Trans. Nonferrous Met. Soc. China 22(2012) s553-s559

Cold-pressing deformation characteristics of steel-aluminum sheets joining

LI Feng1, LIN Jun-feng2, SUI Xiao-chong1, BIAN Nan1, XU Ming-da3

1. College of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China;

2. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

3. Physics Department, Qiqihaer Normal College, Qiqihaer 161006, China

Received 28 August 2012; accepted 25 October 2012

Abstract: In order to overcome the deficiencies of the traditional connection of dissimilar sheet metals, a new method “cold-pressing deformation joining” was proposed. By using finite element simulation software DEFORMTM-3D, the joining process of the pure aluminium and stainless steel was simulated while the sample size is 100 mm×30 mm and the thicknesses are 1 mm and 0.5 mm, respectively. The results indicate that the punching load presents an increasing trend with the increase of the punch downward displacements. The thickness of stainless steel sheet decreases gradually from the centre to the two sides in the process. In contrast, the thickness of aluminum sheet changes a lot. Experimental scheme and simulation are in good agreement. The unidirectional tensile test demonstrates that with the increase of punch downward displacements, the average thickness of connection area decreases while the connection strength increases before decreasing. The thicknesses in gauge length of connection are not uniformly distributed and the position 15 mm away from the aluminum end shows the largest thickness.

Key words: cold-pressing joining method; dissimilar sheet metal; unidirectional tensile test; thickness distribution; connection strength

1 Introduction

The lightweight design of automobiles is one of the major measures to realize energy conservation and emission reduction, thus the utilization of light material and structure has become the preferential approach [1,2]. The connection of dissimilar sheet metals is one of the problems of lightweight material needed to confront and solve [3]. However, the formulation of the joining process is difficult due to the remarkable difference between them. Take the connection between stainless steel sheet and aluminum sheet as example. Since the melting point of steel is much higher than that of aluminum, it is difficult to connect them by spot welding [4-7], which is usually applied to the connection of the same material. The cost of laser welding is too high and it is also difficult to connect multilayer sheets. Pressing circle joining [8,9] is an effective method in connection of dissimilar sheet metals, but the process of this method is strict and the sheets are prone to crack as well as drop along the load direction. Riveting [10,11] and screwed joining [12-14] can be used to connect dissimilar sheets. However, the technique of riveting is relatively complex and the price of riveting equipment is too high. Additionally, the reliability of connections by screwed joining method is poor.

In view of the above problems, to achieve the connection of dissimilar sheets metals and overcome the deficiencies of spot welding, laser welding, pressing circle joining etc, as well as to free from the restrictions of melting points, thicknesses and other factors in the sheet connection and bear great tension in the sheet thickness direction, the cold-pressing deformation method for connection of dissimilar sheet metals was proposed. It can be used to connect the sheets with same or different materials, and the sheets with same or different thickness. In this work, designing and preprocessing were conducted to realize the connection of the edge with dissimilar sheet metals. The load was inflicted to the connection by press for the purpose of connection deforming and interlocking. Appropriate process scheme was made for the simulation and experimental, then a systematic analysis is indispensable to cold-pressing deformation according this scheme. Simulation was used to analyze the joining process. Conducting a tensile test after normal loaded, then measuring the strength of the connection in its longitudinal direction, the thickness distribution and reliability of the connection area were evaluated by the experiments. This method breaks away from various ideological shackles about the connection of dissimilar sheet medals, inspiring by the ideas of shot-peening [15] connecting provided by Japanese scholar. But they are not exactly the same. The Japanese scholar used the shot-peening to exert pressure while this method used it to inflict load.

2 Principle of cold-pressing joining

2.1 Principle

The edges of dissimilar sheets metals were preprocessed into the needed shapes, and then they were lapped into each other in order to realize elementary connection. After this, place them on the workbench of the press, load until the joints were connective by deformation joining. The schematic diagram is shown in Fig. 1.

Fig. 1 Schematic diagram of cold-pressing deformation joining

As shown in Fig. 1, reasonable design of the joint structure can realize the interlock between sheets, but the connection strength was limited. After normally pressing on the connection, large deformation occurred in the joints. During the press process, the sheets with higher yield strength were embedded into the sheets with lower yield strength, and the sheets with lower yield strength deformed greatly along the horizontal direction and locked the embedded sheets. The deformation joining would realize after all above.

2.2 Research procedure

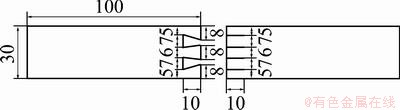

Samples in this work were 100 mm×30 mm rectangle aluminum sheets with the thickness of 0.7 mm and stainless steel sheets with the thickness of 0.5 mm. The samples were preprocessed as introduced before, as shown in Fig. 2.

