DOI:10.19476/j.ysxb.1004.0609.2018.07.21

基于三维离散元法的罐式炉排料运动行为

李 静1,黄金堤1, 2,肖 劲1

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 江西理工大学 能源与机械工程学院,南昌 330013)

摘 要:罐式炉排料过程中石油焦颗粒运动行为对煅后焦的质量至关重要。基于离散元法,建立罐式炉内石油焦排料过程的颗粒尺度运动行为的三维数学模型,并通过1/15比例的冷态模型实验验证离散元法模拟的可靠性,研究料罐内固体石油焦颗粒的运动模式、颗粒间相互作用应力及力链分布特性。结果表明:离散元法模拟能很好的再现实验结果;石油焦颗粒在料罐内的加热带区域基本符合活塞流的运动特征,在冷却水套区域呈漏斗流的运动特征;料罐内石油焦颗粒间的作用力分布不均匀,强力链主要分布在料罐的中下部区域以及冷却水套区域。

关键词:罐式炉;排料行为;力链;离散元;物理模型

文章编号:1004-0609(2018)-07-1471-11 中图分类号:TF806.1 文献标志码:A

罐式炉(又称为罐式煅烧炉)是铝用炭阳极制备工序中的一个关键设备[1]。罐式炉为典型的逆流移动床式的黑箱反应器,石油焦颗粒在重力作用下自上而下缓慢移动,煅烧过程中产生的水分、挥发分穿过石油焦颗粒自由表面并经由挥发分通道排出。石油焦煅烧过程中,石油焦颗粒固相层与析出的挥发分气相间进行着复杂的传热、传质、动量传输及颗粒热分解反应。前期研究表明[2],单位排料量严重影响料罐(又称为煅烧罐)中石油焦的温度分布及煅烧时间,进而影响石油焦中水分和挥发分的析出行为。文献[3]中指出,罐式炉生产运行中,不合理的温度分布易导致罐内结焦、下生料等异常情况从而影响炉况顺行。同时,石油焦颗粒在料罐中的分布情况影响石油焦堆积层的孔隙度、气相(水分、挥发分)溢出速度及热效应。因此,罐式炉内石油焦颗粒的运动行为是影响石油焦煅烧质量的关键因素之一。研究罐式炉排料过程中石油焦颗粒的运动行为及石油焦在煅烧带中的停留时间,对提高石油焦煅烧质量及确保罐式炉的稳定生产运行具有重要的工程应用价值。

目前,针对固相炉料运动行为的研究,主要采用物理模型实验研究[4]、连续拟流体模型计算[5]和离散元法模拟计算[6-9]方法。使用冷态物理模型及连续拟流体模型仅能简单定性描述颗粒运动模式,无法描述颗粒间的微观动力学行为和细节。而基于拉格朗日坐标系包含颗粒之间及颗粒/壁面相互作用关系的离散元法(DEM)可根据颗粒尺寸和性质,不做过多的假设条件,通过计算即可获得颗粒之间各类宏观和微观力学信息。因此国内外学者采用离散元法针对工业生产中的各类颗粒物料输送过程开展了广泛的研究,如皮带输送[10]、提升管[11]、流态化床[12]以及高炉料罐内颗粒流动的研究[8, 13-15]。

目前,关于罐式炉内固相炉料运动行为的研究鲜有报道。李猛等[16]采用SolidWorks建立罐式炉排料机构模型,使用多体动力学分析进行了排料机构受力分析。XIAO等[2, 17-18]基于质量、动量、能量守恒及化学反应动力学建立了罐式炉数学模型,通过连续性方程描述了罐式炉内的气相、固相颗粒的温度场及石油焦颗粒热分解反应程度,该模型中将石油焦排料运动过程假设为粘性流,未考虑颗粒间的相互作用,无法获得颗粒层内微观动力学行为及受力、应力分布。石油焦在整个煅烧过程都处于封闭的料罐内,对于这样一个封闭性的反应器,无法直接观察到其内部的炉料运动状态,因此,借助于冷态物理模型实验和离散元法模拟计算是研究罐式炉内炉料运动行为的有效手段。

本文作者以24罐8层火道顺流式罐式炉炉内的石油焦排料运动行为为研究对象,基于离散元法建立罐式炉炉料颗粒尺度运动行为的三维数学模型,并通过1/15比例的冷态模型实验验证了离散元法(DEM)模拟的可靠性。利用该数学模型研究石油焦颗粒在罐式炉炉内的运动特征,并深入颗粒尺度给出颗粒运动过程的接触力链的分布及应力分布情况。

1 研究方法

1.1 离散元模型

罐式炉排料过程中,石油焦颗粒下降运动为密集堆积慢速流。采用三维无粘连干颗粒圆球模型,假定石油焦颗粒为相互独立的离散单元并视其为刚性体,颗粒间相互接触采用软球模型描述[4, 13, 19],如图1所示。采用无滑Hertz-Mindlin模型,颗粒运动分为平动和转动,其运动符合牛顿第二定律,颗粒i的平动及转动方程可描述为

