文章编号:1004-0609(2014)04-0919-07

随焊超声波激振法控制铝合金薄板焊接应力及变形

周广涛1, 2,黄海瀚1,方洪渊2

(1. 华侨大学 机电及自动化学院,厦门 361021;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:从力学角度出发提出随焊超声波激振控制高强硬铝合金薄板焊接变形的新方法,阐明其控制焊接应力及变形的机理。基于数值模拟分析,利用Marc建立铝合金薄板的随焊超声波激振热力耦合模型,找出最优焊接参数以及加载冲击与热源的最佳距离。利用自行研制的随焊超声波激振装置进行焊接试验。结果表明:激振距离为22 mm时,板长方向中截面残余拉应力峰值由常规焊的248 MPa下降到63 MPa,压应力峰值从-77 MPa降低到-27 MPa,低于薄板的临界失稳应力,薄板挠曲变形完全消失,且板边最大挠度由8.66 mm下降到0.9 mm。试验结果与模拟结果吻合较好。

关键词:随焊超声波激振;数值模拟;焊接残余应力;挠曲变形

中图分类号:TG404 文献标志码:A

Controlling welding stress and distortion of aluminum alloy sheet by welding with trailing ultrasonic vibration method

ZHOU Guang-tao1, 2, HUANG Hai-han1, FANG Hong-yuan2

(1. College of Mechanical Engineering and Automation, Huaqiao University, Xiamen 361021, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: A new method of welding with trailing ultrasonic vibration (WTUV) to control the welding distortion of high strength aluminum alloy sheet was put forward, and the mechanism was illustrated. Based on numerical simulation analysis, the model of thermo-mechanical coupled welding with ultrasonic vibration was established using Marc software. The optimal welding parameters and the best distance between the vibrating position and heat source are obtained. The welding experiments were conducted on the self-developed device. The results show that when the distance between vibrating point and heat source is 22 mm, the residual tensile stress in the middle cross-section in longitudinal direction reduces from 248 MPa of conventional welding to 63 MPa. The maximum compressive residual stress reduces from -77 MPa to -27 MPa, which is below the critical buckling stress of the sheet, the deflection distortion disappears entirely, and the maximum deflection of plate edges drops from 8.66 mm to 0.9 mm. There are better agreements between the test results and simulation results.

Key words: welding with trailing ultrasonic vibration; numerical simulation; welding residual stress; deflection distortion

高强铝合金具有良好的比强度、比刚度以及可焊接性等优点,在航空航天、船舶及国防军工等领域具有广泛的应用前景[1]。但是高强铝合金焊接过程中,由于热膨胀系数大和热导率较高等特点,焊后不可避免地产生焊接残余应力与变形,从而严重影响焊接结构的可靠性和稳定性,大大限制该材料在焊接结构中的应用,因此控制焊接应力及变形成了研究热点。

目前,控制铝合金焊接残余应力及变形的措施主要从力学角度,采用随焊控制,如温差拉伸、随焊锤击、随焊碾压及预拉伸等方法[2-9],这些方法在控制焊接残余应力方面能取得一定的效果。

本文作者从力学角度出发,提出“随焊超声波激振”方法,即利用自行研制的超声波激振装置在焊接过程中随热源同时运动,对铝合金薄板焊缝及其附近区域进行激振延展,弥补焊接过程中产生的压缩塑性应变,减小焊接瞬态应力,最终降低焊接残余应力,进而减小焊后挠曲变形。“随焊超声波激振法”是一种将功率超声波合理应用于焊接变形领域的有效方法,它利用了超声波的力学效应[10-12],具有设备简单、易于控制实施、受空间限制小等优点;与随焊锤击相比[5],其激振频率更高,作用在焊缝上的激振力柔性可控,并且焊缝成型美观,具有很强的实用性。

