文章编号:1004-0609(2012)07-1976-08

微波烧结WC-Co硬质合金致密化与晶粒生长

娄 静1,易健宏1, 2,周承商1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 昆明理工大学 材料科学与工程学院,昆明 650093)

摘 要:分别采用微波烧结和常规烧结制备WC-8Co硬质合金,通过1 000~1 400 ℃温度范围烧结以及1 400 ℃保温0~240 min的微波和常规烧结实验,测量各样品的收缩率、密度和晶粒尺寸,分析其致密化行为和晶粒生长,研究烧结温度和保温时间对合金致密化和晶粒生长的影响。结果表明,与常规烧结比较,微波烧结促进YG8硬质合金的致密化,且获得的合金组织均匀,晶粒细小。另外,保温时间对微波烧结YG8硬质合金的晶粒生长几乎没有影响。

关键词:微波烧结;YG8硬质合金;致密化;晶粒生长

中图分类号:TG135 文献标志码:A

Densification and grain growth of microwave sintered WC-Co cemented carbide

LOU Jing1, YI Jian-hong1, 2, ZHOU Cheng-shang1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: Microwave and conventional technology were used to sintering WC-8Co cemented carbide. In order to research the effects of temperature and holding time on the densification and grain growth of the alloys, experiments with the temperature in range of 1 000-1 400 ℃, and the holding time in range of 0-240 min at 1 400 ℃ were conducted. The shrinkage, density and grain size of samples were systematically measured to analysis the densification behavior and the grain growth. The result shows that, in contrast to conventional sintering, microwave sintering enhances the densification behavior of WC-8Co alloys, and promotes homogeneous microstructure and finer grains. In addition, no evident influence of holding time on the grain growth of alloys sintered by microwave processing is observed.

Key words: microwave sintering; YG8 cemented carbide; densification; grain growth

硬质合金是一种以难熔金属化合物(WC、TiC、Cr2C3等)为基体,以过渡金属(Co、Ni、Fe等)或合金作粘结剂,采用粉末冶金方法制备的一种材料。由于具有高弹性模量、高硬度和强度、良好的热稳定性和优异的耐磨性,且抗冲击性、耐腐蚀性、导热导电性、红硬性均较好,硬质合金自问世以来一直备受关注,在切削加工、凿岩采掘、成形模具、耐磨零件等方面得到了广泛应用[1]。随着金属加工业、电子工业、医疗以及城市建设的迅速发展,世界范围内对高性能硬质合金材料的需求日益扩大,如集成电路板的微型钻头、用于印刷电路板引线切头的圆片切刀等材料,且对强度、韧性、刚度(弹性模量)等性能均提出严格要求[2]。具有高硬度、高强度的超细硬质合金(晶粒尺寸0.1~0.5 μm)可满足对硬质合金性能的严格要求,成为硬质合金特别是高性能硬质合金的研究热点[3]。

孔隙度对硬质合金的力学性能、物理性能和工艺性能都有很大影响。如在WC-Co合金中只要剩余孔隙度达0.5%(体积分数),抗弯强度就大大降低[4]。为了降低材料的孔隙率,实现材料全致密,通常需要提高烧结温度或延长保温时间。 然而对于常规烧结硬质合金,这将不可避免地造成晶粒长大[5]。由此可见,对于硬质合金特别是超细硬质合金而言,致密化与晶粒长大通常是相互制约的[6],但两者又同是影响硬质合金性能的关键因素。研究者为了获得性能优异的合金,一直致力于尝试开发一种既能使合金全致密化,又能最大限度地控制WC晶粒长大的烧结方法。

