained, which is in favor of the increase of specific capacitance of the cathode foil.

Key words: AA3003 aluminium alloy; cathode foil; precipitation; recrystallization

众所周知, 合金中析出的弥散相, 对合金的再结晶行为、 织构、 晶粒尺寸以及合金的力学性能都有着强烈的影响。 人们就其影响机理开展了大量研究[1-6]。 第二相粒子的存在可以增大变形储能, 增大再结晶驱动力, 且大尺寸粒子(>1μm)可作为再结晶形核点而促进再结晶形核(PSN), 但密排、 细小弥散相对大角晶界及小角晶界都有很强的钉扎作用(Zener阻力), 从而抑制再结晶过程[7]。

AA3003铝合金中的(Fe, Mn)Al6相和Al(Fe, Mn)Si相构成较弱的阴极相, 使该合金产生“海绵体”状的腐蚀形貌, 这种腐蚀形貌明显地扩大了表面积, 增大了比电容, 因此该合金箔广泛应用于铝电解电容器的阴极。 一方面, AA3003铝合金阴极箔比电容的高低在很大程度上取决于合金中第二相化合物的大小、 形貌以及分布, 而第二相化合物的大小、 形貌及其分布又受热处理制度的强烈影响; 另一方面, AA3003铝合金是热处理不可强化的铝合金, 其力学性能是通过晶粒大小和位错密度控制的。 电容铝箔要求晶粒细小。 再结晶退火时, 晶粒大小受析出和形变程度的控制。

本文作者研究了两种冷轧量的箔经不同温度等时退火过程中AA3003铝合金电阻率的变化, 以探讨退火过程中第二相的析出行为及其对再结晶显微组织的影响规律。

1 实验

实验中配制了一种AA3003铝合金, 其成分列于表1。

表1 合金化学成分

Table 1 Chemical composition of alloy (mass fraction, %)

除铝外其他合金元素均采用中间合金加入。 在电阻炉中采用石墨坩埚熔炼, 熔炼温度为770℃。 用铝合金专用覆盖剂覆盖, C2Cl6除气。 铁模铸造, 浇铸温度为720~730℃。

实验流程如图1所示。

图1 样品的制备过程

Fig.1 Experimental procedures of samples

将AA3003铝合金板材分别热轧至3.5mm和1.7mm, 之后都冷轧至0.5mm, 冷轧变形量分别为85%和70%。 两种不同冷变形样品各分为8组, 在250~600℃之间每隔50℃取一个温度进行等时退火, 退火时间均为30min, 之后测量其电阻率。

采用双臂电桥电阻测量仪测量电阻。 为了消除接触电势的影响, 采用电流换向法, 取一个正向读数和一个反向读数, 取两次电阻测量值的算术平均值。 试样经电解抛光、 阳极复膜后在POLYVAR-MET型光学显微镜(OM)上进行显微组织观察。 透射电镜观察在Tecnai G220型透射电镜上进行。 样品在HMV-2型显微硬度计上进行显微硬度(HV)测试, 载荷为0.1N, 加载持续时间为10s。

2 结果与讨论

2.1 不同温度退火时电阻率的变化

再结晶退火过程中, AA3003合金电阻率的变化取决于两个方面, 即合金中第二相粒子的析出以及点阵缺陷的消失。 研究表明[8], 由溶质原子从基体中析出引起的电阻率的降低远远大于由于其他点阵缺陷的消失而引起的电阻率的降低, 因此, 本研究中电阻率的变化主要归于第二相粒子的析出。

Altenpohl[9]研究表明, AA3003铝合金的电导率σ与固溶体中合金元素之间的关系可以表达为

1/σ=0.0267+0.36w(Mn)+0.032w(Fe)+

0.0068w(Si)+0.0032w(Cu)(1)

式中 w(Fe), w(Mn), w(Si), w(Cu)分别为固溶体中Fe, Mn, Si, Cu的质量分数, %。

由式(1)可知, Si, Cu对合金电导率的影响远小于Mn的影响, 再加上Si, Cu的含量相对较低, 以及它们在铝中的溶解度较大, 它们对电导率变化所起的作用相对较小, 可忽略不计。 有研究表明, 在3003铝合金的半连续铸锭中, 几乎所有的Fe都形成了中间化合物[10], 而大部分的Mn存在于固溶体中[11]。 因此, 电阻率的变化可以表征固溶体中Mn含量的变化, 并且基本可以反映出退火过程中过饱和固溶体的分解以及含Mn第二相粒子的析出情况。

