DOI: 10.11817/j.issn.1672-7207.2017.07.002

抽锭电渣重熔大截面高速钢过程的碳化物偏析控制

李万明1, 2,姜周华1,臧喜民1,邓鑫1,邵青立2,谢志彬2

(1. 辽宁科技大学 材料与冶金学院,辽宁 鞍山,114051;

2. 河冶科技股份有限公司,河北 石家庄,050000)

摘要:采用抽锭式双极串联电渣重熔工艺并对抽出结晶器的钢锭进行二次气雾冷却的方法实现高速钢的快速凝固,以期实现对大截面高速钢碳化物偏析的控制;通过钨粉检测熔池结构、评估高速钢碳化物质量等手段研究该工艺对碳化物偏析的改善效果;通过数值模拟分析二次气雾冷却对电渣重熔过程温度场的影响。研究结果表明:双极串联式抽锭电渣二次气雾冷却方法可以明显降低电渣重熔过程的熔池深度,减小金属熔池的结晶角;有效地减小高速钢碳化物的不均匀度和碳化物颗粒度,在相同锻压工艺条件下的碳化物合格率明显提高。

关键词:高速钢;碳化物;偏析;熔池结构;电渣重熔

中图分类号:TF744 文献标志码:A 文章编号:1672-7207(2017)07-1697-07

Carbide segregation control in electro-slag remelting withdrawal process of large cross-section high-speed steels

LI Wanming1, 2, JIANG Zhouhua1, ZANG Ximin1, DENG Xin1, SHAO Qingli2, XIE Zhibin2

(1. School of Materials and Metallurgy, University of Science and Technology Liaoning, Anshan 114051, China;

2. HEYE Special Steel Co. Ltd, Shijiazhuang 050000, China)

Abstract: Electroslag remelting (ESR) was a predominant method for smelting high-quality high-speed steels, but the molten bath structure of conventional stationary-mould ESR restricts its ability to control carbide segregation. In order to control carbides segregation of large cross section high-speed steels, secondary aerosol cooling was adopted in the electroslag remelting withdrawal process to make the high-speed steel rapid solidification. Molten pool structure of ESR process was obtained by tungsten powder detection and high speed steel carbide quality was evaluated, which can verify the effect of the process. Effect of secondary aerosol cooling on the temperature field of ESR process was analyzed through numerical simulation. The results show that electroslag remelting withdrawal with secondary aerosol cooling technology can significantly decrease the depth of molten bath, reduce the crystallization angle of the metal molten pool, effectively reduce the high speed steel carbide uneven and carbide particles degrees, and carbide qualified rate increases significantly in the same forging process.

Key words: high-speed steels; carbides; segregation; molten structure; electroslag remelting

高速钢是高碳高合金莱氏体钢,具有硬度高、红硬性好、耐热耐磨等特点,主要用于制作各种切削工具、高载荷模具等。随着大型装备制造业的迅速发展,对高速钢的尺寸规格和性能要求不断提高[1]。然而,高速钢的高碳高合金的成分特点使其容易发生碳化物偏析,而且钢锭截面越大碳化物偏析越严重[2-3],严重影响了高速钢的加工性能和使用性能[4]。目前我国生产的M2高速钢钢锭最大直径只能达到500 mm[5],M42高速钢钢锭的最大直径只能达到350 mm,这使得高速钢产品的锻压比受到铸锭截面尺寸的限制,质量难以达到要求。国内外冶金学者通过加孕育剂或微合金化元素[6-8]、机械或电磁搅拌[9-11]、扁锭铸造等方式调控高速钢凝固过程的碳化物尺寸、分布等特征,这些方法对较小截面钢锭的偏析控制有一定效果,但对大截面钢锭心部碳化物的改善效果有限。电渣重熔方法是生产高品质高速钢的主要方法,电渣重熔过程的熔池结构(熔池形状和深度)与碳化物偏析关系密切,研究表明浅平形熔池能够缩短高速钢的局部凝固时间并减小碳化物偏析[12]。传统的结晶器固定式电渣重熔过程通常采用降低电极熔速的方法来控制金属熔池的深度[13],但单纯依靠降低熔速的熔池结构调控方法会使电渣锭的表面质量和内部质量互相矛盾[14],而且熔速与局部凝固时间并不是呈单一线性关系,当熔速降低到临界值后,局部凝固时间反而随熔速降低而增大[15],因此,传统的结晶器固定式电渣重熔的工艺模式限制了其控制高速钢碳化物偏析的能力。为优化电渣重熔过程的熔池结构和改善高速钢的碳化物特征,采用抽锭式双极串联电渣重熔并对抽出结晶器的钢锭进行二次气雾冷却的方法。本文作者对在双极串联抽锭电渣重熔过程中增加二次气雾冷却对液态金属熔池结构和高速钢碳化物特征的影响规律进行研究。

