采用盐浸法从包头稀土精矿中提取稀土研究

李梅1, 2,张晓伟1, 2,柳召刚1,阳建平1,刘佳1

(1. 内蒙古科技大学,材料与冶金学院 内蒙古 包头,014010;

2. 北京化工大学,材料科学与工程学院 北京,100029)

摘要:以包头混合型稀土精矿为研究对象,在密闭条件下,采用Al(NO3)3-HNO3盐溶液浸出包头混合型稀土精矿中的稀土。考察Al(NO3)3浓度、HNO3浓度、浸出时间、液固比、浸出温度和搅拌速度等因素对包头混合型稀土精矿中稀土浸出率的影响规律以及稀土浸出过程中的动力学分析。研究结果表明:当HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,浸出温度为100 ℃,搅拌时间为90 min,液固比为30 mL/g,搅拌速度为300 r/min为最优浸出工艺条件。在此优化条件下,精矿中稀土的浸出率为73.5%,而稀土的理论浸出率为74.82%,即精矿中稀土浸出率达98.24%;浸出过程属于收缩反应核模型,反应活化能为34.213 kJ/mol,受边界传质和扩散混合控制。

关键词:稀土;Al(NO3)3-HNO3盐溶液;浸出

中图分类号:TF845 文献标志码:A 文章编号:1672-7207(2014)06-1759-07

Extracting rare earth from Baotou rare earth concentrate with salt leaching method

LI Mei1, 2, ZHANG Xiaowei1, 2, LIU Zhaogang1, YANG Jianping1, LIU Jia1

(1. School of Material and Metallurgy, Inner Mongolia University of Science and Technology, Baotou 014010, China;

2. Beijing University of Chemical Technology, Materials Science and Engineering, Beijing 100029, China)

Abstract: The Al(NO3)3-HNO3 was used as an assisted leaching agent leaching of Baotou mixed rare earth concentrate in closed system. In this work, we study the effects of Al(NO3)3 concentration, HNO3 concentration, temperature, time, liquid to solid ratio, stirring speed and other factors on the leaching of bastnaesite by the quadratic regression orthogonal. At last, we get the regression equation about the various factors on the impact of the leaching ratio, and determine the optimum conditions: HNO3 concentration of 3 mol/L, Al(NO3)3 concentration of 1.5 mol/L, the leaching temperature of 100 ℃, stirring time of 90 min, liquid to solid of 30 mL/g, the stirring speed of 300 r/min. The leaching of rare earth concentrates is 73.5%, and the rare-earth theory leaching rate is 74.82%, so the rare earth leaching rate is 98.24%. The leaching process belongs to the contractile response of the nuclear model, and the activation energy is 34.213 kJ/mol, indicating that the leaching process is controlled by the border mass transfer and diffusion.

