文章编号:1004-0609(2012)10-2916-08

复杂高硅钴白合金碱焙烧脱硅预处理

徐志峰1,月日辉1,严 康1,王成彦2

(1. 江西理工大学 冶金与化学工程学院,赣州 341000;

2. 北京矿冶研究总院,北京 102206)

摘 要:针对高硅钴白合金结构复杂、难以直接硫酸浸出问题,开展碱焙烧脱硅预处理研究以破坏稳定致密的硅铁合金结构。结果表明:经碱焙烧预处理后,钴白合金形貌发生明显改变。碱焙烧条件如下:温度600 ℃,NaOH用量为硅、铁反应所需理论量0.64倍。在上述条件下焙烧2 h后,所得渣经水洗,硅的脱除率达到66.57%;再经常压硫酸浸出,钴、铁浸出率均高达99%以上,而铜则完全保留在浸出渣中,实现了钴和铜分离,渣中的铜经第二段氧化浸出得以回收。进一步基于工艺矿物学分析,对碱焙烧脱硅预处理后钴白合金的常压浸出行为进行解析。

关键词:钴白合金;碱焙烧;脱硅;预处理;常压浸出

中图分类号:TF811;TF816 文献标志码:A

Alkali-roasting and desilication pretreatment of refractory high-silicon cobalt white alloy

XU Zhi-feng1, YUE Ri-hui1, YAN Kang1, WANG Cheng-yan2

(1. School of Metallurgical and Chemical Engineering, Jiangxi University of Science and Technology,

Ganzhou 341000, China;

2.Beijing General Research Institute of Mining and Metallurgy, Beijing 102206, China)

Abstract: The refractory high-silicon cobalt white alloy is difficult to be leached directly by sulfuric acid because of its complex structure. The pretreatment of alkali-roasting and desilication was carried out to destroy the stable ferro-silicon alloy structure. The results show that the alloy structure is changed greatly after alkali-roasting and 66.57% of silicon can be removed by water-washing after the alkali-roasting at 600 ℃ for 2 h. The optimum dosage of NaOH for alkali-roasting is 0.64 times of the theoretical amount for the reactions of silicon and iron with NaOH. After the desilication, more than 99% of cobalt and iron can be leached from the pretreated alloy while all of copper is kept in the residue during the atmospheric leaching, by which the ideal separation of cobalt from copper is achieved easily. The copper in the residue can be recovered by the second stage oxidative leaching. Based on the mineralogical analysis, the leaching behavior of pretreated alloy was further discussed.

Key words: cobalt white alloy; alkali roasting; desilication; pretreatment; atmospheric leaching

基金项目:国家重点基础研究发展计划资助项目(2007CB613505);江西省第四批青年科学家培养对象项目(赣科发计字[2010]209号文)

收稿日期:2011-09-09;修订日期:2012-01-10

通信作者:王成彦,教授,博士;电话:010-88399551;E-mail: wchy3207@sina.com

钴是重要的战略金属,我国钴资源多与黄铁矿和铜镍矿伴生,品位低[1]。就我国金属钴消费而言,2000年开始突破4 000 t;至2004年,仅电池行业消费的钴就已突破4 500 t;2010年,钴消费量更达到9 800 t[2]。我国铜消费量也迅速增长,从2000年194.2万t增长到2007年486.7万t,年均递增14.0%。由于我国资源短缺,铜、钴金属供需缺口日趋增大。

非洲刚果(金)境内有着世界上最大的铜、钴资源富集区[3]。其中,加丹加铜矿带的铜储量达5 500万t,钴储量360万t,拥有大量地表及浅埋的品位高达2%~ 9%的氧化铜钴矿石,目前有多家公司在当地采用电炉还原熔炼方法处理氧化铜钴精矿生产钴白合金。钴白合金将成为国内各大钴业公司外购主要原料之一。

合金的湿法浸出行为受合金还原熔炼工艺[4]和成分及结构[5]的明显影响。对于低硅合金湿法冶金而言,除硫酸浸出[6]外,氨-铵盐体系[5, 7-8]或硫酸-硫酸铜体系[9-10]电化学溶解也是一种行之有效的方法。但对于高硅合金而言,由于其结构致密稳定、抗酸蚀性强,因此不仅浸出困难,而且浸出矿浆固液分离困难,导致有价金属回收率低。

