DOI: 10.11817/j.issn.1672-7207.2020.09.005

挤压比对Mg-Gd-Ni合金微观组织、力学及腐蚀性能的影响

万佳,刘楚明,许诗源,王必正

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:制备3种挤压比分别为7.0,9.6,19.6的Mg-1.5Gd-0.2Ni(质量分数,%)合金,研究挤压比对合金微观组织、力学性能及腐蚀性能的影响。研究结果表明:随着挤压比从7.0增加至19.6,Mg基体再结晶越充分,其组织更加细小、均匀,因而提高了合金的综合力学性能。当挤压比为19.6时,合金的抗拉强度为228 MPa,屈服强度为167 MPa,断后伸长率为22.5%。挤压态合金在质量分数为3%KCl中的腐蚀速率比铸态合金的低。

关键词:镁合金;挤压比;力学性能;腐蚀性能

中图分类号:TG113.25;TG379;TG178 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)09-2405-08

Effect of extrusion ratio on microstructure, mechanical and corrosion properties of Mg-Gd-Ni alloy

WAN Jia, LIU Chuming, XU Shiyuan, WANG Bizheng

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The Mg-1.5 Gd-0.2 Ni (mass fraction, %) alloys with three kinds of extrusion ratio (7.0, 9.6, 19.6) were prepared. The effects of extrusion ratio on microstructure, mechanical properties and corrosion properties of Mg-1.5 Gd-0.2 Ni alloy were investigated. The results show that as the extrusion ratio increases from 7.0 to 19.6, α-Mg grains are more sufficiently dynamic recrystallized, achieving the finer and more uniform microstructure as well as the improved comprehensive properties. The alloy with extrusion ratio of 19.6 exhibits the ultimate tensile strength of 228 MPa, tensile yield strength of 167 MPa, and elongation of 22.5%. The corrosion rate of the as-extruded alloys in 3% (mass fraction) KCl is much lower than that of the as-cast alloy.

Key words: magnesium alloys; extrusion ratio; mechanical properties; corrosion performance

可溶镁作为一种结构/功能一体化材料,在开发低渗透非常规油气资源中具有很大的应用价值[1-2]。结构/功能一体化是指可溶镁既要达到一定的力学性能,比如高伸长率,又能在电解质中自行快速溶解,这对合金的成分设计和塑性加工提出了较高的要求。在成分设计上,合金元素的选择既要保证合金的力学性能,又要确保其实现快速溶解。近年来,Mg-Gd系合金备受关注[3]。少量Gd元素的添加对合金起到固溶强化的作用[4],同时可以通过影响塑性变形中的组织演变来提高合金的伸长率。如HADORN等[5]指出,经相同的挤压变形后,Mg-0.06Gd (原子数分数,%)合金的织构要显著弱于Mg-0.01Gd (原子数分数,%)合金的织构,这是由于相对较高的Gd含量更容易形成原子团簇和晶界偏聚,进而对晶界迁移和旋转起到钉扎作用。而在对Mg-1.5Gd (质量分数,%)和AZ31合金热压缩变形行为的对比研究中发现[6],相比于AZ31合金,Mg-1.5Gd (质量分数,%)在热变形过程中会形成更小的再结晶晶粒,并且在其变形晶粒内部产生了更高的储能,导致其更容易发生完全再结晶。此外,TANG等[7]利用密度泛函理论系统研究了单独或混合添加Gd和Y元素对Mg的基面和一级柱面的广义平面层错能(GPFE)的影响,结果表明,Gd或Y的添加可以显著降低GPFE,尤其是柱面GPFE,有效促进了柱面滑移的发生,使得Mg-Gd(Y)合金具有比纯Mg更强的塑性变形能力。不难理解,通过弱化变形织构、制备完全再结晶及细晶组织、促进非基面滑移的开动,少量Gd的添加可以有效提高Mg的伸长率。而向Mg-Gd中加入少量Cu,Fe,Ni和Co等元素时,会极大降低合金的耐蚀性[8],因为这些元素会促进电偶腐蚀而加速合金的溶解。也就是说,这些元素的添加显著提高了合金的可溶性。特别是,向Mg-Gd中添加Ni还可能形成LPSO相[9],能在提高合金强度的基础上又进一步提高合金的伸长率[10]。GONZALES等[11]确定了Mg-Gd-Ni合金中的14H型LPSO相并报道了该相的热稳定性。LIU等[12]认为Ni取代Zn可以提高合金的强度和塑性。因此,低Gd和Ni含量的Mg-Gd-Ni合金可以作为高延展性可溶镁的成分设计方案之一。如前所述,Gd元素主要通过影响合金塑性变形中的组织演变来改善其力学性能,而挤压作为最常见的热变形方式,具备工艺简单、变形量大、成型性好等优点,可以实现大批量各类型材的生产[13-16],因此,本文作者研究不同挤压比(ER)对Mg-1.5Gd-0.2Ni (质量分数,%)合金显微组织、力学性能和腐蚀性能的影响,以期为可溶镁合金成分设计及组织和性能调控提供参考。