Key words: rare earth; Al(NO3)3-HNO3 system; leaching

稀土是我国重要的战略性资源,在现代高精尖科技中扮演着重要的角色[1-4]。因而,稀土元素被称为“21世纪的材料”。包头混合型稀土矿是全球最大稀土矿床之一,蕴含着十分丰富的稀土资源。包头混合型稀土精矿现行处理工艺主要是浓硫酸高温焙烧工艺,此工艺虽对稀土精矿品位适应范围广,但在焙烧过程中会产生大量SO2,HF以及H2SO4等使尾气的处理难度加大,对环境以及资源综合利用造成不利影响,从而限制我国稀土行业的发展[5-7]。近年来,我国稀土科研工作者研究多项清洁工艺来处理包头混合型稀土矿物,如:Wu等[8-9]研究CaO-NaCl-CaCl2焙烧包头稀土矿,Zhang等[10]采用化学气相传输法处理包头稀土矿,这2种工艺均能避免精矿中氟碳铈矿分解过程中氟的逸出,从而抑制氟的气态化,达到环境保护的目的。但两者均是在高温下进行焙烧,对设备和能耗要求较高,且化学气相传输法需要氯气进行氯化[11],故对操作带来困难。本文作者采用Al(NO3)3-HNO3盐溶液处理包头混合型稀土精矿,此工艺是在低温状态下利用Al3+对F-具有较强的络合作用[12-14],可形成稳定的络合离子[AlF6]3-,其不稳定常数为6.9×10-19。在浸出过程中,精矿中的氟碳铈矿被溶解,且氟碳铈矿中的稀土和氟分别以硝酸稀土和氟铝络合物形式进入浸出液中。而精矿中的独居石不与Al(NO3)3-HNO3盐溶液反应留在滤渣中,可通过氢氧化钠溶液分解工艺进行处理[15-16]。所以,Al(NO3)3-HNO3盐溶液处理包头混合型稀土精矿可以将精矿中的氟碳铈矿和独居石分开,且能将氟碳铈矿中的稀土和氟浸出。从而实现了在低温状态下使氟碳铈矿与独居石分离,能使精矿中的氟以络合物状态存在于浸出液中,便于后期对氟的回收利用。本文主要研究精矿中稀土在Al(NO3)3-HNO3盐溶液的溶解特性,确定浸出稀土的最佳工艺条件以及对浸出过程中动力学的研究,从而为新工艺的开发提供便利。

1 实验

1.1 原料及试剂

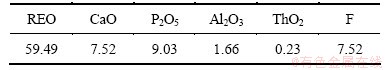

实验所用原料是浮选后的包头混合型稀土精矿,其主要化学组成见表1。

实验所用硝酸和结晶硝酸铝等试剂均为市售分析纯试剂。

表1 混合稀土精矿的成分(%,质量分数)

Table 1 Composition of a mixed rare earth concentrate

其中氟碳铈矿中的稀土质量分数为44.51%,独居石中稀土质量分数为14.98%。

1.2 实验方法及步骤

按照条件实验方案考察HNO3浓度、Al(NO3)3浓度、浸出时间、液固比、浸出温度以及搅拌速度对精矿中稀土浸出率的影响。按照一定比例将配制好的Al(NO3)3-HNO3盐溶液转移至带球形冷凝管的三口烧瓶中形成密闭冷凝回流系统,加热至预定温度后加入10 g烘干的稀土精矿并用JJ-1精密增力电动搅拌器进行搅拌时间和搅拌速度的控制。浸出渣和浸出液中的稀土采用硫酸亚铁铵定铈容量法进行测定。

精矿中稀土浸出率S的计算方法如下:

式中:m1为浸出渣中稀土质量(g);m为精矿中稀土质量(g)。

2 结果与讨论

2.1 硝酸浓度对稀土浸出率的影响

为研究HNO3浓度对精矿中稀土浸出率的影响,选取Al(NO3)3浓度1.5 mol/L,浸出时间为90 min,液固比为20 mL/g,浸出温度为85 ℃,搅拌速度为300 r/min得到不同HNO3浓度条件下,精矿中稀土浸出率随HNO3浓度变化的规律,见图1。

图1 精矿中稀土浸出率与HNO3浓度的关系

Fig. 1 Relationship between of HNO3 concentration and rare earth leaching ratio

从图1可见:精矿中稀土浸出率初期随着HNO3浓度的增加而增加,当HNO3浓度达到3.0 mol/L后,继续增加HNO3浓度对稀土的浸出率影响较小。这是因为随着HNO3浓度的增加,反应物中酸量增加。有利于反应(1)朝正向进行,从而提高精矿中稀土的浸出率。

2RE2(CO3)3·REF3+Al3++12H+ 6RE3++[AlF6]3-+6H2O+6CO2↑ (1)

6RE3++[AlF6]3-+6H2O+6CO2↑ (1)

同时,随着HNO3浓度的增加,即H+浓度增大,H+进入矿物晶格的概率增大[17],有利于破坏矿物结构,从而提高稀土浸出率;当酸量超过精矿浸出所需酸量时,继续增大酸量,对浸出率的影响较小。而且HNO3浓度过大,试剂的消耗较大,增加生产成本。故综合考虑Al(NO3)3-HNO3盐溶液浸出稀土过程,选择HNO3浓度为3 mol/L合适。