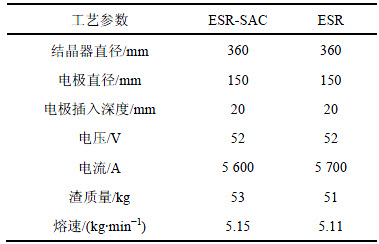

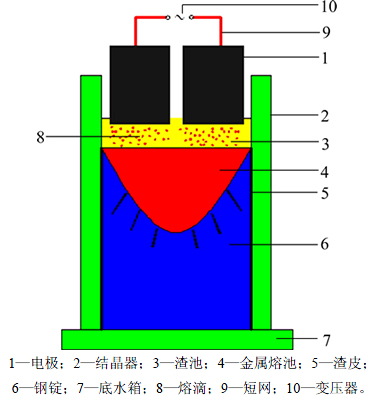

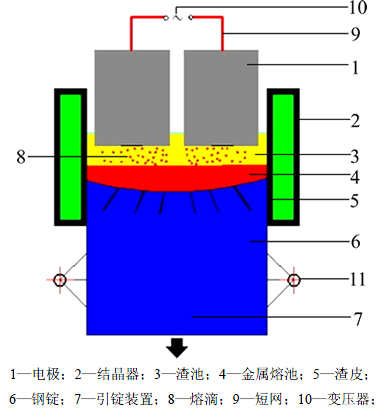

1 实验

实验采用M42高速钢,其化学成分如表1所示。为了研究双极串联抽锭式电渣重熔过程中增加二次气雾冷却对高速钢凝固过程的碳化物偏析的影响,采用2种电渣重熔工艺,一种是双极串联结晶器固定式电渣重熔(electroslag remelting,缩写为ESR),其原理图如图1所示;另一种是带二次气雾冷却的双极串联抽锭式电渣重熔(electroslag remelting withdrawal with secondary aerosol cooling,缩写为ESRW-SAC),其原理图如图2所示。2种工艺的主要区别在于ESRW-SAC法采用抽锭电渣重熔方法,并在距离结晶器下沿50 mm位置采用12个喷嘴进行周向全覆盖的气雾冷却喷水,带宽为80 mm,水量为0.15 m3/h,抽出结晶器150 mm时开始喷水,补缩时停止喷水。通过调整输入电压、电流等工艺参数使2种工艺的电极熔速接近,2种工艺在正常重熔期的过程工艺参数如表2所示,通过调整工艺使双极串联抽锭电渣重熔工艺的熔速为5.15 kg/min,而双极串联固定式电渣重熔工艺的熔速为5.11 kg/min,2种方法条件下的熔速接近。2种工艺所使用的渣系均采用50%CaF2-25%CaO- 25%Al2O3渣系。

表1 M42高速钢的主要成分(质量分数)

Table 1 Chemical composition of M42 high-speed steels %

表2 ESR-SAC法与ESR法冶炼M42高速钢的工艺参数

Table 2 Process parameters in process of remelting M42 high-speed steels with ESR-SAC and ESR