Fig. 2 Preprocess of research sheets (unit: mm)

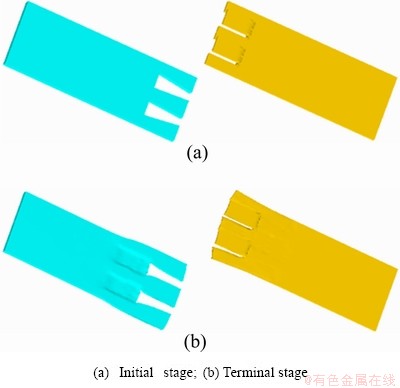

The finite element simulation software, DEFORMTM-3D, was employed to analyze the forming process. Four nodes tetrahedron isoparametric elements were used to disperse the sheets in simulation. So as to improve the calculation accuracy and convergence, only half of the model was researched, and fine mesh division was conducted to the joint. The finite element model was shown in Fig. 3.

Fig. 3 Finite element model

The research was based on room temperature environment, and the friction boundary condition between mould and blank was defined according to coulomb friction model. The edges of the sheets against the joint were fixed to prevent them from lifting up in the forming process.

3 Cold-pressing joining process

3.1 Stress analysis of forming process

Figure 4 shows the equivalent stress distribution of the sheets at different stages of the cold-pressing process.

As shown in Fig. 4(a), at the beginning of forming, with the downward displacements of punch, the equivalent stress of stainless steel sheet and aluminum at the connection area was large, and the largest equivalent stress located at the connection of the stainless steel sheet, indicating that plastic deformation occurred in the connection area at the moment. With the increase of the press load, the equivalent stress also concentrated in the connection area, as shown in Fig. 4(b), but the value increased significantly. As shown in Fig. 4(c), when the load further increased, plastic deformation expanded to 3/4 of the sheet. Meanwhile, the plastic deformation area expanded and located at the connection of aluminum sheet. In the dwell process, as shown in Fig. 4(d), the area with plastic deformation was similar with that in Fig. 4(c), but the deformation flowed evidently in the area. The forming model can be concluded that stainless steel sheet was embedded into and locked by aluminum sheet when the connection area was pressed.

Fig. 4 Equivalent stress distribution in joining process

3.2 Deformation characteristics and load analysis

The connection load of the pressed sheets increased during the forming process. However, as there were differences of transformative order in the connection, the variation trend can be concluded to four stages (I, II, III and IV), as indicated in Fig. 5.

Fig. 5 Connection load and deformation characteristic

At stage I, the load increased slowly when the samples were pressed. The salient of the stainless steel sheet deformed downward and the other area deformed limitedly. As the press continued (stage II), the load increased rapidly. It can be seen from the deformation characteristic that the salient area increased obviously and the load was about 200 kN. At stage III, the load increased but the increasing rate decreased. As shown in Fig. 5, the deformation area spread and locked other sheets. At the final stage (stage IV), the sheets were totally embedded and connected.

Figure 6 shows the deformation characteristics of the connection area during the forming process.

Fig. 6 Deformations during connection

As indicated in Fig. 6, the edge shape of the stainless steel sheet was preformed into a concavo-convex. Meanwhile, the edge shape of the aluminium sheet was smooth. The edge shapes of the sheets changed after being pressed. The edge convex degree of the stainless steel sheet decreased obviously, but its edge shape changed limitedly in the crosswise directions.

However, the edge size of the aluminium convexes increased in the crosswise directions, but the edge thickness of the aluminium convexes decreased prominently. This is because the yield strength of the aluminium sheet is lower than that of the stainless steel sheet. When the load punch pressed downward, the edge of the steel convexes moved downward, and the edge of the aluminium convexes deformed. Accordingly, the thickness of the concavo-convex area of the aluminium sheet decreased in a punching deformation mode.

3.3 Thickness distribution of typical point

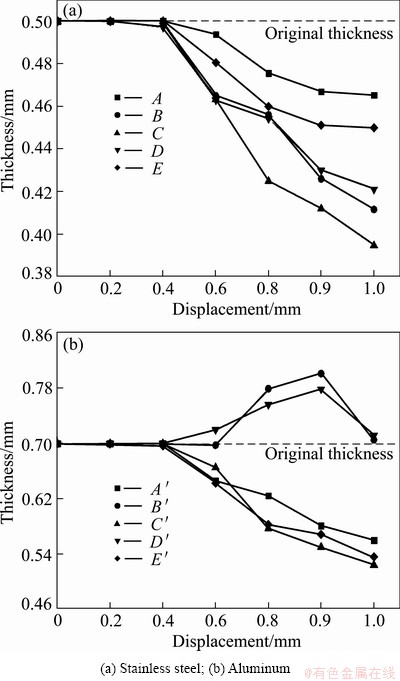

Figure 7 shows the variation of the sheet thickness during the joining process. The investigated points are shown in Fig. 5(b).