2.2 硝酸铝浓度对稀土浸出率的影响

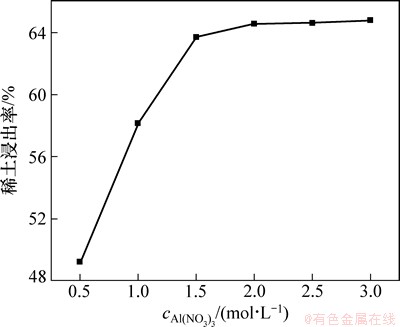

为了研究Al(NO3)3浓度对精矿中稀土浸出率的影响,选取HNO3浓度为3 mol/L,浸出时间为90 min,液固比为20 mL/g,浸出温度为85 ℃,搅拌速度为300 r/min,得到不同Al(NO3)3浓度下,精矿中稀土浸出率随Al(NO3)3浓度变化的规律,见图2。

图2 精矿中稀土浸出率与Al(NO3)3浓度的关系

Fig. 2 Relationship between Al(NO3)3concentration and rare earth leaching ratio

由图2可见:精矿中稀土浸出率随着Al(NO3)3浓度的增加而增加,当Al(NO3)3浓度增加到1.5 mol/L后,继续增加Al(NO3)3浓度,稀土浸出率几乎不发生变化。这是因为Al(NO3)3浓度从0.5 mol/L增加到1.5 mol/L时,溶液中Al3+浓度不断增加,有利于与矿物中的氟络合,促进反应式(1)的正向进行;当反应达到平衡后,继续增加Al(NO3)3浓度对精矿中稀土浸出率影响较小;同时,若Al(NO3)3浓度过高,溶液的黏度增加,不利于反应物与矿物表面的接触以及新生成物扩散进入浸出液中。故综合考虑Al(NO3)3-HNO3盐溶液浸出稀土过程,选择Al(NO3)3浓度为1.5 mol/L合适。

2.3 时间对稀土浸出率的影响

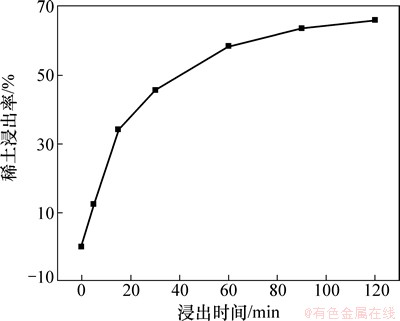

为了研究浸出时间对精矿中稀土浸出率的影响,选取HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,液固比为20 mL/g,浸出温度为85 ℃,搅拌速度为300 r/min,得到不同浸出时间下,精矿中稀土浸出率随浸出时间变化的规律见图3。

图3 精矿中稀土浸出率与浸出时间的关系

Fig. 3 Relationship between time and rare earth leaching ratio

由图3可见:精矿中稀土浸出率随着时间的延长而增加,当时间达到90 min后继续延长浸出时间,稀土浸出率增加幅度较小。这是因为随着反应的进行,稀土的浸出率增加,当时间达到90 min时,反应式(1)基本上达到平衡状态,继续延长时间,对稀土浸出率的影响较小。且随着时间的延长,Al(NO3)3-HNO3盐溶液中各反应物的浓度降低,对矿物的侵蚀能力下降,不利于反应式(1)朝正向进行。故在考虑精矿中稀土浸出率的同时,为提高浸出效率,Al(NO3)3-HNO3盐溶液浸出稀土过程中选择浸出时间为90 min合适。