现有的高硅钴白合金浸出工艺主要有混酸多级浸出、盐酸体系强氧化浸出、氧压浸出等。在硫酸、硝酸混酸体系中,高硅合金能有效浸出,但该工艺存在流程长、硝酸用量大、浸出液脱硝困难等缺憾,而硫酸、盐酸混酸氧化浸出体系[11]则可以回避上述问题;在盐酸体系中密闭条件下通氯气氧化浸出[12]或者在其他氧化剂[13-14]作用下,也可以取得理想的铜、钴浸出效果,但盐酸浸出工艺对设备防腐及环保提出较高要求;国内金川公司于20世纪80年代后期,将富钴合金加压浸出工艺成功实现工业化[15],2001年赞比亚谦比希COSAC工厂5级高压釜连续浸出钴白合金的工艺也已投产[16],氧压浸出工艺对设备安全的要求比较苛刻。

为破坏致密的合金结构以利于后续酸性浸出,有研究提出对高硅钴白合金进行“造渣熔炼”[17]预处理,即在1 300 ℃左右添加CaCO3熔剂进行熔炼,使合金中的硅以硅酸盐渣形式脱除。本文作者则在相对温和的条件下,通过碱焙烧破坏硅铁合金结构,使合金中的硅转型为水溶性硅酸钠,进而水洗脱硅,最终实现合金在常压条件硫酸介质中顺利浸出,并实现钴、铜比较理想的分离。

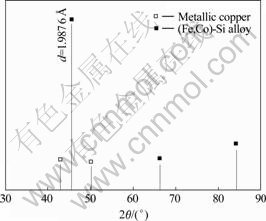

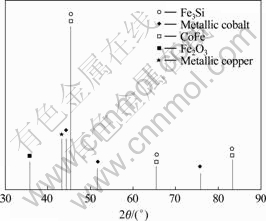

1 实验

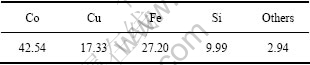

试验原料为某难处理钴白合金(简称白合金,以下同),其中钴、铜、铁、硅的含量较高(见表1)。白合金的X射线衍射(XRD)谱见图1。图1中1.9876 ?处的最强衍射线与Cu-Fe合金(Fe4Cu3)、Co-Si合金(CoSi、Co2Si、CoSi2、Co2Si3)以及Cu-Si合金(Cu5Si、Cu4Si)等特征线均不尽相同,只与Fe3Si特征线接近。此外,图1中仅存在明显的金属铜相特征线,而未见金属钴或其他钴物相的特征线。因此,尽管目前尚无标准的Fe-Co-Si合金衍射数据可供比照,但可以认为铁、钴元素主要是以Fe-Si、Co-Si合金相形式存在。图1中1.9876 ?处的最强衍射线暂标识为(Fe,Co)-Si合金。

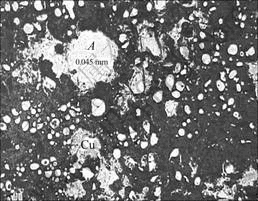

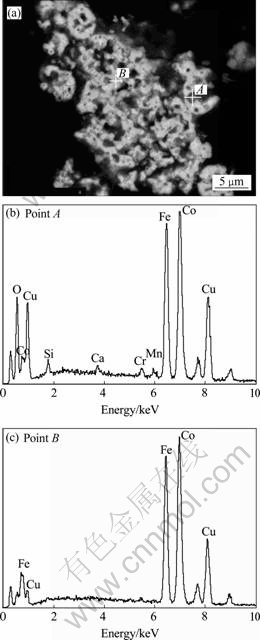

白合金中各物相的形貌见图2。图2中A点颗粒为白色的合金相集合体,该集合体内部有两种合金相和细粒金属铜。由图2可见,金属铜除以弥散态存于合金相中外,还有部分金属铜包裹了合金相,结构复杂。

