固溶温度对激光沉积制造Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金组织及力学行为影响

来源期刊:稀有金属2021年第3期

论文作者:杨光 邵帅 王超 王向明 刘艳梅

文章页码:264 - 271

关键词:激光沉积制造;固溶温度;显微组织;力学性能;

摘 要:以Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金球形粉末为原料,采用激光沉积制造技术制备钛合金试样,通过光学显微镜(OM)、扫描电子显微镜(SEM)、硬度测试以及室温拉伸试验对比分析了不同固溶温度对激光沉积制造钛合金显微组织及力学行为影响。研究结果表明:α+β两相区固溶+时效处理后,合金宏观组织依旧为粗大的柱状β晶,晶内组织主要由初生α相、β转变组织以及少量的片层状次生α相组成,随着固溶温度的升高,初生α相含量降低,次生α相析出量逐渐增加,使晶内组织间界面增多,变形协调能力变差,导致合金的强度上升,塑性和硬度略有下降;β相区固溶+时效处理后,合金的宏观组织由柱状晶全部转化为等轴晶,晶内初生α相完全消失,全部为细长片层状的次生α相,随着固溶温度的升高,次生α相片层宽度变大,使晶界减少,塑性变形能力进一步减弱,导致钛合金的强度、塑性和显微硬度有所下降。在920℃/2 h,AC(空冷)+540℃/4 h,AC固溶时效时,合金的室温拉伸强度为1183.5 MPa,屈服强度为1066 MPa,延伸率为7.1%,断面收缩率为18.2%,具有最佳的强度和塑性匹配。沉积态试样与两相区固溶时效态试样的断口表面布满形状大而深的韧窝,为韧性断裂,β单相区固溶时效态试样韧窝少而浅,且存在解理平面,为典型的准解理断裂。

网络首发时间: 2019-09-12 10:55

稀有金属 2021,45(03),264-271 DOI:10.13373/j.cnki.cjrm.xy19070024

杨光 邵帅 王超 王向明 刘艳梅

沈阳航空航天大学航空制造工艺数字化国防重点学科实验室

中国航空工业集团公司沈阳飞机设计研究所

沈阳飞机工业(集团)有限公司

以Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金球形粉末为原料,采用激光沉积制造技术制备钛合金试样,通过光学显微镜(OM)、扫描电子显微镜(SEM)、硬度测试以及室温拉伸试验对比分析了不同固溶温度对激光沉积制造钛合金显微组织及力学行为影响。研究结果表明:α+β两相区固溶+时效处理后,合金宏观组织依旧为粗大的柱状β晶,晶内组织主要由初生α相、β转变组织以及少量的片层状次生α相组成,随着固溶温度的升高,初生α相含量降低,次生α相析出量逐渐增加,使晶内组织间界面增多,变形协调能力变差,导致合金的强度上升,塑性和硬度略有下降;β相区固溶+时效处理后,合金的宏观组织由柱状晶全部转化为等轴晶,晶内初生α相完全消失,全部为细长片层状的次生α相,随着固溶温度的升高,次生α相片层宽度变大,使晶界减少,塑性变形能力进一步减弱,导致钛合金的强度、塑性和显微硬度有所下降。在920℃/2 h,AC(空冷)+540℃/4 h,AC固溶时效时,合金的室温拉伸强度为1183.5 MPa,屈服强度为1066 MPa,延伸率为7.1%,断面收缩率为18.2%,具有最佳的强度和塑性匹配。沉积态试样与两相区固溶时效态试样的断口表面布满形状大而深的韧窝,为韧性断裂,β单相区固溶时效态试样韧窝少而浅,且存在解理平面,为典型的准解理断裂。

中图分类号: TG156.94;TG146.23

作者简介:杨光(1978-),男,辽宁沈阳人,博士,教授,研究方向:激光/电弧增材制造工艺与装备;航空航天结构增材制造、性能考核、评价和应用,电话:024-89723852,E-mail:yangguang@sau.edu.cn;