As shown in Fig. 7(a), the thickness of the typical connection points of stainless steel sheet decreased as the load punch pressed downward. The decrease rate at point C was 21%, which was the largest of the five typical points. Meanwhile, the decrease rates at the two side-points, point A and point E, were 7% and 10%, respectively. It can be seen that the decrease rate of the sheet thickness decreased from the centre to the sides.

Fig. 7 Variation of sheet thickness at typical connection points

Due to the material and geometrical differences, the thickness variation of the typical connection points showed various trends on aluminum sheet. The sheet thickness at point B′ and point D′ increased as the pressed load increased. After reaching the largest thickness (increased by 10%) when the load punch pressed downward for 0.9 mm, the sheet thickness decreased. The sheet thickness at points A′, C′ and E′ decreased as the load increased. When the punch pressed downward for 0.9 mm, the decrease rate of the sheet thickness was about 15%, as shown in Fig. 7(b).

4 Experimental verification

4.1 Connection properties

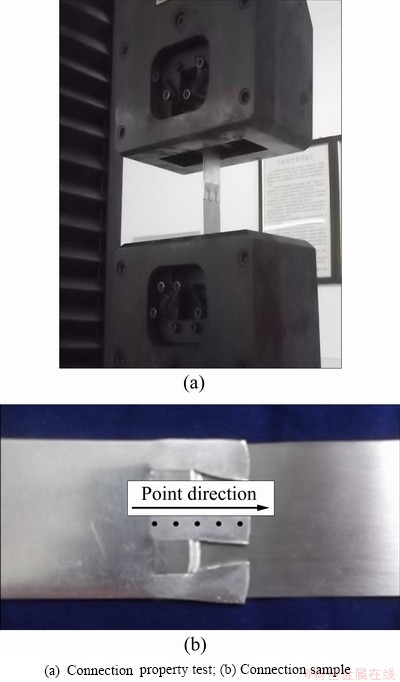

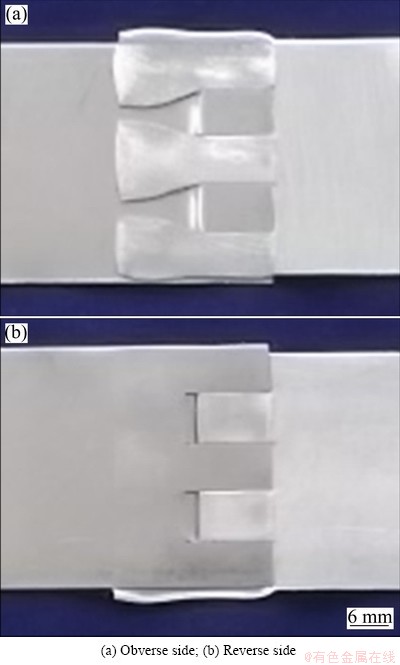

In order to verify the result of the simulation, experimental study was carried out by the mechanical property testing machine. The connections were realized at various loading conditions (20, 25, and 29 kN, respectively), and then the reliability was verified by the unidirectional tensile test, as shown in Fig. 8.

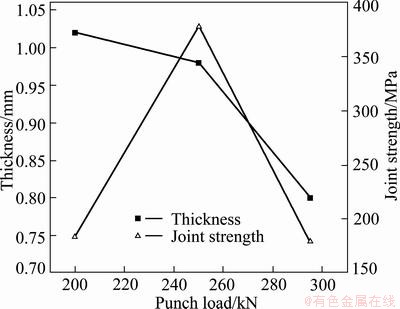

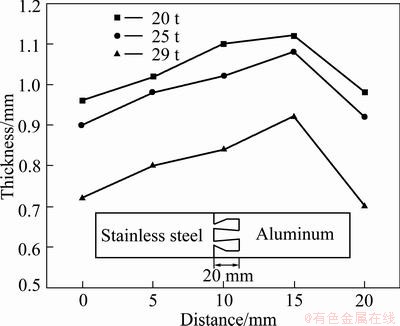

Figure 9 shows the effect of punch load on the thickness and connection strength of the connection area. As a critical evaluation of the connection reliability, the corresponding relationship between loading distance and sheet thickness were also discussed in Fig. 10. (the selected points were indicated in Fig. 8(b).

