文章编号:1004-0609(2010)10-1949-06

LY12铝合金微弧氧化膜层的形成与生长机制

杨 巍,蒋百灵,时惠英

(西安理工大学 材料科学与工程学院,西安 710048)

摘 要:在硅酸钠电解液中利用交流脉冲微弧氧化电源对LY12铝合金进行表面处理,研究微弧氧化初期成膜和后期生长膜层的微观结构差异,探讨铝合金微弧氧化陶瓷层的形成与生长机制。结果表明:初期成膜过程中发生电化学沉积反应,形成电解液中溶质元素的氧化物,增大铝合金表面的阻抗值;后期生长过程中,基体铝与OH-放电所产生的活性氧发生化合反应,形成Al2O3陶瓷层,溶质元素消耗极少;铝合金样品表面获取的预制备膜重新参与陶瓷层的生长,可明显缩短微弧氧化起弧时间、降低起弧电压,同时提升击穿电压的稳定值。

关键词: 铝合金;微弧氧化;陶瓷层;生长机制;预制备膜

中图分类号 TG174.2 文献标志码:A

Formation and growth mechanism of microarc oxidation coating on LY12 aluminium alloy

YANG Wei, JIANG Bai-ling, SHI Hui-ying

(School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: LY12 aluminium alloy was surface treated by microarc oxidation in the Na2SiO3 solution using AC pulse electrical source. The microstructure difference of the coatings formed at different stages of microarc oxidation was researched, and the growth mechanism of ceramic coating on aluminium alloy was discussed. The results show that electrochemical deposition reaction happens during forming incipient coating, and the oxide containing the element of the electrolyte forms. So, this oxide coating increases the impedance value of aluminium alloy. The combination of Al from the substrate and active O generated by the discharge of OH- ion forms Al2O3 coating, and in this process, the element of the electrolyte is consumed little. Since the prefab coating is participated in the process of forming ceramic coating, the prefab coating is prepared on the aluminum alloy surface, it is helpful to shortening arc starting time, reducing the voltage and increasing the steady value of broken down voltage.

Key words: aluminium alloy; microarc oxidation; ceramic coating; growth mechanism; prefab coating

微弧氧化技术因其工艺简单、环保,生成物具有陶瓷质属性而在轻金属表面改性领域具有较大发展潜力[1-3]。经微弧氧化处理铝、镁合金可在样品表面分别形成氧化铝和氧化镁陶瓷层而提高了基体的耐磨性能和抗腐蚀性能,扩大了轻合金的应用领域[4-5]。当前,对微弧氧化技术的研究多集中在陶瓷层的制备工艺、组织性能及设备开发等相关领域,对陶瓷层形成机制研究涉及较少[6-10],而制约该技术进步的关键因素是能量消耗和电解液维护这两大问题。通过对陶瓷层形成与生长机制的研究,使微弧氧化处理在短时间、低电压条件下发生起弧现象将有利于降低陶瓷层形成过程中的能量消耗,明确溶质元素在微弧氧化成膜过程中的作用机理也将为电解液使用的日常维护提供理论依据。

观察实验现象发现,微弧氧化陶瓷层生长过程可明显分为无弧光的初期成膜和后期的弧光放电生长两个阶段,微弧氧化膜层在两个阶段的形成与生长机理存在差异,其试验现象截然不同,前者在试样表面产生大量气泡但并无弧光产生,后者在试样表面产生大量弧光,且随处理时间延长,弧光颜色、大小及密度均发生改变。因此,本文作者尝试以LY12铝合金为研究对象,分析微弧氧化初期成膜和后期生长这两个阶段所得膜层的微观结构和成分,揭示微弧氧化初期成膜在陶瓷层后期生长阶段的作用,量化样品表面状态对陶瓷层后期生长过程的影响规律,探讨微弧氧化膜层形成与生长机制,以期为在低能耗条件下实现铝合金表面陶瓷层的快速生长提供理论依据。

