文章编号:1004-0609(2011)05-1186-06

基于改进互相关函数的氧化铝碳分过程多重时滞辨识

黄 灿, 桂卫华, 谢永芳, 阳春华

(中南大学 信息科学与工程学院,长沙 410083)

摘 要:为了解决复杂工业生产过程多重时滞辨识难题,提出一种基于改进互相关函数的多重时滞辨识方法。对于工业过程中多个受控制信号作用的过程变量,确定一个参考变量,分别考虑其他各变量和参考变量之间的相关性,选择变量某个时间段内的一组数据作为辨识对象,通过计算两个变量的数据组在不同相对时间延迟对应的互相关矩阵,比较互相关矩阵的奇异值,其最大奇异值对应的滞后时间,即为所要辨识的时滞。将所提方法应用于某铝厂连续碳分过程多重时滞的辨识,基于工业现场采集的生产数据,分析变量间的关联关系,辨识出多重时滞,然后将辨识所得的时滞代入碳分过程模型。结果表明:计算值和实测值的最大平均相对误差仅为3.23%,验证了所提方法辨识多重时滞的有效性。

关键词:互相关函数;多重时滞;辨识;碳分过程

中图分类号:TF821 文献标志码:A

Multi-delays identification for alumina carbonation decomposition process based on improved cross-correlation function

HUANG Can, GUI Wei-hua, XIE Yong-fang, YANG Chun-hua

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In order to resolve the problem of multi-delays identification for complex industrial process, an improved cross-correlation function was proposed. In all the process variables affected by control signals, the reference variable was selected by considering the correlation with the other variables respectively. For the considered variable, a set of data in a continuous time segment sampled was selected as identification object. The cross-correlation matrix for the data sets of the reference variable and the other variables was calculated. By comparing the singular values of cross-correlation matrix, the delay corresponding to the maximum singular value was the required delay. The proposed method was applied to identifying the multi-delays of alumina carbonation decomposition process using the field data. At last, the identified delays were substituted to alumina carbonation decomposition process model. The results show that the maximum average relative error between the calculated and tested results is only 3.23%, and the proposed multi-delays identification method based on improved cross-correlation function is effective.

Key words: cross-correlation function; multi-delays; identification; carbonation decomposition process

复杂工业生产过程通常由不同的生产工序组成,各工序的生产设备地域跨度大。为确保产品质量,需要对各工序生产指标进行控制以保证工艺指标的稳定。由于物料传质输送和完成物理化学反应需要一定的时间,对工艺指标进行闭环控制会出现反馈信息延时。为提高产品质量,在生产工序的不同地方,设置多个控制点,而不同控制点到工序出口处的距离不同,物料传质所需要的时间也不同,使得控制点的控制量到出口处的输出量产生不同的时滞,因此,时滞具有多重性。

时滞辨识是复杂工业过程实现工艺指标闭环控制的前提条件,是控制研究的重要领域之一。RAD等[1]和孙建平等[2]提出互相关函数辨识方法,通过分析输入/输出之间的互相关函数,以互相关函数的最大值辨识输入/输出之间的时滞。该方法根据两个时间序列相关特性进行辨识,仅适用于单时滞辨识。SVANTE和LANNART[3]、RAMES[4]和LIU等[5]采用基于频域特性的继电反馈方法辨识时滞,但该方法需要检测Nyquist曲线信号,而实际生产过程中的Nyquist曲线难以获取。NI等[6]和孟昕元及薛东亮[7]通过小波变换的方法辨识时滞,由于实际工业生产过程信号变化缓慢,小波变换方法的母函数选择困难,难以得到实际工业应用。神经网络、遗传算法等智能辨识方法[8-10],因其算法复杂且运行时间较长,主要用于单时滞辨识,很少看到这些方法应用于多重时滞辨识的报道。

