轧制温度和道次变形量对铝阳极Al-Mg-Sn-Bi-Ga-In

性能的影响

梁叔全,官迪凯,毛志伟,张勇,潘安强,唐艳

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:采用析氢测量法、计时-电位法(E-T曲线)、Tafel曲线、扫描电镜和能谱分析等分析测试方法研究不同轧制工艺的Al-Mg-Sn-Bi-Ga-In铝合金阳极在80 ℃、在浓度为5 mol/L NaOH电解液中添加缓蚀剂Na2SnO3的电化学性能和耐腐蚀性能。研究结果表明:按道次变形量40%进行轧制时,随着轧制温度的升高,开路电位负移,而活性和耐腐蚀性能先提高后降低;在370 ℃进行轧制时,随着道次变形量增大,开路电位正移,活性逐渐降低,而耐腐蚀性能先提高后降低;在370 ℃,按道次变形量40%进行轧制时,铝合金阳极的综合性能最佳。

关键词:铝合金;阳极;轧制;缓蚀剂;电化学性能;耐腐蚀性能

中图分类号:TM911.41 文献标志码:A 文章编号:1672-7207(2010)03-0906-06

Effect of rolling temperature and pass deformation on Al anode Al-Mg-Sn-Bi-Ga-In performances

LIANG Shu-quan, GUAN Di-kai, MAO Zhi-wei, ZHANG Yong, PANG An-qiang, TANG Yan

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Modern examination techniques such as hydrogen production test, galvanodynamic (E-T curves) methods, Tafel curves, scanning electron microscope and energy spectrum analysis were applied to analyze the electrochemical properties of Al alloys anode through different rolling processes in alkaline solution (80 ℃, Na2SnO3+5 mol/L NaOH). The results show that under 40% pass deformation, with the increase of the rolling temperature, the open-circuit potential falls, but the anti-corrosion properties and electrochemical activity first increase and then decrease; at the rolling temperature of 370 ℃, with the increase of pass deformation, the open-circuit potential increases and electrochemical activity gradually decreases, and at the same time the anti-corrosion properties first decreases and then increases; at 370 ℃, under 40% pass deformation, Al alloy anode has the best comprehensive property.

Key words: aluminum alloy; anode; rolling; inhibititors; electrochemical properties; anti-corrosion properties

铝合金作为阳极材料具有电化学活性高、放电能力大、电极电位负等独特优势, 但同时存在电化学活性低、耐腐蚀性能差2大突出问题[1]。为了解决这些问题,高性能铝电池的电解质一般采用碱性介质并添加缓蚀剂,以满足大电流放电需要,同时采用合金化方法, 以保持铝阳极的活性溶解[2-4]。热处理也是一种常用的提高耐腐蚀性能的方法,祁洪飞等[5]研究了均匀化退火对铝合金阳极活化性能的影响,结果表明:当退火温度低于400 ℃时,晶体缺陷的大量减少是导致铝阳极活性变化的主导因素,铝阳极活性随退火温度提高而降低;当退火温度高于400 ℃,析出相大量固溶成为导致铝阳极活性变化的主要因素,铝阳极随着温度的提高而增强;当退火温度达到550 ℃时,合金元素已基本溶解于铝基体,且分布弥散均匀。龙萍等[6]研究了固溶处理对阳极电化学性能的影响。结果表明:固溶处理对常温下铝阳极的电化学性能影响不大,但可改善高温下的阳极性能。固溶处理能有效提高阳极的电流效率,降低晶间腐蚀。张林森等[7]研究了固溶处理和回火处理对铝合金电极在3.5% NaCl溶液中的电化学性能。结果表明:经过固溶处理后,铝合金阳极的电化学活性得到显著提高,但自腐蚀速率加快。经过500 ℃固溶处理6 h后,再在150 ℃回火8 h的铝合金电极,不仅电化学活性高,而且自腐蚀速率也低。然而,热轧工艺对铝阳极性能的影响却很少见报道。为了满足高温下大电流放电的需要,本文作者在研制性能优良的铝合金阳极的基础上,研究不同轧制温度和道次变形量对铝阳极性能的影响,以完善铝阳极的制造工艺。

