剥落腐蚀对7055铝合金板材力学性能的影响

廖文博1, 2,刘心宇1, 2,刘胜胆1,张新明1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 桂林电子科技大学 广西信息材料重点实验室,广西 桂林,541004)

摘要:通过室温拉伸、金相显微镜和扫描电镜研究剥落腐蚀(腐蚀时间为0~48 h)对7055铝合金板材力学性能的影响。研究结果表明:随着腐蚀时间的延长,板材的强度和伸长率在最初6 h内快速下降,6 h后慢速下降;腐蚀24 h后,板材的抗拉强度降至500 MPa以下,伸长率降至1%左右;腐蚀48 h后,板材的强度和伸长率分别下降约28%和87%;剥落腐蚀后板材表层产生了大量的沿晶腐蚀裂纹和腐蚀缺口;在拉伸时,腐蚀缺口处产生应力集中,增加了裂纹源数量,这是力学性能下降的主要原因。

关键词:7055铝合金;剥落腐蚀;力学性能

中图分类号:TG174.3 文献标志码:A 文章编号:1672-7207(2012)06-2137-05

Effect of exfoliation corrosion on mechanical properties of 7055 aluminum alloy sheet

LIAO Wen-bo1, 2, LIU Xin-yu1, 2, LIU Sheng-dan1, ZHANG Xin-ming1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Guangxi Key Laboratory for Information Materials, Guilin University of Electronic Technology, Guilin 541004, China)

Abstract: The effect of exfoliation corrosion on the mechanical properties of 7055 aluminum alloy sheet was investigated by ambient tensile testing, optical microscopy and scanning electron microscopy. The results show that with the increase of the corrosion exposure time, both strength and elongation decrease rapidly within the initial 6 h and then slowly after 6 h. After corrosion exposure for 24 h, the ultimate strength is decreased to below 500 MPa and elongation is decreased to about 1%. After 48 h the strength and elongation are decreased by about 28% and 87%, respectively. Exfoliation corrosion exposure leads to a number of intergranular cracks and corrosion notches in the surface layer of the sheet. During the tensile test, stress concentration occurs at the bottom of corrosion notches, and thus the number of crack sources is increased, which is supposed to primarily be responsible for the decrease in the mechanical properties.

Key words: 7055 aluminum alloy; exfoliation corrosion; mechanical properties

高强铝合金一直用作飞机的结构材料。在实际服役条件下尤其是沿海环境,这些铝合金材料往往会发生局部腐蚀。剥落腐蚀是其中的一种典型形式,会导致材料表面金属分层甚至和基体剥离[1]。剥落腐蚀可降低铝合金的拉伸性能[2-4]、疲劳性能[5-6]和断裂韧 性[2, 7]等性能,无疑这对飞机的安全构成严重威胁。因此,研究剥落腐蚀对铝合金材料力学性能的影响显得尤为重要,这可为飞机设计选材、评价材料的可靠性及预测材料的使用寿命提供依据。7000系铝合金是热处理强化合金,时效后可获得很高的强度,是飞机的典型结构材料。剥落腐蚀也是该系铝合金一种常见的局部腐蚀形式[6, 8]。随着航空工业的发展,不仅要求结构材料具有更高强度,而且要具有更好的耐腐蚀性能。为了使7000系合金兼备高强耐蚀性能,人们在热处理制度方面进行了大量研究[8-12],开发的T77工艺可使合金获得接近T6态的强度和近T73态的耐腐蚀性能,通常被认为是一种基于回归再时效(RRA)的三级时效处理工艺[11-12]。如7055铝合金经T77处理后,具有较高的强度、良好的耐蚀性及较高的韧性等综合性能,被用于制备军用运输机及大型客机的上翼蒙皮、龙骨梁等关键承力构件[13]。人们对该系合金的耐腐蚀性能及其机理进行了大量研究[8-10, 14-15],但就剥落腐蚀对其力学性能的影响的研究较少[5-6]。为此,本文作者以7055铝合金板材为对象,通过剥落腐蚀加速实验,研究腐蚀时间对其强度和伸长率的影响规律,并通过金相显微镜和扫描电镜对其原因进行分析和讨论。