图1 双极串联固定式电渣重熔系统

Fig. 1 Schematic diagram of bipolar ESR

图2 双极串联抽锭电渣二次气雾冷却系统

Fig. 2 Schematic diagram of bipolar ESR-SAC

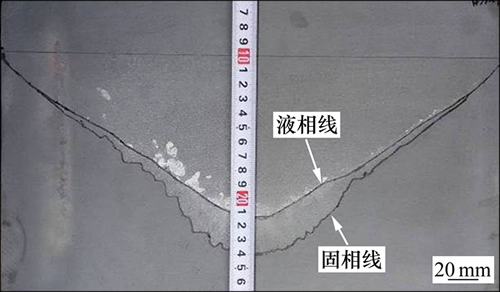

在电渣重熔过程的正常重熔期即将结束时加入钨粉,重熔结束后将电渣锭在1 183 K温度下退火10 h后,经过剖锭、锯切、磨制和酸洗得到电渣重熔过程的熔池结构。定义D为钢锭的直径,测定D/2处的金属熔池深度和D/4处的结晶角度(固相线上某点的切线与水平方向的夹角)。将2种工艺条件下的电渣锭采用相同的锻轧工艺进行开坯和轧制后,对热加工后的高速钢材经制样、磨样,用体积分数为4%的硝酸-酒精溶液腐蚀后对高速钢试样进行扫描电镜观测,研究其1/4D处的碳化物不均匀度和颗粒粒度,并对试样碳化物颗粒度的合格率进行统计分析。

2 实验结果与分析

2.1 液态金属的熔池结构

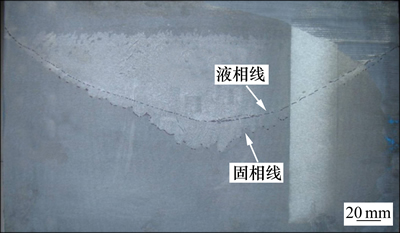

用2种不同的电渣重熔工艺方法冶炼M42高速钢时的液态金属熔池结构如图3和图4所示,熔池结构的检测结果如表3所示。由表3可见:与双极串联固定式电渣重熔M42高速钢的过程相比,ESR-SAC方法的熔池深度降低了19 mm,比固定式电渣重熔过程降低了16.5%,这说明ESR-SAC法能够显著降低电渣重熔过程中的熔池深度。另外,由于熔池深度降低,钢锭D/4处固相线附近的结晶角减小了6.5%,这说明该方法能够明显改变高速钢凝固过程中的枝晶生长方向。

图3 固定式电渣重熔φ360 mm M42时的熔池结构

Fig. 3 Molten bath structure in process of remelting φ360 mm M42 high-speed steels with ESR

图4 ESR-SAC法重熔φ360 mm M42时的熔池结构

Fig. 4 Molten bath structure in process of remelting φ360 mm M42 high-speed steels with ESR-SAC

表3 ESR-SAC法与ESR法冶炼M42高速钢的熔池结构尺寸

Table 3 Molten bath structure size in process of remelting M42 using ESR-SAC and ESR

双极串联工艺有利于减小熔池深度,这是因为双极串联技术使得渣池的发热区主要集中在2个电极的导电端头之间,这改变了传统电渣重熔的热场分布,使渣池发温区与渣-金界面的距离更大,这样就打破了单极固定式电渣重熔过程中电极熔化速度和金属熔池深度的正比关系,使其各自相对独立,熔化速度比传统电渣重熔工艺提高3~5倍的情况下,凝固组织仍然能够达到传统电渣锭的质量[16]。同时,ESR-SAC过程中铸锭自结晶器中不断抽出,这为增加二次气雾冷却装置提高钢锭的冷却速度提供了可行性。从图3和图4中熔池结构的检测结果可以看出,二次气雾冷却装置的加入能够使熔池深度明显变浅。