表1 钴白合金主要化学成分

Table 1 Chemical composition of cobalt white alloy (mass fraction, %)

图1 钴白合金的XRD谱

Fig. 1 XRD pattern of cobalt white alloy

图2 钴白合金的显微结构

Fig.2 Microstructure of cobalt white alloy

白合金焙烧预处理在实验室用马弗炉中完成,之后采用热水洗涤以脱除硅,进而送常压浸出。鉴于白合金密度较大,为便于搅拌,浸出过程采用一较大液固比值(15 mL/1 g),搅拌转速为600 r/min。浸出过程中连续鼓入空气。浸出结束后,液固分离并分别送分析。铜、钴、铁、硅等元素浸出率及硅脱除率计算均按渣计。

2 结果与讨论

2.1 对比试验

首先,在硫酸体系中,对白合金进行直接浸出(常压-加压联合浸出)的对比试验。常压预浸条件为:液固比为15 mL/g,初始硫酸浓度[H2SO4]ini=145 g/L,90 ℃保温6 h。常压预浸矿浆进而送高压釜进行加压浸出,浸出条件为:氧分压0.5 MPa,150 ℃保温4 h,搅拌转速600 r/min。在上述条件下,钴、铜浸出率仅分别为74.82%和5.40%,铁、硅浸出率分别为42.65%和9.19%,浸出渣中不溶性钴、铜的含量分别高达14.28%和21.86%,浸出矿浆过滤困难。由上述可见,在硫酸体系中难以取得理想的白合金直接浸出效果。

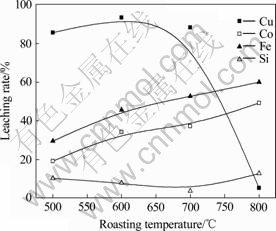

进一步进行了白合金直接焙烧预处理进而常压浸出的对比实验。焙烧时间恒定2 h,常压浸出条件为 [H2SO4]ini=109.48 g/L,90 ℃保温4 h。焙烧温度对后续常压浸出结果的影响见图3。由图3可见,白合金经直接焙烧预处理后,浸出性能得以一定程度改善,在焙烧温度600 ℃条件下,铜浸出率达到93.29%,渣含铜量降至1.74%,但钴浸出率偏低(仅34.24%),渣含钴量高达42.50%,而铁浸出率亦高达45.59%。因此,即使设置多段浸出或进一步提高焙烧温度,也难以同时兼顾有价金属浸出率及金属分离效果。

图3 焙烧温度对预处理后钴白合金常压浸出的影响

Fig. 3 Effect of roasting temperature on atmospheric leaching of pretreated cobalt white alloy

鉴于此,提出白合金碱焙烧预处理工艺思想,即通过碱焙烧有效破坏硅铁合金结构,使合金中硅转型成可溶性钠盐进而水洗脱除。在熔融碱中,单质硅、铁将发生如下反应,分别生成硅酸钠及铁酸钠:

Si+4NaOH=Na4SiO4+2H2 (1)

2Fe+6NaOH=Na2Fe2O4+2Na2O+3H2 (2)

2.2 焙烧碱用量

考察了碱用量分别为硅、铁反应所需NaOH理论量的0.52、0.64、0.71、0.77和0.97倍时对白合金焙烧渣水洗脱硅及进一步常压酸浸的影响。碱焙烧温度暂定700 ℃,保温2 h。常压浸出条件为:[H2SO4]ini= 96.02 g/L,90 ℃保温4 h。实验结果见图4和5。

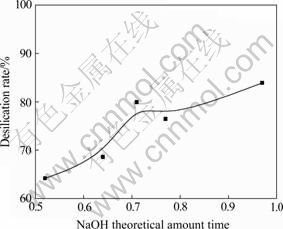

由图4可见,当碱用量由理论量的0.52倍增至0.71倍时,白合金焙烧渣水洗脱硅率由64.18%明显升高至79.95%,随碱用量进一步提高至理论量的0.97倍,脱硅率略增至83.93%,增幅不明显。