1 实验

1.1 实验材料

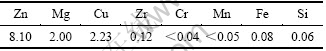

研究的是材料厚度为2 mm的7055铝合金板材,其化学成分如表1所示。板材于盐浴炉中经470 ℃/1 h固溶后淬入室温水中,然后进行回归再时效处理,即121 ℃/24 h+190 ℃/0.5 h+水淬+121 ℃/24 h。

表1 7055铝合金板材的化学成分(质量分数)

Table 1 Chemical compositions of studied 7055 aluminum alloy sheet %

1.2 腐蚀实验

按国际标准GB/6497—14将板材加工成拉伸试样,经粗磨、细磨后依次用NaOH和HNO3溶液进行表面处理,然后用清水冲洗干净,晾干。试样留出中间标距为30 mm的区域,其余部分用松香封住。剥落腐蚀(EXCO)浸泡按国家标准GB/T 22639—2008进行,腐蚀液为:234 g NaC1+50 g KNO3+6.3 mL HNO3加蒸馏水稀释至1 L,容面比为15 mL/cm2。试验在(25±3) ℃的恒温水浴箱中进行,试样在腐蚀液中分别浸泡3,6,12,24和48 h后取出用水漂洗,在浓硝酸中浸泡30 s再次用水漂洗,然后吹干。采用Olympusμ760数码相机记录样品腐蚀后的表面形貌。

1.3 性能检测及分析

测试板材腐蚀前后(0~48 h)及去除了表面腐蚀层样品(腐蚀48 h)的拉伸性能。拉伸实验在CSS-44100电子万能试验机上进行,测得屈服强度σ0.2、抗拉强度σb及伸长率δ5,取3个平行样品进行测量。

板材腐蚀后切取样品制备金相观察腐蚀情况,金相样品经粗磨、细磨及抛光后在XJP-6A金相显微镜上进行观察。采用FEI Quanta 200扫描电镜(SEM)对拉伸断口进行观察和分析。

2 实验结果

2.1 室温拉伸性能

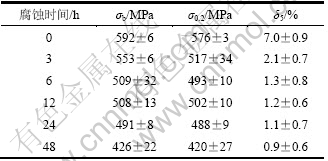

表2所示为7055铝合金板材腐蚀不同时间后的拉伸性能。由表2可知:经剥落腐蚀后,7055铝合金板材的强度和伸长率都降低;腐蚀24 h后,板材的抗拉强度降至500 MPa以下,伸长率也降至1.1%;腐蚀48 h后伸长率降至0.9%,屈服强度和抗拉强度接近。以未腐蚀板材的性能P(0)为基准,计算腐蚀不同时间后性能P(t)的下降程度ΔP(t):

ΔP(t)=[(P(0)-P(t))/P(0)] (1)

表2 7055铝合金板材腐蚀前后的拉伸性能

Table 2 Tensile properties of 7055 aluminum alloy sheet before and after corrosion

计算结果与腐蚀时间的关系如图1所示。腐蚀时间对2024和2091等铝合金的拉伸性能的下降程度的影响可用以下关系表示[3]:

ΔPs(t)=C×tn (2)

ΔPe(t)=A(1-e-kt) (3)

其中:ΔPs(t)为强度下降幅度;ΔPe(t)为伸长率下降幅度;t为腐蚀时间,C,A,n和k都为拟合得到的常数。采用式(2)和(3)对图1中的实验数据进行拟合,得到7055铝合金板材拉伸性能下降程度与剥落腐蚀时间的关系式如下。

屈服强度下降程度:

ΔPys(t)=6.17×t0.356 (4)

抗拉强度下降程度:

ΔPus(t)=4.86×t0.440 (5)

伸长率下降程度:

ΔPe(t)=84.7×(1-e-0.576t) (6)

根据式(4)~(6)绘制的曲线如图1所示。在所研究的时间范围内,上述关系式可较好地描述腐蚀时间对拉伸性能下降程度的影响规律。当腐蚀时间相同时,板材的屈服强度和抗拉强度的下降程度相差不大,但明显小于伸长率的下降程度;在最初6 h,板材的强度和伸长率的下降程度迅速增大,强度下降约15%,而伸长率下降程度达80%;随着腐蚀时间的延长,强度和伸长率的下降程度缓慢增加,至48 h时,强度下降约28%,伸长率下降87%。由此可知:腐蚀对板材的伸长率比强度有更大的影响。