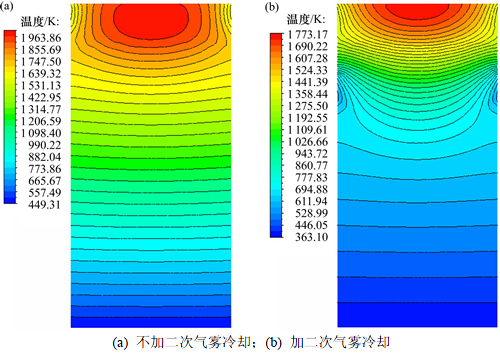

2.2 二次气雾冷却对电渣重熔过程温度场影响的数值模拟

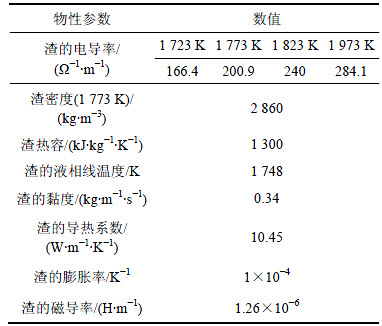

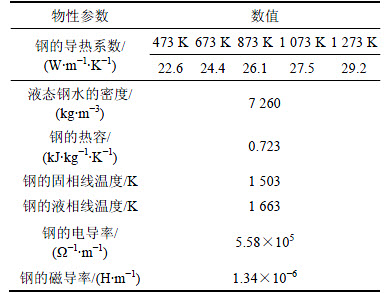

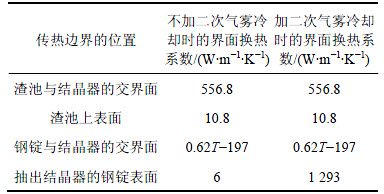

由于熔池内的钢水的温度和速度等参数很难测定,国内外学者普遍采用数学模型和数值模拟的方法研究电渣重熔过程中的基本规律。为了分析二次气雾冷却对电渣重熔过程熔池结构的影响,对双极串联抽锭电渣重熔过程在有无加载二次气雾冷却时的温度场分别进行了数值模拟。模拟过程中采用的渣系的热物性参数如表4所示,钢的物性参数通过Jmatpro软件计算得出,如表5所示。模拟采用的控制方程与文献[17]中的一致。不同传热形式条件下的数值模拟采用的传热边界条件如表6所示,其中钢锭与结晶器的交界面的界面换热系数为(0.62T-197) W/(m2·K),T为钢锭表面的热力学温度,单位为K;对于抽出结晶器的钢锭,在不加二次气雾冷却时为空气自然冷却,其界面换热系数为6 W/(m2·K),而加二次气雾冷却时在二次气雾冷却段的界面换热系数为1 293 W/(m2·K),二次气雾冷却段下面的钢锭是空气自然冷却条件。

图5(a)和图5(b)所示分别为无二次气雾冷却时和有气雾冷却时电渣重熔过程的钢锭温度场分布。从图5可以看出:在抽锭电渣重熔过程中增加二次气雾冷却使结晶器下方的钢锭位置形成一个恒定的低温区,明显改变了电渣重熔过程的温度场分布,整个熔池的温度明显降低,熔池低温区上移。