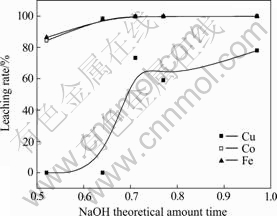

由图5可见,随焙烧碱用量由理论量的0.52倍增大至0.64倍,后续常压浸出中钴浸出率由84.44%增大至98.47%,铁浸出率也由86.40%增大至97.95%,渣含钴、铁分别降至2.10%和2.09%,而铜则完全保留在渣中。随碱用量进一步增大至理论量的0.71倍,铜开始明显浸出。由此可见,在700 ℃焙烧2 h条件下,碱用量选择理论量的0.64倍是适宜的,有利于后续常压浸出中钴、铜的分离。

图4 焙烧碱用量对钴白合金焙烧渣水洗脱硅的影响

Fig. 4 Effect of alkali dosage in roasting on water-washing desilication of roasted cobalt white alloy

图5 焙烧碱用量对预处理后钴白合金常压酸浸的影响

Fig. 5 Effect of alkali dosage in roasting on atmospheric leaching of pretreated cobalt white alloy

2.3 碱焙烧温度

在焙烧碱用量为理论量的0.64倍条件下,分别考察了焙烧温度对白合金焙烧渣水洗脱硅及进一步常压酸浸的影响。碱焙烧时间固定为2 h,常压浸出条件为[H2SO4]ini.=96.02 g/L,90 ℃保温4 h。实验结果见图6和7。

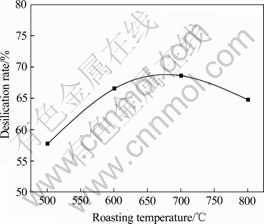

由图6可见,随焙烧温度由500 ℃升高至600 ℃,白合金焙烧渣水洗脱硅率由57.75%升高至66.57%,渣含硅降至2.87%。随焙烧温度进一步升高,硅脱除情况未见改善。

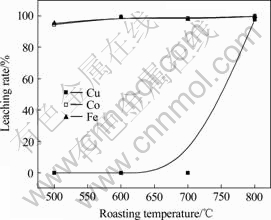

由图7可见,白合金在焙烧温度700 ℃范围内经预处理后,在常压浸出中钴、铁浸出比较完全,而铜则完全保留在浸出渣中,钴、铜分离效果理想。

图6 碱焙烧温度对钴白合金焙烧渣水洗脱硅的影响

Fig. 6 Effect of roasting temperature on water-washing desilication of roasted cobalt white alloy

图7 碱焙烧温度对预处理后钴白合金常压酸浸的影响

Fig. 7 Effect of roasting temperature on atmospheric leaching of pretreated cobalt white alloy

虽然当碱焙烧温度升高至800 ℃后,金属铜也将大量溶出,但此时浸出渣含铜仍高达4.11%,有待二次浸出才能保证铜回收率。且浸出液中铜、钴、铁浓度均较高,不利于金属分离,影响有价金属铜、钴的回收率。

因此,综合考虑,碱焙烧温度选择600 ℃为宜,可使白合金在后续常压浸出中钴、铁浸出比较完全,浸出率分别高达99.24%和99.18%,渣含钴、铁分别降至1.2%和0.93%。浸出液经黄钠铁矾法除铁后,溶液含铁低于1 mg/L,可送钴回收工序。浸出渣中铜富集至65.40%,可送第二段氧化浸出以回收铜。

实验证明,第二段采用CuSO4+H2SO4体系(初始铜离子浓度[Cu2+]ini=24 g/L,[H2SO4]ini=137 g/L),经三级逆流浸出,在浸出温度90 ℃、各级保温3 h及液固比为5 mL/g等条件下,Cu浸出率达99.12%,渣中含Cu低至3.37%,浸出效果良好。为保证铜、钴的回收率,第二段残余浸出渣可以返回铜浸出,而脱铜后液则可以返回钴浸出系统。

2.4 碱焙烧脱硅预处理对白合金物相的影响

白合金经碱焙烧脱硅预处理后XRD谱见图8。经与图1比较可见,经预处理,白合金原有的(Fe,Co)-Si合金结构遭到破坏,出现Co-Fe合金相,但由于Si只是部分脱除,因此,残余Si主要还是以Fe3Si合金相形式存在。