收稿日期:2019-07-17

基金:国家重点研发计划项目(2018YFB1105805,2017YFB1104002);工信部民用飞机专项科研项目(MJZ-2016-G-71);国防科技创新特区项目(18-H863-31-ZD-003-001-01)资助;

Yang Guang Shao Shuai Wang Chao Wang Xiangming Liu Yanmei

Key Laboratory of Fundamental Science for National Defence of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University

Shenyang Institute of Aircraft Design,China Aviation Industry Group Corporation

Shenyang Aircraft Corporation

Abstract:

Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V titanium alloy spherical powder was used as raw material to prepare titanium alloy samples by laser deposition. The size of titanium alloy spherical powder ranged from 80 to100 μm. The effects of different solid solution temperatures on the microstructure and mechanical behavior of laser-deposited titanium alloy were analyzed by optical microscopy(OM),scanning electron microscopy(SEM),hardness test and tensile test at room temperature. The results showed that in the process of laser deposition manufacturing,the metal powder was melted in the dynamic molten pool formed by laser beam irradiation. Most of the heat dissipated vertically in the molten pool and downward through the substrate in the form of heat conduction when the laser molten pool solidified,and resulting in the small melt in the molten pool epitaxial grown against the heat flow direction,formed coarse columnar β grains penetrating multiple deposition layers. A uniform and orderly basket structure braided in the columnar β grains,which was composed of a large number of slender α lamellae and a small amount of β phase. The macrostructure of the alloy was still coarse columnar β grains after solution and aging treatment in the α+β phase field. The intragranular structure was mainly composed of primary α phase and β transformation structure,and a small amount of lamellar secondary α phase. With the increase of solution temperature,the content of primary α phase decreased,and ratio of secondary α phase increased gradually,which increased the inter-tissue interface and decreased the compatibility of deformation,resulting in the increase of strength and a slight decrease of plasticity and hardness of the alloy. After solution and aging treatment in the β phase region,the macrostructure of the alloy was transformed from columnar crystals to equiaxed crystals,and the primary α phase disappeared completely,all of which were thin lamellar secondary αphases. With solution temperature increased,the width of the secondary α phase layer became larger,the grain boundary was reduced,and the plastic deformation ability was further weakened,resulting in the decrease of strength,plasticity and microhardness.At 900 ℃/2 h,AC(air cooling)+540 ℃/4 h,AC solution aging,the tensile strength and yield strength increased from 1024.2 and 933.1 MPa to 1177.1 and 1064.8 MPa respectively,and the plasticity also increased. The elongation increased from 6.0% to 7.5%,and the reduction of area increased from 14.1% to 20.4%;When the temperature exceeded the transformation point,at 920 ℃/2 h,AC+540 ℃/4 h,AC solution aging,the tensile strength and yield strength further increased to 1185.6 and 1078.4 MPa respectively,and the elongation and reduction of area decreased to 6.2% and 11.5%,respectively. At 960 ℃,the tensile strength and yield strength decreased slightly,reaching 1172.0 and 1057.1 MPa,and the plasticity decreased obviously. The elongation and reduction of area were only 2.6% and 6.2%. Compared with conventional TC4 titanium alloy,the strength of TC4 titanium alloy increased obviously,but the plasticity decreased slightly. And at 920 ℃/2 h,AC(air cooling)+540 ℃/4 h,AC solution aging,the alloy tensile strength at room temperature was 1183.5 MPa,yield strength was 1066 MPa,elongation was 7.1%,the area shrinkage was 18.2%,and the alloy had the best strength-plasticity matching. With the increased of solution temperature,the microhardness value of titanium alloy increased first and then decreased,because the microstructure of primary α phase was very important to the hardness of titanium alloy.When the titanium alloy was solution aged in the α+β two-phase region,the lamellar size of the primary α phase was significantly reduced compared with that of the deposited phase,and a small amount of acicular secondary α phase precipitated,which led to the increase of interphase interface ratio. Under the same pressure,the grain slip distance decreased,which was reflected in the increase of micro hardness. When the solution temperature rose to above the phase transformation point,the secondary α phase grew into a thin lamellar layer,the proportion of interphase interface increased,and the deformation coordination ability of secondary α phase was lower than that of primary α phase,so that the microhardness of titanium alloy at 940 ℃ was significantly higher than that at 920 ℃. When the solution temperature increased to 960 ℃,the secondary α phase layer coarsens,the interface proportion and the hardness of the alloy decreased slightly. The fracture mechanism of the sedimentary sample was the same as that of the two-phase solution aging sample.A large number of dimples were distributed in the micro morphology,which was a typical ductile fracture feature. Compared with the as deposited dimples,the dimples in the solution and aging state were larger and deeper,and the plasticity was better. The results showed that no obvious necking phenomenon in the β single-phase region,a small amount of dimples existed in the micro morphology,and obvious cleavage plane appeared in some regions,resulting in poor plasticity,and the fracture mode was quasi cleavage fracture.

