文章编号:1004-0609(2011)04-0901-07

复杂铜铅锌银混合精矿两段逆流氧压浸出工艺

徐 斌1, 2,钟 宏3,王魁珽4,姜 涛1

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 四川鑫源矿业有限责任公司,成都 610000;

3. 中南大学 化学化工学院,长沙 410083;

4. 中国恩菲工程技术有限公司,北京 100038)

摘 要:通过对呷村铜铅锌银多金属混合精矿的矿物分析可知,铅、锌主要赋存于方铅矿、闪锌矿中,而大部分铜、银均为难浸出的黝铜矿所载。采用两段逆流氧压浸出工艺进行处理该矿,条件试验研究得出一、二段最佳浸出条件分别为硫酸浓度150 g/L、液固比3?1、反应温度135 ℃、氧分压0.75 MPa、浸出时间2.0 h;硫酸浓度80 g/L、液固比3?1、反应温度180 ℃、氧分压1.0 MPa、浸出时间2.5 h。9轮扩大验证循环浸出试验运行顺利,Cu和Zn的平均两段总浸出率分别为 93.23%和99.47%,而杂质元素Fe和As的浸出率仅15.77%和6.9%, 元素硫的硫磺转化率为54.26%。Pb和Ag大部分转化为铅矾、铅铁矾和硫化银而留在浸出渣中,铜锌与铅银彻底分离。

关键词:多金属混合精矿;氧压浸出;两段逆流;黝铜矿

中图分类号:TF803.21 文献标志码:A

Two stage adverse current oxygen pressure acid leaching of complex Cu-Pb-Zn-Ag bulk concentrate

XU Bin1, 2, ZHONG Hong3, WANG Kui-ting4, JIANG Tao1

(1. School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Sichuan Xinyuan Mining Limited Liability Company, Chengdu 610000, China;

3. School of Chemistry and Chemical Engineer, Central South University, Changsha 410083, China;

4. Enfei Engineering Technology Limited Company, Beijing 100038, China)

Abstract: By mineralogical analysis, the primary lead and zinc minerals in the complex Cu-Pb-Zn-Ag bulk concentrate are separately galena and sphalerite. While the primary copper mineral of the concentrate and most of silver indwell in the tetrahedrite is difficult to be leached. The treatment of the complex Cu-Pb-Zn-Ag bulk concentrate by a two-stage adverse current oxygen pressure acid leaching was studied. The optimum process operating parameters of the initial sulfuric acid concentration 150 g/L, the first stage that liquid-to-solid ratio of 3, temperature of 135 ℃, oxygen partial pressure of 0.75 MPa and time of 2.0 h, and the initial sulfuric acid concentration of 80 g/L, the optimum parameters of the second stage that liquid-to-solid ratio of 3, temperature of 180 ℃, oxygen partial pressure of 1.0 MPa and time of 2.5 h were both established by conditional experiments. The enlarged verification experiment was carried out under the optimum conditions, and the average leaching efficiencies of copper and zinc are separately as high as 93.23% and 99.47% in the experiment while the average leaching efficiencies of Fe and As as impurities are only 15.77% and 6.9%, respectively. The lead and silver stayed in residue in the main forms of sulfate and sulfide separately after the leaching, so the lead and silver are separated with copper and zinc completely.

Key words: complex multimetal bulk concentrate; oxygen pressure acid leaching; two stage adverse current; tetrahedrite