1 实验材料和方法

1.1 材料制备

采用半连续电磁铸造技术制备直径为310 mm、名义成分为Mg-1.80Gd-0.20Ni (质量分数,%)的合金铸锭。铸锭所用原料为质量分数为99.9%高纯镁、Mg-30Gd (质量分数,%)和Mg-30Ni (质量分数,%)中间合金,熔炼在750 ℃下进行,并在SF6和CO2体积比为1:99的混合气体保护下浇铸。利用ICP测得铸锭的实际成分为Mg-1.54Gd-0.20Ni (质量分数,%)。铸锭经400 ℃/24 h均匀化处理后,进行室温水淬。对均匀化态合金进行挤压变形,挤压温度为390 ℃,挤压速度为0.6 mm/s,挤压比分别为7.0,9.6和19.6(在文中分别标注为ER7.0,ER9.6及ER19.6样品)。

1.2 显微组织表征和力学性能测试

对挤压前后、不同状态的样品分别进行光学显微镜(OM)、X线衍射(XRD)、扫描电子显微镜(SEM)以及电子背散射衍射(EBSD)表征。OM观察在Leica光学显微镜上进行。样品经砂纸打磨后,用4%HNO3+96%乙醇(体积分数)溶液腐蚀。XRD物相分析和SEM相表征分别在D/Max 2500 X线衍射仪和配有EDS能谱仪的FEI Sirion200场发射扫描电镜上进行。对均匀化态和挤压态样品进行EBSD观察,其观察面分别平行于铸锭心部和挤压棒材的纵截面。EBSD观察在配有HKL EBSD系统的HELIOS Nanolab 600i扫描电镜上进行,步长为2.6 μm,对每种状态样品至少扫描1 000个晶粒。EBSD数据采用Channel 5软件进行分析,并利用线性截距法计算再结晶晶粒的平均晶粒粒度。室温拉伸实验在Instron3369万能拉伸试验机上进行,拉伸速率为1 mm/min,拉伸试样呈“狗骨头”形状,其平行段的直径×长度为5 mm×25 mm。为确保数据准确性,每个状态样品至少测试3根试样。

1.3 腐蚀性能测试

分别从ER7.0,ER9.6和ER19.6样品上切取长×宽×厚为20 mm×20 mm×4 mm的薄片,薄片法线方向与挤压方向垂直。每个状态各取3个平行样进行浸泡实验,在浸泡实验前将试样打磨、干燥并称质量,放置在温度为(25±0.5) ℃、质量分数为3% KCl溶液中浸泡12 h。浸泡后,取出试样在超声波清洗仪中用铬酸溶液(18% CrO3+1% AgNO3+81%蒸馏水,质量分数)清洗腐蚀产物15 min,温度为25 ℃,再用酒精清洗试样至酒精不变色,然后干燥并称质量,再根据下式计算腐蚀速率:

(1)

(1)