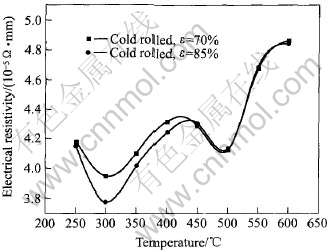

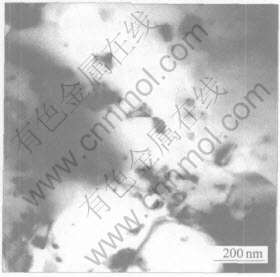

图2所示为分别经70%以及85%冷轧变形的AA3003合金在不同温度退火后测得的电阻率的变化。 可以看出, 在低温阶段, 300℃, 30min退火后合金电阻率下降到最低, 固溶体中Mn含量最低, 表明此时有大量第二相粒子析出。 图3所示为经85%冷轧的AA3003合金于300℃, 30min退火后的TEM形貌。 可以看出, 在位错及亚晶界处析出了大量第二相粒子。 此后随温度升高电阻率有所回升, 在500℃时又出现一个低谷, 表明此时又有第二相粒子的大量析出。 之后, 随着温度进一步升高, Mn在铝中的固溶度增大, 部分前期析出的较细小的含Mn第二相粒子又重新溶入基体, 合金元素的溶解成了主要过程, 并导致电阻率的急剧升高。 此外, 从图2还可以看出, 不同冷轧变形量对电阻率的变化也有一定影响。 经85%冷轧的样品在低温(〈450℃)退火后的电阻率明显低于经70%冷轧的样品, 而在高温(>450℃)退火后, 两种冷轧变形量样品的电阻率基本一致, 这表明低温阶段即300℃时第二相粒子的析出受到点阵缺陷的影响, 与之前的冷变形量有关, 即大的冷轧变形量导致更多的析出。 而高温阶段即500℃时第二相粒子的析出与冷轧变形量无关。

图2 AA3003铝合金电阻率随退火温度的变化

Fig.2 Variations of electrical resistivity of

AA3003 aluminium alloy with annealing temperature

图3 AA3003铝合金经300℃, 30min

退火后的TEM形貌

Fig.3 TEM image of AA3003 aluminium alloy annealed at 300℃ for 30min

析出是一个热激活过程, 包括形核与长大。 根据经典形核理论, 形核速率I可表示为[12]

I=cexp[-(ΔG*+Q)/(kT)](2)

式中 c为常数; ΔG*为形核激活能; Q为溶质原子的扩散激活能; k为玻耳兹曼常数; T为绝对温度。

在Al-Mn合金中, 形核激活能(ΔG*)一般很高, 已报道的Mn的扩散激活能为212.1kJ/mol[13], 相对于铝自扩散的激活能142.8kJ/mol[8]是很大的。 由于ΔG*和Q都很高, 根据式(2)可以推断出均匀形核速率是非常低的。 因此, 点阵缺陷处的择优形核占据了主导地位。

晶体中的位错是晶格畸变管道, 且互相连通成位错网络。 扩散原子沿位错管道扩散, 其扩散激活能可以降低一半, 所以增加位错密度可以加速扩散过程。 同样, 亚晶界上亦是如此, 因为亚晶界上包含有大量位错。

析出过程有一定的孕育期τp, 它与形核激活能ΔG*有关, 而ΔG*是合金位错密度ρ、 过冷度ΔT、 界面能γ和相应扩散激活能Q的函数。 因此, 增大位错密度能够降低形核激活能ΔG*, 从而大大缩短析出过程的孕育期τp, 增大了形核速率。 Cahn[14]从理论上研究了位错上的形核, 发现位错形核比一般条件下的均匀形核快了1078倍。