四川省甘孜州白玉县呷村铜铅锌银多金属硫化矿属特大型银多金属矿床,被誉为“三江成矿带上的一颗明珠”。资源丰富,铜、铅、锌、银平均品位分别为0.5%、3%、5%、200 g/t,探明储量按金属量计各约为10万t、60万t、100万t、2 000 t。该矿与日本黑矿类似,各矿物嵌布粒度细、易浮难分选[1-2]。目前呷村矿的采选系统已经建成投产,采用优先浮选工艺产出铜精矿、锌精矿和铅精矿,并已出售。但精矿产品中铜铅锌的互含现象非常严重,以铜精矿为例,含Cu 15%~16%,Pb 16%~17%,Zn 15%。国内诸多浮选试验也证明,采用优先浮选工艺,不仅主金属回收率低,且分选出的铜精矿、铅精矿、锌精矿中杂质含量高,质量不合格[3-5]。因此,有必要采用选冶联合的方法进行处理,先采用混合浮选得混合精矿,再利用冶炼手段将各金属分离。

呷村复杂铜铅锌银混合精矿由于杂质砷和锑的含量高,以及处理规模较小,不适宜采用传统的火法冶金工艺,而含铅大于10%,也不适宜采用沸腾焙烧-浸出工艺[6-7]。在湿法工艺中,针对黄铜矿的细菌氧化浸出研究较多,对呷村以黝铜矿为主的铜矿物的生物浸出鲜有研究[8-10]。常温下的氯化浸出,对黝铜矿浸出率偏低[11]。而矿浆电解工艺较难现实产业化[12-13]。与上述工艺相比,氧压浸出在处理复杂混合精矿上具有较强的优势:混和精矿中的硫元素转化为单质硫,不产生SO2,砷、铁等杂质以稳定的化合物形态固定在渣中,有利于环保;元素硫氧化释放的热量能更有效地被利用;硫酸产量的显著减少使厂址的选择更灵活[14-17]。

1 实验

1.1 实验原料

实验矿样为呷村复杂铜铅锌银混合浮选精矿,化学成分分析及粒度分布分别见表1和2。试验用98%浓硫酸、硫酸铁、硫酸铜、硫酸锌、木质素磺酸钠均为化学纯,氧气为工业用瓶装纯氧。

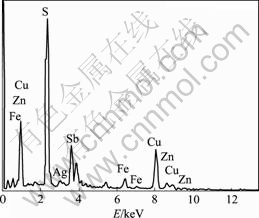

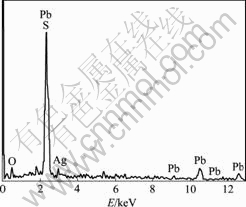

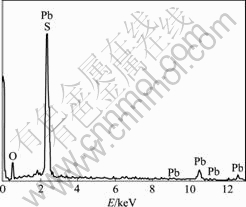

对混合精矿进行了矿物工艺学研究。分析结果表明,精矿中的金属矿物主要有闪锌矿、方铅矿、黄铁矿、黝铜矿(Cu12Sb4S13)。脉石矿物主要有长石、重晶石、石英及少量的白云石、绿泥石等。利用电子探针对金属矿物进行分析后发现,银主要赋存于黝铜矿中,显微镜下也极少见到其他银矿物。图1显示部分黝铜矿中含As丰富,图2显示部分黝铜矿中含Ag显著。

表1 矿样的主要化学成分

Table 1 Main chemical compositions of sample (mass fraction, %)

表2 混合精矿的粒度分布

Table 2 Distribution of granularity about bulk concentrate

图1 含砷黝铜矿的EDS谱

Fig.1 EDS pattern of tetrahedrite containing arsenic

图2 含银黝铜矿的EDS谱

Fig.2 EDS pattern of tetrahedrite containing silver

1.2 实验装置

试验装置主要包括2 L和10 L内加钛胆的机械搅拌高压釜,搅拌轴、桨叶、冷却盘管均为钛制。另外还包括真空抽虑设备和干燥箱等。

1.3 实验方法

两段逆流氧压浸出实验流程见图3,一段浸出渣进二段高压釜进行第二段浸出,二段浸出液返一段高压釜。将混合精矿、硫酸溶液等以一定液固比调浆后放入高压釜内,检查高压釜气密性后开始通氧、搅拌、加热。浸出结束后,采用真空抽虑设备对浸出矿浆进行液固分离,量取滤液体积,称取滤渣湿样的质量和干样的质量并取样送分析。分别考察始酸浓度、氧分压和反应温度等因素对铜锌浸出率的影响。