Fig. 8 Connection sample and property test

Fig. 9 Average thickness and joint strength as functions of punch load

As shown in Fig. 9, the increase of the punch load led to the decrease of the thickness of the connection. Since the strain status of the punch end was “one press, two tensile”, it belongs the coarsening deformation mode. The sheet materials flowed horizontally as the press load increased, and the connection thickness decreased. With the increase of the punch load, the strength of connection increased and then decreased. The peak strength was about 375 N. It was obvious that appropriate increase of the punch load can increase the inter-embedded degree between the sheets, and thus increased the connection strength. However, excessive load led to the excessive thinning of the connection area, which dramatically decreased the connection reliability.

Fig. 10 Relationship between connection thickness and pressing load

As demonstrated in Fig. 9, the connection thickness decreased with the increase of the punch load. The thickness of the connection area increased and then decreased from the left to the right, and the thickness at the edge of embedded area between stainless steel sheet and aluminum sheet was the thinnest. Based on the former analysis, the area with maximum amount of deformation, and the thickness of that had the largest reduction. The position 15 mm away from the edge of aluminum showed the largest thickness.

4.2 Connection characteristics analysis

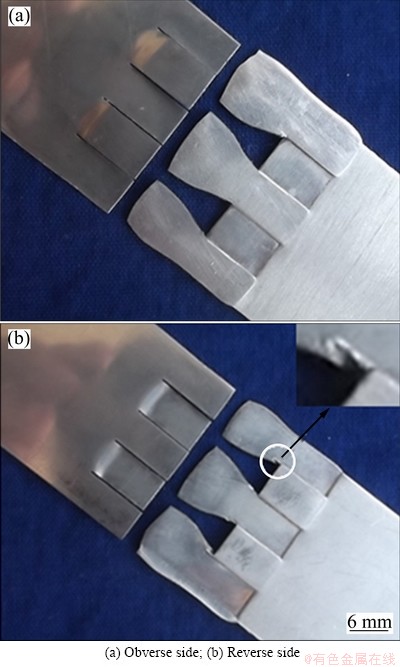

Figures 11 and 12 indicate the deformation characteristics and typical defect forms of the connection.

As indicated in Fig. 11(a), the size of the aluminium convexes increased evidently after the sample was punched. Meanwhile, the edge of the aluminium sheet was deformed and connected with the stainless steel sheet. And thus the cold-pressing deformation joining was realized between the different sheets. As demonstrated, proper increase of the punch load improved the connection degree and connection strength. Additionally, aluminium sheet is more prone to present plastic deformation than stainless steel sheet. Therefore, the trapezoid design of the edge of the aluminium sheet increased its deformation degree on the crosswise directions, and improved the final connection.

Fig. 11 Deformation connection characteristics of connection

Fig. 12 Defects of connection

As indicated in Fig. 11, the deformation degree of the middle convex of the aluminium sheet was lower at its root area than that of the side areas. This is because that the root area was restrained on two sides, but the side area was restrained by only one side.

As indicated in Fig. 12, the convexes of the stainless steel sheet were embedded into the aluminium sheet, and were locked by the convexes of the aluminium sheet during the pressing process. However, excessive punch load greatly decreased the thickness of the aluminium sheet, which might decrease the final connection strength. In Fig. 12, the magnified image showed the groove on the root area of the aluminium convexes. This is mainly due to the deformation of the steel convexes on the crosswise directions. Proper amount of grooves can improve the connection degree between the two sheets, but excessive amount of grooves may lead to the decrease of the connection strength.

5 Conclusions

1) A new joining method for dissimilar sheet metals named cold-pressing deformation joining method is proposed. Based on the preprocessing and preliminary connection of the sheets, the press loads to the connection in order to urge the sheets embed and lock the offside. And the connection between dissimilar sheet medals is realized.

2) The thickness of stainless steel sheet decreases gradually from the centre to the two sides in the joining process. In contrast, the thickness of aluminum changes greatly. The sheet thickness at point B′ and D′ increases by 10% equally, but the thickness at point A′, C′, and E′ decreases after pressing.

3) With the increase of the punch load, the average thickness of connection decreases. Meanwhile, the connection strength firstly increases and then decreases. Due to reliability concerns, the punch load should be strictly controlled. The thickness of the connection area increases and then decreases from the left point to the right point, and the position 15 mm away from the aluminum end shows the largest thickness.