表4 CaF250%+Al2O325%+CaO25%渣系的物性参数

Table 4 Physical property of CaF250%+Al2O325%+CaO25% slag

表5 M42高速钢钢种的物性参数

Table 5 Physical property of M42 high speed steel

表6 不同传热形式条件下的传热边界条件

Table 6 Heat transfer boundary conditions at different heat transfer modes

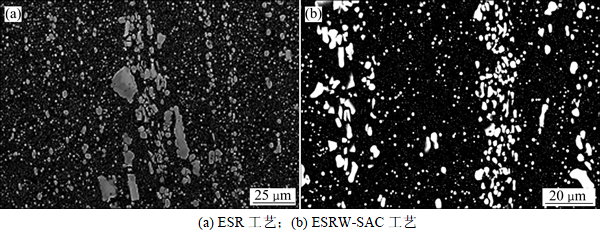

2.3 碳化物不均匀度和颗粒度

M42高速钢的使用量逐年递增,但在生产和使用中发现该钢存在韧性较差、在热加工时易裂、成材率较低、使用时易脆断崩刃和使用寿命较低等问题,研究[18]表明这些问题与碳化物尺寸和分布有重要关系。为研究抽锭电渣二次气雾冷却对碳化物特征的影响,对2种不同工艺条件下重熔得到的直径为360 mm电渣锭经相同的加工工艺锻压成圆材,对圆材D/4位置处的高速钢碳化物不均匀度、颗粒粒度进行观察,并对不同锻比得到的锻材的碳化物颗粒度合格率进行统计分析。

图6所示为φ360 mm的M42高速钢电渣锭经锻轧加工为φ82 mm的圆材时1/4D处的碳化物分布和形貌。由图6可见:与ESR工艺相比,ESRW-SAC工艺得到的钢材的大角块状碳化物明显减少,碳化物不均匀度较小,碳化物颗粒更加细小弥散。

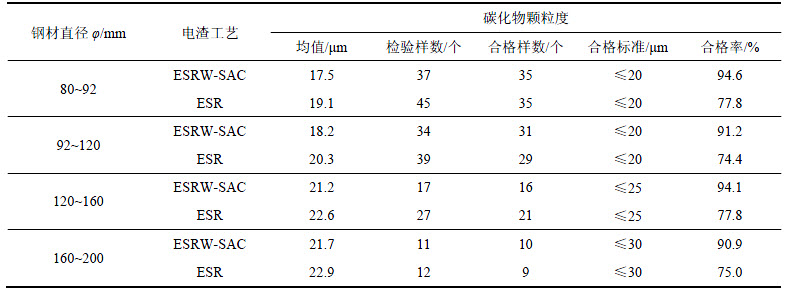

对2种工艺条件下冶炼的电渣锭锻压而成的不同规格钢材的碳化物颗粒度进行统计分析,结果如表7所示。从表7可以看出:与ESR工艺相比,ESRW-SAC工艺得到的钢材的碳化物粒度更加小,碳化物颗粒度的合格率明显提高。

图5 二次气雾冷却对电渣重熔过程的钢锭温度场的影响

Fig. 5 Effect of secondary aerosol cooling on ingot temperature field of ESR process

图6 2种工艺条件生产的M42高速钢材D/4位置的碳化物形貌

Fig. 6 Morphology of carbides in location of D/4 of ingot under two kinds of process conditions

表7 2种工艺重熔M42钢锭生产锻轧材的碳化物颗粒粒度统计结果

Table 7 Carbide particle size results of forged M42 steel remelted by two kinds of process

BOCALLINI等[19]的研究表明增大高速钢的冷却速度可以促进包晶反应L+δ→γ的进行,使δ铁素体迅速被奥氏体完全包裹,降低元素的扩散速度,抑制成分偏析。FLEMINGS等[20-21]指出,局部凝固时间是合金在固液两相区的停留时间,它决定着合金及其碳化物的偏析程度,局部凝固时间与两相区宽度、局部凝固速度、二次枝晶间距等的关系为:

(1)

(1)

(2)

(2)

(3)

(3)

式中:tLS为局部凝固时间,s;X为固液两相区距离,mm;vr为局部凝固速度,mm/s,G为液相温度梯度,K/mm;Rc为局部冷却速度,K/s;d为二次枝晶间距,mm;k1,k2,n和b为与材料属性有关的常数。