1 实验

实验材料为LY12铝合金,其化学成分(质量分数)为Cu 3.8%~4.9%,Mg 1.2%~1.8%,Mn 0.3 %~0.9%,Ti小于0.15 %,Zn小于0.3 %,Fe小于0.5 %,Si小于0.5 %,Ni小于0.15%,杂质小于0.1%,余量为Al。试样尺寸为d 20 mm×5 mm;微弧氧化、阳极氧化处理工艺均采用自行研制的65 kW微弧氧化装置,该装置包括专用高压电源控制柜、电解槽、搅拌系统和冷却系统;微弧氧化电解液选取0.05 mol/L硅酸钠与去离子水配制而成,采用恒流模式,其电流密度为5 A/dm2,频率为400 Hz,占空比为10,将在微弧氧化起弧瞬间所得膜层定义为初期成膜,其厚度小于1 ?m,而经15 min微弧氧化处理所得膜层定义为后期生长陶瓷层,其厚度在10 ?m左右,电解液温度控制在30 ℃左右。为了研究样品表面状态对微弧氧化膜层形成与生长过程的作用规律,本试验中分别采用阳极氧化或化学转化工艺在铝合金样品表面获取预制备膜,其中,阳极氧化处理电解液选取38 g/L的草酸溶液与去离子水配制而成[11],采用恒压模式(100 V)经10 min处理获得具有一定阻抗值的预制备膜,其厚度在6 ?m左右,电解液温度控制在21 ℃;化学转化处理采用钼酸钠+高锰酸钾+氟化钠复合溶液在65 ℃条件下处理15 min,其膜层厚度小于5 ?m。

采用AXIS ULTRA 型X射线光电子能谱仪分别对微弧氧化初期成膜和后期生长所得膜层的表面成分进行分析,使用JSM-6700F型场发射扫描电子显微镜观察铝合金样品表面和截面形貌,运用TT-240涡流测厚仪测量微弧氧化初期成膜和后期生长膜层的厚度,借助X射线衍射仪分析样品表面的相组成,使用IM6e型电化学工作站测定分析铝合金样品微弧氧化初期成膜和预制备膜的阻抗值,采用传统的三电极体系,其中参比电极为饱和甘汞电极(SCE),铂电极(Pt)为辅助电极,研究电极为用环氧树脂封装的氧化膜试样,暴露面积约为1 cm2,腐蚀介质为3.5%的NaCl水溶液,pH=7;测量参数:交流信号振幅5 mV,扫描速度0.1 mV/s,频率0.01Hz~100 kHz,以恒电位方式扫描。

2 结果与讨论

2.1 微弧氧化初期成膜的微观结构

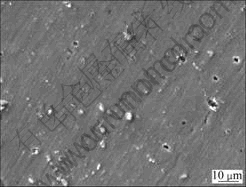

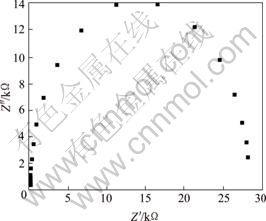

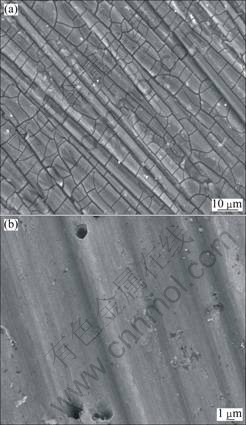

硅酸钠电解液中铝合金微弧氧化起弧时间为97 s,起弧电压为338 V,所得初期成膜形貌如图1所示。由图1 可知,样品表面基体划痕清晰可见,其表面局部存在放电微孔。涡流测厚仪测量膜层厚度小于1 ?m,初期成膜的电化学阻抗值高达28 175 Ω(见图2),相对于硅酸钠溶液的电导率3.2×104 ?S/cm,微弧氧化

图1 铝合金微弧氧化初期成膜表面形貌

Fig.1 Surface morphology of incipient coating on aluminium alloy at arc starting time

图2 铝合金微弧氧化初期成膜交流阻抗谱

Fig.2 EIS spectra of incipient coating on aluminium alloy at arc starting time

工件阳极已从低阻抗值的铝合金基体转变为由初期成膜包裹的高阻抗铝合金。

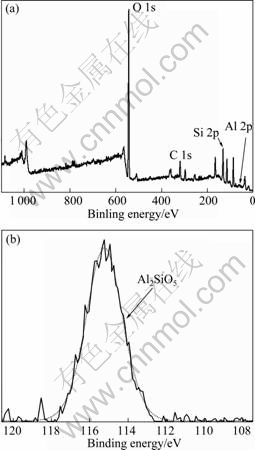

通过对微弧氧化初期成膜XPS分析(见图3)发现,Si 2p峰在103.05 eV或101.59 eV处,分别对应Al2SiO5或SiOx。可见,电解液中溶质元素Si强烈参与了初期成膜过程,发生电化学沉积反应,形成了以溶质元素Si为主的氧化物。