微波烧结硬质合金由程吉平[7]于1991年提出,接着德国多特蒙德大学的GERDES和WILLERT- PORADA[8]也对微波烧结WC-Co硬质合金进行了研究,通过纯W、C、Co的反应烧结制取WC-Co硬质合金,获得较传统方法更好的组织和性能。美国宾夕法尼亚州立大学的AGRAWAL等[9-10]通过微波烧结和常规烧结的对比实验,得出在相当致密化程度下,微波烧结得到的晶粒平均粒度 (0.6 μm)远低于常规烧结所得(2 μm)的平均晶粒。另外,武汉理工大学的全峰[11]对WC-10Co硬质合金进行了一系列研究,设定烧结温度为1 320 ℃,保温15 min,得到均匀正常的组织,但延长保温时间,合金WC晶粒将发生再结晶长大,引起合金晶粒粗化。众多研究报道了微波烧结可以控制硬质合金晶粒长大的现象,但是有关系统分析微波烧结硬质合金致密化和晶粒生长的研究鲜有报道。本文作者对微波烧结WC-8Co硬质合金的致密化行为和晶粒长大现象进行了较为系统的分析研究。

1 实验

本实验使用株洲硬质合金集团有限公司提供的WC-8Co混合料。压制成 d 18 mm的圆柱样,利用氢气炉脱脂,然后进行微波烧结和常规烧结。微波烧结实验设备为 MW-L0616V 微波高温炉,微波频率为2.45 GHz,功率为6 kW,烧结过程中通过手动调节微波输出功率实现温度控制。温度测量采用 MarathonTMMM 系列高性能红外测温仪(测温范围:450~2 250 ℃)。微波烧结使用N2+H2为保护气氛,升温速率为30 ℃/min,选定烧结温度为1 000~1 400 ℃,并在1 400 ℃时保温0~240 min,然后随炉冷却。常规烧结使用氢气炉,烧结温度、保温时间与微波烧结相同。

压坯经过烧结后测量其密度和径向尺寸。烧结密度在精度为10-4的AEL-200电子分析天平上用排水法测量,为了防止孔隙对结果的影响,采用凡士林封孔。密度计算公式由下式给出:

ρ=ρw ×[m0/(m1-m2)] (1)

式中:ρ为烧结坯密度;ρw为水的密度;m0为坯块在涂抹凡士林前的质量;m1为坯块涂抹凡士林后的质量;m2为涂抹凡士林坯块在水中的质量。

用游标卡尺测量烧坯径向尺寸,试样径向烧结收缩率按下式计算:

S=(1-Ds/Dc) ×100% (2)

式中:S为烧结径向收缩率;Dc为压坯径向尺寸;Ds为烧结样品径向尺寸。

将样品磨平抛光,然后在MeF3A光学显微镜上观察组织形貌,最后用SIRION200场发射扫描电镜进行组织分析。使用Image Pro软件分析测量FESEM照片中的WC晶粒尺寸,测量1 000个以上WC晶粒,取平均值得到WC晶粒的平均尺寸。

2 结果与分析

2.1 致密化行为分析

硬质合金是典型的液相烧结,烧结过程可大致划分为3个阶段:液相流动与颗粒重排阶段,固相溶解再析出阶段和固相烧结阶段。致密化过程大多在前两个阶段完成,特别是颗粒重排阶段。在烧结过程中,在所有影响致密化的因素中,烧结温度和保温时间的作用是显著的,首先讨论其作用。

2.1.1 烧结温度和时间对致密化的影响

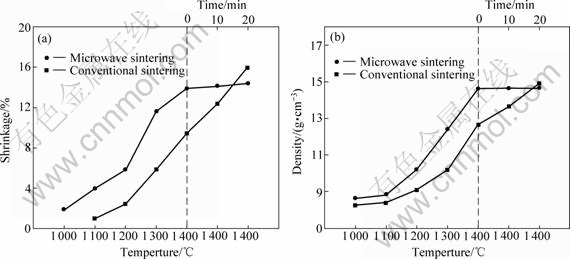

图1(a)和(b)所示分别为烧结温度和时间对YG8硬质合金的微波烧结、常规烧结样品收缩率和密度的影响。如图1所示,微波烧结和常规烧结硬质合金样品的密度和收缩率均随烧结温度升高而增加。由图1 (a)可见,随温度的升高,微波烧结与常规烧结样品收缩率增大。并且,与常规烧结样品的收缩率相比,微波烧结样品能在低于常规烧结100~200 ℃的条件下,获得与常规烧结样品大致相当的收缩率。与之对应,如图1(b)所示,在1 000~1 400 ℃范围,微波烧结样品的密度高于常规烧结样品的,其在1 400 ℃烧结时的相对密度达到99.25%;常规烧结样品的密度一直低于微波烧结样品的,直至1 400 ℃保温20 min实现全致密。