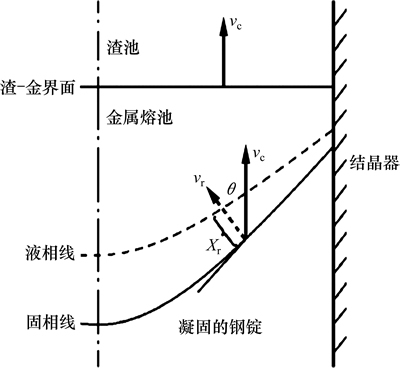

电渣重熔过程中局部凝固时间与冷却速率的关系如图7所示,图7中夹角θ为结晶角。从式(1)~(3)和图7可以看出:局部凝固时间受到固液两相区宽度、局部凝固速度、液相温度梯度等因素的共同制约,通过减小固-液两相区宽度、增大局部凝固时间和液相温度梯度均可以减小局部凝固时间从而抑制碳化物偏析。本研究采用在抽锭电渣重熔过程中增加二次气雾冷却的方法,在改变钢锭温度场分布的同时使铸锭心部的液-固两相区宽度减小,并通过减小结晶角提高了钢水的局部凝固速度,二者均可以减小高速钢的局部凝固时间,因此能够有效的抑制碳化物偏析,改善高速钢的碳化物特征。

图7 电渣重熔过程中的局部凝固时间与冷却速率的关系

Fig. 7 Relationship between local solidification time and cooling rate in ESR process

3 结论

1) 抽锭电渣二次气雾冷却工艺使结晶器下方钢锭位置处形成一个恒定的低温区,改变了电渣重熔过程的温度场分布,整个熔池的温度明显降低,熔池低温区上移,使电渣重熔过程的熔池深度降低,减小了高速钢凝固过程的结晶角。

2) 抽锭电渣二次气雾冷却工艺能够降低M42高速钢钢材的碳化物不均匀度,并减小其碳化物颗粒粒度。在相同锻压工艺条件下,该工艺冶炼的高速钢锭制备的产品碳化物颗粒度合格率明显提高。

参考文献

[1] WENG Yuqing, DONG Han, GAN Yong. Advanced steels: the recent scenario in steel science and technology[M]. Beijing: Metallurgical Industry Press & Heidelberg: Springer, 2011: 453-461.

[2] DONG Yanwu, JIANG Zhouhua, LI Zhengbang. Investigation on solidification quality of industrial-scale ESR ingot[C]// TMS2009-International Symposium on Liquid Metal Processing and Casting. Santa Fe, 2009: 309-315.

[3] 邵青立, 谢志彬, 张国平. 电渣重熔锭的直径和压缩比对M2高速钢碳化物不均匀度的影响[J]. 特殊钢, 2015, 36(3): 21-22.

SHAO Qingli, XIE Zhibin, ZHANG Guoping. Effect of diameter of ESR ingot and reduction ratio on non-uniformity of carbide in high-speed steel M2[J]. Special Steel, 2015, 36(3): 21-22.

[4] RODENBURG C, RAINFORTH W M. A quantitative analysis of the influence of carbides size distributions on wear behavior of high-speed steel in dry rolling/sliding contact[J]. Acta Materialia, 2007, 55(7): 2443-2454.

[5] 吴立志, 丁培道, 谢志彬. 大截面刀具用高速钢: 中国, 201010288295.9[P]. 2012-04-11.

WU Lizhi, DING Peidao, XIE Zhibin. High-speed steels for large section tools: China, 201010288295.9[P]. 2012-04-11.

[6] PAN F S, DING P D, ZHOU S Z, et al. Effects of silicon addition on the mechanical properties and microstructure of high speed steels[J]. Acta Materialia, 1997, 45(11): 4703-4712.

[7] 王维青, 潘复生, 吴立志, 等. 硅对热处理态M2高速钢中共晶碳化物的影响[J]. 重庆大学学报(自然科学版), 2011, 34(11): 44-49.

WANG Weiqing, PAN Fusheng, WU Lizhi, et al. Effect of silicon on the eutectic carbides in as-heated M2 high speed steel[J]. Journal of Chongqing University (Natural Science Edition), 2011, 34(11): 44-49.

[8] ZHOU Xuefeng, FANG Feng, TU Yiyou, et al. Carbide refinement in M42 high speed steel by rare earth metals and spheroidizing treatment[J]. Journal of Southeast University, 2014, 30(4): 445-448.