式中:v为腐蚀速率,g/(cm2·h);m和m0分别为腐蚀前后的质量,g;S为金属的表面积,cm2;t为腐蚀时间,h。

2 结果与分析

2.1 挤压比对Mg-1.5Gd-0.2Ni合金微观组织的影响

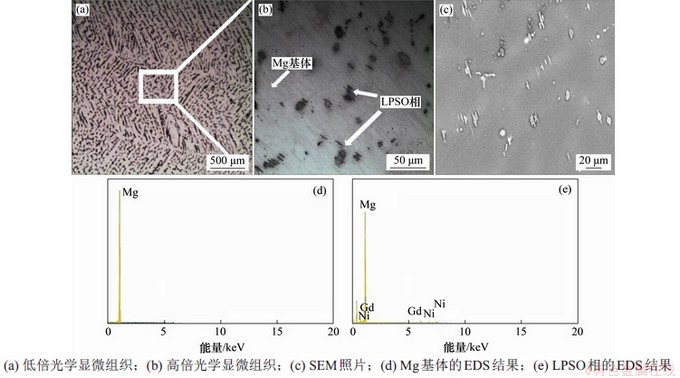

不同状态Mg-1.5Gd-0.2Ni合金的微观组织如图1所示。铸态合金由树枝状的镁基体和枝晶臂间层片状的第二相构成,呈典型的枝晶结构,这是因为合金在快速凝固的过程中发生了非平衡凝固[17]。研究表明[17],该层片状的第二相为具有18R结构的LPSO相。对铸态合金进行SEM及EDS能谱分析,结果如图1(c)和(e)所示,结果表明镁基体由100%的Mg原子组成,而并未探测到固溶原子,这可能源于EDS测试略低的测量精度及固溶原子易形成LPSO相的倾向。而LPSO相由Mg,Gd和Ni这3种元素组成,且原子数分数分别为96.28%,2.25%和1.46%,这与YIN等[17]在Mg-Gd-Ni中发现的LPSO相成分一致。

图1 铸态Mg-1.5Gd-0.2Ni合金的光学显微组织及SEM和EDS结果

Fig. 1 Optical micrographs, SEM image and EDS results of as-cast Mg-1.5Gd-0.2Ni alloy

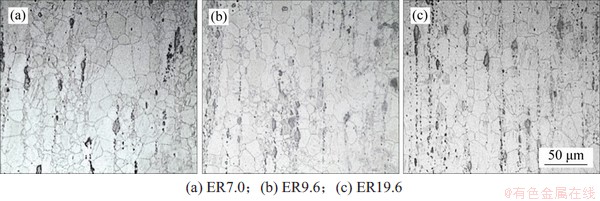

图2所示为3种不同挤压比合金棒材纵截面光学显微组织照片。由图2可见:挤压后合金中的LPSO相沿挤压方向排列形成流线,且晶粒粒度相对于铸态合金明显变小,这源于热挤压过程中充分发生的动态再结晶[18]。利用线性截距法求得ER7.0合金平均晶粒粒度为16.5 μm。当挤压比增大后,平均晶粒粒度随之减小。ER19.6合金平均晶粒粒度降为10.9 μm。ER7.0合金中虽有大量细小的再结晶晶粒,但也有被拉长的变形晶粒,相对高挤压比合金而言其组织均匀性最低。ER9.6合金中只有很少比例的粗晶,而ER19.6合金基本完全再结晶,呈细小、均匀、等轴分布。由此可见,增大挤压比(即累计应变量)有利于提高组织均匀性和细密程度。