2.4 液固比对稀土浸出率的影响

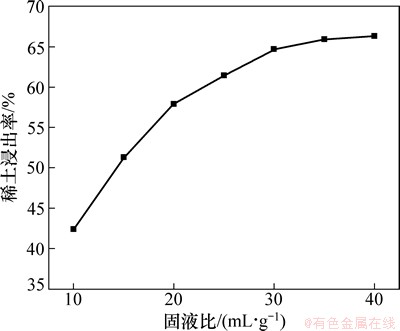

为了研究液固比对精矿中稀土浸出率的影响,选取HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,浸出时间为90 min,浸出温度为85 ℃,搅拌速度为300 r/min,得到不同液固比条件下,精矿中稀土浸出率随液固比变化的规律,见图4。

由图4可见:液固比对精矿中稀土浸出率的影响较大,随着液固比的增大,精矿中稀土的浸出率不断增加;当液固比达到 30 mL/g后,继续增大液固比值,精矿中稀土浸出率继续增加,但增加幅度较小。这是因为,在液固比达到30 mL/g前,矿浆黏度高,Al(NO3)3-HNO3盐溶液在浸出界面容易达到过饱和,从而阻止界面物质浸出反应的进行;当液固比达到30 mL/g后,继续增大液固比,矿浆浓度下降,可提高溶液中的传质速度,固液界面的可溶物质不断向外扩散,从而提高浸出速度[18-19]。但液固比过大,导致反应物用量大大增加,增加成本。故在考虑精矿中稀土浸出率的同时,为降低成本,Al(NO3)3-HNO3盐溶液浸出稀土过程中选择液固比为30 mL/g合适。

图4 精矿中稀土浸出率与液固比的关系

Fig. 4 Relationship between liquid solid ratio and rare earth leaching ratio

2.5 温度对稀土浸出率的影响

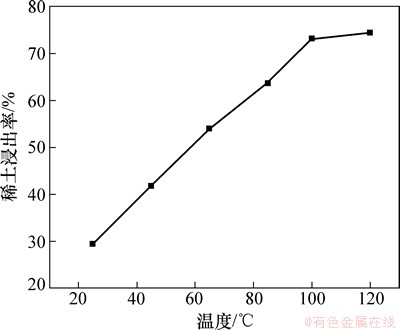

为了研究浸出温度对精矿中稀土浸出率的影响,选取HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,浸出时间为90 min,液固比为30 mL/g,搅拌速度为300 r/min,得到不同浸出温度条件下,精矿中稀土浸出率随浸出温度变化的规律,见图5。

图5 精矿中稀土浸出率与液固比的关系

Fig. 5 Relationship between of temperature and rare earth leaching ratio

由图5可见:温度对精矿中稀土的浸出率影响非常明显,精矿中的稀土浸出率随着温度的增加而增加,温度达到100 ℃以后,继续增加温度精矿中稀土浸出率增加,但幅度较小;当温度从25 ℃增加到100 ℃,精矿中稀土浸出率增加了43.74%,而温度从100 ℃增加到120 ℃仅增加了1.27%。这是因为温度的增加有助于提高反应分子活化能,从而有利于反应活化分子数量的增加,促使反应式(1)正向进行。当反应达到平衡后,继续增加温度对稀土浸出率影响不大,而且温度过高对设备的要求以及能耗大大增加。故在考虑精矿中稀土浸出率的同时,为降低能耗,Al(NO3)3-HNO3盐溶液浸出稀土过程中选择浸出温度为100 ℃合适。

2.6 搅拌速度对稀土浸出率的影响

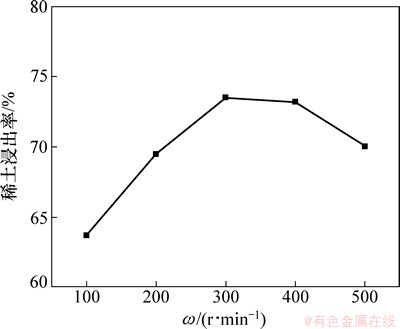

为了研究搅拌速度对精矿中稀土浸出率的影响,选取HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,浸出时间为90 min,液固比为30 mL/g,浸出温度为100 ℃,得到不同浸出温度条件下,精矿中稀土浸出率随搅拌速度变化的规律,见图6。