1 实验方法

1.1 试样制备

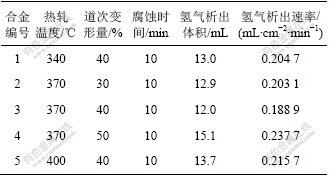

采用传统浇铸工艺制得所需铝合金Al-Mg-Sn- Bi-Ga-In。经过铣面后,在510 ℃保温5 h、水淬,以减少铝合金中的晶体缺陷,提高合金元素在铝基体中的固溶度。将固溶处理后的铝合金在双辊冷轧机上轧制成约0.5 mm厚的板材, 制得5种铝合金如表1所示。将上述合金制备成工作面积为1 cm2的正方形电极片,用AB胶将电极的非工作区域覆盖,工作区用金相砂纸逐级打磨后抛光,丙酮去油,蒸馏水清洗后晾干备用。以石墨为辅助电极,Hg/HgO电极为参比电极。

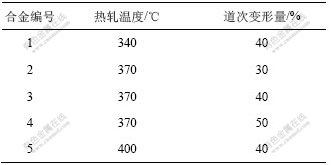

表1 铝合金的轧制工艺

Table 1 Rolling technology of Al alloy

1.2 显微组织分析

将试样表面经水磨砂纸和金相砂纸打磨、抛光后,用0.5% HF腐蚀30 s,蒸馏水清洗后烘干,用日本电子公司型号为Sirion-200的扫描电镜分析铝合金阳极表面形貌,对典型的偏析相进行能谱分析。

1.3 铝阳极的性能测试

采用容量瓶和刻度管测量80 ℃下铝合金在碱液中的析氢反应速度。析氢速度用单位时间单位面积的铝合金所析出的氢气体积即析氢速度v来表示,单位为 mL/(cm2?min)。

采用上海辰华仪器公司制造的CHI660电化学工作站和CHI680电流放电器及其配套软件进行测试。在三电极体系下,电解液为添加Na2SnO3的5 mol/L NaOH溶液,用计时-电位法测试铝阳极在700 mA/cm2电流密度下的性能;Tafel曲线的扫描范围为-2.0~ -1.6 V,扫描速度为10 mV/s,测试温度为80 ℃。

2 实验结果与讨论

2.1 铝阳极的显微组织

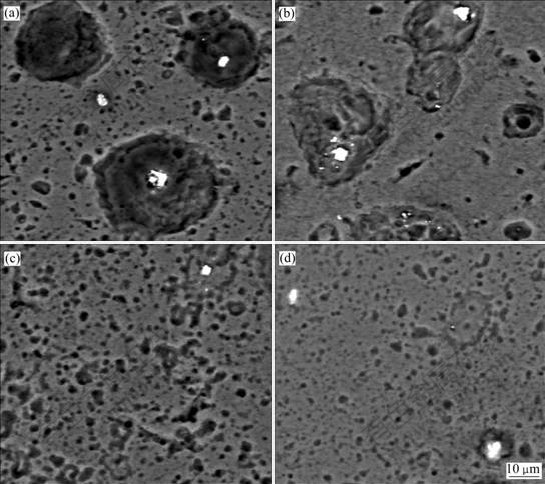

1号、2号、3号和5号合金的扫描电镜像如图1所示。由图1可以看出:1号合金偏析相多,表面存在大且深的腐蚀坑;3号合金偏析相少,腐蚀坑细小均匀;5号合金偏析相分布不均匀,粗大的析出相周围腐蚀严重。轧制温度对铝合金性能和组织的影响主要通过动态再结晶过程来实现[8-9]。通过动态再结晶形成细小的新晶粒,使平均晶粒尺寸变小,当轧制温度较低时,动态再结晶进行得不充分,其中新晶粒的尺寸特别细小,使得基体内的合金元素分布不均,偏析相多且粗大;随着轧制温度的升高,动态再结晶逐渐变得充分,新晶粒逐渐长大,各晶粒之间尺寸差距减小,组织逐步均匀,使得合金元素均匀分布,偏析相减少,从而使铝合金的活性和耐腐蚀性提高;但当轧制温度进一步升高时,新晶粒的长大趋势增大,反而影响组织的均匀性和合金元素的分布,使得偏析相增多,从而降低了铝合金的综合性能。