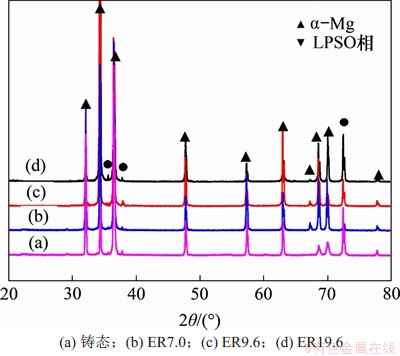

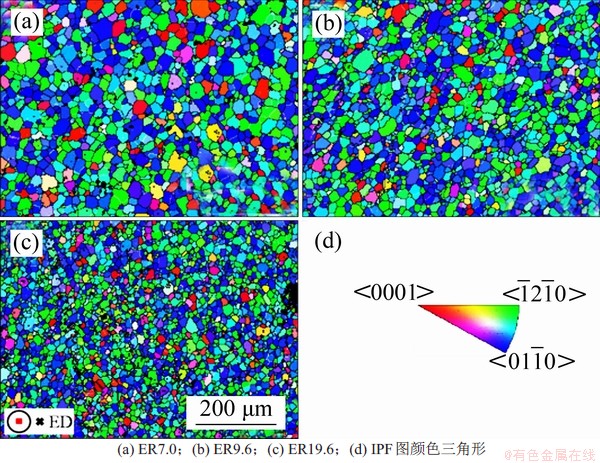

图3所示为铸态和不同挤压比状态下合金的XRD结果。由图3可知:合金经过挤压后,相的种类并未发生变化,仍由α-Mg和LPSO相组成。图4所示为不同挤压比的合金横截面的IPF图,其中颜色表示相对于样品法线(即ED)的晶体取向。挤压态合金晶粒粒度随挤压比增大而明显减小,且变得更加均匀,这与光学显微镜观察结果(图2)一致。各合金的晶粒颜色以绿色和蓝色居多,红色所占比例明显较低,结合颜色标识三角形可知挤压态合金晶粒的< >晶向与<

>晶向与< >晶向倾向与ED平行,表明挤压态合金存在晶粒的择优取向即织构。

>晶向倾向与ED平行,表明挤压态合金存在晶粒的择优取向即织构。

图2 3种不同挤压比合金的光学显微组织

Fig. 2 Optical microstructure of alloys with different extrusion ratios

图3 铸态和挤压态合金的XRD图谱

Fig. 3 XRD patterns of as-cast and as-extruded alloys

图4 挤压态合金的IPF图

Fig. 4 IPF maps of as-extruded alloys

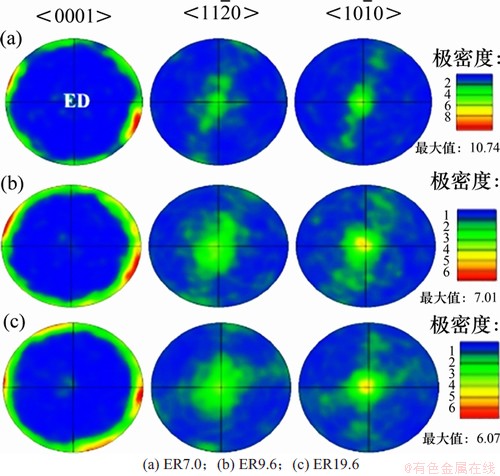

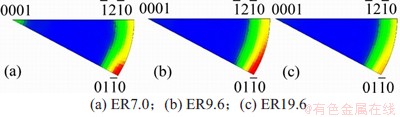

图5所示为各合金由EBSD数据衍生出的极图,图6所示为各合金相对于ED的反极图。由图5和图6可见:所有挤压态合金均展现出典型的基面织构特征,即α-Mg晶粒(0002)基面与ED方向平行。但不同于之前所报道的非稀土镁合金棒材的织构特征[19]。本文中α-Mg晶粒的< >轴并未取代<

>轴并未取代< >轴而形成<

>轴而形成< >平行于ED的丝织构,上述两晶向平行于ED的概率相当,在IPF图(图4)中也展现出了蓝色和绿色晶粒数量相近的趋势,这可能源于稀土元素的添加对织构的弱化作用[5]。当挤压比为7.0时,合金织构最强,极密度为10.7,织构强度随挤压比增加而减弱,这是因为动态再结晶有助于弱化织构[20]。

>平行于ED的丝织构,上述两晶向平行于ED的概率相当,在IPF图(图4)中也展现出了蓝色和绿色晶粒数量相近的趋势,这可能源于稀土元素的添加对织构的弱化作用[5]。当挤压比为7.0时,合金织构最强,极密度为10.7,织构强度随挤压比增加而减弱,这是因为动态再结晶有助于弱化织构[20]。

图5 挤压态合金EBSD衍生极图

Fig. 5 EBSD-derived pole figures of as-extruded alloys

图6 挤压态合金相对于挤压方向的反极图

Fig. 6 Inverse pole figures referring to extrusion direction of as-extruded alloys