图3 二段逆流氧压浸出工艺流程图

Fig.3 Flowsheet of two stage adverse current oxygen pressure acid leaching

2 结果和讨论

2.1 一段浸出条件实验

试验每次使用200 g混合精矿,加入木质素磺酸钠1 g,为模拟存在二段浸出液的返回情况,用硫酸锌、硫酸铜、硫酸铁将入釜矿浆中的Zn2+、Cu2+、Fe3+浓度分别调节到60 g/L、5 g/L、5 g/L。固定搅拌速度为550 r/min,将待考察的5个因素液固质量比、始酸浓度、反应温度、氧分压、浸出时间分别确定为3?1、160 g/L、130 ℃、0.75 MPa、3 h,依次改变其中一个条件来考察其对铜、锌、铁浸出率及釜内残酸浓度的影响,考察液固比的影响时加酸量固定为49 mL,其结果如图4~8所示。

混合精矿浸出过程可以由一些简单的化学方程式来描述。其总反应非常简单:硫化物中的硫元素在富

图4 液固比对铜锌铁浸出率及浸出液残酸的影响

Fig.4 Effect of fluid solid ratio on extraction of Cu, Zn and Fe and superfluous acid in lixivium

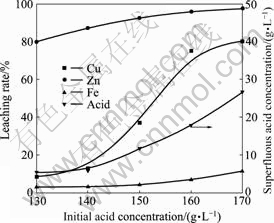

图5 始酸浓度对铜锌铁浸出率及浸出液残酸的影响

Fig.5 Effect of acid concentration on extraction of Cu, Zn and Fe and superfluous acid in lixivium

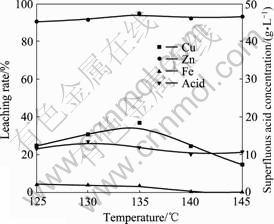

图6 温度对铜锌铁浸出率及浸出液残酸的影响

Fig.6 Effect of temperature on extraction of Cu, Zn and Fe and superfluous acid in lixivium

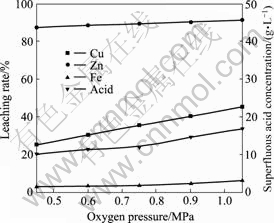

图7 氧分压对铜锌铁浸出率及浸出液残酸的影响

Fig.7 Effect of oxygen pressure on extraction of Cu, Zn and Fe and superfluous acid in lixivium

图8 浸出时间对铜锌铁浸出率及浸出液残酸的影响

Fig.8 Effect of leaching time on extraction of Cu, Zn and Fe and superfluous acid in lixivium

氧条件被氧化为单质硫,而金属元素转移到硫酸盐中。

MeS + H2SO4 + 0.5O2 → MeSO4 + H2O + S0 (1)

如果没有某种物质来加速氧气在溶液中的扩散的话,反应(1)的反应速率非常慢。溶液中的铁离子可以促进氧气扩散,其作用原理如反应(2)和(3)所示:

MeS+Fe2(SO4)3→MeSO4+2FeSO4 + S0 (2)

2FeSO4+H2SO4 +0.5O2→Fe2(SO4)3+H2O (3)

Cu2++ZnS→Cu+Zn2++S↓ (4)

由图4可知,在加酸量一定的情况下,液固比增大到3?1后,铜浸出率显著下降。由图5可看出,铜、锌和铁的浸出率及残酸浓度都随着始酸浓度的增加而增大。为控制铁的浸出和釜内残酸在较低的水平,始酸浓度不宜超过150 g/L。由图6可见,在温度超过135 ℃后,铜浸出率显著降低,可能是较高温度下,浸出的铜离子与未反应的硫化锌发生了反应(4)。由图7可看出,铜、锌和铁的浸出率及残酸浓度都随着氧分压的增加而增大。为控制残酸浓度氧分压应不超过0.75 MPa。由图8可见,浸出时间超过2 h后,各项指标变化不大。综上所述,一段浸出的最佳条件如下:液固质量比3、始酸浓度150 g/L、反应温度135 ℃、氧分压0.75 MPa、浸出时间2 h。