Keyword:

laser deposition manufacturing; solution temperature; microstructure; mechanical property;

Received: 2019-07-17

激光沉积制造技术(laser deposition manufacturing,LDM)是一种区别于传统“减材”加工的新兴技术,利用同轴送粉技术和高功率的激光束实现金属粉末的熔化、凝固成形以及逐层沉积

TC4(Ti-6Al-4V)是一种典型的α+β两相钛合金,具有比强度高、耐高温、疲劳寿命长等优良性能,被广泛应用于国防军工、生物医疗等高新技术领域

激光沉积制造钛合金试件的组织较为复杂,对新型钛合金建立优良的热处理制度是一大难题。国内外学者对激光沉积制造传统TC4钛合金热处理制度有了大量研究。王文博等

本文选用了Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V球形钛合金粉末作为研究对象,研究在(α+β)/β相区不同固溶温度对激光沉积制造钛合金显微组织及力学性能影响,完善新型钛合金在(α+β)/β相区热处理工艺,为探索激光沉积新型钛合金成形力学性能最佳热处理工艺提供参考。

1实验

1.1试样制备

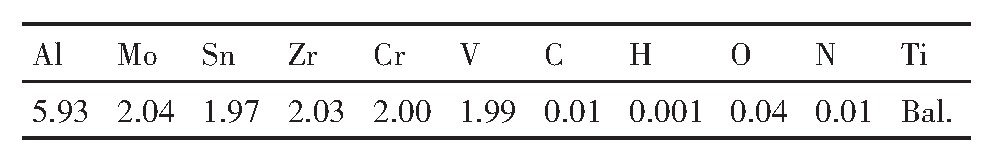

本次研究选用了利用气体雾化法制备的Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金粉末作为研究对象,粒度范围80~100μm,粉末化学成分如表1所示。为保证激光沉积质量,实验之前对钛合金粉末进行12 h真空烘干处理。实验基材采用锻造TC4基板,并对基材待沉积表面进行打磨、擦洗。利用沈航LDM 800激光沉积制造系统沉积制造实验试样块,并采用图1分割方式分为5组,每组试样尺寸为x×y×z:40 mm×80 mm×20 mm。

表1 钛合金粉末化学成分 下载原图

Table 1 Chemical composition of titanium alloy powders(%,mass fraction)