2.2 挤压比对Mg-1.5Gd-0.2Ni合金力学性能的影响

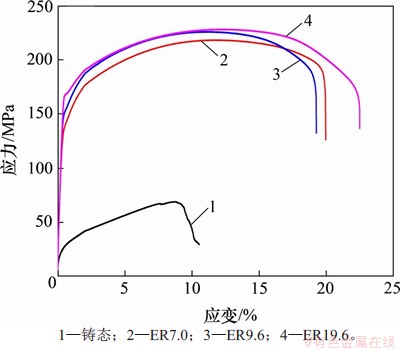

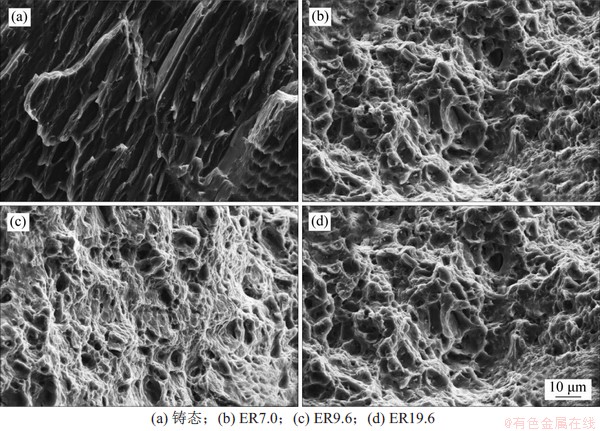

图7所示为不同状态样品的室温工程应力-应变曲线,对应的力学性能如表1所示,铸态合金的抗拉强度为147 MPa,屈服强度为55 MPa,伸长率为12.4%。ER7.0合金的抗拉强度为217 MPa,屈服强度为136 MPa,伸长率为19.9%。当挤压比增加为9.6时,ER9.6合金的抗拉强度和屈服强度分别提升为225 MPa和152 MPa,而伸长率略有下降。当挤压比增加到19.6时,ER19.6合金的抗拉强度和屈服强度为228 MPa和167 MPa,其屈服强度比ER7.0合金的屈服强度增加了22.8%,伸长率也增加了13.1%。图8所示为各状态拉伸试样的断口形貌,铸态合金的断裂类型为解理断裂,展现出偏脆性的断裂特征,而挤压态合金断口明显粗糙且存在许多韧窝,展现出了韧性断裂的特征,这与试样的伸长率相一致。相对于铸态合金而言,挤压态合金的晶粒粒度明显降低,晶粒内部和晶界附近的应力差较小,有效减少了应力集中现象。而且细小均匀的晶粒在拉伸变形的过程中可以相互协调,导致挤压态合金具有比较高的断裂伸长率。挤压态合金的伸长率差别不大,总体而言,ER19.6的伸长率最高,这可能是较弱的织构在一定程度上促进了其伸长率升高[21]。

表1 铸态及挤压态合金的拉伸性能

Table 1 Tensile properties of as-cast and as-extruded alloys

图7 铸态及挤压态合金合金的工程应力-应变曲线

Fig. 7 Typical engineering stress and strain curves of as-cast and as-extruded alloys

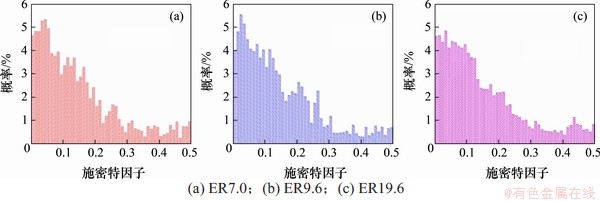

研究表明影响合金强度的主要机制包括固溶强化、细晶强化、沉淀强化、第二相强化及织构强化等[22]。图9所示为挤压态合金基于{0001} < >滑移系的施密特因子(SF)分布。由图9可知:3种挤压比下的施密特因子分布及平均施密特因子差别不大,可以认为织构的差别并不是引起不同挤压比合金屈服强度差异的主要原因。ER7.0的平均晶粒粒度为ER19.6的1.5倍(ER7.0和ER19.6的平均晶粒粒度分别为16.5和10.9 μm),根据细晶强化的Hall-Petch关系[23],晶粒粒度的较大差距是导致大挤压比试样的强度优于小挤压比试样的强度的主要原因,也是挤压态试样屈服强度明显高于铸态屈服强度的一个重要因素。此外,经统计,铸态合金中LPSO相的体积分数较高,为12.7%,平均长度为14.2 μm,平均直径为6.3 μm,3种挤压态合金中LPSO相体积分数相差不大,均为7.5%~8.5%,且平均长度为14.8~16.5 μm,平均直径为5.5~6.9 μm。虽然铸态合金具有更高的LPSO相体积分数,但其LPSO相的取向与分布较为随机,而挤压态中沿ED定向排列的LPSO相具备“短纤维强化”效应[24-26],可显著增强合金的抗拉强度,并且在材料变形的过程中,LPSO相能够形成扭折带[27],从而提高材料的屈服强度,这导致挤压态与铸态合金的强度差异更加显著。对于挤压态合金而言,它们之间的LPSO相体积分数和尺寸相差不大,因此,LPSO相不是引起它们力学性能出现差异的主要原因。