2.2 二段浸出条件实验

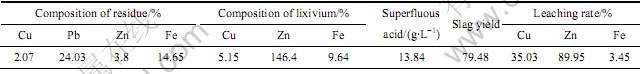

按2.1中确定的最佳条件,用10 L高压釜进行一段浸出为二段浸出准备原料。浸出结果见表3。

一段浸出渣经洗涤、烘干、研碎混匀后作为二段浸出条件试验原料。仿照2.1中方法进行条件试验,得出二段浸出的最佳条件如下:液固质量比3、始酸浓度80 g/L、反应温度180 ℃、氧分压1.0 MPa、浸出时间2.5 h。

2.3 扩大验证实验

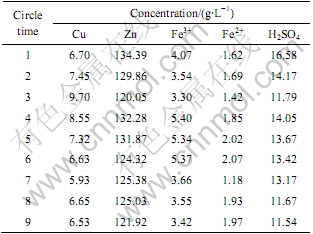

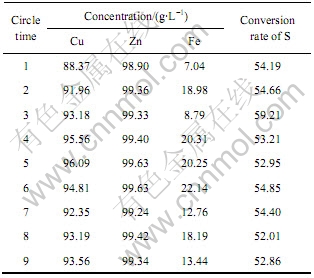

按照图7所示的流程和2.1、2.2节中确定的最优条件,采用10 L高压釜进行扩大验证实验。一段浸出矿浆真空抽滤,不洗涤,浆化后进二段浸出。共进行9轮循环共18次浸出实验,结果见表4~6。

9轮循环浸出铜、锌、铁渣计平均两段总浸出率及单质S平均转化率分别为93.23%、99.47%、15.77%、54.26%。硫磺转化率通过对二段浸出渣进行CS2萃取得到单质硫磺而求得。

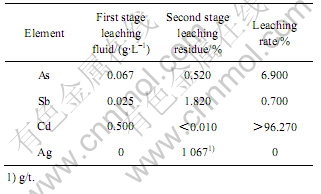

为考察As、Sb、Cd、Ag在两段氧压浸出中的浸出率及二段渣的物相组成,根据各轮试验产出一段浸出液体积和二段浸出渣质量,按比例取样混和送分析。分析结果见表7,其中As和Sb是在液体中浸出,Cd是在渣中浸出。二段渣的XRD谱如图9所示。

由图9可看出,在氧压浸出过程中方铅矿中的铅

表3 10 L高压釜一段浸出结果

Table 3 Leaching result of first stage leaching with 10 L autoclave

表4 循环试验一段浸出液成分

Table 4 Composition of first stage leaching fluid

表5 循环试验二段浸出渣成分

Table 5 Composition of second stage leaching residue

表6 循环试验Cu、Zn、Fe渣计两段总浸出率及单质S转化率结果

Table 6 Leaching rate of Cu, Pb, Zn and conversion rate of sulfur in circle experiment for validate

表7 As、Sb、Cd、Ag浸出率结果

Table 7 Leaching results of As, Sb, Cd and Ag

图9 浸出渣的XRD谱

Fig.9 XRD pattern of leaching residue

主要转化为铅矾和铅铁矾。原料中含银黝铜矿虽然可在氧压酸浸过程中分解,使Ag+进入溶液,但由于H2S在该工艺过程中可作为中间产物不断释出,所以,浸出的Ag+将不可避免地和S2-形成Ag2S沉淀而留在渣中。由于Ag在原料中的含量仅0.082 1%,不够形成较粗大的独立结晶,而只能以极细小的晶粒分散在其它相中,如图10~13所示在残余方铅矿边缘,即硫化