同时利用有限元数值计算方法,以LY12硬铝合金薄板为研究对象,建立随焊超声波激振原理模型,对焊接过程进行数值模拟,并进行大量的焊接试验,最终获得了减小焊接残余应力及变形的最佳作用区域和超声冲击功率最佳匹配,从理论上和实际上验证了该方法的可行性。

1 随焊超声波激振模型的建立

1.1 随焊超声波激振控制模型

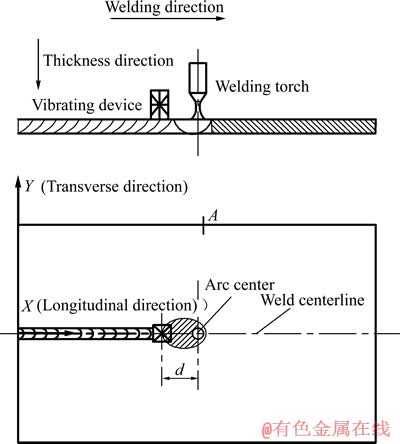

建立随焊超声波激振原理模型如图1所示。其原理是在焊接过程中,在熔池后方离焊枪一定距离d内,沿焊件厚度方向施加超声波,沿焊缝中心线与焊接热源同时移动,对处于冷凝收缩状态的焊缝金属激振产生纵向塑性延展,降低焊接过程中产生的压缩应变,使薄板焊后残余应力降低,进而减小焊接变形。

1.2 控制薄板残余变形的机理

薄板在焊接过程中,焊接区冷却阶段的拉伸塑性应变远比加热阶段产生的压缩塑性应变小,导致焊后焊缝及其附近区域残留有一定的压缩塑性应变,以致在焊件中产生残余应力及变形。薄板焊后应力分布为焊缝中心是拉应力,两侧为压应力,当压应力大于薄板的临界失稳应力σc时,薄板产生挠曲变形[13]。

UEDA等[14]提出固有应变理论,他指出固有应变由焊接过程中产生的压缩应变和冷却过程中产生的拉伸应变组成。其表达式为

(1)

(1)

图1 超声波激振随焊原理图

Fig. 1 Schematic diagram of welding with trailing ultrasonic vibration

式中:[ε*]为固有应变,[ε*]总为负值,只要[ε*]不为0,即产生残余应力;[εy]为压缩应变,通常取负值;[εl]为拉伸应变。

由此可见,控制焊接应力及变形的目标是减小固有应变,要达到该目的可通过增大拉伸应变的方法来减小最终压缩残余应变。

基于上述原理,采用随焊超声波激振的方法,通过功率超声产生的激振力,对熔池后方塑性区的金属进行激振,高温下材料的屈服极限下降,易产生塑性变形,可使该区域金属沿焊缝方向上产生纵向塑性流动,这样抵消了一部分在焊接过程中产生的压缩应变,从而使固有应变得到一定的降低甚至消除,最终达到降低焊接残余应力和消除挠曲变形的目的。

2 随焊超声激振数值模拟

2.1 有限元模型建立

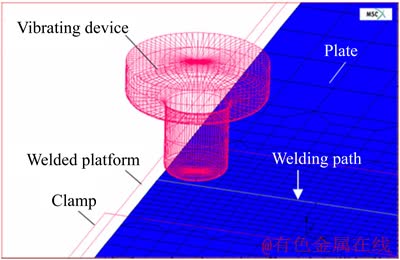

图2 随焊超声波激振有限元模型

Fig. 2 FEM of welding with trailing ultrasonic vibration

采用热力耦合附以接触分析的方法,来模拟实际的焊接工况,夹具、焊接平台、超声波激振装置均建成刚体,焊件建为变形体,模型尺寸为320 mm×200 mm×2 mm,模型单元为8节点六面体单元,共有14295个节点,9360个体单元,如图2所示。由于本模型涉及多种接触关系,计算量非常庞大,为节约计算时间,对模型网格划分进行简化。靠近焊缝温度梯度较大的区域采用较细密的网格单元,温度变化较小远离焊缝的区域,利用一定的网格过渡形式,将网格单元稀疏化。