(1)

(1)

式中:mi与vi分别为颗粒i的质量和速度;t为时间;mi为颗粒i的质量;ki为所有与颗粒i接触的颗粒总数;Fcn,ij为颗粒i与j之间的法向接触力;Fct,ij为颗粒i与j之间的切向接触力;Fdn,ij为颗粒i与j之间的法向粘性接触阻尼力;Fdt,ij为颗粒i与j之间的切向黏性接触阻尼力;g为重力加速度。

(2)

(2)

式中:Ii与ωi分别为颗粒i的转动惯量与角速度,dij为从单元i质心到单元j质心的位移向量。

图1 颗粒接触受力示意图

Fig. 1 Schematic diagram of particle contact

参照参考文献[4, 19-20],颗粒i所受接触力如下所述:

(3)

(3)

式中: ;

; ;

; ;

; ;E*为等效弹性模量;Ei、Ej为颗粒i、j的弹性模量;

;E*为等效弹性模量;Ei、Ej为颗粒i、j的弹性模量; 、

、 为颗粒i、j的泊松比;R*为颗粒等效半径;Ri、Rj为颗粒i、j的半径;δn为颗粒i在法向方向的变形即法向重叠量;n为单位法向向量。

为颗粒i、j的泊松比;R*为颗粒等效半径;Ri、Rj为颗粒i、j的半径;δn为颗粒i在法向方向的变形即法向重叠量;n为单位法向向量。

(4)

(4)

式中: ;

; ;

; ;

; ;β为阻尼系数;e为恢复系数;Sn为法向刚度;m*为等效质量;vn,ij为法向相对速度;vij为颗粒i与颗粒j的相对速度。

;β为阻尼系数;e为恢复系数;Sn为法向刚度;m*为等效质量;vn,ij为法向相对速度;vij为颗粒i与颗粒j的相对速度。

(5)

(5)

式中: ;

; ;

; ;φ为内摩擦角;St为切向刚度;δt为切向位移失量;

;φ为内摩擦角;St为切向刚度;δt为切向位移失量; 为等效剪切模量;Gi、Gj为颗粒i、j的剪切模量。

为等效剪切模量;Gi、Gj为颗粒i、j的剪切模量。

(6)

(6)

式中: 为切向的相对速度,

为切向的相对速度, 。

。

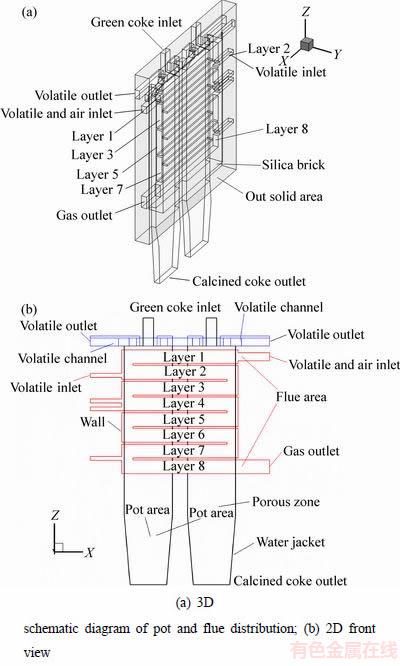

1.2 模拟条件

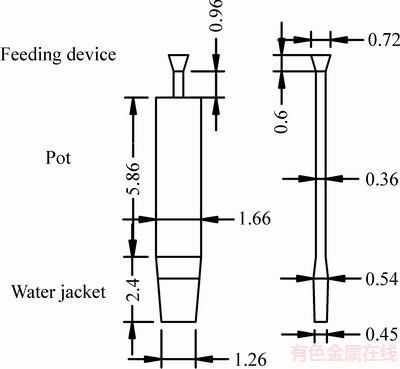

针对国内广泛采用的24罐8层火道顺流式罐式炉,采用离散元法建立罐式炉内石油焦排料运动过程的三维数学模型。罐式炉的各罐罐体结构一致,罐式炉中每个料罐的左右两侧都有8层水平走向的加热火道,火焰不与原料直接接触,如图2所示。石油焦由炉顶加料装置加入料罐内,物料在重力作用下自上而下缓慢移动,并依次通过预热带、煅烧带以及冷却带,受热并发生复杂的物理化学变化,最后由罐底的排料装置排出炉外[21]。