图6 精矿中稀土浸出率与搅拌速度的关系

Fig. 6 Relationship between stirring speed and rare earth leaching ratio

由图6可见:精矿中稀土浸出率随搅拌速度的增加而增加,当搅拌速度达到300 r/min时,浸出率达到最大,继续增加搅拌速度则稀土浸出率下降;当搅拌速度从100 r/min增加至300 r/min时,精矿中稀土浸出率由63.69%增加至73.5%,而当搅拌速度达到500 r/min时,精矿中稀土浸出率下降至70.03%。这是因为在300 r/min之前,搅拌速度的增加有利用Al(NO3)3-HNO3盐溶液和矿物的接触以及可以使新生成的液相及时的脱离矿相表面进入溶液中,从而有利于Al(NO3)3-HNO3盐溶液对矿物的近一步侵蚀。但搅拌速度过高容易使矿物与Al(NO3)3-HNO3盐溶液的接触时间缩短,不利于Al(NO3)3-HNO3盐溶液对矿物的侵蚀,从而导致精矿中稀土浸出率的降低。故在Al(NO3)3-HNO3盐溶液浸出稀土过程中选择搅拌速度为300 r/min合适。

2.7 浸出过程工艺综合分析

综合上述各因素在Al(NO3)3-HNO3盐溶液浸出稀土过程中对稀土浸出率的影响分析,并考虑降低能耗和节约生产成本等问题,选择Al(NO3)3-HNO3盐溶液浸出条件为:HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,浸出温度为100 ℃,搅拌时间为90 min,液固比为30 mL/g,搅拌速度为300 r/min为最优浸出工艺条件。

通过对优化条件下得到的浸出液和浸出渣中稀土进行含量测定,得出优化条件下稀土的浸出率为73.5%,而氟碳铈矿中稀土的理论浸出率为74.82%,即氟碳铈矿中稀土浸出率达98.24%。

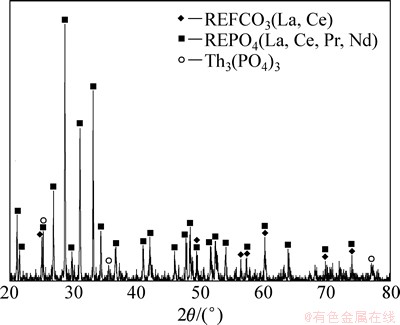

将优化实验所得滤饼进行XRD物相分析和SEM形貌分析。

2.7.1 XRD物相分析

将实验中所用包头混合型稀土精矿以及浸出过程中所得滤渣进行XRD物相分析,结果分别如图7和图8所示。

由图7和图8可见:原矿中的氟碳铈矿相在经过Al(NO3)3-HNO3盐溶液浸出后几乎完全消失,且浸出渣中衍射峰显示为独居石相和磷酸钍相。这说明Al(NO3)3-HNO3盐溶液可有效地浸出包头混合型稀土精矿中的氟碳铈矿,且精矿中的独居石不与Al(NO3)3-HNO3盐溶液反应,从而使独居石富集在浸出渣中,而氟碳铈矿中的稀土被浸出进入浸出液中。同时,在此低温体系中包头混合型稀土精矿中的钍同时和独居石富集在渣中便于进一步处理。