图1 7055铝合金板材拉伸性能下降程度与剥落腐蚀时间的关系

Fig.1 Relationship between drop percentage in tensile properties of 7055 aluminum alloy sheet and exfoliation corrosion exposure time

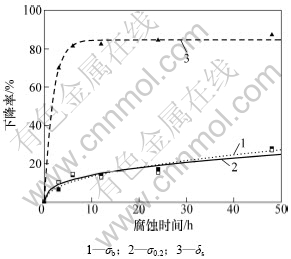

2.2 腐蚀形貌

样品腐蚀后的表面形貌如图2所示。样品刚放入溶液中时表面出现大量的气泡,腐蚀3 h后表面有些腐蚀迹象,并开始变色;约6 h后表面气泡明显减少,腐蚀迹象更加明显,分布不均匀,表面颜色变化不大,如图2(a)所示;腐蚀12 h时,在样品表面可观察到一些小爆皮(PC级),而其他区域未见明显的腐蚀,如图2(b)所示;腐蚀时间延长至24 h时,样品表面均为深灰红色的腐蚀产物所覆盖,一些腐蚀产物已脱落并沉到容器底部(EA级),如图2(c)所示;至48 h时,样品表面脱落的腐蚀产物增加,腐蚀更加深入到样品内部(EB级),如图2(d)所示。

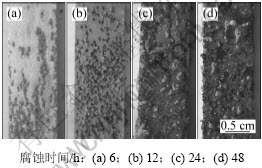

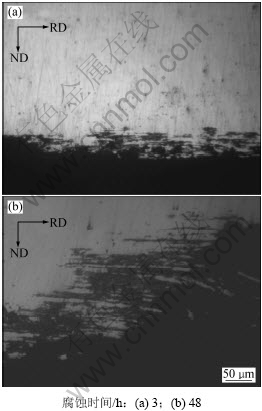

图3所示为7055铝合金板材剥落腐蚀后截面的金相照片。当腐蚀时间较短时,样品表层可观察到沿晶腐蚀迹象(如图3(a)所示),此时,腐蚀深度较小;随着时间延长,腐蚀不断地沿着晶界进行,深入到样品内部,同时,由于腐蚀产物膨胀产生的力将表层的金属顶起而呈层状脱落,如图3(b)所示。此外,由于腐蚀沿着晶界进行,将晶粒的形状衬托出来。

图2 样品腐蚀不同时间后的表面形貌

Fig.2 Surface morphology of specimen after corrosion exposure for different time

图3 样品腐蚀后的截面的金相照片(RD:轧向,ND:法向)

Fig.3 Optical micrographs of cross-section of specimen after corrosion

2.3 断口形貌

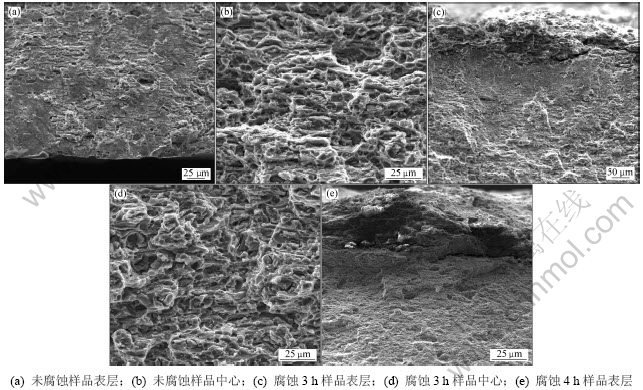

通过扫描电镜对样品的断口观察发现:在样品的中心部分,腐蚀对其断裂特征几乎没有影响,但在样品表层有较大的差别,典型的SEM照片如图4所示;对于未腐蚀样品,拉伸断口表层呈现出典型的准解理特征(见图4(a));而中心是典型的韧性断裂特征,以穿晶韧断为主,可观察到大量的韧窝(见图4(b));经过 3 h腐蚀后,样品拉伸断口从表层至中心可分成3个区域,如图4(c)所示。表层为沿晶断裂层,可观察到很多沿晶裂纹,显然为表层发生了腐蚀的区域;次表层呈现准解理特征,中心层仍主要是穿晶韧断,都与未腐蚀样品的表层类似;随着腐蚀时间的延长,表面的腐蚀层厚度不断增加(如图4(e)所示),不仅可观察到沿晶裂纹,还可观察到一些白色的腐蚀产物。