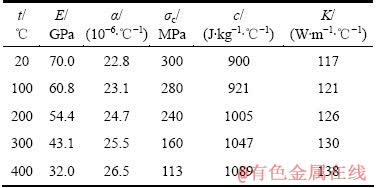

表1 材料性能参数[9]

Table 1 Properties of material[9]

材料采用LY12硬铝合金,弹性模量E、线膨胀系数α、屈服极限σc、比热容c和热导率K等均为随温度变化的物理参数(见表1),泊松比λ及质量密度ρ为定值。采用TIG焊对薄板表面进行熔敷,等效于薄板对接焊[15]。热源模型采用双椭球热源[16],该模型前半部分椭球内热源分布表达式为

(2)

(2)

后半部分椭球内热源分布的表达式为

(3)

(3)

式中:Q=ηUI,η为热源效率,U为焊接电压(V),I为焊接电流(A);a、b、c为椭球形状参数;f1、f2为前后椭球热量分布函数,f1+f2=2。

焊接前,模型约束在建成的刚性平台上,焊接过程中与热源同步随动的超声波激振装置的上下激振运动方程由式(4)决定:

(4)

(4)

式中:Y为位移;A为振幅,由超声波激振功率决定;t为时间。

焊接结束的模拟,需保证激振装置离开薄板并停止激振,待薄板温度完全冷却,分离夹具。

2.2 温度场模拟结果

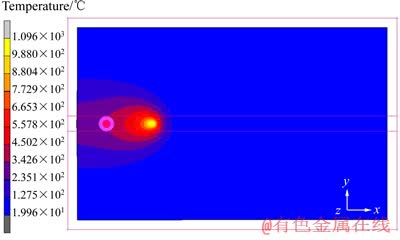

温度场数值模拟能够反映模型的正确性,图3所示为焊接进行到t为20 s时的瞬态温度场,温度场中间为明亮的椭球状,最高温度为1096 ℃,符合实际焊接情况,表明了模型建立的正确性。

图3 瞬态温度场云图(t=20 s)

Fig. 3 Cloud picture of transient temperature field (t=20 s)

2.3 激振力的确定

激振力大小需要通过激振装置沿铝板厚度方向的加载深度来度量。通过功率超声波产生的磁致伸缩应力对薄板进行激振[17],磁致伸缩应力与磁感应强度具有如下关系:

(5)

(5)

式中:Tm为磁致伸缩应力;Y为弹性模量;B为磁感应强度;K(B)为磁致伸缩应力常数,是关于B的函数。

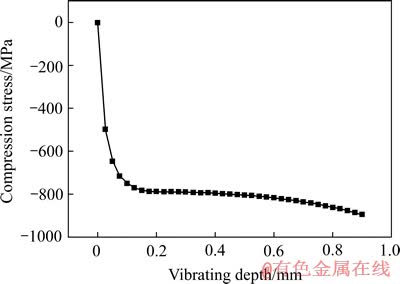

利用MARC对超声波激振装置在铝合金薄板上不同加载深度产生的激振力进行模拟,找出了压应力与加载深度的对应非线性关系曲线,如图4所示。从图4中可以看出,随着加载深度的增加,产生的压应力逐渐增大;加载深度在0~0.1 mm之间时,压应力变化趋势明显,显著增大;当加载深度超过0.1 mm时,应力变化趋势变缓。

图4 加载冲击深度与压应力关系

Fig. 4 Relationship between vibration depth and compressive stress

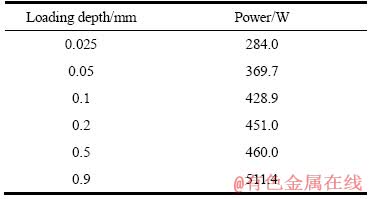

计算得出加载深度与激振功率的对应关系如表2所示。当加载深度为0.025 mm,超声波激振装置的激振功率为284 W,符合实际的激振功率。因而,选用0.025 mm作为模拟激振作用的深度。