References

[1] KIM S O, KWAK J S. Magnetic force improvement and parameter optimization for magnetic abrasive polishing of AZ31 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(S1): 369-373.

[2] LEE K S, SEO H K, YANG Y J, HWANG W C, IM K H, YANG I Y. Collapse behavior evaluation of hybrid thin-walled member by stacking condition [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S1): 135-140.

[3] de CASTRO P M S T, de MATOS P F P, MOREIRA P M G P, da SILVA L F M. An overview on fatigue analysis of aeronautical structural details: Open hole, single rivet lap-joint, and lap-joint panel [J]. Materials Science and Engineering A, 2007, 468-470(SP1): 144-157.

[4] CHEN J Z, FARSON D F. Analytical modeling of heat conduction for small scale resistance spot welding process [J]. Journal of Materials Processing Technology, 2006, 178(1-3): 251-258.

[5] EISAZADEH H, HAMEDI M, HALVAEE A. New parametric study of nugget size in resistance spot welding process using finite element method [J]. Materials and Design, 2010, 31(1): 149-157.

[6] PODRZAJ P, SIMONCIC S. Resistance spot welding control based on fuzzy logic [J]. International Journal of Advanced Manufacturing Technology, 2011, 52(9-12): 959-967.

[7] DOI M. Coaxial hybrid process of hollow cathode tig and yag laser welding [J]. Welding International, 2010, 24(3): 188-196.

[8] VARIS J P. The suitability of round clinching tools for high strength structural steel [J]. Thin-Walled Structures, 2002, 40(3): 225-238.

[9] LEE C J, KIM J Y, LEE S K, KO D C, KIM B M. Design of mechanical clinching tools for joining of aluminium alloy sheets [J]. Materials and Design, 2010, 31(4): 1854-1861.

[10] ABE Y, KATO T, MORI K. Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die [J]. Journal of Materials Processing Technology, 2009, 209(8): 3914-3922.

[11] BAHA II S, KLAPP O, HESEBECK O. Simulation of the solid rivet installation process [J]. SAE International Journal of Aerospace, 2010, 3(1): 187-197.

[12] BAZHENOVV G, RYABOVA A, ROMANOVV I, KUKANOV S S. Experimental design analysis of dynamic deformation and destruction of a screw joint [J]. Journal of Machinery Manufacture and Reliability, 2010, 39(6): 575-579.

[13] ALVES P, FORCINITO M, XU J, FERGUSON M, TARDIF P, JENSEN P. Analysis of threaded connection reliability for compression application [J]. Journal of Canadian Petroleum Technology, 2010, 49(6): 8-12.

[14] KORIN I, PEREZ IPINA J. Experimental evaluation of fatigue life and fatigue crack growth in a tension bolt-nut threaded connection [J]. International Journal of Fatigue, 2011, 33(2): 166-175.

[15] HARADA Y, FUKUNAGA M, YAMAMOTO A. Butt joining of magnesium alloy sheet by shot peening [J]. Materials Transactions, 2008, 49(5): 1132-1136.

钢-铝板冷压变形连接成形规律

李 峰1,林俊峰2,隋小冲1,边 楠1,徐明达3

1. 哈尔滨理工大学 材料科学与工程学院,哈尔滨 150040;

2. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

3. 齐齐哈尔高等师范专科学校 理工系,齐齐哈尔 161006

摘 要:为解决传统方法进行异质板材连接时的不足,提出一种实现异质板材连接的新工艺,冷压变形连接法。利用有限元模拟软件DEFORMTM-3D对长宽和宽度为100 mm×30 mm,厚度分别为1 mm和0.5 mm的长方形纯铝板和不锈钢板试样进行数值模拟。结果表明:随着冲头压下量的增加,所需载荷呈增大趋势变化。连接过程中不锈钢板壁厚由中间向两侧逐渐减薄,而铝板壁厚变化差异较大。实验与模拟结果相符,随着冲头压下量的增加,平均连接厚度逐渐减小而连接强度则先增大后减小。连接标距内的板厚呈非均匀分布且离铝板端部15 mm处的板厚最大。

关键词:冷压变形连接;异质板材;单向拉伸;壁厚分布;连接强度

(Edited by HE Yun-bin)

Foundation item: Project (E201128) supported by the Natural Science Foundation of Heilongjiang Province, China; Project (20112303120001) supported by Specialized Research Fund for the Doctoral Program of Higher Education, China; Project (12520140) supported by the Foundation of Heilongjiang Educational Committee, China

Corresponding author: LI Feng; Tel: +86-451-86392501; E-mail: hitlif@126.com

DOI: 10.1016/S1003-6326(12)61760-9