尽管低的ΔG*容易发生形核, 但形核速率还受到溶质原子扩散激活能Q的影响。 Q与析出相的长大有关。 由于Mn的扩散激活能较高, 所以Mn的扩散速率在低温下是非常低的, 因此, 冷变形促进析出不能简单的归因于位错形核点的增加。

Chen等[15]研究发现, 在AA3003铝合金的冷轧变形中, 溶质原子Mn在位错网处的偏析能够促进形核。 因此, 位错密度的增加能够增加形核点密度和析出相组成元素的扩散能力, 以及溶质原子Mn的偏聚, 共同促进了第二相粒子的析出。 本实验中, 经85%冷轧变形样品的位错密度比经70%冷轧变形样品的高, 低温退火时更能促进细小弥散第二相在位错密度高处的析出, 其电阻率相应就更低。

AA3003铝合金在热处理过程中, 再结晶与析出交错进行, 并强烈地相互制约。 在300℃低温退火时, 析出过程先于再结晶过程发生, 析出物质点通过管扩散, 倾向于在位错、 亚晶界等点阵缺陷处形核并长大。 因此, 低温退火时合金的析出与之前的冷变形量有关。 而在500℃高温退火时, 再结晶过程发生在析出过程之前, 冷轧时形成的位错在析出开始之前就消失了, 析出相通过体扩散在再结晶基体中形核。 因此, 冷轧对析出动力学的影响随着退火温度的升高而减小, 高温退火时合金的析出行为与之前的冷轧变形量无关(如图2所示)。

2.2 不同退火温度时的再结晶行为

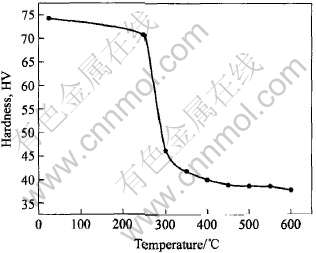

不同温度下退火后材料的显微硬度变化如图4所示。 理论上, 显微硬度变化是软化和析出共同作用的结果。 但由于3003铝合金为不可热处理强化合金, 析出强化作用可忽略不计, 因此, 显微硬度对析出过程并不敏感, 它只反映再结晶软化过程。 由图4可以看出, 试样经300℃, 30min退火后, 硬度迅速降低, 表明此时再结晶已基本完成。

图4 合金显微硬度随退火温度的变化

Fig.4 Variation of microhardness of

alloy with annealing temperature

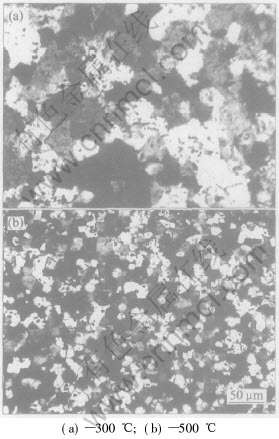

图5所示为AA3003合金经85%冷轧变形之后分别在300和500℃退火后的显微组织。 可以看出, 试样经高温退火(500℃, 30min)后, 再结晶过程已经完成, 组织均匀一致, 且晶粒细小, 约为10~20μm; 而经低温退火(300℃, 30min)后的试样, 虽然也完成了再结晶, 但晶粒粗大, 约为40~50μm。

图5 不同温度中间退火后AA3003铝合金的显微组织

Fig.5 Microstructures of AA3003 aluminium

alloy after intermediate annealing at different temperatures

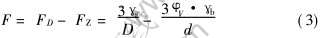

过饱和可析出合金的再结晶驱动力可表示为

式中 FD为由直径为D的亚晶界面能引起的驱动力; FZ为由于第二相粒子的钉扎而引起的Zener阻力(假设第二相粒子均匀析出); φV, d分别为第二相粒子体积分数和直径; γs, γb分别为亚晶界和大角度晶界的界面能。 当第二相粒子在小角晶界或大角晶界择优析出时, Zener钉扎力会更高[2]。