图10 残余方铅矿的背散射电子扫描图像

Fig.10 SEM image of galena in leaching residue

图11 图10中A点方铅矿的EDS谱

Fig.11 EDS spectrum of galena lying at point A shown in Fig.10

图12 图10中B点含Ag铅矾的EDS谱

Fig.12 EDS spectrum of sardinianite which contains silver and lies at point B shown in Fig.10

图13 图10中C点铅矾的EDS谱

Fig.13 EDS spectrum of sardinianite lying at point C shown in Fig.10

氢释出的反应界面上可以发现相对富集的Ag。

由表4~7可知,验证实验运行平稳,铜、锌浸出率高,杂质元素铁、砷浸出率低。由图9~13可知,Pb、Ag大部分转化为铅矾、铅铁矾和硫化银而留在浸出渣中,铜锌与铅银分离较彻底。

3 结论

1) 针对四川呷村复杂铜铅锌银混合精矿,通过条件优化实验确定一、二段氧压浸出的条件分别如下:始酸浓度150 g/L、液固质量比3?1、反应温度135 ℃、氧分压0.75 MPa、浸出时间2.0 h;始酸浓度80 g/L、液固质量比3?1、反应温度180 ℃、氧分压1.0 MPa、浸出时间2.5 h。最优条件下扩大验证循环浸出试验运转顺利,Cu、Zn的平均两段总浸出率分别为93.23%、99.47%,而杂质元素Fe、As浸出率仅15.77%、6.9%,元素硫的硫磺转化率为54.26%。Pb、Ag大部分转化为铅矾、铅铁矾和硫化银而留在浸出渣中,铜、锌与铅、银分离彻底。

2) 该混合精矿较难处理,采用两段逆流氧压浸出工艺,可以大幅提高各有价金属的回收率。本工艺针对该精矿高铁、高铅、高银以及含难浸(锑、砷)黝铜矿的特点,采用一段中低温、二段高温,限制二段酸量的方法,实现了铜、锌的高效浸出以及硫的转化。铜锌进入浸出液,可用常规方法回收电铜、电锌,浸出渣亦可进一步回收铅、银、锑、硫磺及少量未反应完全的铜、锌硫化物。

REFERENCES

[1] 侯增谦, 杜安道, 孙卫东. 黑矿型矿床成矿物质来源: 日本上向黑矿铼—锇和氦同位素证据[J]. 地址学报, 2001, 75(1): 97-105.

HOU Zen-qian, DU An-dao, SUN Wei-dong. Sources of ore-forming metals in kuroko-type deposits: evidence from the re-os and he isotopes for the Uwamuki Kuroko deposit of Japan[J]. Acta Geologica Sinica, 2001, 75(1): 97-105.

[2] 于际民, 蒋少涌. 伊比利亚型—一种新类型块状硫化物矿床地质地球化学及成因[J]. 地质找矿论丛, 2000, 15(3): 246-253.

YU Ji-min, JIANG Shao-yong. Iberian type—a new type of massive sulphide deposits and the geology, geochem istry and genetic model[J]. Contributions to Geology and Mineral Resources Research, 2000, 15(3): 246-253.

[3] 王荣生, 师建忠, 唐顺华, 高新章, 周少珍, 魏明安. 某银铜铅锌多金属矿选矿工艺试验研究[J]. 矿冶, 2004, 13(3): 38-41.

WANG Rong-sheng, SHI Jian-zhong, TANG Shun-hua, GAO Xin-zhang, ZHOU Shao-zhen, WEI Ming-an. Study on mineral processing technology for a copper-lead-zinc-silver ore[J]. Mining and Metallurgy, 2004, 13(3): 38-41.

[4] 华金仓, 李崇德, 魏明安. 某难选复杂多金属矿的浮选研究[J]. 有色金属: 选矿部分, 2005(6): 1-5.