表2 不同加载深度下的激振功率

Table 2 Vibration power under different loading depths

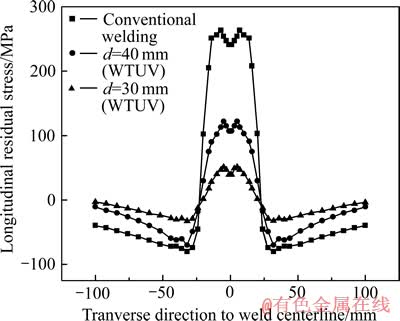

2.4 激振距离对纵向残余应力的影响

常规焊和超声波焊条件下模型焊缝长度方向中心横截面A-A上纵向残余应力分布如图5所示。从图5中可以看出,纵向焊接残余应力对称分布于焊缝两侧,焊缝及其附近区域为残余拉应力,焊缝中心应力比较低,最大拉应力出现在距焊缝中心线一定距离的位置,而远离焊缝区域的纵向残余应力为压应力。常规焊残余拉应力峰值为263 MPa约为0.8σs,残余压应力峰值为-80.3 MPa,符合铝合金薄板的实际焊接情况[13]。

采用随焊超声波激振法后,加载冲击与激振距离(d)为40 mm时,焊后残余拉应力和压应力峰值分别为122 MPa和-70 MPa;当d=30 mm时,焊后最大残余拉应力和压应力峰值分别为51 MPa和-32.6 MPa。由此可见,随焊超声波激振法能够显著降低焊后残余应力,且d=30 mm时,残余压应力等效平均值为15.3 MPa,低于该尺寸薄板的临界失稳应力值22.2 MPa(由公式(6)计算得到),此时变形消失,得到控制。

=22.2 MPa (6)

=22.2 MPa (6)

式中:k为屈曲系数,与应力分布和边界条件有关;E为弹性模量;δ为板厚;μ为泊松比;b为板的长度。

图5 不同激振距离下中截面(A-A面)残余应力分布

Fig. 5 Residual stress distribution under different vibration distance in middle cross-section (A-A section)

3 超声波激振法焊接试验

为验证模拟结果的正确性,自行研制了专用装置,并进行了焊接试验,如图6所示。试验材料选用LY12硬铝合金薄板,实际尺寸为320 mm×200 mm×2 mm。焊接方法采用TIG焊,焊接电流95 A,焊接速度4 mm/s,氩气流量17 L/min,激振功率300 W。

图6 随焊超声波激振控制装置

Fig. 6 Control device of welding with trailing ultrasonic vibration

3.1 有效激振距离对焊接过程的影响

激振端与热源之间有效激振距离D的范围从15 mm到40 mm变化,对铝合金薄板挠曲变形与应力进行试验研究。结果表明:当D范围为15 mm到18 mm时,由于激振装置作用于完全塑性状态的焊缝金属区,激振过程中会发生“打滑”或者“粘头”现象,造成焊接试验的中断;当D大于37 mm时,由于作用区的焊缝金属已完全凝固,激振装置的激振已经无法使焊缝金属产生塑性流动,因此,无法减小焊接残余应力;最终确定有效激振区域为18~37 mm,在此范围内能够减小激振试板残余应力及变形,与模拟结果提供的参考值相吻合。

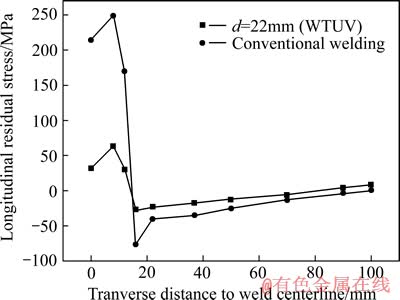

3.2 纵向焊接残余应力测试

采用切条法,对比分析铝合金薄板常规焊与随焊超声波激振 (d =22 mm)的纵向残余应力。在薄板试件上选择X为160 mm处的横截面作为纵向残余应力测量截面。由于焊后纵向残余应力分布对称于焊缝[13],只需粘贴一半的应变片即可,将电阻应变片从焊缝到板边一侧由密到疏贴于薄板上,沿试验位置切条后,应力得到释放,利用CM-1A-20应变测量仪测出释放出的应变值,并按胡克定律换算成应力。