在AA3003铝合金中, 弥散相优先在变形组织中的点阵缺陷处(如亚晶界或位错)形核, 导致Zener钉扎力急剧增大。 这就表明, 如果再结晶过程中伴随析出行为的发生, 再结晶将受到抑制。 析出驱动力随固溶体过饱和度增大而增大, 因此在300℃低温再结晶退火时伴随有析出行为的发生, 析出行为会阻碍合金回复时位错的移动、 再结晶晶核的生成, 造成最后的再结晶组织晶粒粗大, 如图5(a)所示。 而在500℃高温退火时, 析出行为发生在再结晶过程之后, 析出物钉扎晶界, 抑制再结晶晶粒长大, 最后得到晶粒细小的再结晶组织, 如图5(b)所示。

3 结论

1) 在300和500℃退火时有大量第二相粒子析出。

2) 析出行为可分为两个区: 温度低于450℃时为第一区, 该区内合金的析出与之前的冷变形量有关; 温度高于450℃时为第二区, 该区内合金的析出与冷变形量基本无关。

3) 受第二相颗粒析出的影响, 低温退火后合金的晶粒粗大, 而高温退火后合金的晶粒细小, 组织均匀。

4) 对于AA3003铝合金阴极箔的生产, 宜采用500℃, 30min快速中间退火制度, 这样既可以保证大量弥散相的析出, 又可以获得细晶组织, 有利于提高阴极箔的力学性能及比电容。

REFERENCES

[1]Vatne H E, Engler O, Nes E. Influence of particles on recrystallization textures and microstructures of aluminium alloy 3103[J]. Mater Sci Tech, 1997, 13(2): 93-102.

[2]Daaland O, Nes E. Recrystallization texture development in commercial Al-Mn-Mg alloys[J]. Acta Mater, 1996, 44(4): 1413-1435.

[3]Kwag Y, Morris J G. Effect of structure on mechanical behavior and stretch formability of constitution ally dynamic 3000 series aluminum alloys[J]. Mater Sci Eng A, 1986, A77(1-2): 59-74.

[4]Humphreys F J. Nucleation of recrystallization at second phase particles in deformed aluminium[J]. Acta Metallurgica, 1977, 25(11): 1323-1344.

[5]Li Z, Ding S X, Morris J G. Influence of precipitate structure on recrystallization and formability behavior of continuous strip cast AA3003 aluminum alloy[A]. Light Metals[C]. Warrendale, Pennsylvania: TMS, 1995. 1149-1154.

[6]Nes E. Effect of a fine particle dispersion on heterogeneous recrystallization[J]. Acta Metallurgica, 1976, 24(5): 391-398.

[7]Humphreys F J, Hatherly M. Recrystallization and Related Annealing Phenomena[M]. Oxford: Elsevier Science Ltd, 1995. 235-237.

[8]Nagahama K, Miki I. Precipitation during recrystallization in Al-Mn and Al-Cr alloys[J].Trans Jap Inst Met, 1974, 15(3): 185-192.

[9]Altenpohl D. Aluminium und Aluminiumlegierungen[M]. Berlin: Springer Verlag, 1965. 526.

[10]Li Y J, Arnberg L. Solidification structure of DC-cast AA3003 alloy and its influence on homogeniza- tion[J]. Aluminium, 2002, 78(10): 834-839.

[11]Li Y J, Arnberg L. Precipitation of dispersoids in DC-cast 3003 alloy[J]. Materials Science Forum, 2002, 396-402: 875-880.

[12]Burke J. The Kinetics of Phase Transformation in Metal[M]. London: Pergamon Press, 1965. 100.

[13]Hood G M, Schultz R J. Diffusion of manganese in aluminium[J]. Phil Mag, 1971, 23(186): 1479-1490.

[14]Cahn J W. Nucleation on dislocations[J] . Acta Metall, 1957, 5(3): 169-172.

[15]Chen S P, Kuijpers N C W, van de Zwaag S. Effect of microsegregation and dislocations on the nucleation kinetics of precipitation in aluminium alloy AA3003[J]. Mater Sci Eng A, 2003, 341(1-2): 296-306.

基金项目: 国家自然科学基金资助项目(50230310; 50301016)

收稿日期: 2004-10-08; 修订日期: 2005-01-19

作者简介: 张新明(1946-), 男, 教授, 博士.

通讯作者: 张新明, 教授; 电话: 0731-8830265; E-mail: xmzhang@mail.csu.edu.cn

(编辑陈爱华)