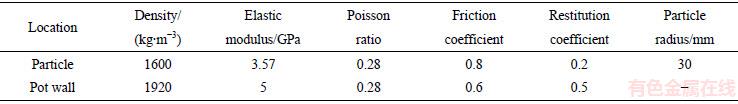

本模型除去与石油焦颗粒运动过程无关的料罐的几何特征(如挥发分通道等),选取单个料罐为研究对象,其几何边界及尺寸如图3所示。使用现有的计算机硬件条件,无法完成工业尺度数亿个颗粒的计算,为了减小计算规模,对模拟颗粒的尺寸进行了适当放大。模拟中假定颗粒为球形,半径为0.03 m,总填充球个数为27226个,计算时间步长为2.0×10-5 s。模拟实现过程为:使用开源离散元法软件Yade,在炉顶随机生成颗粒,并在重力作用下颗粒下落堆积直至填满炉顶料斗中部;由于罐式炉排料过程为排料-静止过程交替进行,为节省计算时间,每个排料周期通过移除冷却水套底部0.06 m厚度的颗粒层完成排料过 程[7],并将底部移除的颗粒移至料斗上方,待颗粒自然下落堆积静止稳定后视为完成一个排料周期并进入下一个排料周期。模型所用石油焦及炉壁物性参数如表1所列,具体参数来源见文献[20,22]。

图2 罐式煅烧炉结构示意图

Fig. 2 Schematic diagram of vertical shaft calciner

图3 料罐几何尺寸

Fig. 3 Geometry size of pot (Unit: m)

1.3 冷态物理实验

冷态物理实验是在1/15等比例缩小的料罐物理模型上进行的,该实验装置由料斗、料罐、冷却水套及排料拉板等四部分组成。物理模型的壁面采用厚度为5 mm的有机玻璃板制作,并以钢支架进行固定安装。采用带有3个与冷却水套底部截面一致的长方形孔洞的有机玻璃板作为排料控制装置,通过反复推拉排料拉板,使拉板的孔洞与冷却水套底部出口重叠打开–分离闭合交替循环来实现石油焦排料过程,具体物理装置结构如图4所示。实验物料采用经过筛分的、粒度为2~3 mm的煅后焦颗粒。采用白色西米作为示踪粒子来表征石油焦颗粒的运动行为。

物理模型实验包括以下步骤。

1) 将物料装入料斗中,将料面整平。

2) 拉动冷却水套下部的排料拉板,当冷却水套底面与拉板孔洞重叠,底部部分物料颗粒沿着冷却水套穿过拉板孔洞排出,随着拉板的继续拉动,水套底面与拉板孔洞不再重叠,底部排料出口封闭,此时视为完成一次排料操作过程。

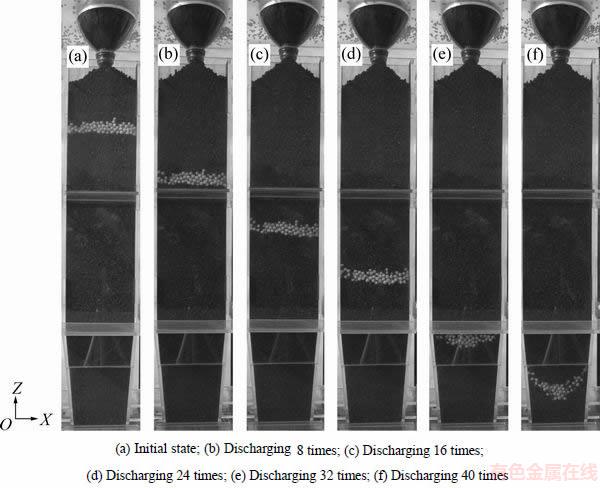

表1 石油焦颗粒及炉壁基本物理参数

Table 1 Basic physical parameters of petroleum coke particles and pot wall

图4 冷态物理模型实验装置示意图

Fig. 4 Schematic diagram of experimental device of cold physical model

3) 步骤(1)、(2)循环。整个实验采用数码摄像机记录颗粒下降过程的位置变化。

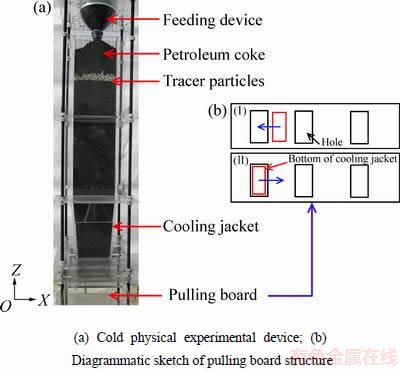

2 物理模型验证

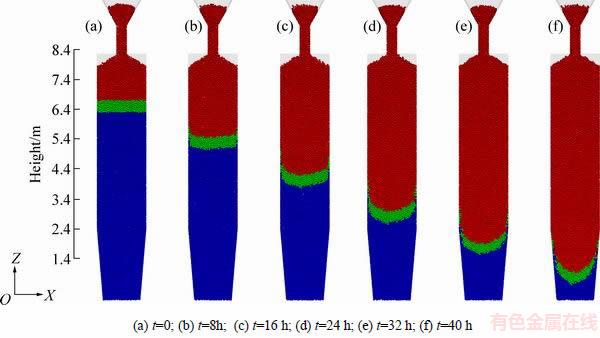

图5所示为冷态物理实验模拟的罐式炉内石油焦颗粒料层运动。图5(a)所示为炉料料层的初始填充状态,示踪颗粒层为直线型,此时开始排料。随着时间的推移,由图5(e)和(f)中可以看出,示踪料层逐渐转变为“U”形,说明炉料在靠近炉壁侧物料下降速度较罐体中心下降速度慢,这主要是由冷却水套出口上宽下窄的结构特征引起的。