>滑移系的施密特因子(SF)分布。由图9可知:3种挤压比下的施密特因子分布及平均施密特因子差别不大,可以认为织构的差别并不是引起不同挤压比合金屈服强度差异的主要原因。ER7.0的平均晶粒粒度为ER19.6的1.5倍(ER7.0和ER19.6的平均晶粒粒度分别为16.5和10.9 μm),根据细晶强化的Hall-Petch关系[23],晶粒粒度的较大差距是导致大挤压比试样的强度优于小挤压比试样的强度的主要原因,也是挤压态试样屈服强度明显高于铸态屈服强度的一个重要因素。此外,经统计,铸态合金中LPSO相的体积分数较高,为12.7%,平均长度为14.2 μm,平均直径为6.3 μm,3种挤压态合金中LPSO相体积分数相差不大,均为7.5%~8.5%,且平均长度为14.8~16.5 μm,平均直径为5.5~6.9 μm。虽然铸态合金具有更高的LPSO相体积分数,但其LPSO相的取向与分布较为随机,而挤压态中沿ED定向排列的LPSO相具备“短纤维强化”效应[24-26],可显著增强合金的抗拉强度,并且在材料变形的过程中,LPSO相能够形成扭折带[27],从而提高材料的屈服强度,这导致挤压态与铸态合金的强度差异更加显著。对于挤压态合金而言,它们之间的LPSO相体积分数和尺寸相差不大,因此,LPSO相不是引起它们力学性能出现差异的主要原因。

图8 不同状态Mg-1.5Gd-0.2Ni合金的断口形貌

Fig. 8 Fracture morphologies of Mg-1.5Gd-0.2Ni alloys under different conditions

图9 挤压态Mg-1.5Gd-0.2Ni合金{0001}< >施密特因子分布

>施密特因子分布

Fig. 9 Distribution of {0001}< > Schmid factor of as-extruted Mg-1.5Gd-0.2Ni alloys

> Schmid factor of as-extruted Mg-1.5Gd-0.2Ni alloys

2.3 挤压比对Mg-1.5Gd-0.2Ni合金腐蚀性能的影响

图10所示为12 h的质量损失实验所得合金的腐蚀速率。与当今商业和工业上最常用的AZ31和ZK61对比,Mg-Gd-Ni合金呈现出优异的可溶解性。张凯[28]测得在常温下质量分数为3.5%NaCl溶液中持续浸泡12 h,铸态AZ31、ZK61和Mg-Gd-Ni合金的平均腐蚀速率分别为0.95,0.34和14.43 mg/(cm2·h),由此也可以看出Mg-Gd-Ni合金比一般商业合金的溶解性更好。由图10可知:铸态合金的腐蚀速率最高,为12.36 mg/(cm2·h),挤压态合金的耐蚀性强于铸态合金的耐蚀性。不同挤压比合金的腐蚀速率相差不大,相较而言,ER19.6合金溶解速率最低。挤压后合金的耐蚀性提高主要是由于晶粒细化。晶界具有更高的能量和更强的化学活性,高密度的晶界通过增加电子活度和扩散来增加表面的反应性,随着晶粒细化程度的增加,合金表面氧化膜成核位点增多,反应活性增加,这导致了氧化膜的快速形成[12],有效降低了腐蚀速率。此外,研究表明第二相尺寸的减小也有助于增加耐蚀性[29]。由于3种挤压态合金中LPSO相的尺寸相差不大,该因素对腐蚀性能的影响可以忽略。

图10 不同状态Mg-Gd-Ni合金浸泡在氯化钾溶液中12 h的腐蚀速率

Fig. 10 Corrosion rates of Mg-1.5Gd-0.2Ni alloys under different conditions immersed in potassium chloride solution for 12 h