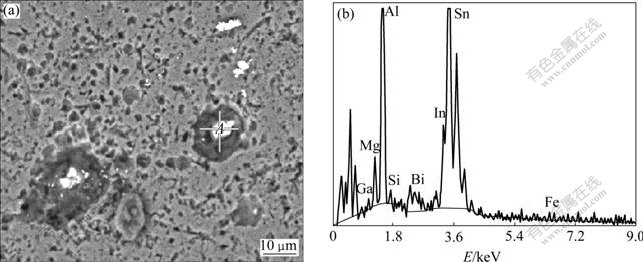

4号合金的扫描电镜像见图2。由图1和2可以看出:2号合金存在大量偏析相,且分布不均,大小不一,表面还存在不同大小的腐蚀坑;3号合金偏析相少,腐蚀坑细小均匀;4号合金表面有粗大的偏析相,腐蚀坑大且深。动态再结晶需要一个临界变形量,当实际变形量超过临界变形量时,才能发生动态再结晶,且随着变形量的增加和动态再结晶的不断进行,组织逐渐变得均匀、细小[8-9]。但是4号合金由于道次变形量过大,可能会使得晶内位错密度增大,内应力增 加,晶格畸变加剧,板材出现裂纹,反而降低了材料的性能。

(a) 1号合金;(b) 2号合金;(c) 3号合金;(d) 5号合金

图1 铝合金的扫描电镜像

Fig.1 SEM images of aluminum alloys

(a) 扫描电镜像;(b) A点的能谱分析结果

图2 4号合金的扫描电镜像和A点的能谱分析

Fig.2 SEM image of sample 4 and EDAX pattern of point A

Sn和In等活性元素与其他元素形成偏析相,用能谱分析该偏析相的组成(图2)。表2所示为A点元素定量分析结果(质量分数)。由表2可以看出:Sn和In是主要组成元素,也存在Fe和Si等杂质元素。高温下In3+等活化元素的再沉积变得困难,所以,高温下铝阳极的活化作用以偏析相的优先溶解为主[10-11]。由于Sn在偏析相中含量最大,所以,在铝合金阳极的活化溶解中,Sn可能起着重要的作用。

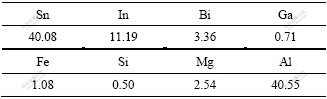

表2 偏析相的定量分析结果(质量分数)

Table 2 Quantity results of precipitation phase %

2.2 铝阳极的电化学性能

2.2.1 轧制温度和变形量对铝阳极开路电位和Tafel曲线的影响

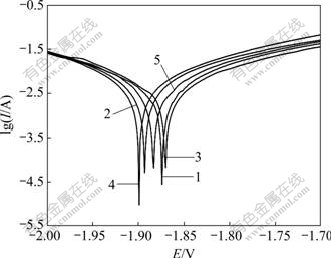

在80 ℃时,铝合金阳极在添加缓蚀剂Na2SnO3的5 mol/L NaOH电解液中的Tafel曲线如图3所示。可见:表3所示为热轧工艺对铝阳极电化学性能的影响。当道次变形量为40%时(图3),随着轧制温度的升高,开路电位负移,自腐蚀电位先正移后负移,而自腐蚀电流先降低后升高(表3),耐腐蚀性能先提高后降低。主要是由于动态再结晶随着轧制温度的升高逐步充分进行[8-9],产生大量的细小新晶粒,使得组织逐步变得均匀、细小,合金元素均匀分布,耐腐蚀性能提高,但当温度超过充分进行动态再结晶的起始温度时,晶粒的长大趋势增大,引起组织的均匀性发生变化,反而降低了耐腐蚀性能。