连续碳酸化分解过程(简称碳分过程)是氧化铝生产的关键工序过程,具有典型的多重时滞特性。碳分过程一般由多个分解槽串级连接,由于物料反应和传输过程需要一定的时间,造成了控制量和输出量之间存在很大的时滞。并且,各个槽中的物料分解程度不同,反应时间各不相同,使得各个分解槽的时滞不同,形成多重时滞。在实际碳分过程中,由于多重时滞的存在,难以实现分解梯度的闭环控制。因此,对碳分过程进行多重时滞的辨识,是实现该过程有效闭环控制、提高生产效率的重要前提。针对氧化铝碳分过程,许多学者做了大量的研究工作[11-14],但对其多重时滞特性的研究较少。邓燕妮等[15]在碳分过程机理分析的基础上,建立了连续碳分过程非线性多重时滞动态数学模型,考虑了碳分过程中的多重时滞,但仅给出了时滞的经验取值范围,没有辨识出其具体值。

本文作者提出改进的互相关函数,基于工业现场数据,考查多个变量之间的时滞关系。以包含更多过程变化信息的一个时间段数据作为对象,定义互相关矩阵,研究多个变量在不同时滞下的关联程度,然后通过计算互相关矩阵的奇异值来比较变量之间的关联程度。因此,可以将多重时滞辨识问题转化为求解一系列互相关矩阵的最大奇异值问题。基于碳分过程现场的运行数据,运用所提方法辨识出该过程多个分解槽的变量之间的相对时滞,并将所求时滞代入邓燕妮等[15]建立的碳分模型中验证所提方法的有效性。

1 改进的互相关函数时滞辨识方法

传统的互相关函数法是描述两个随机信号在不同时刻的取值之间的相关程度,对于单输入、单输出系统,一般通过输入、输出信号的相关性来辨识时滞。

在实际工业过程中,一个过程往往由几个环节串联而成,前一个环节的输出作为后一个环节的输入,这一类同时充当不同环节的输出和输入的变量,可以通过考查多个变量之间的关联关系来辨识时滞。对于工业过程中由反应或者传输过程的缓慢变化造成的时滞,用一个连续时间段内的数据辨识其大小,通过对反映变量变化过程的一组数据的辨识,更能准确获取变量之间的关联关系。

令数据矩阵X=[x1, x2,…, xN]表示多变量时滞系统中N个受控制信号作用的过程变量,其中

xi=[xi, 1, xi, 2, …, xi, K, xi, K+1, xi, K+2, …, xi, P-1, xi, P]T (i=1, 2, …, N; P>K)表示过程变量xi在连续P个采样时间点的值。选取参考过程变量x1,其余N-1个变量相对于x1的时滞表示为[τ2, τ3, …, τN]。将现场采集的原始数据标准化,以消除数值型属性大小不一造成计算的偏差。

采用最大最小标准化方法对初始数据进行处理。对样本数据集xi=[xi, 1, xi, 2, …, xi, P]T (i=1, 2, …, N),令ximax和ximin分别为集合xi中的最大值和最小值,则 xi, l (l=1, 2, …, P)在区间[0, 1]的映射值为

(1)

(1)

将数据矩阵标准化得到

根据工业现场经验、物料传输和反应速度分析,可以获得多重时滞区间[τjmin, τjmax](j=2, 3, …, N),其中,τjmax和τjmin分别为变量xj(j=2, 3, …, N)相对于x1的时滞估计值的最大值和最小值。

为分析参考变量x1和其他变量xj(j=2, 3, …, N)之间的关联关系,取过程变量xj一个连续时间段的fj个

数据 (tn=1, 2, …,

(tn=1, 2, …,

K),满足fjT≥τjmax,其中T为采样周期,保证所取数据段能够包含一个时滞范围内的有效信息。为使tn=K时能取到一组完整的数据,K+fj-1≤P,即K<P+1-fj-1。当变量xj取fj个数据时,参考变量x1相应的取fj个数

据, (tm=1, 2, …,

(tm=1, 2, …,

K)。由于xj的变化比x1滞后时间τj,所取数据组应满足tn>tm。

定义x1和其他变量xj(j=2, 3, …, N)之间的互相关矩阵

(2)

(2)

式中: 表示x1的第tm组数据和xj的第tn组数据之间的互相关矩阵;

表示x1的第tm组数据和xj的第tn组数据之间的互相关矩阵; 为x1的第tm组数据和xj的第tn组数据之间的协方差矩阵,

为x1的第tm组数据和xj的第tn组数据之间的协方差矩阵, 和

和 为标准差。

为标准差。

考查x1的第tm组数据依次和xj的第tn(tn=tm+1, tm+2, …, K)之间的互相关矩阵

(3)