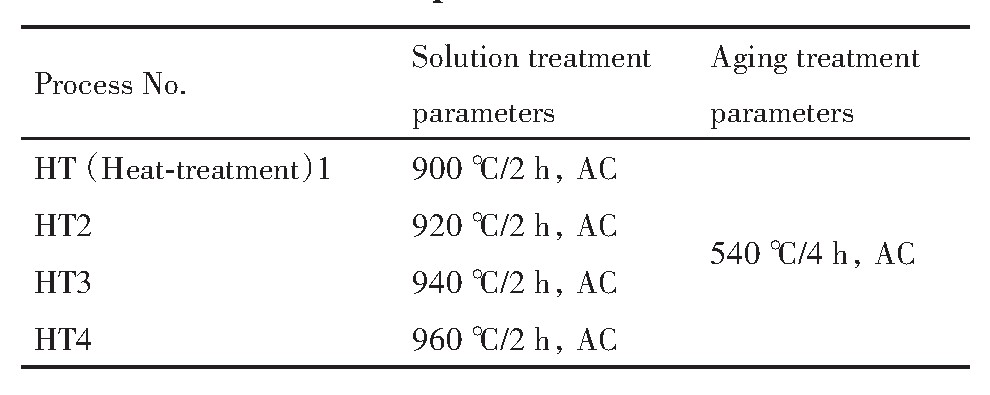

1.2固溶时效处理

选取4组试样分别在(α+β)/β相区进行固溶时效处理(利用金相法测得合金相变点为(930±5)℃),工艺参数如表2所示。热处理后在5组试样块上分别切取并制备如图2所示拉伸试样3个,对拉伸试样进行打磨,达到精度要求,使用丙酮进行擦洗,然后对试样进行编号和实验。

图1 沉积试样示意图

Fig.1 Deposition sample diagram

表2 热处理方案 下载原图

Table 2 Heat treatment process

1.3金相试样制备及观察

金相试样制备包括沉积态金相试样、固溶时效态金相试样,金相试样经过镶嵌、预磨、抛光,然后使用Kroll腐蚀剂(HF∶HNO3∶H2O体积比为1∶6∶7)进行腐蚀,采用GX51 OLYMPUS光学成像系统(OM)观察显微组织;通过ZEISSΣIGMA扫描电子显微分析技术(SEM)分析断口形貌特征;利用金相组织分析系统软件Nano Measure测量α相尺寸;利用HVS-1000A数显显微硬度计测试显微硬度;并在Exceed电子万能试验机上测试其力学性能。

2结果与讨论

2.1沉积态显微组织

图3为激光沉积制造Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金沉积态的显微组织。由图3可以看出,钛合金沉积态宏观组织由贯穿多个沉积层的粗大β柱状晶组成,其生长方向近似平行于沉积方向。这是由于激光沉积制造过程中,金属粉末熔于激光束辐照形成的动态熔池中,当激光熔池凝固时,熔池中绝大部分热量以热传导的形式通过基材沿垂直向下的方向散失,熔池小熔体将在熔池底部同质材料上逆着热流方向外延生长

图2 拉伸取样示意图

Fig.2 Schematic diagram of tensile specimen sampling(mm)

图3 激光沉积制造钛合金沉积态显微组织

Fig.3 Microstructure of titanium alloy fabricated by laser de-position

(a)Macrostructure(OM image);(b)Microstructure(SEMimage)

2.2不同热处理制度下组织形貌特征

图4为不同热处理制度下新型钛合金显微组织。由图4可知,当固溶温度在相变点以下时,钛合金的宏观组织依旧为粗大β柱状晶,β基体上弥散分布着大量初生α相,由图5,6可知,900℃时初生α相为短棒状,平均长度为6.13μm,宽度为1.18μm,α相含量约为23.1%,α相间有少量针状次生α相产生;温度上升到920℃时,钛合金的宏观组织有柱状晶向等轴晶转化的趋势,晶内初生α相长度减小,宽度基本不变,含量降低到19.2%,相间针状次生α相含量增多。相变点以上固溶时,钛合金宏观组织全部转化为等轴晶,晶内初生α相完全消失,晶内组织全部为细长片层状次生α相。固溶温度为940℃时,β晶粒尺寸约为995.4μm,次生α相平均宽度约为0.45μm,960℃时β晶粒尺寸约为1146.8μm,次生α相宽度略有上升,约为0.57μm。即相变点以下,随着固溶温度升高,初生α相尺寸减小,含量降低;相变点以上,随着固溶温度升高,等轴β晶粒的尺寸和次生α相宽度同时增大。

相较于常规TC4钛合金(β相变点为(975±10)℃)

图4 激光沉积制造钛合金不同热处理制度下显微组织(SEM)

Fig.4 SEM images of laser deposited titanium alloy under different heat treatment systems

(a)900℃/2 h,AC+540℃/4 h,AC;(b)920℃/2 h,AC+540℃/4 h,AC;(c)940℃/2 h,AC+540℃/4 h,AC;(d)960℃/2 h,AC+540℃/4 h,AC266