于元素铁而言,除主要物相Fe3Si合金以及一定量Co-Fe合金相外,另有部分铁以Fe2O3相形式存在,Fe2O3应是碱焙烧产物铁酸钠在水洗脱硅过程中进一步发生水解反应的产物,反应式如下:

图8 碱焙烧脱硅预处理后钴白合金XRD谱

Fig. 8 XRD pattern of cobalt white alloy after alkali-roasting and desilication pretreatment

Na2Fe2O4+2H2O=Fe2O3·H2O+2NaOH (3)

进一步比较图8和图1可知,经预处理后,白合金中钴除以Co-Fe合金相形式存在外,还有相当数量以金属钴相形式存在。

经碱焙烧脱硅预处理后,白合金的形貌见图9。由图9可见,经预处理后,细小合金颗粒受蚀严重并形成疏松蜂窝状聚合体,即使有大颗粒合金尚未完全分解,其外层也已形成了结构疏松的边缘层,经X射线能谱分析可知,该边缘层含有大量氧。由上述可见,经碱焙烧预处理后,白合金形貌发生明显改变,原有的致密结构被明显破坏。

对由细小合金颗粒形成的聚合体进行X射线能谱分析,其结果如图10所示。由图10可见,聚合体A点处含有大量氧。据图8分析结果可知,该处铁应该是以氧化态形式存在;聚合体B点处几乎不含氧,该处钴、铁应该是以金属态存在,这与图8分析结果一致。

图9 碱焙烧脱硅预处理后钴白合金的SEM像

Fig. 9 SEM image of cobalt white alloy after alkali-roasting and desilication pretreatment

图10 碱焙烧脱硅预处理后钴白合金颗粒聚合体的SEM像及能谱分析结果

Fig. 10 SEM image(a) and energy spectra((b), (c)) of particles aggregate in cobalt white alloy after alkali-roasting and desilication pretreatment

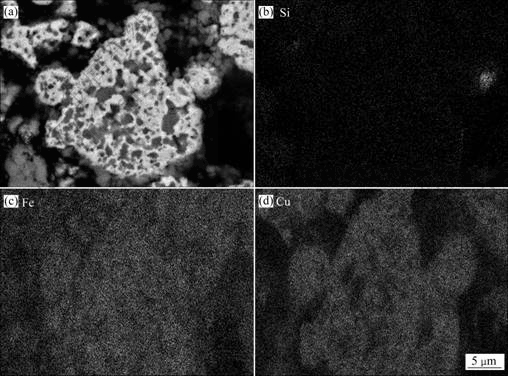

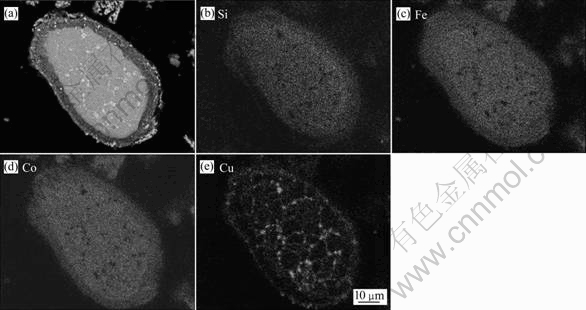

进一步对聚合体和大合金颗粒分别进行背散射电子像及元素面分布分析,结果见图11和12所示。由图11中见,聚合体中主要含铁、钴,而硅分布量很低。对于大合金颗粒而言,如图12所示,虽然碱向合金颗粒内部渗透,合金基体不断氧化并分解,但颗粒内核仍保持原有形貌,这说明碱焙烧脱硅预处理的效果受合金颗粒大小明显影响。

图11 碱焙烧脱硅预处理后钴白合金颗粒聚合体背散射电子像及相关元素面分布图

Fig. 11 Backscattered electron image(a) and element surface distributions((b)-(d)) of particles aggregate in cobalt white alloy after alkali-roasting and desilication pretreatment