图6所示为间隔24个排料周期(单罐排料量取85 kg/h,堆积层密度为850 kg/m3,根据式(7)计算可等效约为8 h)的罐式炉内DEM模拟石油焦颗粒料层运动计算结果,为了便于与实验对照观察颗粒流动状态的变化,将石油焦颗粒按高度分为3层,由上至下分别用红色、绿色、蓝色标记石油焦颗粒层。对比图5和6可知,实验结果与离散元模拟结果较为吻合,表明离散元模型的适用性,可用于罐式炉炉料运动模拟研究。

(7)

(7)

式中:Vbottom为每个排料周期删除的颗粒总体积;ρcoke为堆积料层密度;Qm为单罐单位排料量;n为模拟周期排料次数。

3 结果与讨论

3.1 粒度对石油焦颗粒运动的影响

模型中以10 h为一个研究时间步长,单罐单位排料量85 kg/h,堆积层密度为850 kg/m3,研究不同颗粒半径(20~30 mm)对石油焦颗粒运动的影响,具体模拟计算条件见表2。模型中根据式(7),算例1、2、3等效换算为31个模拟排料周期。

图5 罐式炉冷态模型排料过程的石油焦颗粒料层运动

Fig. 5 Experimental result of discharging process in cold physical model of vertical shaft calciner

图6 罐式炉排料过程的石油焦颗粒料层运动DEM模拟图

Fig. 6 DEM simulation of movement of petroleum coke bed during discharging process in vertical shaft calciner

表2 不同算例的计算条件

Table 2 Calculation conditions of different cases

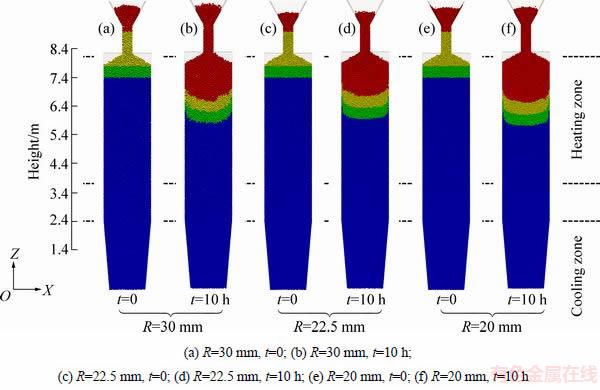

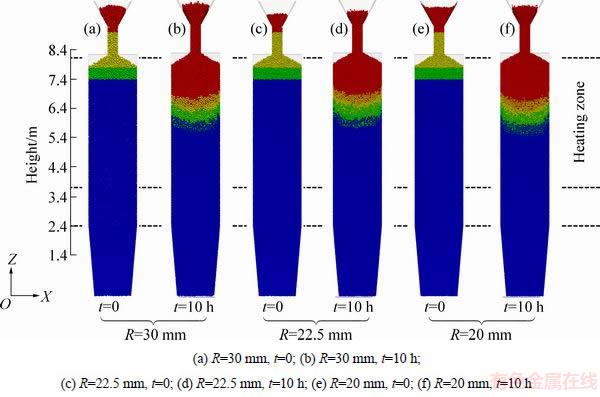

图7~9所示分别为表2中各算例条件下料罐中心XZ、YZ截面及料罐壁面XZ截面处示踪石油焦颗粒运动行为,其中由红、黄、绿、蓝四色(红(>9.0 m)、黄(>7.8 m且<9.0 m)、绿(>7.4 m且<7.8 m)、蓝(<7.4 m))进行颗粒初始位置示踪标记。由图7和8可知,不同粒度石油焦在料罐内下降运动趋势基本一致,粒度越小,黄色及绿色示踪层呈现的凹形轮廓越平缓,同时经历10 h后不同粒度的颗粒下降距离基本一致,表明颗粒粒度对石油焦在料罐内下降运动趋势影响较小,均呈现中心快两边慢的下凹形运动分布;在加热带区域,颗粒运动呈现活塞流特征,黄色示踪层颗粒并未超越绿色颗粒示踪层进行下降运动,主要是由于料罐的几何结构的对称性,不会因非对称的边壁的作用形成局部排料偏析。由图8可知,不同粒度的石油焦在料罐壁面下降运动幅度较中心截面颗粒运动幅度小,表明颗粒在壁面处的下降运动速度小于料罐中心处,部分黄色示踪层颗粒越过绿色示踪层颗粒向下运动,表明由于受壁面摩擦力作用,石油焦颗粒在壁面处存在一定程度的滚动。