3 结论

1) 铸态Mg-1.5Gd-0.2Ni合金为典型的枝晶状组织,α-Mg晶界附近存在块状的LPSO相,挤压变形导致α-Mg晶粒细化,且LPSO相沿挤压方向定向排列。随着挤压比由7.0增至19.6,合金的平均晶粒粒度由16.5 μm下降至10.9 μm。挤压态合金展现出典型的基面织构特征,即(0002)基面与挤压方向平行,且织构强度随挤压比增大而下降。

2) 粒度较小的晶粒及定向排列的LPSO相是挤压态合金的力学性能明显优于铸态合金力学性能的主要原因。均匀细小的再结晶晶粒及相对较弱的基面织构导致ER19.6合金展现出更优的综合力学性能。其抗拉强度为228 MPa,屈服强度为167 MPa,断后伸长率为19.5%。

3) 挤压变形能有效降低Mg-1.5Gd-0.2Ni合金的腐蚀速率,使合金的耐蚀性增强。

参考文献:

[1] 赵晨光, 刘继东, 刘计国, 等. 非常规天然气系统及其在中国的勘探前景[J]. 石油天然气学报, 2009, 31(3): 193-195.

ZHAO Chenguang, LIU Jidong, LIU Jiguo, et al. The current development and exploration future of the conventional gas in China[J]. Journal of Oil and Gas Technology, 2009, 31(3): 193-195.

[2] 张抗, 谭云冬. 世界页岩气资源潜力和开采现状及中国页岩气发展前景[J]. 当代石油石化, 2009, 17(3): 9-12.

ZHANG Kang, TAN Yundong. The status of world shale gas resources potential and production status as well as development prospect of China's shale gas[J]. Petroleum & Petrochemical Today, 2009, 17(3): 9-12.

[3] CAO Liang, LIU Wencai, LI Zhongquan, et al. Effect of heat treatment on microstructures and mechanical properties of sand-cast Mg-10Gd-3Y-0.5Zr magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 611-618.

[4] GAO Lei, CHEN Rongshi, HAN Enhou. Effects of rare-earth elements Gd and Y on the solid solution strengthening of Mg alloys[J]. Journal of Alloys and Compounds, 2009, 481(1/2): 379-384.

[5] HADORN J P, SASAKI T T, NAKATA T, et al. Solute clustering and grain boundary segregation in extruded dilute Mg–Gd alloys[J]. Scripta Materialia, 2014, 93: 28-31.

[6] STANFORD N, CALLAGHAN M D, DE JONG B. The effect of rare earth elements on the behaviour of magnesium-based alloys: part 1. hot deformation behaviour[J]. Materials Science and Engineering: A, 2013, 565: 459-468.

[7] TANG Lingling, LIU Wei, DING Zhigang, et al. Alloying Mg with Gd and Y: increasing both plasticity and strength[J]. Computational Materials Science, 2016, 115: 85-91.

[8] RAPP R A. Hot corrosion of materials: a fluxing mechanism[J]. Corrosion Science, 2002, 44(2): 209-221.

[9] PENG Qiuming, HOU Xiuli, WANG Lidong, et al. Microstructure and mechanical properties of high performance Mg-Gd based alloys[J]. Materials and Design, 2009, 30(2): 292-296.

[10] ZHENG Liang, LIU Chuming, WAN Yingchun, et al. Microstructures and mechanical properties of Mg-10Gd-6Y-2Zn-0.6Zr(wt.%) alloy[J]. Journal of Alloys and Compounds, 2011, 509(35): 8832-8839.

[11] GONZALEZ S, GARCES G, ADEVA P, et al. Influence of processing route on microstructure and mechanical properties of two Mg-Ni-Y-RE alloys[J]. Materials Characterization, 2012, 64: 53-61.

[12] LIU Huan, XUE Feng, BAI Jing, et al. Effect of substitution of 1at% Ni for Zn on the microstructure and mechanical properties of Mg94Y4Zn2 alloy[J]. Materials Science and Engineering: A, 2013, 585: 387-395.

[13] ZHANG Xiaobo, YUAN Guangyin, WANG Zhangzhong. Effects of extrusion ratio on microstructure, mechanical and corrosion properties of biodegradable Mg-Nd-Zn-Zr alloy[J]. Materials Science and Technology, 2013, 29(1): 111-116.