(3)

用矩阵奇异值定量描述互相关矩阵的信息,求R(x1, xj)中每个元素的奇异值 ,令其最大奇异值为

,令其最大奇异值为

(4)

(4)

当 为最大时,表示两个变量相关性最大,对应的两个变量数据之间的时间差,为所要辨识的时滞大小,从而辨识出多变量系统的多重时滞 [τ2, τ3, …, τN]。

为最大时,表示两个变量相关性最大,对应的两个变量数据之间的时间差,为所要辨识的时滞大小,从而辨识出多变量系统的多重时滞 [τ2, τ3, …, τN]。

基于改进互相关函数的多重时滞辨识步骤如下:

步骤 1 对原始数据进行初始化,选择参考变量x1,估计其他变量xj(j=2, 3, …, N)相对于x1的时滞取值范围[τjmin, τjmax];

步骤2 根据时滞取值范围,选取变量xj在某个时

间段内的数据组 作为

作为

辨识数据,满足fjT≥τjmax;

步骤3 相应地选取x1的fj个数据

,考虑到xj的变化比x1

,考虑到xj的变化比x1

滞后,变量xj的数据组

依次取tn=tm+1, tm+2, …, K;

依次取tn=tm+1, tm+2, …, K;

步骤4 用式(2)分别计算变量xj(j=2, 3, …, N)和

参考变量x1取不同时间段内数据 和

和 时的互

时的互

相关矩阵,得到互相关矩阵组R(x1, xj),求其最大奇

异值 ,

, 最大时对应的两个变量所取数据组

最大时对应的两个变量所取数据组

之间的相对时间差,即为所求时滞值τj(i=2, 3, …, N),从而求得多重时滞序列[τ2, τ3, …, τN]。

2 氧化铝碳分过程多重时滞辨识

2.1 氧化铝连续碳分过程工艺分析

氧化铝连续碳分过程是在铝酸钠溶液中通入CO2气体,中和溶液中的苛性碱,使溶液的苛性比值降低,使铝酸钠溶液过饱和度增大,产生铝酸钠溶液自发分解的析出反应,从而析出氢氧化铝沉淀。其主要化学反应为

(5)

(5)

(6)

(6)

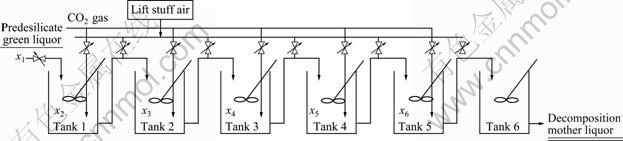

实际生产中连续碳分过程由6个连续分解槽组成,整个过程从原料入槽到出料一般需要3~4 h。如图1所示,经脱硅送来的合格精液首先进入高位槽,从高位槽底部自压进入1#分解槽,用低压风提料进2#分解槽,采用同样的方法依次将料提入后面槽。前5台槽子根据分解率要求通入一定量CO2气体进行分解,通过调节CO2气体的通入量,控制各槽的分解率。6#槽作为出料槽,检测合格后由出料泵打到沉降槽,沉降底流送往氢氧化铝过滤机过滤,得到氢氧化铝 产品。

图1 氧化铝连续碳分过程工艺流程图

Fig.1 Flowsheet of continuous alumina carbonation decomposition process

由于每个分解槽内的反应处于晶体析出的不同时期,溶液分解程度不同,导致各槽的反应时间不相同,即CO2气体通入分解槽中到其作用到分解率的变化上所需的时间不相同,故每个槽的时滞不同,为多重时滞过程。

碳分过程每个分解槽有不同的分解率,各分解槽要满足一定的分解梯度,才能保证末槽的分解率要求。分解率是自铝酸钠溶液中分解析出的氧化铝数量与精液中所含氧化铝数量的百分比,实际上,常用溶液分解前后的苛性比值来计算,如式(7)所示:

(7)

(7)

式中:ρ(Al2O3)J为精液中氧化铝浓度,g/L;ρ(Al2O3)母为母液(精液和CO2气体反应后的溶液,即1#~6#槽中的溶液)中的氧化铝浓度,g/L;ρ(Na2OT)M为精液中的全碱浓度,g/L;ρ(Na2OT)M为母液中的全碱浓度,g/L。