图1 微波烧结与常规烧结样品的收缩率(a)及密度(b)曲线

Fig. 1 Curves of sintering shrinkage (a) and density (b) for microwave and conventional sintered samples

图2所示为微波烧结与常规烧结样品不同温度时的FESEM像。由图2可见,在相同温度下,微波烧结样品的致密化程度均高于常规烧结样品的。烧结温度为1 100 ℃时,由于处于烧结样品的初期,两种烧结方法所得样品致密化程度均不高,但仍可看出微波烧结样品的孔隙(见图2(a))少于常规烧结样品的(见图2(b))。温度升至1 200 ℃时,微波烧结样品(见图2(c))WC颗粒间表面接触较明显,形成烧结颈,连通孔隙减少;常规烧结样品(见图2(d))WC颗粒间距离缩短,但表面接触不多。当烧结温度为1 300 ℃时,微波烧结样品(见图2(e))连通孔隙明显减少,逐渐被液相填充;常规烧结样品(见图2(f))颗粒间接触增加,连通孔隙数量有所降低。烧结温度为1 400 ℃时,温度已超过共晶温度(1 320 ℃),合金进入液相烧结阶段;微波烧结样品(见图2(g))WC颗粒间孔隙基本被液相填充,而常规烧结样品(见图2(h))还有部分孔隙存在,这表明常规烧结样品的致密化仍在进行。综上所述,在相同烧结温度下,微波烧结样品的孔隙数量明显少于常规烧结试样的,且孔隙较小。

另外,从WC颗粒形状来看,烧结温度为1 100 ℃时,在两种烧结方法得到的样品中,WC颗粒基本上都还处于原始粉末形态;烧结温度升至1 200 ℃时,微波烧结样品中多角状的WC颗粒明显增多,而常规烧结样品中几乎没有此现象;微波烧结至1 300 ℃之后,所得样品中WC颗粒几乎全为多角状,而常规烧结至1 300和1 400 ℃时,所得样品中多角状WC颗粒有所增加,但并不明显。由此可以推测,微波烧结能够促进物质的扩散,因此WC颗粒才会发生形状的改变。文献[12-13]报道微波烧结可在1 250~1 320 ℃烧结出性能良好,显微组织正常的合金。最近,DEMIRSKYI等[14]研究了WC球形粉末在微波场加热中烧结颈生长现象后指出:微波烧结的扩散系数高于常规烧结的,且微波烧结使激活能明显降低;据他们推测,在微波加热条件下,粉末颗粒烧结颈处可能温度较高,甚至有液相的出现。由于微波场加热可能导致局部液相出现,一方面加快物质扩散,使合金在更低的温度下加速致密化;另一方面,在较低的烧结温度下,能够使WC晶粒形貌改变,形成典型的WC-Co硬质合金组织。

2.1.2 保温时间对密度的影响

如图3所示,保温时间由0 min延长至30 min,微波烧结样品的密度由14.64 g/cm3增加至14.81 g/cm3;之后随保温时间延长,密度仍继续增加。而常规烧结样品在1 400 ℃保温0 min时密度较低,为12.68 g/cm3;延长保温时间至20 min,样品密度快速增加至14.93 g/cm3;继续延长保温时间,密度同样地有所增加。然而,由图3可见,常规烧结样品的密度最终高于微波烧结样品的,这可能与在微波烧结样品表面观察到的空隙有关。