3.2 料罐中不同区域的颗粒运动模式及停留时间

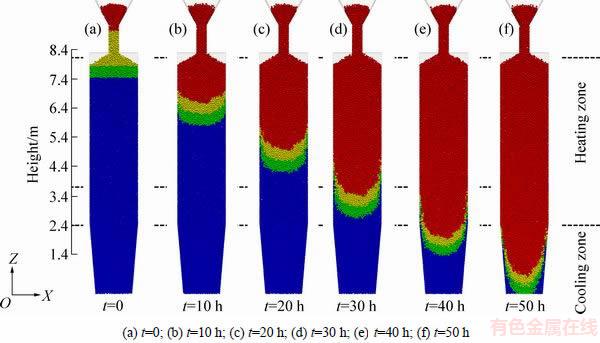

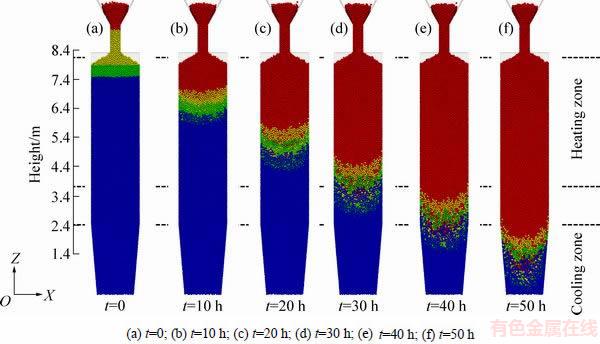

图10所示为不同时间下料罐中心截面石油焦颗粒的运动行为,该模拟是在表2中算例1条件下进行的。为了追踪石油焦颗粒从料罐顶部下移至料罐底部的运动轨迹变化过程,将石油焦颗粒按高度分为4层,各层颗粒以不同的颜色表示(由下到上依次是蓝(<7.4 m)、绿(>7.4 m且<7.8 m)、黄(>7.8 m 且<9.0 m)、红(>9.0 m))。图11所示为罐式炉壁面的石油焦颗粒随时间运动行为。表3所列为不同时间下示踪石油焦颗粒的运动距离。由图10 (a)可知,在料斗下方喉口处,石油焦颗粒自然堆积形成约为30°~40°的堆积角;结合罐式炉挥发分通道高于堆积层的几何结构特征(见图2(b))可知,石油焦颗粒不会堵塞挥发分通道。由图10(a)和(b)可知,料斗喉部的黄色示踪颗粒由最初的倒三角形转变为直线型,表明由料斗下降至料罐的颗粒以平铺方式堆积。由图10、图11和表3可知,随着排料运动的进行,单位时间间隔内示踪颗粒下降运动的相对偏移值由1.44 m逐渐减小为1.19 m;受壁面摩擦作用,料罐壁面处的石油焦颗粒的下降速度较料罐中心处慢,表明颗粒在料罐内中心区域的停留时间较壁面区域短,煅烧不如罐壁处充分。由图10(a)~(d)可知,在排料初始阶段,示踪颗粒层呈直线排布,石油焦在料罐内以先进先出的方式向下运动,表明石油焦颗粒在煅烧带(对应于火道加热区域)基本符合活塞流特征;在给定的单位排料量下,石油焦颗粒在加热带的停留时间约为30 h,这与文献[1]所述原料通过料罐中煅烧带的时间需24~36 h基本吻合。由图10(d)~(f)可知,随着排料的进行,示踪颗粒层在冷却带(冷却水套区域)逐渐转变为中心快两边慢的漏斗流的特征,这是由底部冷却水套上宽下窄的几何结构特征引起的。

图7 料罐中心XZ截面处不同粒度的石油焦颗粒运动行为

Fig. 7 Motion behavior of petroleum coke particles with different grain sizes on XZ cross section of pot center

图8 料罐中心YZ截面处不同粒度的石油焦颗粒运动行为

Fig. 8 Motion behavior of petroleum coke particles with different grain sizes on YZ cross section of pot center

图9 料罐壁面处不同粒度的石油焦颗粒运动行为

Fig. 9 Motion behavior of petroleum coke particles with different grain sizes on pot wall

图10 不同时间下料罐中心截面的石油焦颗粒运动行为

Fig. 10 Motion behavior of petroleum coke particles on pot central section at different time

图11 不同时间下料罐壁面石油焦颗粒运动行为

Fig. 11 Motion behavior of petroleum coke particles on pot wall area at different time