[9] CHUMANOV V I, CHUMANOV I V. Control of the carbide structure of tool steel during electroslag remelting: part Ⅰ[J]. Russian Metallurgy, 2011(6): 22-28.

[10] SHI X.F., CHANG L.Z., WANG J J. Effect of mold rotation on the bifilar electroslag remelting process[J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(10): 1033-1041.

[11] 刘海明, 安永太, 宋绪丁, 等. 转速对电磁离心铸造高碳高速钢碳化物的影响[J]. 材料热处理学报, 2013, 34(8): 118-123.

LIU Haiming, AN Yongtai, SONG Xuding, et al. Influence of centrifugal speed on carbide of high-carbon high speed steel prepared by electromagnetic centrifugal casting[J]. Transactions of Materials and Heat Treatment, 2013, 34(8): 118-123.

[12] 董艳伍, 姜周华, 肖志新, 等. 电渣重熔工艺对钢锭凝固质量影响研究[J]. 东北大学学报(自然科学版),2009, 30(11): 1598-1602.

DONG Yanwu, JIANG Zhouhua, XIAO Zhixin, et al. Influence of ESR process parameters on solidification quality of remelting ingots[J]. Journal of Northeastern University (Natural Science), 2009, 30(11): 1598-1602.

[13] SUH S H, CHOI J. Effect of melting rate on the carbide cell size in an electroslag remelted high speed steel ingot[J]. ISIJ international, 1986, 26(4): 305-309.

[14] HOYLE G. Electroslag remelting processes principle and practice[M]. London & New York: Applied Science Publishers, 1983: 1-12.

[15] 常立忠, 李正邦. 电渣重熔过程中金属凝固的控制方法[J]. 炼钢, 2007, 23(4): 56-58.

CHANG Lizhong, LI Zhengbang. Method of controlling solidification quality in electroslag remelting process[J]. Steelmaking, 2007, 23(4): 56-58.

[16] 姜周华, 董艳伍, 臧喜民, 等. 新一代电渣冶金技术的开发[J]. 材料与冶金学报, 2011, 10(S1): 17-18.

JIANG Zhouhua, DONG Yanwu, ZANG Ximin, et al. Development of new-generation electroslag remelting technology[J]. Journal of Materials and Metallurgy, 2011, 10(S1): 17-18.

[17] 李万明. 电渣重熔大型板坯和电渣液态浇注复合轧辊的数值模拟及工艺优化[D]. 沈阳: 东北大学材料与冶金学院, 2012: 39-53.

LI Wanming. Numerical simulation and process optimization of electroslag remelting large slab and ESS LM process of composite rolls[D]. Shenyang: Northeastern University, School of Material and Metallurgy, 2012: 39-53.

[18] 赵步青, 龚真忠, 纪正祥. 碳化物对高速钢刀具寿命的影响[J]. 热处理技术与设备, 2011, 32(3): 60-64.

ZHAO Buqing, GONG Zhenzhong, JI Zhengxiang. Influence of carbide to high-speed steel cutting tool life[J]. Heat Treatment Technology and Equipment, 2011, 32(3): 60-64.

[19] BOCCALINI M, GOLDENSTEIN H. Solidification of high speed steels[J]. International Materials Reviews, 2001, 46(2): 92-115.

[20] FLEMINGS M C. Solidification processing[J]. Metallurgical and Materials Transactions B, 1974, 5(10): 2121-2134.

[21] KURZ W, FISHER D J. Fundamentals of solidification[M]. Aedermannsdorf, Switzerland: Trans Tech Publications, 1984: 71-92.

(编辑 杨幼平)

收稿日期:2016-10-18;修回日期:2017-01-09

基金项目(Foundation item):国家自然科学基金资助项目(51474126,U1560203,51604149,51674140) (Projects(51474126, U1560203, 51604149, 51674140) supported by the National Natural Science Foundation of China)

通信作者:姜周华,博士,教授,从事电渣重熔工艺理论研究;E-mail: jiangzh@smm.neu.edu.cn