图7 包头稀土精矿XRD图

Fig. 7 XRD pattern of Baotou rare earth concentrate

图8 浸出渣XRD图

Fig. 8 XRD pattern of leaching residue

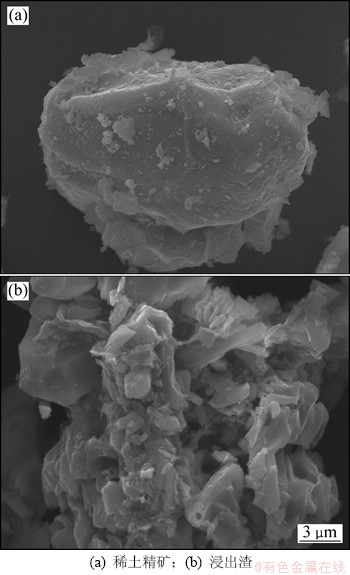

2.7.2 SEM形貌分析

将实验中所用包头混合型稀土精矿以及Al(NO3)3-HNO3盐溶液浸出过程中所得浸出渣进行SEM形貌分析,如图9所示。

图9 稀土精矿和浸出渣SEM图

Fig. 9 SEM images of rare earth concentrate and leaching residue

图9(a)所示为稀土精矿SEM图,图9(b)所示为Al(NO3)3-HNO3盐溶液浸出后所得浸出渣SEM图。由图9可见:稀土精矿颗粒表面光滑,浸出渣表面凹凸不平,孔洞较多,且表面也没有新生成物质的包裹。这说明Al(NO3)3-HNO3盐溶液对矿物的侵蚀能力较强,且新生成的物相易脱落进入液相中。综上所述,采用Al(NO3)3-HNO3盐溶液处理包头混合型稀土精矿工艺是可实施的。

2.8 精矿中稀土浸出过程动力学分析

精矿中稀土浸出过程是Al(NO3)3-HNO3盐溶液与稀土精矿颗粒固相反应的复杂多相反应过程,其动力学模型可以为体积反应模型或收缩反应核模型。将浸出时间和对应的稀土浸出率带入各种动力学模型进行模拟,模拟曲线发现与收缩反应核模型控制的边界传质和扩散混合控制的曲线拟合程度较高。且由图9(a)和(b)图对比可知,浸出后的颗粒粒径减小。因此Al(NO3)3-HNO3盐溶液浸出精矿中稀土动力学方程可为:1/3ln(1-x)+[(1-x)-1/3-1]=Kt。

为了确定精矿中稀土浸出过程的动力学反应速度的限制条件,研究了温度对反应动力学的影响。选择HNO3 浓度为3 mol/L, Al(NO3)3浓度为1.5 mol/L, 液固比为30 mL/g,搅拌速度为300 r/min,在不同温度条件下,精矿中稀土浸出率随时间关系如图10所示。

图10 不同温度下稀土浸出率和时间的关系

Fig. 10 Relationship between time and rare earth leaching ratio at various temperatures

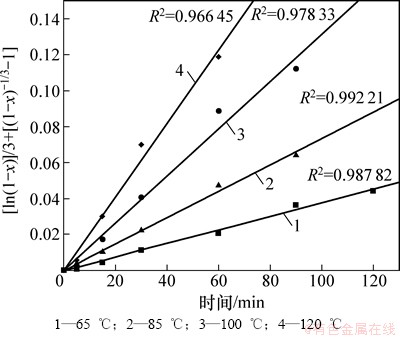

将图10中的实验数据代入1/3ln(1-x)+[(1-x)-1/3- 1]=Kt方程式中得到1/3ln(1-x)+ [(1-x)-1/3-1]与时间的关系,如图11所示。

由图11可见:1/3ln(1-x)+[(1-x)-1/3-1]与时间呈较好的线性关系,表明其符合所选择的收缩反应核模型。

将图11中1/3ln(1-x)+[(1-x)-1/3-1]与t之间的关系进行线性回归,根据Arrhenius 方程:lgK=lgK0-Ea/(2.303RT)做作lgK-1/T关系曲线,如图12所示。

由图12可得其直线斜率为-1 786.824 42 J/mol,则由-1 786.824 42 J/mol=-Ea/2.303R,计算得出Ea=34.213 kJ/mol;截距为1.867 23,则由1.867 23= lgK0,计算得出K0=73.660。则精矿中稀土浸出的动力学方程为:1/3ln(1-x)+[(1-x)-1/3-1]=73.660e-34 213/(RT)t。且活化能在10 kJ/mol与40 kJ/mol之间,为边界传质和扩散混合步骤控制[20]。

图11 不同温度条件下1/3ln(1-x)+[(1-x)-1/3-1]与时间关系图

Fig. 11 Relationship between 1/3ln(1-x)+[(1-x) -1/3-1] and time at various temperatures