图7所示为常规焊与激振距离d为22 mm的随焊超声波激振法焊后试件中截面纵向残余应力分布测试曲线。对比图5可以看出,纵向残余应力分布曲线与模拟结果符合良好。采用本方法后,焊后最大残余拉应力值由常规焊的248 MPa(与模拟结果相比的误差为5.7%)降低到63 MPa;残余压应力峰值从-77 MPa降低到-27 MPa,均值小于该尺寸LY12薄板的临界失稳应力σcr,薄板挠曲变形完全消失。

图7 薄板焊后A-A面残余应力分布

Fig. 7 Residual stress distribution of A-A section after welding

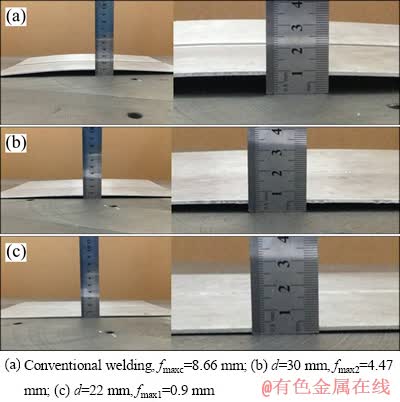

3.3 焊后挠曲变形的测量

为能直观地分析不同激振距离d下控制焊接变形的效果,文中选用常规焊与激振距离为22和30 mm两种比较典型距离下的随焊超声波激振试件进行了对比分析。不同激振距离d下,试板长度方向边缘挠度峰值,如图8所示。常规焊条件下,板边最大挠度fmaxc为8.66 mm,当激振距离d为30 mm时,板边最大挠度fmax2为4.47 mm;当激振距离d为22 mm时,板边最大挠度fmax1下降到0.9 mm,较常规焊降低了89.6%左右,薄板挠曲变形得到控制。

图8 板边最大挠度测量

Fig. 8 Maximum deflection measurement at edge of plate

不同激振距离下板边挠度的测量曲线如图9所示,当d=22 mm时,板边挠度曲线曲率最小;板长方向上相同位置的挠度常规焊最大,d=30 mm时,次之;d=22 mm,最小。结果表明:铝合金薄板在超声波的激振下能够有效的降低残余变形,且激振端与热源的最佳激振距离为d=22 mm。

图9 不同激振距离下的板边挠度

Fig. 9 Deflection of plate edges under different vibration distances

4 分析与讨论

焊接时,焊接热源经过焊接区,该区域被瞬间加热到材料的熔点,熔池附近的材料受热膨胀引起热变形和组织变形,并且受到周围较冷材料的约束,产生不均匀的压缩塑性变形;冷却阶段,产生压缩塑性变形的这部分金属因受到周围较冷金属的制约,阻碍了其自由收缩,使这部分金属受到一定的拉应力,产生拉伸塑性变形。如果在焊接过程中,能够减小加热阶段产生的压缩应变或者增大冷却阶段产生的拉伸应变,便能够在一定程度上降低焊接残余应力。此外,若薄板焊缝两侧的残余压应力低于该尺寸薄板的临界失稳应力,薄板的挠曲变形也能够完全消除。