图5 不同固溶温度下α相平均尺寸

Fig.5 Average size ofαphase at different solution tempera-tures

图6 不同固溶温度下初生α相体积分数

Fig.6 Volume fraction of primaryαphase at different solution temperatures

图7 固溶+时效热处理下次生α相形成示意图

Fig.7 Schematic diagram of secondaryαphase formation in solid solution aging heat treatment

(a)Solution and aging ofα+βtwo-phase zone;(b)Solutionand aging ofβphase zone

2.3室温力学性能

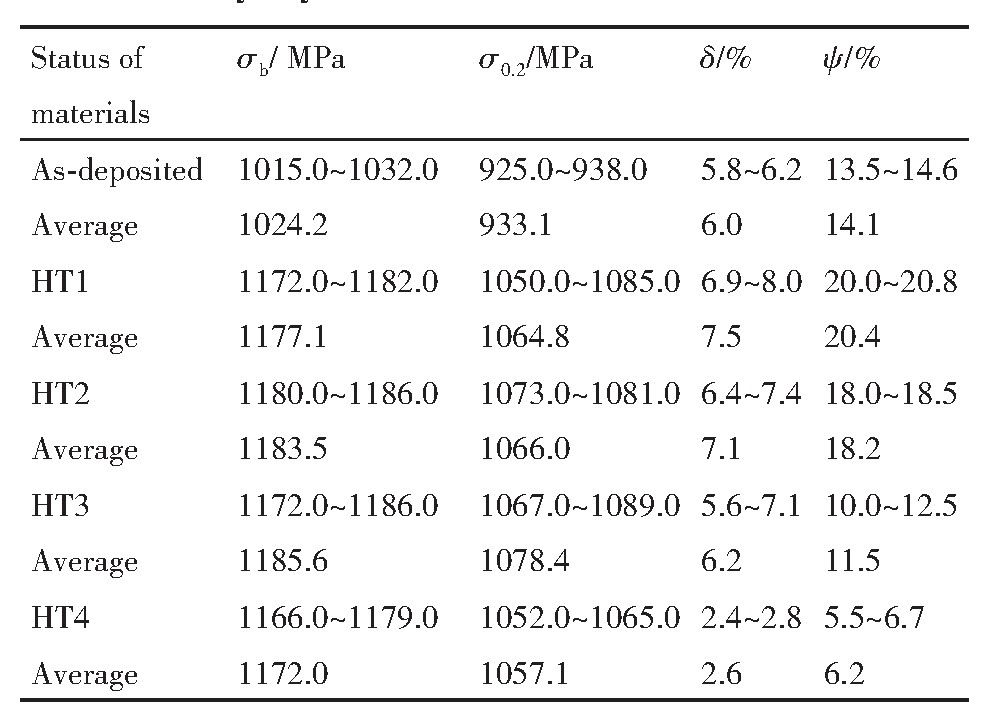

表3为激光沉积制造钛合金不同固溶温度试样的拉伸数据。由表可知,固溶温度在900℃时,拉伸强度(σb)与屈服强度(σ0.2)分别从沉积态的1024.2和933.1 MPa提高到1177.1和1064.8 MPa,塑性也有所上升,延伸率(δ)由6.0%提升到7.5%,断面收缩率(ψ)由14.1%提升到20.4%;当固溶温度为920℃时,相较于900℃时,拉伸强度和屈服强度略有上升,分别为1183.5和1066.0 MPa,塑性略有下降,延伸率和断面收缩率分别达到7.1%和18.2%;当温度超过钛合金相变点,达到940℃时,拉伸强度和屈服强度进一步上升,分别为1185.6和1078.4 MPa,延伸率和断面收缩率下降为6.2%和11.5%,960℃时,拉伸强度和屈服强度略有下降,达到1172.0和1057.1 MPa,塑性下降较为明显,延伸率和断面收缩率只有2.6%和6.2%。相较于常规TC4钛合金,强度有明显上升,但塑性略有下降。