表3 不同时间下颗粒运动距离

Table 3 Motion distance of particles at different time

由表3可知,在给定工况条件下,石油焦自料斗喉部下落至冷却水套中部约经历了50 h,平均下移距离为6.75 m。石油焦在冷却区域停留的时间约为20 h,在炉内的总体停留时间大于50 h。

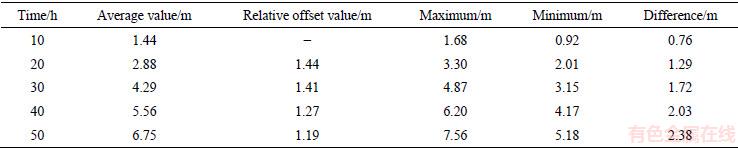

3.3 料罐内部的应力分布及接触力网络结构

图12所示为料罐中不同区域的堆积石油焦剪切应力值。由图12可知,随着料罐高度的下降,高剪切应力比例逐渐增加,由最初的0.62%上升至10.87%。图13所示为料罐中不同位置的堆积石油焦法向应力值。由图13可知,随着料罐高度的下降,高法向应力比例逐渐增加,由最初的0.57%上升至26.35%。

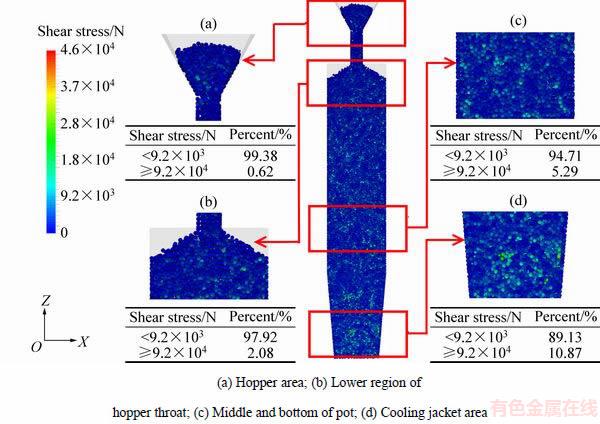

图14所示为料罐中不同位置的堆积石油焦接触力网络结构,通过线条粗细表示接触力的大小。为了便于与实验对照观察颗粒的流动状态的变化,将石油焦颗粒按高度分为8层,自下到上依次使用白、蓝、浅蓝、浅绿、浅黄、绿、黄、红8种颜色进行料层区域划分。由图14可知,随着料罐高度降低,两侧炉壁所受应力逐渐增大;料罐内部应力分布不均匀,料罐顶部区域(见图14(a)和(d))区域主要为弱力链(细线条),石油焦对硅砖壁面上的接触力较小;在中下部区域(见图14(g)、(i)、(k))分布着强力链,尤其是冷却水套壁面的区域(见图14(i)和(k))承受着料罐内石油焦颗粒的绝大部分重量,颗粒之间的接触力较大,通过强力链(粗线条)承担了上方堆积层的质量,因此水套壁面受到较大的压力,根据摩擦定律可知,在排料过程中,石油焦与水套壁面的摩擦力较料罐硅砖壁面大,因此,对于冷却水套需要定期进行更换,防止冷却水套过度磨损。

图12 料罐中不同区域的堆积石油焦剪切应力分布

Fig. 12 Shear stress distribution of petroleum coke accumulation at different regions of pot

图13 料罐中不同区域的堆积石油焦法向应力分布

Fig. 13 Normal stress distribution of petroleum coke accumulation at different regions of pot

图14 料罐内不同区域的颗粒接触力的链网络结构

Fig. 14 Network distribution of particle contact force in different regions of pot

4 结论

1) 离散元模拟结果与物理实验结果吻合度较好,表明离散元模型能很好地描述罐式炉排料过程的石油焦颗粒运动行为。

2) 颗粒尺寸大小对石油焦运动行为的影响并不显著;在煅烧带区域,石油焦颗粒运动基本符合活塞流的特征,因此,石油焦在罐式炉内煅烧以先进先出的方式进行,在给定的排料量下,石油焦颗粒在煅烧带中的停留时间约为30 h。随着排料的进行,在冷却水套区域,石油焦颗粒运动逐渐转变为漏斗流。

3) 罐式炉内冷却水套壁面及底部存在较强的应力区,料斗料面及挥发分通道附近料面应力最弱。冷却水套的上宽下窄的几何特征,使得料罐中的石油焦颗粒的作用力大部分由冷却水套壁面承担,水套内壁受到较大的颗粒摩擦力,因此需要定期更换冷却水套,防止过度磨损。

REFERENCES

[1] 王平甫, 罗英涛, 宫 振, 李庆义, 谭芝运, 贾鲁宁, 于易如. 中国竖罐式炉煅烧石油焦技术分析与研讨[J]. 炭素技术, 2009, 28(4): 41-45.

WANG Ping-fu, LUO Ying-tao, GONG Zhen, LI Qing-yi, TAN Zhi-yun, JIA Lu-ning, YU Yi-ru. Analysis on calcining technologies for pot calciner in China[J]. Carbon Techniques, 2009, 28(4): 41-45.