本方法对焊接残余应力的控制主要取决于激振功率的大小和加载冲击与热源的距离。激振功率过大容易将焊缝金属击穿;过小则产生的激振力不足以对焊缝金属产生塑性延展,无法控制焊后残余应力。激振端与热源的距离亦要适当,若过大,焊接时超声激振装置处于完全凝固的焊缝金属区,激振力已无法使焊缝金属产生塑性流动,无法降低焊接过程产生的压缩塑性应变;若过小,激振装置由于直接激振“糊状”焊缝金属,导致焊接中断,皆对焊接变形没有明显作用。激振功率为300 W,激振端与热源距d=30 mm时,最大残余拉应力σ+max有所降低,由于拉压应力平衡,残余压应力σ-也随之减小,减小后的幅值仍大于σcr,薄板挠曲变形依然存在,但是挠度f变小,并且挠度随着σ-的减小而变小。当d=22 mm时,焊后残余应力显著降低,且残余压应力均值低于σcr,薄板挠曲变形完全消失。

5 结论

1) 从力学角度提出了控制薄板焊接残余应力及变形的新方法即随焊超声波激振法,建立了该方法原理模型,从数值模拟与焊接试验两个方面验证了该方法的可行性,丰富了控制焊接应力及变形的理论。

2) 利用数值模拟优化出了超声波激振功率与激振深度的对应关系,完成振幅与激振力、振幅与激振功率的匹配。

3) 随焊超声波激振法可有效地控制焊接应力及变形,针对文中给定的薄板试件尺寸,确定了有效激振范围d在18 mm到37 mm之间;其中d为22 mm时,随焊超声波激振焊后最大残余拉应力降为63 MPa,相比常规焊降低了76.6%;残余压应力峰值从-77 MPa降到-27 MPa,平均压应力值低于该尺寸LY12薄板的临界失稳应力σcr,薄板挠曲变形完全消失,板边挠度峰值由8.66 mm降低到0.9 mm,降幅为89.6%。

REFERENCES

[1] 万明珍, 张在强, 吕 鹏, 季 乐, 邹 阳, 蔡 杰, 关庆丰. 热循环作用下2A12铝合金的微观结构与性能[J]. 中国有色金属学报, 2013, 23(4): 939-943.

WAN Ming-zhen, ZHANG Zai-qiang,  Peng, JI Le, ZOU Yang, CAI Jie, GUAN Qing-feng. Microstructure and properties of 2A12 aluminum alloy under thermocycling[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 939-943.

Peng, JI Le, ZOU Yang, CAI Jie, GUAN Qing-feng. Microstructure and properties of 2A12 aluminum alloy under thermocycling[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 939-943.

[2] 郭绍庆, 徐文立, 刘雪松, 田锡唐. 温差拉伸控制铝合金薄板的焊接变形[J]. 焊接学报, 1999, 20(1): 34-41.

GUO Shao-qing, XU Wen-li, LIU Xue-song, TIAN Xi-tang. Control of welding distortion in thin aluminum alloy plate by thermal tensioning[J]. Transactions of the China Welding Institution, 1999, 20(1): 34-41.

[3] GUO S Q, LI X H, XU W L, LIU X S, WAN X, TIAN X T. Welding distortion control of thin Al alloy plate by static thermal tensioning[J]. Journal of Material Science & Technology, 2001, 17(1): 163-164.

[4] 符 浩, 刘希林, 卢 海, 张 浩, 李 宁. 钛合金焊接接头残余应力的消除方法[J]. 中国有色金属学报, 2010, 20(S1): s713-s716.

FU Hao, LIU Xi-lin, LU Hai, ZHANG Hao, LI Ning. Relieving residual stress of titanium alloy welded joint[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s713-s716.

[5] LIU X S, WANG P, ZHOU G T, FANG H Y. Controlling of stress and distortion in thin copper plate by welding with trailing peening[J]. Rare Metals, 2007, 26(Sl): 216-219.

[6] 范成磊, 方洪渊, 杨建国, 王霄腾, 黎 明. 随焊冲击碾压控制焊接应力变形新方法[J]. 机械工程学报, 2004, 40(8): 87-90.