图12 碱焙烧脱硅预处理后钴白合金颗粒背散射电子像及相关元素面 分布

Fig. 12 Backscattered electron image(a) and element surface distributions((b)-(d)) of particles in cobalt white alloy after alkali- roasting and desilication pretreatment

无论图11还是图12中,元素铜都是保持金属态并分散于基体物中,这与图8分析结果也是一致的。

综上所述,白合金经碱焙烧脱硅预处理后,不仅结构去稳定化,而且元素铁和钴均出现了易与酸反应的物相(如Co-Fe合金、Fe2O3和金属钴),因此,较预处理前,元素钴、铁浸出将变得容易得多。由于金属铜溶出需强氧化氛围,其浸出要远比钴、铁难得多,因此,在常压浸出环节是易于控制并实现钴、铜分离的,这与浸出实验结果也是相吻合的。

3 结论

1) 高硅钴白合金结构复杂,难以直接硫酸浸出。在600 ℃及NaOH用量为硅、铁反应所需NaOH理论量的0.64倍等条件下焙烧2 h后,经水洗硅脱除率达到66.57%,再经常压硫酸浸出,可使钴、铁浸出分别高达99.24%和99.18%,而铜则完全保留在浸出渣中,渣中铜富集至65.40%,实现了钴、铜的较理想分离。

2) 经碱焙烧脱硅预处理后,钴白合金形貌发生明显改变,铁主要以Fe3Si合金相形式存在,此外还以Co-Fe合金相形式存在,另有部分铁以Fe2O3形式存在;元素钴除以Co-Fe合金相形式存在外,还有相当数量以金属钴相存在;元素铜则保持相对独立的金属相态。

3) 复杂钴白合金经碱焙烧脱硅预处理后,可以采用两段常压酸浸工艺分段回收有价金属钴、铜,即钴、铁在第一段高效浸出,浸出液经黄钠铁矾除铁后可回收钴;富铜渣经第二段氧化浸出以回收铜。

致谢:

在复杂钴白合金工艺矿物学分析过程中,得到了北京矿冶研究总院矿产资源所汤集刚教授、隋娟玲高工的帮助,在此深表谢意!

REFERENCES

[1] 王永利, 徐国栋. 钴资源的开发和利用[J]. 河北北方学院学报: 自然科学版, 2005, 21(3): 19-21.

WANG Yong-li, XU Guo-dong. The development and use of cobalt resource[J]. Journal of Hebei North University: Natural Science Edition, 2005, 21(3): 19-21.

[2] 王海北, 刘三平, 蒋开喜, 林江顺, 王玉芳. 我国钴生产和消费现状[J]. 矿冶, 2004, 13(3): 54-64, 55.

WANG Hai-bei, LIU San-ping, JIANG Kai-xi, LIN Jiang-shun, WANG Yu-fang. Present situation of cobalt’s production and consumption in China[J]. Mining & Metallurgy, 2004, 13(3): 54-64, 55.

[3] 焦翠燕, 郭学益. 钴白合金处理工艺进展及研究方向[J]. 金属材料与冶金工程, 2011, 39(2): 58-62.

JIAO Cui-yan, GUO Xue-yi. Progress and research direction of treatment technique for cobalt white alloy[J]. Metal Materials and Metal Metallurgy Engineering, 2011, 39(2): 58-62.

[4] ACMA E. The effect of sulfur and reduction temperature on cobalt dissolution during sulfuric acid leaching of metallic matte[J]. Can Metall Q, 1997, 36(1): 25-29.

[5] BURZYNSKA L, GUMOWSKA W, RUDNIK E. Influence of the composition of Cu-Co-Fe alloys on their dissolution in ammoniacal solutions[J]. Hydrometallurgy, 2004, 71(3/4): 447-455.

[6] WHYTE R M, ORJANS J R, HARRIS G B, THOMAS J A. Development of a process for the recovery of electrolytic copper and cobalt from Rokana converter Slag[C]// SONES M S. Advances in Extractive Metallurgy. Montreal, Quebec: IMM, 1977: 57- 68.

[7] RUDNIK E, BURZYNSKA L, GUMOWSKA W. Hydrometallurgical recovery of copper and cobalt from reduction-roasted copper converter slag[J]. Minerals Engineering, 2009, 22(1): 88-95.