图12 稀土浸出Arrhenius图

Fig. 12 Arrhenius plot for leaching of rare earth

3 结论

(1) Al(NO3)3-HNO3盐溶液处理包头混合型稀土精矿可以有效地将精矿中的氟碳铈矿等矿物浸出,同时避免氟的逸出,而独居石在浸出过程中不参与反应。

(2) Al(NO3)3-HNO3盐溶液浸出包头混合型稀土精矿中稀土最优条件如下:HNO3浓度为3 mol/L,Al(NO3)3浓度为1.5 mol/L,浸出温度为100 ℃,搅拌时间为90 min,液固比为30 mL/g,搅拌速度为300 r/min。在此优化条件下,精矿中稀土的浸出率为73.5%,而稀土的理论浸出率为74.82%,即精矿中稀土浸出率达98.24%。

(3) Al(NO3)3-HNO3盐溶液浸出包头混合型稀土精矿中稀土过程属于收缩反应核模型,反应活化能为34.213 kJ/mol,受边界传质和扩散混合控制。

参考文献:

[1] LUO Shaohua, TANG Zilong, LU Junbiao et al. Physical and elec-trochemical properties of ladoped lithium iron phosphate electrodes[J]. Rare Metal Materials and Engineering, 2007, 36(8): 1366-1368.

[2] 张吉林, 洪广言. 稀土纳米发光材料研究进展[J]. 发光学报, 2005, 26(3): 285-290.

ZHANG Jilin, HONG Guangyan. Progress on the study of nanoscale rare earth luminescent materials[J]. Chinese Journal of Luminescence, 2005, 26(3): 285-290.

[3] 陈占恒. 稀土新材料及其在高技术领域的应用[J]. 稀土, 2000, 21(1): 55-57.

CHEN Zhanheng. Rare earth new materials and their application in the field of high technology[J]. Chinese Rare Earths, 2000, 21(1): 55-57.

[4] 钱九红, 李国平. 中国稀土产业的发展现状[J]. 稀有金属, 2003, 27(6): 813-818.

QIAN Jiuhong, LI Guoping. Status of development of rare earth industry in China[J]. Chinese Journal of Rare Metals, 2003, 27(6): 813-818.

[5] HUANG Xiaowei, LONG Zhiqi, LI Hongwei et al. Development of rare earth hydrometallurgy technology in China[J]. Journal of Rare Earths, 2005, 23(1): 1-4.

[6] 黄小卫, 李红卫, 王彩凤, 等. 我国稀土工业发展现状及进展[J]. 稀有金属, 2007, 31(3): 279-288.

HUANG Xiaowei, LI Hongwei, WANG Caifeng, et al. Development status and research progress in rare earth industry in China[J]. Chinese Journal of Rare Metal, 2007, 31(3): 279-288.

[7] WU Wenyuan, BIAN Xue, SUN Shu-chen, et al. Study on roasting decomposition of mixed rare earth concentrate in CaO-NaCl-CaCl2[J]. Journal of Rare Earths, 2006(24): 23-27.

[8] WU Wenyuan, BIAN Xue, WU Zhiying, et al. Reactionprocess of monazite and bastnaesite mixed rare earth minerals calcined by CaO-NaCl-CaCl2[J]. Trans Nonferrous Met Soc China, 2007, 17(4): 864-868.

[9] BIAN Xue, CHEN Jianli, ZHAO Zhihua, et al. Kinetics of mixed rare earths minerals decomposed by CaO with NaCl-CaCl2 melting salt[J]. Journal of Rare Earths, 2010, 28: 86-90.

[10] ZHANG Liqing, WANG Zhichang, TONG Shuxun, et al. Rare earth extraction from bastnaesite concentrate by stepwise carbochlorination chemical vapor transport oxidation[J]. Metall Mater Trans B, 2004, 35B: 217-221.

[11] 张丽清, 张凤春, 姚淑华, 等. 加碳氯化-氧化反应方法从氟碳铈矿-独居石混合精矿中提取稀土[J]. 过程工程学报, 2007, 7(1): 75-78.