FAN Cheng-lei, FANG Hong-yuan, YANG Jian-guo, WANG Xiao-teng, LI Ming. New technology to control welding stress and distortion with trailing and impactive rolling[J]. Chinese Journal of Mechanical Engineering, 2004, 40(8): 87-90.

[7] 初雅杰, 李晓泉, 吴申庆. 热碾压对AZ31镁合金焊接接头组织和性能影响[J]. 中国有色金属学报, 2011, 21(11): 2739-2743.

CHU Ya-jie, LI Xiao-quan, WU Shen-qing. Effect of hot rolling on microstructure and mechanical properties of welded joints of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2739-2743.

[8] 周广涛, 刘雪松, 方洪渊. 纵向预置应力法控制薄板焊接残余应力与变形[J]. 机械工程材料, 2008, 32(3): 78-81.

ZHOU Guang-tao, LIU Xue-song, FANG Hong-yuan. Controlling of welding residual stress and deflection distortion for flat plate by longitudinal pre-stress method[J]. Materials for Mechanical Engineering, 2008, 32(3): 78-81.

[9] 周广涛, 刘雪松, 杨建国, 闫德俊, 方洪渊. 预置横向挤压载荷法防止铝合金薄板焊接热裂纹[J]. 中国有色金属学报, 2009, 19(4): 613-618.

ZHOU Guang-tao, LIU Xue-song, YANG Jian-guo, YAN De-jun, FANG Hong-yuan. Transverse compressive pre-stress method for controlling welding hot cracking of aluminum thin-plate[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(4): 613-618.

[10] LI Yuan-xing, ZHAO Wei-wei, LENG Xue-song, FU Qiu-jiao, WANG Lei, YAN Jiu-chun. Microstructure evolution and mechanical properties of ultrasonic-assisted soldering joints of 2024 aluminum alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1937-1943.

[11] YAO Lei, HAO Hai, JI Shou-hua, FANG Can-feng, ZHANG Xing-guo. Effects of ultrasonic vibration on solidification structure and properties of Mg-8Li-3Al alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1241-1246.

[12] 李英龙, 李宝绵, 刘永涛, 高彩茹, 戴恩泰. 功率超声对Al-Si合金组织和性能的影响[J]. 中国有色金属学报, 1999, 9(4): 719-722.

LI Ying-long, LI Bao-mian, LIU Yong-tao, GAO Cai-ru, DAI En-tai. Effect of high-intensity ultrasonic on structures and properties of Al-Si alloys[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 719-722.

[13] 方洪渊. 焊接结构学[M]. 北京: 机械工业出版社, 2010: 62-71.

FANG Hong-yuan. Welding structure[M]. Beijing: China Machine Press, 2010: 62-71.

[14] UEDA Y, RASHED S M H, ABDEL-NASSER Y. An improved ISUM rectangular plate element taking account of post-ultimate strength behavior[J]. Marine Structures, 1994, 7(2/5): 139-172.

[15] HE Zhen-bo, PENG Yong-yi, YIN Zhi-min, LEI Xue-feng. Comparison of FSW and TIG welded joints in Al-Mg-Mn-Sc-Zr alloy plates[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1685-1691.

[16] GOLDAK J, CHAKRAVARTI A, BIBBY M. New finite element model for welding heat sources[J]. Metallurgical Transactions B, 1984, 15B(2): 299-305.

[17] 谢海涛, 斯永敏, 杨德明, 刘希从. 超磁致伸缩薄膜材料及其应用[J]. 中国有色金属学报, 2000, 10(Sl): s266-s270.

XIE Hai-tao, SI Yong-min, YANG De-ming, LIU Xi-cong. Giant magnetostrictive thin film and its application[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): s266-s270.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51075158);福建省自然科学基金资助项目(2012J01212)

收稿日期:2013-07-11;修订日期:2013-11-26

通信作者:周广涛,副教授,博士;电话:18650002711;E-mail: zhouguangtao@hqu.edu.cn