图3 铝合金微弧氧化初期成膜表面的XPS谱及Si2p的高分辨谱

Fig.3 XPS spectrum (a) of surface of arc starting coating formed by microarc oxidation and high-resolution spectra (b) of Si2p region

2.2 微弧氧化陶瓷层的微观结构

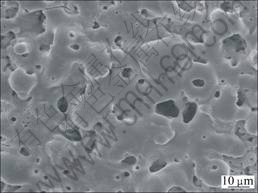

微弧氧化陶瓷层在后期击穿放电过程中,由于铝合金基体表面高阻抗膜层的存在而使后期生长机制发生了改变,通过对15 min微弧氧化处理所得陶瓷层的表面形貌观察(见图4),其表面存在大量孔径不均一的放电微孔,局部产生微裂纹,测量陶瓷层厚度为10 ?m左右。

由XPS分析可知(见图5),溶质元素Si在微弧氧化陶瓷层的生长过程中仅微量参与形成Al2SiO5相,结合微弧氧化陶瓷层的相组成分析可知,其组成已由初期成膜Si的氧化物转变为Al2O3相,实现了铝合金基体表面陶瓷层的生长增厚。

图4 铝合金微弧氧化15min所得陶瓷层表面形貌

Fig.4 Surface morphology of ceramic coating formed by MAO for 15 min

图5 铝合金微弧氧化后期生长陶瓷层表面XPS谱及Si2p的高分辨谱

Fig.5 XPS spectra (a) from surface of growing coating formed by microarc oxidation and high-resolution spectra (b) of Si2p region

2.3 有预制备膜铝合金微弧氧化过程

微弧氧化初期成膜具有较高阻抗值,而为后续陶瓷层生长提供了条件。本实验中在铝合金表面预先制备具有一定阻抗的膜层,将微弧氧化过程分为两个独立工艺进行,观察并分析微弧氧化起弧现象和生长过程,研究样品表面状态对铝合金微弧氧化膜层形成与生长过程的作用规律。实验中分别采用化学转化处理和阳极氧化工艺在铝合金样品表面获取预制备膜,其阻抗值分别为4 126 Ω和9 985 Ω,表面形貌如图6所示,铝合金表面化学转化膜呈干枯的“河床状”,存在大量微裂纹;阳极氧化膜表面致密,局部存在微孔但并无微弧氧化陶瓷层击穿熔融形成的火山喷射状孔洞。

图6 化学转化或阳极氧化处理铝合金样品表面形貌

Fig.6 Surface morphologies of coatings formed by different technologies on aluminium alloy: (a) Chemical translation; (b) Anodize oxidation

图7所示为在硅酸钠电解液中对有无阳极氧化膜铝合金进行微弧氧化处理15 min所得陶瓷层的XRD谱。由图7可见,有阳极氧化膜铝合金的Al2O3相明显强于无阳极氧化膜铝合金,结合陶瓷层生长曲线可认为阳极氧化膜重新参与微弧氧化膜的生长增厚,加速了陶瓷层的生长,但XRD检测结果未发现有溶质元素形成的相,即溶质元素微量参与氧化成膜。

图7 不同处理工艺所得膜层的XRD谱

Fig.7 XRD patterns of coatings formed by different technologies: (a) Anodize oxidation 10 min+MAO 15 min; (b) MAO 15 min; (c) Anodize oxidation 10 min

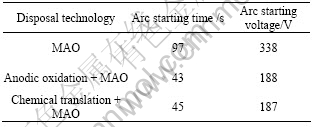

对比硅酸钠电解液中不同表面状态铝合金微弧氧化起弧时间和电压(见表1)。相对于无预制备膜铝合金,有预制备膜铝合金微弧氧化起弧时间明显缩短,起弧电压显著降低,但预制备膜种类对微弧氧化起弧时间与电压影响均较小。可见,微弧氧化击穿放电现象的发生依赖于样品表面高阻抗膜的形成,高阻抗膜的作用在于抑制活性阳极的放电,同时为陶瓷层击穿放电生长提供易失稳的表面状态。

表1 不同表面状态铝合金微弧氧化起弧时间和起弧电压

Table 1 Arc starting time and voltage on aluminium alloy at different surface states treated by M AO

图8所示为3种不同表面状态铝合金微弧氧化电压随时间的变化曲线。由图8可知,3种表面状态铝合金微弧氧化电压—时间曲线均表现为前期快速增加后期趋于稳定。不同之处在于样品表面状态不同,稳定电压值存在较小差异,其中阳极氧化处理铝合金稳定电压值最高为484 V,其次为化学转化处理铝合金的462 V,最小为无预制备膜铝合金的452 V。可见,样品表面化学转化膜或阳极氧化膜作为阻挡层隔离了铝合金基体与电解液的接触,促使微弧氧化击穿放电现象提前发生,同时,铝合金表面预制备膜有助于提升微弧氧化击穿稳定电压值,加速陶瓷层的生长。