[14] HOMMA T, KUNITO N, KAMADO S. Fabrication of extraordinary high-strength magnesium alloy by hot extrusion[J]. Scripta Materialia, 2009, 61(6): 644-647.

[15] ZHANG Xinming, LI Li, DENG Yunlai, et al. Superplasticity and microstructure in Mg-Gd-Y-Zr alloy prepared by extrusion[J]. Journal of Alloys and Compounds, 2009, 481(1/2): 296-300.

[16] LIN Li, CHEN Lijia, LIU Zheng. Tensile strength improvement of an Mg-12Gd-3Y (wt.%) alloy processed by hot extrusion and free forging[J]. Journal of Materials Science, 2008, 43(13): 4493-4502.

[17] YIN Jian, LU Chunhui, MA Xiujun, et al. Investigation of two-phase Mg-Gd-Ni alloys with highly stable long period stacking ordered phases[J]. Intermetallics, 2016, 68: 63-70.

[18] BOHLEN J, YI S B, SWIOSTEK J, et al. Microstructure and texture development during hydrostatic extrusion of magnesium alloy AZ31[J]. Scripta Materialia, 2005, 53(2): 259-264.

[19] HANTZSCHE K, BOHLEN J, WENDT J, et al. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets[J]. Scripta Materialia, 2010, 63(7): 725-730.

[20] YAMASAKI M, HASHIMOTO K, HAGIHARA K, et al. Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy[J]. Acta Materialia, 2011, 59(9): 3646-3658.

[21] ZHOU Xiaojie, LIU Chuming, GAO Yonghao, et al. Evolution of LPSO phases and their effect on dynamic recrystallization in a Mg-G-Y-Zn-Zr alloy[J]. Metallurgical and Materials Transactions A, 2017, 48(6): 3060-3072.

[22] HE S M, ZENG X Q, PENG L M, et al. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy[J]. Journal of Alloys and Compounds, 2007, 427(1/2): 316-323.

[23] CORDERO Z C, KNIGHT B E, SCHUH C A. Six decades of the Hall-Petch effect: a survey of grain-size strengthening studies on pure metals[J]. International Materials Reviews, 2016, 61(8): 495-512.

[24] HAGIHARA K, KINOSHITA A, FUKUSUMI Y, et al. High-temperature compressive deformation behavior of Mg97Zn1Y2 extruded alloy containing a long-period stacking ordered(LPSO) phase[J]. Materials Science and Engineering: A, 2013, 560: 71-79.

[25] PENG Tao, WANG Qudong, HAN Y, et al. Microstructure and high tensile strength of Mg-10Gd-2Y-0.5Zr alloy by solid-state recycling[J]. Materials Science and Engineering: A, 2010, 528(2): 715-720.

[26] HUANG Song, WANG Jingfeng, HOU Fan, et al. Effect of Sn on the formation of the long period stacking ordered phase and mechanical properties of Mg-RE-Zn alloy[J]. Materials Letters, 2014, 137: 143-146.

[27] SHAO Xiaohong, YANG Zhiqing, MA Xiuliang. Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure[J]. Acta Materialia, 2010, 58(14): 4760-4771.

[28] 张凯. 含LPSO相Mg-Gd-Ni合金腐蚀特性的研究[D]. 西安: 长安大学材料科学与工程学院, 2019: 28-29.

ZHANG Kai. Study on corrosion characteristics of Mg-Gd-Ni alloy containing LPSO phase[D]. Xi′an: Chang′an University. College of Materials Science and Engineering, 2019: 28–29.

[29] BIRBILIS N, RALSTON K D, VIRTANEN S, et al. Grain character influences on corrosion of ECAPed pure magnesium[J]. Corrosion Engineering, Science and Technology, 2010, 45(3): 224-230.

(编辑 杨幼平)

收稿日期: 2020 -03 -12; 修回日期: 2020 -05 -24

基金项目(Foundation item):国家自然科学基金资助项目(51574291, 51874367)(Projects(51574291, 51874367) supported by the National Natural Science Foundation of China)

通信作者:刘楚明,博士,教授,从事变形镁合金研究;E-mail:cmliu803@sina.com