2.2 晶粒生长

图4所示分别为YG8硬质合金微波烧结和常规烧结样品在1 400 ℃保温0、30和120 min的FESEM像。由图4(a)可见,微波烧结样品中WC晶粒尺寸随保温时间的延长无明显变化,即使保温时间为120 min,晶粒的长大也不明显。由图4(d)可见,常规烧结样品在1 400 ℃保温0 min时未实现全致密,晶粒尺寸较小。在1 400 ℃保温30 min时,常规烧结样品(见图4(e))与相同条件下的微波烧结样品相比,WC晶粒尺寸有所增大;继续延长保温时间至120 min(见图4(f))时, WC晶粒长大明显。

图2 微波烧结与常规烧结样品FESEM像

Fig. 2 FESEM images of microwave and conventional sintered samples: (a) Microwave sintering, 1 100 ℃; (b) Conventional sintering, 1 100 ℃; (c) Microwave sintering, 1 200 ℃; (d) Conventional sintering, 1 200 ℃; (e) Microwave sintering, 1 300 ℃; (f) Conventional sintering, 1 300 ℃; (g) Microwave sintering, 1 400 ℃; (h) Conventional sintering, 1 400 ℃

图3 微波烧结和常规烧结样品的密度—保温时间关系曲线

Fig. 3 Relationship curves of density—holding time of microwave and conventional sintered samples

图5所示为烧结温度为1 400 ℃时微波烧结和常规烧结样品中WC晶粒尺寸与保温时间的对数关系。由图5可见,随保温时间的延长,微波烧结样品中WC晶粒尺寸无明显变化:保温10 min时,晶粒尺寸为0.84 min;保温时间延长至120 min时,晶粒尺寸为0.86 μm。而常规烧结样品中WC晶粒尺寸与保温时间的对数呈线性增长关系:常规烧结样品保温0 min时,晶粒尺寸为0.50 μm;保温30 min时,晶粒尺寸增长至1.03 μm;保温120 min时,晶粒尺寸达1.13 μm。

图4 YG8硬质微波烧结和常规烧结在1 400 ℃不同保温时间的组织

Fig. 4 Microstructures of YG8 cemented carbide with various holding time at 1 400 ℃ under microwave and conventional sintering: (a) Microwave sintering, 0 min; (b) Microwave sintering, 30 min; (c) Microwave sintering, 120 min; (d) Conventional sintering, 0 min; (e) Conventional sintering, 30 min; (f) Conventional sintering, 120 min

图5 微波烧结和常规烧结样品中WC晶粒尺寸与保温时间的对数的关系

Fig. 5 Relationship between WC grain size and ln(t/min) in microware and conventional sintered samples

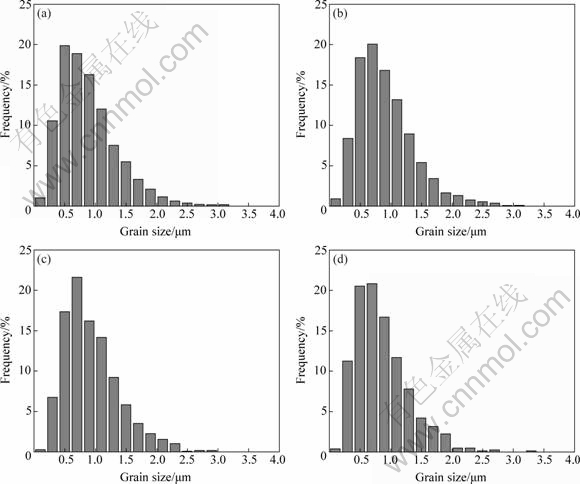

通过对不同保温时间微波烧结样品的晶粒尺寸—频率分布图(见图6)进行分析,发现微波烧结YG8硬质合金中大多数WC晶粒粒径集中在0.50~1.00 μm之间,不同保温时间的晶粒尺寸分布差别不明显。并且,在所有微波烧结样品中都没有观察到晶粒异常长大现象。