由图3可见:在370 ℃下,随着道次变形量的增大,开路电位正移,自腐蚀电位先正移后负移,自腐蚀电流先降低后升高(表3),由此可知耐腐蚀性能随着道次变形量的增大先提高后降低。随着变形量的增大,动态再结晶从不充分进行到充分进行,组织逐渐均匀细化,从而使铝阳极的耐腐蚀性能提高。由于动态再结晶需要1个临界变形量[8-9],所以,道次变形量大时更容易发生动态再结晶,但是,当道次变形量过大时,可能会使得晶内位错密度增大,晶格畸变加剧,产生许多晶体缺陷,从而降低了铝阳极的耐腐蚀性能,板材也出现裂纹,影响材料的后续加工。

变形温度和变形量:1—340 ℃, 40%; 2—370 ℃, 30%;

3—370 ℃, 40%; 4—370 ℃, 50%;5—400 ℃, 40%

图3 不同变形条件下铝合金阳极的Tafel曲线

Fig.3 Tafel polarizing curves of Al alloys anode after being compressed under different conditions

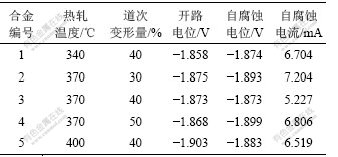

表3 不同轧制工艺对铝阳极电化学性能的影响

Table 3 Effects of different rolling technologies on electrochemical properties of Al anode

2.2.2 轧制温度和道次变形量对铝阳极恒电流放电性能的影响

Venugop等[12]提出了Sn的活化机制,Sn能以Sn2+和Sn4+进入合金表面氧化膜中,从而产生很多阳离子、阴离子缺陷,促进合金的活化溶解。Sn还可以和Ga形成低熔点合金Sn-Ga[13]。Sn-Ga合金具有良好的流动性,有效地分离了氧化膜,促使铝合金的活化溶解。此外,由于Sn离子不需要再沉积就能造成氧化膜的破坏,所以,在高温下Sn对铝阳极的活性起着重要的作用。Reboul等[14]提出的溶解-再沉积机理认为:阴极性阳离子In3+可以通过电化学置换反应重新沉积到Al的氧化膜表面,In3++Al→A13++In;使得A1的氧化膜局部分离,促使铝表面均匀溶解,提高电流效率。

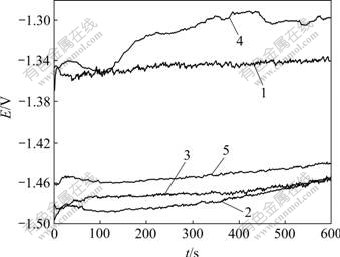

图4所示为在80 ℃下添加缓蚀剂的碱液中,5种铝合金阳极在电流密度为700 mA/cm2时的放电性能。可见:当道次变形量为40%时,随着热轧温度的提高,活性先提高后降低(图4)。1号样品的放电性能较差,其E-T曲线不如3号和5号样品的E-T曲线光滑,呈锯齿状,可能由于动态再结晶不够充分,产生了少量细小晶粒且分布不均匀,使得Sn和In等活性元素分布不均匀造成的。5号样品的活性略低于3号样品的活性,可能是轧制温度过高时,新晶粒的长大趋势增大,引起组织不均匀,影响了活性元素的均匀分布造成的。

在370 ℃热轧2~4号样品,随着道次变形量的增大,活性逐渐降低(图4)。但是3号样品放电时的稳定性略高于2号样品,是因为3号样品的动态再结晶比2号样品更加充分,组织更加均匀、细小,促使Sn和Ga等活性元素分布更加均匀。而4号样品的放电性能很差,电压不稳,下降也快,主要是道次变形量过大,热轧时板材出现裂纹,造成晶体缺陷过多,组织不均匀,活性元素分布不均,大量存在于偏析相中造成的。

变形温度和变形量:1—340 ℃, 40%; 2—370 ℃, 30%;