[2] XIAO J, HUANG J D, ZHONG Q F, LI F H, ZHANG H L, LI J. A real-time mathematical model for the two-dimensional temperature field of petroleum coke calcination in vertical shaft calciner[J]. JOM, 2016, 68(8): 2149-2159.

[3] 张 志, 孙 毅, 周善红. 提高罐式煅烧炉产品质量的方法浅析[J]. 炭素技术, 2011, 30(6): 60-62.

ZHANG Zhi, SUN Yi, ZHOU Shan-hong. The analysis on the ways for improving the production quality of shaft kiln[J]. Carbon Techniques, 2011, 30(6): 60-62.

[4] 邱家用, 张建良, 孙 辉, 闫炳基, 李峰光, 国宏伟. 并罐式无钟炉顶装料行为的离散元模拟及实验研究[J]. 应用数学和力学, 2014, 35(6): 598-609.

QIU Jia-yong, ZHANG Jian-liang, SUN Hui, YAN Bing-ji, LI Feng-guang, GUO Hong-wei. DEM simulation and experimental investigation of burden distribution in the parallel-hopper bell-less top blast furnace[J]. Applied Mathematics and Mechanics, 2014, 35(6): 598-609.

[5] FENG Y H, ZHANG X X, YU Q, SHI Z Y, LIU Z C, ZHANG H, LIU H F. Experimental and numerical investigations of coke descending behavior in a coke dry quenching cooling shaft[J]. Applied Thermal Engineering, 2008, 28(11/12): 1485-1490.

[6] 李 强, 冯明霞, 高 攀, 邹宗树. 高炉内炉料流动模式及力链分布的离散元模拟[J]. 东北大学学报(自然科学版), 2012, 33(5): 677-680.

LI Qiang, FENG Ming-xia, GAO Pan, ZOU Zong-shu. Discrete element simulation of flow pattern of burden and distribution of force chains in blast furnace[J]. Journal of Northeastern University(Natural Science), 2012, 33(5): 677-680.

[7] 周 恒, 游 洋, 罗志国, 邹宗树. COREX竖炉物料运动流型及瞬态特性的离散元模拟[J]. 东北大学学报(自然科学版), 2015, 36(9): 1293-1296.

ZHOU Heng, YOU Yang, LUO Zhi-guo, ZOU Zong-shu. Discrete element simulation of solid flow pattern and transient features of burden descending in COREX shaft furnace[J]. Journal of Northeastern University(Natural Science), 2015, 36(9): 1293-1296.

[8] 韩立浩, 罗志国, 邹宗树, 张玉柱. COREX熔化气化炉物料运动行为[J]. 钢铁研究学报, 2015, 27(11): 26-32.

HAN Li-hao, LUO Zhi-guo, ZOU Zong-shu, ZHANG Yu-zhu. Solid flow behavior in COREX melter gasifier[J]. Journal of Iron and Steel Research, 2015, 27(11): 26-32.

[9] WANG M, ZHU W, SUN Q, ZHANG X. A DEM simulation of dry and wet particle flow behaviors in riser[J]. Powder Technology, 2014, 267: 221-233.

[10] HONUS S, BOCKO P, BOUDA T,  M. The effect of the number of conveyor belt carrying idlers on the failure of an impact place: A failure analysis[J]. Engineering Failure Analysis, 2017, 77: 93-101.

M. The effect of the number of conveyor belt carrying idlers on the failure of an impact place: A failure analysis[J]. Engineering Failure Analysis, 2017, 77: 93-101.

[11] TANG T, HE Y, REN A, ZHAO Y. Investigation on wet particle flow behavior in a riser using LES-DEM coupling approach[J]. Powder Technology, 2016, 304: 164-176.

[12] 沈 骝, 梁 财, 陈晓平, 许 盼, 徐贵玲, 袁高洋, 韩泽洲, 赵长遂. 气力输送中不同物料的流动特性及倾斜管阻力特性[J]. 东南大学学报(自然科学版), 2014, 44(5): 975-980.

SHEN Liu, LIANG Cai, CHEN Xiao-ping, XU Pan, XU Gui-ling, YUAN Gao-yang, HAN Ze-zhou, ZHAO Zhang-sui. Flow behaviors and resistance properties of inclined pipe for different materials in pneumatic conveying[J]. Journal of Southeast University(Natural Science Edition), 2014, 44(5): 975-980.

[13] 李 超, 程树森, 赵国磊, 尹怡欣. 串罐式无钟高炉炉顶炉料运动的离散元分析[J]. 过程工程学报, 2015, 15(1): 1-8.

LI Chao, CHENG Shu-sen, ZHAO Guo-lei, YIN Yi-xin. Analysis of particles movement in the serial-hopper bell-less top of blast furnace with discrete element method[J]. The Chinese Journal of Process Engineering, 2015, 15(1): 1-8.