结合表3和图8可知,固溶时效处理可以有效改善钛合金的强度与塑性,当固溶温度在合金相变点以下,合金的强度随着固溶温度的升高而上升,塑性则相反,随着固溶温度提升到相变点以上,随着固溶温度的升高强度先上升后下降,塑性持续下降,原因在于当固溶温度在合金相变点以下时,随着固溶温度的升高导致初生α相含量和平均尺寸同时减小,亚稳β相中的溶质原子有所增加,在相同的时效工艺下,次生α相的形核率和析出量都有所增加

表3 激光沉积(LDM)制造钛合金室温拉伸性能 下载原图

Table 3 Room temperature tensile properties of titanium alloys by LDM

图8 固溶温度对激光沉积制造钛合金性能影响

Fig.8 Effect of solution temperature on properties of titanium alloy made by laser deposition.

2.4显微硬度

固溶温度对新型钛合金硬度的影响如图9所示,由图9可知,固溶时效处理对钛合金显微硬度具有明显作用,随着固溶温度的上升,钛合金的显微硬度值先上升后下降,原因在于初生α相组织形态对试样硬度的影响至关重要。当钛合金在α+β两相区固溶时效时,相较于沉积态,初生α相的片层尺寸明显减小,且有少量针状次生α相析出,导致相间界面比例增大,在同等压力下,晶粒滑移距离减小,宏观体现为显微硬度的上升。当固溶温度上升到相变点以上时,次生α相充分析出生长为细长的片层状,相间界面比例增大,且次生α相变形协调能力低于初生α相,从而使940℃时钛合金显微硬度明显高于920℃时。当固溶温度提升到960℃,次生α相片层产生粗化,界面比例略有减小,合金硬度略有下降。

图9 固溶温度对钛合金显微硬度影响

Fig.9 Effect of solid solution temperature on microhardness of titanium alloy

2.5室温拉伸断口分析

图10为激光沉积Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金经不同温度固溶时效处理后的拉伸断口,其中图10(a~e)为拉伸断口的的宏观形貌,图10(f~g)为拉伸断口的显微形貌。沉积态试样与两相区固溶时效态试样的宏观颈缩现象较为明显,微观形貌中分布有大量密集的韧窝,为典型的韧性断裂特征。相较于沉积态,固溶时效态的韧窝大而深,塑性更好。β单相区固溶时效态试样的无明显颈缩现象,微观形貌上有少量的韧窝存在,部分区域出现明显的解理平面,导致塑性较差,其断裂方式为准解理断裂。

图1 0 激光沉积制造钛合金拉伸断口SEM照片

Fig.10 SEM images showing tensile fracture of titanium alloy

(a,f)As-deposited;(b,g)900℃/2 h,AC+540℃/4 h,AC;(c,h)920℃/2 h,AC+540℃/4 h,AC;(d,i)940℃/2 h,AC+540℃/4 h,AC;(e,j)960℃/2 h,AC+540℃/4 h,AC

3结论

本文对比分析了不同固溶温度下激光沉积制造钛合金试样的显微组织和力学性能,得到以下结论:

1.激光沉积制造Ti-6Al-2Mo-2Sn-2Zr-2Cr-2V钛合金试样的宏观组织为贯穿多个沉积层的粗大β柱状晶,晶内由大量细长α片层和少量残留β相组成。

2.当固溶温度在α+β两相区时,随着固溶温度的上升,柱状β晶有等轴化趋势,晶内初生α相含量和尺寸减小,且有少量次生相析出;当固溶温度上升到β相区时,柱状晶完全转变为等轴晶,晶内初生α相完全消失,次生α相析出生长为片层状,且随固溶温度的上升,片层发生粗化。

3.固溶时效热处理能够明显提升钛合金的强度,当固溶温度在α+β两相区时,合金强度随固溶温度上升而提高,塑性则相反;当固溶温度在β相区时,合金强度和塑性随固溶温度上升而下降。钛合金在920℃/2 h,AC+540℃/4 h,AC固溶时效时,具有较高的强度与塑性,为最佳热处理制度。

4.两相区固溶时效后与沉积态试样断裂相貌相似,断裂方式相同,均为韧性断裂,β单相区固溶时效后试样断裂相貌明显不同,断裂方式为准解理断裂。

参考文献