3—370 ℃, 40%; 4—370 ℃, 50%; 5—400 ℃, 40%

图4 不同变形条件下铝合金阳极恒电流放电曲线

Fig.4 Discharge curves of Al alloys anode after being compressed under different conditions

2.3 轧制温度和道次变形量对铝阳极耐腐蚀性能的影响

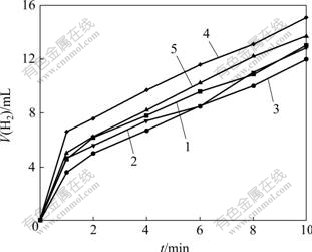

实验样品尺寸(长×宽×厚)为2.00 cm×1.50 cm× 0.05 cm的薄板,表面积为6.35 cm2,其析氢速率见表4。从铝阳极在80 ℃的5 mol/L的NaOH溶液中添加缓蚀剂Na2SnO3后的析氢曲线(图5),可以看出:在道次变形量为40%时,随着轧制温度的升高,析氢量先降低后升高;在370 ℃轧制时,随着道次变形量的增大,析氢速量先降低后升高。耐腐蚀性能都是先提高后降低,这与前面的扫描电镜图谱分析结果以及Tafel曲线分析结果一致。

在370 ℃,当道次变形量为40%时,轧制的3号样品的析氢速率最小,只有0.188 9 mL/(cm2·min)(表4),耐腐蚀性能最佳。其主要原因是:在适当的轧制温度和道次变形量下可以获得均匀细小的组织,使Sn和In等活性元素分布均匀[15],减少偏析相。Sn和In等活性元素分布均匀能减少杂质铁硅铜等的不利影响,使铝阳极发生均匀腐蚀,提高耐腐蚀性能。反之,会在晶界处出现大量以Sn和In为主的偏析相(表2),使晶界优先溶解,造成晶粒脱离,降低电流效率,自腐蚀增加且极不均匀,孔蚀严重,这与图1和2所示的扫描电镜图谱分析结果相符。

变形温度和变形量:1—340 ℃, 40%; 2—370 ℃, 30%;

3—370 ℃, 40%; 4—370 ℃, 50%; 5—400 ℃, 40%

图5 不同变形条件下铝合金阳极的析氢量曲线

Fig.5 H2 evolution curves of Al alloys anode after being compressed under different conditions

表4 不同轧制工艺对铝合金阳极耐腐蚀性能的影响

Table 4 Effects of different rolling technologies on corrosion-resistant properties of Al anode

3 结论

(1) 按道次变形量40%进行轧制时,随着轧制温度的升高,动态再结晶逐步充分进行,新晶粒的长大趋势也逐步增大,引起开路电位降低,而材料活性和耐腐蚀性能先提高后降低。

(2) 在370 ℃进行轧制时,随着道次变形量增大,组织逐渐变得均匀、细小,开路电位升高,活性逐渐降低,耐腐蚀性能提高,但当道次变形量过大时,会产生大量晶体缺陷,降低材料的耐腐蚀性能。

(3) 适当的轧制温度和道次变形量使得Sn和In等活性元素均匀分布、偏析相减少,从而使材料活性和耐腐蚀性能提高,在370 ℃时,按道次变形量40%进行轧制的样品的综合性能最佳。

参考文献:

[1] 王兆文, 李延祥, 李庆峰, 等. 铝电池阳极材料的开发与应用[J]. 有色金属, 2002, 54(1):19-22.

WANG Zhao-wen, LI Yan-xiang, LI Qing-feng, et al. Development and application of aluminum battery anode materials[J]. Non-ferrous Metals, 2002, 54(1): 19-22.

[2] LI Q, Hjuler H A, Berg R W, et a1. Electrochemical deposition and dissolution of aluminum in NaAlCl4 melts[J]. J Electrochem Soc, 1990, 137(9): 2794-2798.

[3] Eishaye H A, Abd E I, Wahab F M. Effect of gallingions on the electrochemical behaviour of Al, Al-Sn, Al-Zn and Al-Zn-Sn alloys in chloride solutions[J]. Corrosion Science, 2001, 43(4): 643-654.