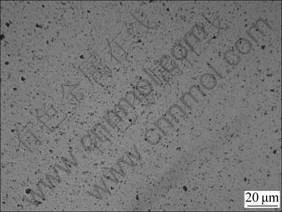

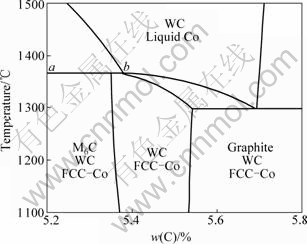

硬质合金晶粒长大机制主要有溶解再析出和固相骨架烧结(WC晶粒接触长大)[4]。BREVAL等[15]在微波烧结的WC-Co的TEM分析中发现,Co相中几乎没有W的存在。如果WC不溶解在Co相中,WC的溶解再析出机制必然受到抑制,这会在一定程度上抑制WC晶粒长大。另外,通过金相观察发现,微波烧结样品中有少量弥散分布的脱碳相存在,如图7所示。KONYASHIN[16]报道,WC-Co硬质合金中脱碳相的存在会导致WC晶粒生长受到抑制。图8所示为Co含量为10%的W-Co-C三元相图垂直截面图[17]。由图8可知,如果出现脱碳相(η相,图中为M6C),将使得以液相存在的Co的含量降低,从而抑制ab温度线之上的WC晶粒生长。Co含量为8%的合金也遵循同样的规律。因此,微波烧结YG8硬质合金中WC晶粒长大趋势不明显,可能与脱碳相的存在以及由于W不溶于Co而使溶解再析出减少有关。

图6 不同保温时间微波烧结样品中WC晶粒尺寸—频率分布

Fig. 6 WC grain size—frequency distribution in microwave sintered samples with different holding times: (a) 0 min; (b) 30 min; (c) 60 min; (d) 120 min

图7 微波烧结样品在1400 ℃保温30 min的金相照片

Fig. 7 Metallographic photos of microwave sintered samples held at 1 400 ℃ for 30 min

图8 10%Co的 W-Co-C三元相图垂直截面图[17]

Fig. 8 Vertical section of ternary phase diagram Co-W-C at 10% Co[17]

本实验在微波烧结条件下观察到了脱碳现象,而SIVAPRAHASAM等[18]、周建等[19]在研究中也观察到类似的脱碳现象。另外,文献[14]指出,W和C在WC中的扩散行为存在差异,而微波效应可能会加剧这种扩散差异,这也可能造成脱碳。周建等[19]认为,W和C在Co中的溶解不平衡造成了微波烧结硬质合金的脱碳。因此,脱碳相的形成与微波作用的联系还有待进一步探讨。

3 结论

1) 微波烧结促进YG8硬质合金的致密化。这可能是由于微波烧结为活化烧结,降低烧结活化能提高扩散系数,使得低于共晶温度有局部液相出现,从而较早实现烧结致密化。

2) 微波烧结YG8硬质合金能获得细小均匀的WC晶粒。实验发现,微波烧结烧结温度和时间均未对WC晶粒尺寸造成明显影响。

REFERENCES

[1] 余立新, 胡惠勇. 世界硬质合金材料技术新进展[J]. 硬质合金, 2006, 23(1): 52-57.

YU Li-xin, HU Hui-yong. Progress on hard metal technology in worldwide [J]. Cemented Carbide, 2006, 23(1): 52-57.

[2] GILLE G, SZESNYA B, DREYERB K, VAN DEN BERGB H, SCHMIDTC J, GESTRICHD T, LEITNERD G. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts [J]. International Journal of Refractory Metal & Hard Materials, 2002, 20(1): 3-22.

[3] 吴其山. 超细WC-Co硬质合金的研究综述[J]. 中国钨业, 2005, 20(6): 35-40.

WU Qi-shan. Summarize of the research on superfine WC-Co cemented carbides [J]. China Tungsten Industry, 2005, 20(6): 35-40.

[4] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 2006: 421.

HUANG Pei-yun. Powder metallurgy principle [M]. Beijing: Metallurgical Industry Press, 2006: 421.

[5] WANG X, FANG Z Z, SOHN H Y. Grain growth during the early stage of sintering of nanosized WC-Co powder [J]. International Journal of Refractory Metals & Hard Materials, 2008, 26(3): 232-241.