图8 不同表面状态铝合金微弧氧化陶瓷层生长电压随时间的变化

Fig.8 Variation of voltage with oxidation time of coatings on aluminium alloy at different surface states treated by MAO

2.4 讨论

根据微弧氧化膜层的形成与生长因的不同现象,将其分为初期成膜和后期生长两个阶段,其形成机制存在明显差异。微弧氧化初期成膜是一个溶质元素参与的化合过程,接通电源后电解液中的阴离子在电场力作用下向阳极区附近移动,铝合金作为活性电极优先放电,表层铝原子失去电子成为Al3+,结合阳极区周边的富集阴离子,形成SiO32-和其水解形成OH-的阴离子富集区,构成了双电层结构,其场强可高达109 V/cm[12],大量SiO32-在强电场作用下优先与Al3+离子结合而附着于基体表面,由于其化学性质的不稳定性而形成溶质元素Si为主的氧化物,其具有较高阻抗值。铝合金基体表面一旦形成以溶质元素氧化物为主的高阻抗膜层,即发生起弧现象并进入微弧氧化膜层后期生长阶段,阳极铝基体因被包裹于高阻抗膜层内而失去活性,阳极区的失电子氧化反应将主要由阳极表面的阴离子放电完成,由于OH-的放电顺序优于SiO32-离子而优先放电形成活性氧,其在双电层的强电场作用下对铝合金表面高阻抗膜的薄弱部位有选择地进行击穿放电,形成等离子态的高温高压区[13-15],进而与基体铝在放电微孔内发生熔融反应而结合形成陶瓷层,同时阳极区附近SiO32-的富集层将结合由于OH-放电产生的瞬态H+,形成弱电解质而减弱对陶瓷层的溶解,使其生长增厚。溶质元素Si在此阶段仅微量被动参与陶瓷层生长形成Al2SiO5相。可见,陶瓷层后期生长是一个消耗电解液中氧的过程,对电解液中的溶质元素消耗甚少,SiO32-起到缓蚀剂的作用,这也是铝合金微弧氧化电解液可长期循环使用的原因之所在。

通过在铝合金基体表面获取预制备膜可明显缩短微弧氧化起弧时间、降低起弧电压和提高陶瓷层的生长速率,但预制备膜种类对微弧氧化起弧现象和生长曲线均影响较小,可见,样品表面预制备膜作用仅是为后期陶瓷层击穿放电过程提供一个易失稳的表面状态;通过对有阳极氧化膜铝合金进行15 min微弧氧化处理所得陶瓷层的截面形貌观察(见图9),陶瓷层并未出现明显的分层现象,阳极氧化膜重新参与陶瓷层的生长,形成了致密氧化膜,这也完善了微弧氧化膜层的形成与生长机制。

图9 有预制备膜铝合金微弧氧化陶瓷层的截面形貌

Fig.9 Cross-section morphology of ceramic coating formed by MAO on aluminium alloy with prefab coating

3 结论

1)微弧氧化过程分为初期成膜和后期生长两个过程,初期成膜过程形成高阻抗膜层,抑制活性阳极放电,后期生长过程实现陶瓷层的生长增厚。

2)初期成膜过程形成以电解液中溶质元素氧化物为主的薄膜层,增大了铝合金表面的阻抗值;后期生长过程中基体铝与OH-放电所产生的活性氧产生化合反应,形成以Al2O3为主相的陶瓷层,溶质元素被动微量消耗。

3)预制备膜重新参与陶瓷层的生长,使微弧氧化起弧时间明显缩短、起弧电压显著降低,并提高击穿电压的稳定值,所得陶瓷层致密无分层;但其种类对微弧氧化起弧现象和电压—时间曲线均影响较小。

REFERENCES

[1] WANG Yan-hua, WANG Jia, ZHANG Ji-biao, ZHANG Zhan. Effects of spark discharge on the anodic coatings on magnesium alloy[J]. Materials Letters, 2006, 60: 474-478.

[2] WRITZ G P, BOWN S D, KRIVEN W M. Ceramic coatings by anodic spark deposition[J]. Materials and Manufacturing Processes, 1991, 6(1): 87-115.