ZHANG Liqing, ZHANG Fengchun, YAO Shuhua, et al. Rare extraction from mixed bastnaesite monazite concentrate by carbochlorination oxidation[J]. The Chinese Journal of Process Engineering, 2007, 7(1): 75-78.

[12] Njegomir R, Marija B. Aluminium fluoride complexation and its ecological importance in the aquatic environment[J]. The Science of the Total environment, 1995, 172: 237-243.

[13] WANG Liangshi, WANG Chunmei, YING Yu, et al. Recovery of fluorine from bastnasite as syntheticcryolite by product[J]. Journal of Hazardous Materials, 2012, 209/210: 77-83.

[14] 徐仁扣, 季国亮. 酸性溶液中铝-氟反应动力学[J]. 环境科学学报, 1999, 19(3): 292-296.

XU Renkou, JI Guoliang. Kinetics of aluminum-fluride complexation in acid solution[J]. Acta Scientiae Circummstantiae, 1999, 19(3): 292-296.

[15] 孙培梅, 李洪桂, 李运姣, 等. 机械活化碱分解独居石新工艺[J]. 中南工业大学学报(自然科学版), 1998, 29(1): 36-38.

SUN Peimei, LI Honggui, LI Yunjiao, et al. New technology on decomposition of monazite by mechanical activation and caustic decomposition[J]. Journal of Central South University of Technology (Natural Science), 1998, 29(1): 36-38.

[16] 许延辉, 刘海蛟, 崔建国, 等. 包头混合稀土矿清洁冶炼资源综合提取技术研究[J]. 中国稀土学报, 2012, 30(5): 632-635.

XU Yanhui, LIU Haijiao, CUI Jianguo, et al. Techniques for clean smelting and resource comprehensive recycle of baotou rare earth concentrates[J]. Journal of the Chinese Society of Rare Earth, 2012, 30(5): 632-635.

[17] 邓志敢, 魏昶, 李兴彬, 等.钒钛磁铁矿提钒尾渣浸取钒[J]. 中国有色金属学报, 2012, 22(6): 1770-1777.

DENG Zhigan, WEI Chang, LI Xingbin, et al. Leaching vanadium form extracted vanadium residue of vanadium titanomagnetite[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1770-1777.

[18] 高亮, 杨建广, 陈胜龙, 等. 硫化锑精矿湿法清洁冶金新工艺[J]. 中南大学学报(自然科学版), 2012, 43(1): 28-37.

GAO Liang, YANG Jianguang, CHEN Shenglong, et al. A new process for cleaning hydrometallurgy of antimony sulfide[J]. Journal of Central South University (Science and Technology), 2012, 43(1): 28-37.

[19] 张亚莉, 李怀梅, 于先进, 等. 高铝硅氰化渣中铁回收工艺[J]. 中南大学学报(自然科学版), 2012, 43(1): 46-53.

ZHANG Yali, LI Huamei, YU Xianjin, et al. Process of Fe extraction from high-aluminum and silicon cyanide tailings[J]. Journal of Central South University (Science and Technology), 2012, 43(1): 46-53.

[20] 覃文庆, 唐双华, 厉超. 高硅低品位氧化锌矿的酸浸动力学[J]. 矿业工程, 2008, 28(1): 62-65.

QIN Wenqing, TANG Shuanghua, LI Chao. Kinetics of sulfuric acid leaching of high silica low-grade zinc oxide ore[J]. Mining and Metallurgical Engineering, 2008, 28(1): 62-65.

(编辑 何运斌)

收稿日期:2013-06-19;修回日期:2013-08-01

基金项目:国家杰出青年基金资助项目(51025416);长江学者和创新团队发展计划项目(IRT1065);国家自然科学基金资助项目(51174115)

通信作者:李梅(1965-),女,内蒙古鄂尔多斯人,博士,教授,从事稀土冶金与材料研究;电话:0472-5954390;E-mail:limei@imust.cn