[6] FANG Z Z, EASON J W. Study of nanostructured WC-Co composites [J]. International Journal of Refractory Metals & Hard Materials, 1995, 13(5): 297-303.

[7] 程吉平. 陶瓷材料微波烧结技术的研究[D]. 武汉: 武汉工业大学, 1991.

CHENG Ji-ping. Research of microwave sintering ceramic materials [D]. Wuahn: Wuhan University of Technology, 1991.

[8] GERDES T, WILLERT-PORADA M. Microwave sintering of metal-ceramic and ceramic-ceramic composites [J]. Materials Research Society Symposium Proceedings, 1994, 347: 531-537.

[9] GIGL P D, BREVAL E, CHENG J P, AGRAWAL D K, ROY R. Structure properties of microwave sintered cemented tungsten carbide materials [C]// Abstract Book of The First World Congress on Microwave Processing. Orlando, Florida. Fredrick, MD: W/L Associates Ltd., 1997: 106.

[10] CHENG J P, AGRAWAL D K, KOMAMENI S, MATHIS M, ROY R. Microwave processing of WC-Co composites and ferroic titanates [J]. Materials Research Innovations, 1997, 1(1): 44-52.

[11] 全 峰. 微波烧结WC-10Co硬质合金的结构与性能研究[D]. 武汉: 武汉理工大学, 2007.

QUAN Feng. Research of structure and properties of microwave sintered WC-10Co cemented carbide [D]. Wuhan: Wuhan University of Technology, 2007.

[12] AGRAWAL D K. Microwave processing of ceramics [J]. Current Opinion in Solid State & Materials Science, 1998, 3(5): 480-485.

[13] AGRAWAL D, PAPWORTH A J, CHENG J P, JAIN H, WILLIAMS D B. Microstructural examination by TEM of WC/Co composites prepared by conventional and microwave Processes [C]// 15th International Plansee Seminar 2001. Plansee, Austria, 2001.

[14] DEMIRSKYI D, RAGULYA A, AGRAWAL D. Initial stage sintering of binderless tungsten carbide powder under microwave radiation [J]. Ceramics International, 2011, 37(2): 505-512.

[15] BREVAL E, CHENG J P, AGRAWAL D K, GIGL P, DENNIS M, ROY R, PAPWORTH A J. Comparison between microwave and conventional sintering of WC/Co composites [J]. Materials Science and Engineering A, 2005, 391(1/2): 285-295.

[16] KONYASHIN I, HLAWATSCHEK S, RIES B, LACHMANN F, DORN F, SOLOGUBENKO A, WEIRICH T. On the mechanism of WC coarsening in WC-Co hardmetals with various carbon contents [J]. International Journal of Refractory Metals & Hard Materials, 2009, 27(2): 234-243.

[17] PETERSSON A. Cemented carbide sintering: Constitutive relations and microstructural evolution [D]. Stockholm: Royal Institute of Technology, 2004.

[18] RATNA SUNIL B, SIVAPRAHASAM D, SUBASRI R. Microwave sintering of nanocrystalline WC-12Co: Challenges and perspectives [J]. International Journal of Refractory Metals & Hard Materials, 2010, 28(2): 180-186.

[19] 周 建, 全 峰, 刘伟波, 刘桂珍. 微波单模腔烧结WC-10Co硬质合金的研究[J]. 武汉理工大学学报, 2007, 29(12): 1-4.

ZHOU Jian, QUAN Feng, LIU Wei-bo, LIU Gui-zhen. Research on microwave sintering WC-10Co cemented carbide in a single-mode cavity [J]. Journal of Wuhan University of Technology, 2007, 29(12):1-4.

(编辑 何学锋)

基金项目:教育部留学回国人员科研启动基金资助项目(教外司留[2008]890);国家自然科学基金青年基金资助项目(51104188)

收稿日期:2011-06-20;修订日期:2011-11-18

通信作者:易健宏,教授,博士;电话:0731-88876420;E-mail: yijianhong2007@sohu.com