[8] WLODYKA J. Electrochemical dissolution of Co-Ni-Fe-Cu alloy[J]. Rudy Met Niezel, 2001, 46(8): 369-372.

[9] 洪 侃, 杨幼明. 铜钴合金单膜电化学溶解造液试验研究[J]. 江西有色金属, 2008, 22(2): 19-22.

HONH Kan, YANG You-ming. On the electrochemistry dissolution of single membrane copper-cobalt alloy[J]. Jiangxi Nonferrous Metals, 2008, 22(2): 19-22.

[10] 洪 侃, 范进军, 卢 博, 杨幼明, 徐仕华, 费文根. 铜钴合金双膜电化学溶解造液造碱研究[J]. 江西理工大学学报, 2010, 31(2): 17-20.

HONH Kan, FAN Jin-jun, LU Bo, YANG You-ming, XU Shi-hua, FEI Wen-gen. Electrochemistry dissolution of copper-cobalt alloy in double membrane cell[J]. Journal of Jiangxi University of Science and Technology, 2010, 31(2): 17-20.

[11] 王多冬, 赵中伟, 陈爱良, 陈星宇, 霍广生, 李洪桂. 难处理铜钴合金的氧化酸浸出[J]. 中南大学学报: 自然科学版, 2009, 40(5): 1188-1193.

WANG Duo-dong, ZHAO Zhong-wei, CHEN Ai-liang, CHEN Xing-yu, HUO Guang-sheng, LI Hong-gui. Oxidative leaching of refractory Cu-Co white alloy in acid solution[J]. Journal of Central South University: Science and Technology, 2009, 40(5): 1188-1193.

[12] 王含渊, 江培海, 张寅生, 黄忠淼. 钴白合金湿法冶金工艺研究[J]. 矿冶, 1997, 6(1): 68-69, 77.

WANG Han-yuan, JIANG Pei-hai, ZHANG Yin-sheng, HUANG Zhong-miao. Research on hydrometallurgical process for cobalt white alloy[J]. Mining & Metallurgy, 1997, 6(1): 68-69, 77.

[13] 夏文堂, 史海燕. 采用无污染氧化剂浸出钴白合金中钴铜的试验研究[J]. 矿冶, 2006, 15(3): 26, 27-29.

XIA Wen-tang, SHI Hai-yan. A novel process for extracting Co and Cu from cobalt white alloy in hydrochloric acid solution with pollution-free oxidant[J]. Mining & Metallurgy, 2006, 15(3): 26, 27-29.

[14] 王振文, 徐晓辉, 阮书锋, 江培海. 钴白合金浸出工艺研究[J]. 矿冶, 2009, 18(4): 41-43, 60.

WANG Zhen-wen, XU Xiao-hui, RUAN Shu-feng, JIANG Pei-hai. Study on leaching process of cobalt white alloy[J]. Mining & Metallurgy, 2009, 18(4): 41-43, 60.

[15] 刘大星. 国内外钴的生产消费与技术进展[J]. 有色冶炼, 2000, 29(5): 4-9, 20.

LIU Da-xing. Cobalt production, consumption and technical development at home and abroad[J]. Nonferrous Metallurgy, 2000, 29(5): 4-9, 20.

[16] MUNNIK E, SINGH H, UYS T, BELLINO M, du PLESSIS J, FRASER K. Development and implementation of a novel pressure leach process for the recovery of cobalt and copper at Chambishi, Zambia[J]. Journal of the South African Institute of Mining and Metallurgy, 2003, 103(1): 1-10.

[17] 彭忠东, 万文治, 胡国荣. 造渣熔炼-浸出方法处理Cu-Co-Fe合金的研究[J]. 有色矿冶, 2007, 23(1): 30-33.

PENG Zhong-dong, WAN Wen-zhi, HU Guo-rong. Study of pre-process slag roasting during leaching Cu-Co-Fe alloy for cobalt[J]. Nonferrous Mining and Metallurgy, 2007, 23(1): 30-33.

(编辑 李艳红)