[4] Gurrappa I. The surface free energy and anode efficiency of aluminum alloys[J]. Corrosion Prevention & Control, 1993, 40(4): 111-114.

[5] 祁洪飞, 梁广川, 李国禄, 等. 均匀化退火对铝合金阳极活化性能的影响[J]. 材料工程, 2005(10): 27-30.

QI Hong-fei, LIANG Guang-chuan, LI Guo-lu, et al. Effects of homogenization treatment on aluminum alloy anode activation properties[J]. Materials Engineering, 2005(10): 27-30.

[6] 龙萍, 李庆芬. 固溶处理对Al-Zn-In-Si-Sn阳极电化学性能的影响分析[J]. 装备环境工程, 2005, 2(2): 12-16.

LONG Ping, LI Qing-fen. Effect of solution treatment on Al-Zn-In-Si-Sn anode electrochemical performance analysis[J]. Environmental Engineering Equipment, 2005, 2(2): 12-16.

[7] 张林森, 王双元, 王为, 等. 热处理对铝合金电极性能的影响[J]. 电源技术研究与设计, 2006, 30(12): 1000-1002.

ZHANG Lin-sen, WANG Shuang-yuan, WANG Wei, et al. Effect of heat treatment on aluminum alloy electrode performance[J]. Power Technology and Design, 2006, 30(12): 1000-1002.

[8] Kassner M E, Myshlyaev M M, MeQueen H J. Large-strain torsional deformation in aluminum at elevated temperatures[J]. Mater Sci Eng A, 1989, 108: 45-61.

[9] McQueen H J, Blum W. Recovery and recrystallization in Al alloys: fundamentals and practical applications[C]//Aluminum Alloys: Their Physical Arm Mechanical Properties (Vo1.1). Tokyo: Japan Institute of Light Metals, 1998: 99-1l2.

[10] 魏宝明. 金属腐蚀理论及应用[M]. 北京: 化学工业出版社, 1984: 22-38.

WEI Bao-ming. Theory and application of metal corrosion[M]. Beijing: Chemical Industry Press, 1984: 22-38.

[11] 廖海星, 朱鸿赫, 齐公台, 等. 温度对铝合金牺牲阳极活化溶解行为的影响[J]. 华中科技大学学报: 自然科学版, 2004, 32(2): 114-116.

LIAO Hai-xing, ZHU Hong-he, QI Gong-tai, et al. Effects of temperature on the activation dissolving behavior of sacrisfice aluminum alloy anode[J]. Huazhong University of Science and Technology Journal: Natural Science, 2004, 32(2): 114-116.

[12] Venugop M A, Veluchamy P, Selvam P, et a1. X-ray photoelectron spectroscopic study of the oxide film on an aluminum-tin alloy in 3.5% sodium chloride solution[J]. Corosion, 1997, 53(10): 808-812.

[13] LI Zhen-ya, QIN Xue, YU Yuan-bin, et a1. The electrochemical behavior of AI alloys containing tin and gallium in alkaline electmlyte[J]. Acta Phys Chem Sin, 1999, 15(4): 381-384.

[14] Reboul M C, Gimenez P H, Ramearu J J. A proposed activation mechanism for A1 anodes[J]. Corrosion, 1984, 40(7): 366-370.

[15] Salinas D R, Bessone J B. Electrochemical behavior of Al-5%Zn-0.1%Sn sacrificial anode in aggressive media: Influence of its alloying elements and its solidification structure[J]. Corrosion, 1991, 47(9): 665-673 .

收稿日期:2009-02-16;修回日期:2009-04-01

基金项目:国家自然科学基金资助项目(50774097);国家自然科学基金创新研究群体科学基金资助项目(50721003)

通信作者:梁叔全(1962-),男,四川成都人,教授,从事铝合金阳极材料研究;电话:0731-88836069;E-mail: sqliang@mail.csu.edu.cn

(编辑 陈爱华)