[14] 张建良, 邱家用, 国宏伟, 刘征建, 孙 辉, 王广伟, 高征铠. 基于三维离散元法的无钟高炉装料行为[J]. 北京科技大学学报, 2013, 35(12): 1643-1652.

ZHANG Jian-liang, QIU Jia-yong, GUO Hong-wei, LIU Zheng-jian, SUN Hui, WANG Guang-wei, GAO Zheng-kai. Charging behavior in a bell-less blast furnace based on 3D discrete element method[J]. Journal of University of Science and Technology Beijing, 2013, 35(12): 1643-1652.

[15] 孙俊杰, 周 恒, 罗志国, 邹宗树. COREX熔化气化炉风口回旋区CFD+DEM数值模拟[J]. 东北大学学报(自然科学版), 2013, 34(6): 824-827.

SUN Jun-jie, ZHOU Heng, LUO Zhi-guo, ZOU Zong-shu. Numerical simulation of COREX raceway by coupling between CFD and DEM[J]. Journal of Northeastern University(Natural Science), 2013, 34(6): 824-827.

[16] 李 猛, 刘 明. 罐式煅烧炉排料机构传动性能仿真与研究[J]. 有色金属设计, 2016, 43(1): 51-56.

LI Meng, LIU Ming. Simulation and study on transmission performance of discharging system of tank calciner[J]. Nonferrous Metals Design, 2016, 43(1): 51-56.

[17] XIAO J, HUANG J, ZHONG Q, ZHANG H, LI J. Modeling and simulation of petroleum coke calcination in pot calciner using two-fluid model[J]. JOM, 2016, 68(2): 643-655.

[18] 肖 劲, 黄金堤, 张红亮, 李 劼. 罐式炉内石油焦煅烧过程的二维传热传质数学模型[J]. 中国有色金属学报, 2016, 26(11): 2440-2448.

XIAO Jin, HUANG Jin-di, ZHANG Hong-liang, LI Jie. Two-dimensional model for heat and mass transfer on petroleum coke calcination in vertical shaft calciner[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(11): 2440-2448.

[19] TSUJI Y, TANAKA T, ISHIDA T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe[J]. Powder Technology, 1992, 71(3): 239-250.

[20] 朱文睿, 雷丽萍, 曾 攀. 溜槽对高炉无料钟布料粒度偏析的影响研究[J]. 力学与实践, 2014, 36(6): 764-769.

ZHU Wen-rui, LEI Li-ping, ZENG Pan. The effect of the chute on the particle size segregation in a bell-less top blast furnace[J]. Mechanics in Engineering, 2014, 36(6): 764-769.

[21] EDWARDS L. The history and future challenges of calcined petroleum coke production and use in aluminum smelting[J]. JOM, 2015, 67(2): 308-321.

[22] 张正德. 粒级对粉体流动性及下料特性的影响[D]. 上海: 华东理工大学, 2015.

ZHANG Zheng-de. The effect of particle fraction on powder flowability and discharge characteristic[D]. Shanghai: East China University of Science and Technology, 2015.

Discharging behavior of petroleum coke in vertical shaft calciner based on three-dimensional discrete element method

LI Jing1, HUANG Jin-di1, 2, XIAO Jin1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. School of Energy and Mechanical Engineering, Jiangxi University of Science and Technology, Nanchang 330013, China)

Abstract: The descending behavior of petroleum coke in vertical shaft calciner (VSC) plays an important role in the quality of calcined petroleum coke. A three-dimensional(3D) mathematical model for the discharging behavior of petroleum coke in the VSC was established. Using this model, the motion trajectory of petroleum coke particles, and the distribution of stress and the contact force chain between particles was investigated. Moreover, the reliability of discrete element method (DEM) simulation was verified by 1/15-scale cold physical model experiment. The DEM simulation results agree very well with the experimental results. The petroleum coke flow in the heating zone of pot basically accords with the plug flow, and it presents a funnel flow in the cooling jacket region. The force distribution among the petroleum coke particles is not uniform and the strong chain is mainly distributed in middle and bottom of pot, especially the wall of the cooling water jacket area.

Key words: vertical shaft calciner; discharging behavior; force chain; discrete element method; physical model

Foundation item: Projects(51374253) supported by National Natural Science Foundation of China; Project(GJJ160664) supported by Science and Technology Plans of Jiangxi Province Education Department, China

Received date: 2017-05-02; Accepted date: 2017-07-05

Corresponding author: HUANG Jin-di; Tel: +86-15079128330; E-mail: hjd041@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374253);江西省教育厅科学技术研究项目(GJJ160664)

收稿日期:2017-05-02;修订日期:2017-07-05

通信作者:黄金堤,讲师,博士;电话:15079128330;E-mail:hjd041@163.com