图4 7055铝合金样品拉伸断口的SEM照片

Fig.4 SEM images of fracture surface of 7055 aluminum alloy after tensile testing

3 分析与讨论

经过剥落腐蚀后,7055铝合金板材表面遭受损伤,出现了大量的沿晶微裂纹和腐蚀缺口(图2和图3)。开始时腐蚀较轻微,虽都沿着晶界发生并扩展,但几乎未看到剥落的迹象。随着时间的延长,腐蚀顺着晶界沿板材轧向和法向扩展,腐蚀产物不断增多,体积膨胀,产生的楔力导致微裂纹形成,表层的金属甚至被顶起而与基体脱离,出现一些腐蚀缺口(如图3(b)所示)。在拉伸过程中,这些腐蚀缺口底部易产生应力集中,而产生的沿晶微裂纹可充当裂纹源,拉应力的作用促使这些微裂纹沿着晶界快速扩展,因此,板材的拉伸强度尤其是伸长率大大降低。随着腐蚀时间的不断延长,板材的损伤程度不断增加,腐蚀得更深,导致拉伸性能不断降低。

将腐蚀48 h后的板材表面的腐蚀层去除再进行拉伸测试,发现板材的抗拉强度恢复至563 MPa,屈服强度恢复至487 MPa,伸长率恢复至5.4%;与未腐蚀的相比,下降程度大大减小,分别约为5%,15%和23%。由表2和图1可知:表面腐蚀层对拉伸性能有很大的不利影响。腐蚀层被除去后,表层的沿晶微裂纹和腐蚀缺口都被除去,因此,板材的拉伸性能得到恢复,但没有完全达到未腐蚀板材的水平。Petroyiannis等[16]通过研究发现,将2024铝合金板材表面腐蚀层去除后,其强度和伸长率虽然得到恢复,但仍未达到未腐蚀合金的水平,认为是腐蚀层下面的富氢脆性区的影响所致。本文作者发现,在7000系铝合金中亦存在同样的情况。其原因是腐蚀沿着晶界发展深入到板材的内部,产生的氢原子扩展至微裂纹附近的金属内部,从而降低了晶格的结合力,产生氢脆[17],降低板材的拉伸性能。但对于板材表面的腐蚀层和富氢脆性区的影响,腐蚀层的影响似乎明显更大,这可从板材去除腐蚀层后拉伸性能的恢复程度得到证明。对于强度的损失程度(约28%),腐蚀层产生的影响约占23%,富氢脆性区的影响约占5%;而对于伸长率的损失(约87%),腐蚀层的影响约占64%,富氢脆性区的影响约占23%。板材被腐蚀后,强度与伸长率永久性下降。板材表面的腐蚀层和基体的结合力大大降低,在拉伸过程中起不到承受载荷的作用,虽然去除表面腐蚀层可恢复强度和伸长率,但板材的实际承载面积更小,能承受的载荷也降低。本研究结果还表明:对于7000系合金,腐蚀后的拉伸性能下降程度与腐蚀时间存在一定的关系,这使得预测剥落腐蚀后材料的拉伸性能成为可能,但在实际应用中需要获得材料服役环境下的相关参数,情况更为复杂,这有待于进一步研究。

4 结论

(1) 剥落腐蚀后7055铝合金板材的拉伸性能降低,在最初6 h,强度和伸长率迅速降低,而后缓慢降低;腐蚀24 h后,板材的抗拉强度低于500 MPa,伸长率只有1%左右;强度的降低程度显著低于伸长率的降低程度。

(2) 板材腐蚀后表层出现大量的沿晶腐蚀裂纹和腐蚀缺口,拉伸时在缺口处产生应力集中,裂纹源的数量增加,这是拉伸性能降低的主要原因。

参考文献:

[1] Robinson M J, Jackson N C. The influence of grain structure and intergranular corrosion rate on exfoliation and stress corrosion cracking of high strength Al-Cu-Mg alloys[J]. Corrosion Science, 1999, 41(5): 1013-1028.