[3] 胡宗纯, 谢发勤, 吴向清. 电解液和电参数对钛合金微弧氧化的影响[J]. 材料导报, 2006, 20: 373-375.

HU Zong-chun, XIE Fa-qin, WU Xiang-qing. The effects of electrolyte and electrical parameters on microarc oxidation of titanium alloy[J]. Materials Review, 2006, 20: 373-375.

[4] VERDIER S, BOINET M, MAXIMOVITCH S, DALARD F. Formation, structure and composition of anodic films on AM60 magnesium alloy obtained by DC plasma anodizing[J]. Corrosion Science, 2005, 47: 1430-1444.

[5] WU K, WANGY Q, ZHENG M Y. Effects of microarc oxidation surface treatment on the mechanical properties of Mg alloy and Mg matrix composites[J]. Materials Science and Engineering A, 2007, 447: 227-232.

[6] 王艳秋, 吴 昆, 郑明毅. SiCw/AZ91镁基复合材料的微弧氧化行为及涂层的耐蚀性能[J]. 金属学报, 2007, 43(6): 631-636.

WANG Yan-qiu, WU Kun, ZHENG Ming-yi. Microarc oxidation behaviors of SiCw/AZ91 Mg alloy matrix composite and corrosion resistance of the coatings[J]. Acta Metallurgica Sinica, 2007, 43(6): 631-636.

[7] LIANG J, HU L T, HAO J C. Improvement of corrosion properties of microarc oxidation coating on magnesium alloy by optimizing current density parameters[J]. Applied Surface Science, 2007, 253: 6939-6945.

[8] 蒋百灵. 赵仁兵, 梁 戈, 李均明, 袁 芳. Na2WO4对铝合金微弧氧化陶瓷层形成过程及耐磨性的影响[J]. 材料导报, 2006, 20(9): 155-157.

JIANG Bai-ling, ZHAO Ren-bing , LIANG Ge, LI Jun-ming, YUAN Fang. Effect of Na2WO4 on properties of micro-arc oxidation (MAO) ceramic coatings and wear resistance of aluminum alloy[J]. Materials Review, 2006, 20(9): 155-157.

[9] 薛文斌. SiC颗粒增强体对铝基复合材料微弧氧化膜生长的影响[J]. 金属学报, 2006, 42(4): 350-354.

XUE Wen-bin. Effect of SiCp reinforcement on growth of microarc oxidation film on aluminium matrix composite[J]. Acta Metallurgica Sinica, 2006, 42(4): 350-354.

[10] 薛文斌, 华 铭, 施修龄, 田 华. 铸造铝合金微弧氧化膜的生长动力学及耐蚀性能[J]. 硅酸盐学报, 2007, 35(6): 731-735.

XUE Wen-bin, HUA Ming, SHI Xiu-ling, TIAN Hua. Growth kinetics of microarc oxidation films on cast aluminium alloy and their corrosion resistance[J]. Journal Chinese Ceramic Society, 2007, 35(6): 731-735.

[11] 朱祖芳. 铝合金阳极氧化与表面处理技术[M]. 北京: 化学工业出版社, 2004: 79-81.

ZHU Zu-fang. Anodic oxidation on aluminium alloy and surface treatment technology[M]. Beijing: Chemical Industry Press, 2004: 79-81.

[12] 杨德钧, 沈卓身. 金属腐蚀学[M]. 北京: 冶金工业出版社, 2003: 48-50.

YANG De-jun, SHEN Zhuo-shen. Metal corrosion science[M]. Beijing: Metallurgical Industry Press, 2003: 48-50.

[13] XUE W B, DENG Z W, CHEN R Y, ZHANGT H. Growth regularity of ceramic coatings formed by microarc oxidation on Al-Cu-Mg alloy[J]. Thin Solid Films, 2000, 372: 114-117.

[14] YEROKHIN A L, NIE X, LEYLAND A, MATTHEWS A, DOWEY S J. Plasma electrolysis for surface engineering[J]. Surf Coat Technol, 1999, 122: 73-93.

[15] XUE W B, WANG C, LI Y L, DENG Z W, CHEN R Y, ZHANG T H. Effect of microarc discharge surface treatment on the tensile properties of Al-Cu-Mg alloy[J]. Materials Letters, 2002, 56: 737-743.

(编辑 龙怀中)

基金项目:陕西省重点学科建设专项资金资助项目

收稿日期:2009-04-17;修订日期:2010-05-28

通信作者:蒋百灵,教授,博士;电话:029-82312617;E-mail:jbl@xaut.edu.cn