HUA Jin-chang, LI Chong-de, WEI Ming-an. Flotation research of a complex multi-metal ores[J]. Nonferrous Metals: Ore Dressing Section, 2005(6): 1-5.

[5] 马 晶, 任金菊, 原连肖. 某难选多金属硫化矿浮选分离试验研究[J]. 有色金属: 选矿部分, 2008(3): 8-11.

MA Jing, REN Jin-ju, YUAN Lian-xiao. Flotation experimental research of multi-metal sulphide ore[J]. Nonferrous Metals: Ore Dressing Section, 2008(3): 8-11.

[6] 姚素平. “双闪”铜冶炼工艺在中国的优化和改进[J]. 有色金属: 冶炼部分, 2008(6): 9-14.

YAO Su-ping. Optimization and improvement of double-flash copper smelting process in China[J]. Nonferrous Metals: Extractive Metallurgy, 2008(6): 9-14.

[7] 张学核, 宋连民. 沸腾炉的特性及在铜冶炼中的应用[J]. 新疆有色金属, 2007, 30(z1): 108-109.

ZHANG Xue-he, SONG Lian-ming. The characteristic of furnace in fluid bed and its use in copper smelting[J]. Xinjiang You Se Jin Shu, 2007, 30(z1): 108-109.

[8] CHEN M L, ZHANG L, GU G H, HU Y H, SU L J. Effects of microorganisms on surface properties of chalcopyrite and bioleaching[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(6): 1421-1426.

[9] AHMAD A, SCHAFFIE M, MANAFI Z, RANJBAR M, Electrochemical bioleaching of high grade chalcopyrite flotation concentrates in a stirred bioreactor[J]. Hydrometallurgy, 2010, 104(1): 99-105.

[10] VILC?EZ J, SUTO K, INOUE C. Bioleaching of chalcopyrite with thermophiles: Temperature-pH-ORP dependence[J]. International Journal of Mineral Processing, 2008, 88(1/2): 37-44.

[11] 李元坤. 某含银高铅复杂多金属矿的分离提取[J]. 矿产综合利用, 2003(5): 3-8.

LI Yuan-kun. The separation technology for silver-and lead-bearing complex poly metallic ore[J]. Multipurpose Utilization of Mineral Resources, 2003(5): 3-8.

[12] WANG C Y, QIU D F, YIN F, WANG H Y, CHEN Y Q. Slurry electrolysis of ocean poly metallic nodule[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s60-s64.

[13] LIU W P, QIU D F, YU Y G. Ultrafine copper powder prepared by slurry electrolysis under ultrasonic field[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1347-1352.

[14] 李小康, 许秀莲. 低品位铜锌混合矿加压浸出研究[J]. 南方冶金学院学报, 2004, 25(24): 5-9.

LI Xiao-kang, XU Xiu-lian. Study on pressure leaching of low-grade copper-zinc bulk concentrate[J]. Journal of Southern Institute of Metallurgy, 2004, 25(24): 5-9.

[15] KRYSA B D. Zinc pressure leaching at HBMS[J]. Hydrometallurgy, 1995, 39: 71-77.

[16] OZBERK E, JANKOLA W A, VECCHIARELLI M, KRYSA B D. Commercial operations of the Sherritt zinc pressure leach process[J]. Hydrometallurgy, 1995, 39: 49-52.

[17] HOFIREK Z, NOFAL P J. Pressure leach capacity expansion using oxygen enriched air at RBMR (Pty) Ltd[J]. Hydrometallurgy, 1995, 39: 91-116.

(编辑 李艳红)

基金项目:国家“十一五”科技支撑计划项目(2007BAB22B01)

收稿日期:2010-03-26;修订日期:2010-05-14

通信作者:钟 宏,教授,博士;电话:0731-88830603;E-mail: zhongh@mail.csu.edu.cn