[2] Alexopoulos N D. On the corrosion-induced mechanical degradation for different artificial aging conditions of 2024 aluminum alloy[J]. Materials Science and Engineering A, 2009, 520 (1/2): 40-48.

[3] Pantelakis S G, Vassilas N I, Daglaras P G. Effects of corrosive environment on the mechanical behavior of the advanced Al-Li alloys 2091 and 8090 and the conventional aerospace alloy 2024[J]. Metall, 1993, 47(2): 135-141.

[4] Pantelakis S G, Daglaras P G, Apostolopoulos C A. Tensile and energy density properties of 2024, 6013, 8090 and 2091 aircraft aluminum alloy after corrosion exposure[J]. Theoretical and Applied Fracture Mechanics, 2000, 33(2): 117-134.

[5] Bellinger N C, Komorowski J P, Liao M, et al. Preliminary study into the effect of exfoliation corrosion on aircraft structural integrity[C]//6th Joint FAA/DoD/NASA Aging Aircraft Conference, 2002: 1-11.

[6] Chubb J P, Morad T A, Hockenhull B S. The effect of exfoliation corrosion on the fracture and fatigue of 7178-T6 aluminum[J]. Int J of Fatigue, 1995, 17(1): 49-54.

[7] Alexopoulos N D, Papanikos P. Experimental and theoretical studies of corrosion-induced mechanical properties degradation of aircraft 2024 aluminum alloy[J]. Materials Science and Engineering A, 2008, 498(1/2): 248-257.

[8] 刘胜胆, 游江海, 张新明, 等. 双重淬火对7055铝合金组织性能的影响[J]. 材料热处理学报, 2009, 30(6): 69-74.

LIU Sheng-dan, YOU Jiang-hai, ZHANG Xin-ming, et al. Influence of double quenching on microstructure and properties of 7055 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2009, 30(6): 69-74.

[9] 张新明, 游江海, 张小艳, 等. 固溶后预析出对7A55铝合金力学及腐蚀性能的影响[J]. 中国有色金属学报, 2007, 17(12): 1922-1927.

ZHANG Xin-ming, YOU Jiang-hai, ZHANG Xiao-yan, et al. Effect of pre-precipitation after solution on mechanical properties and corrosion resistance of aluminium alloy 7A55[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1922-1927.

[10] 郑子樵, 李红英, 莫志民. 一种7055型铝合金的RRA处理[J]. 中国有色金属学报, 2001, 11(5): 771-776.

ZHENG Zi-qiao, LI Hong-ying, MO Zhi-min. Retrogression and reaging treatment of a 7055 type aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 771-776.

[11] Holt R T, Parameswaran V R, Wallace W. RRA treatment of 7075-T6 aluminum components[J]. Canadian Aeronautics and Space Journal, 1996, 42(2): 83-87.

[12] Oliveira A F J, Barros M C, Cardoso K R. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys[J]. Materials Science and Engineering A, 2004, 379: 321-326.

[13] Williams J C, Starke J E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[14] Henon C, Pouget G, Warner T. Exfoliation corrosion mechanism:interplay between intergranular corrosion and stress corrosion cracking during exfoliation corrosion of AA7449[J]. Materials Science Forum, 2006, 519/520/521: 693-698.

[15] Li J F, Jia Z Q, Birbilis N. Exfoliation corrosion of 7150 Al alloy with various tempers and its electrochemical impedance spectroscopy in EXCO solution[J]. Materials and Corrosion, 2009, 60(6): 407-414.

[16] Petroyiannis P V, Kamoutsi E, Kermanidis A T. Evidence on the corrosion-induced hydrogen embrittlement of the 2024 aluminium alloy[J]. Fatigue Frac Engng Mater Struct, 2005, 28: 565-574.

[17] Bobby Kannan M, Raja V S. Hydrogen embrittlement susceptibility of over aged 7010 Al-alloy[J]. Journal of Materials Science, 2006, 41(17): 5495-5499.

(编辑 陈灿华)

收稿日期:2011-06-18;修回日期:2011-08-09

基金项目:湖南省科技厅计划项目(2010GK3116)

通信作者:刘胜胆(1980-),男,江西吉水人,博士,副教授,从事轻合金材料组织与性能的研究;电话:0731-88830265;E-mail:csuliusd@163.com