2.2 碳分过程多重时滞辨识

生产过程中,采集了与分解率密切相关的全碱浓度和氧化铝浓度数据计算分解率的大小,由于在连续碳分过程中,全碱浓度变化不明显,而氧化铝浓度变化较大,因此用氧化铝浓度作为过程变量进行多重时滞辨识。令原液的氧化铝浓度为x1,1#~5#槽反应后的氧化铝浓度分别为x2、x3、x4、x5、x6,则初始数据矩阵为X=[ x1, x2, …, x6]。将原液的氧化铝浓度x1作为参考变量,分别考查1#~5#槽的氧化铝浓度x2、x3、x4、x5、x6与原液的氧化铝浓度x1之间的关联关系。

以某铝厂的工业现场数据为例,选取稳定工况条件下连续15 h的生产数据,每10 min采样1次,剔除生产异常状况下的数据,经预处理后得到90组有效数据,则P=90。对数据矩阵X进行标准化处理,得

。

。

根据现场经验,物料在每个槽中的反应和传输造成的时间滞后范围是[30, 60] min。以1#分解槽为例,数据采样周期T=10 min,取f2=6,则f2T=60 min,即取变量60 min时间段内的数据,满足f2T≥τ2max的条件。考查在60 min时间段内各变量之间的关联程度,可得数据矩阵为:

(8)

(8)

为保证所有变量辨识的最后一组数据能取到完整的fj(j=2, 3, …, 6)个数据,取K=60。辨识各槽之间的相对滞后时间,由式(4)可得当原液数据取第1组值

,原液和1#分解槽内的氧化铝浓度数据之间的

,原液和1#分解槽内的氧化铝浓度数据之间的

互相关矩阵最大奇异值为

(9)

(9)

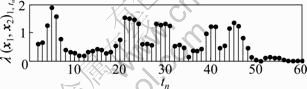

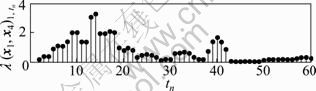

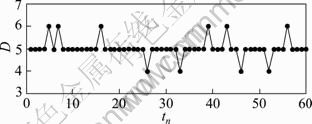

图2所示为1#槽的 变化图,其中横坐

变化图,其中横坐

标表示1#分解槽内的氧化铝浓度所取的第tn(tn=1, 2, …, 60)组数据,纵坐标表示对应的互相关矩阵的最

大奇异值 。相对原液的氧化铝数据,1#槽

。相对原液的氧化铝数据,1#槽

在tn取5时,对应数据矩阵的互相关矩阵的奇异值为最大值,表示此时原液和分解槽内的氧化铝具有最大相关性,因此,可以辨识出1#槽相对于原液的时滞为50 min。

图2 原液和1#槽内氧化铝浓度数据的相关性

Fig.2 Correlation of alumina concentration data between stock solution and tank 1

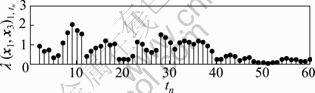

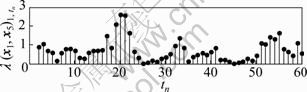

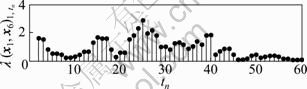

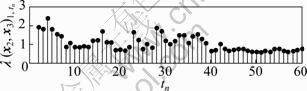

粗略估计2#~5#分解槽内的氧化铝浓度相对于原液的氧化铝浓度的时滞范围。因为每个槽的滞后时间范围为[30, 60] min,分别取辨识数据组长度f3=12、f4=18、f5=24、f6=30。满足fjT≥τjmax(j=3, 4, 5, 6)。用同样的方法辨识2#~5#槽的时滞,图3~6所示分别为2#~5#

槽的 (j=3, 4, …, 6; tn=2, 3, …, 60)变化图。由图3~6可知,2#、3#、4#、5#分解槽在tn分别取9、14、20、25时,

(j=3, 4, …, 6; tn=2, 3, …, 60)变化图。由图3~6可知,2#、3#、4#、5#分解槽在tn分别取9、14、20、25时, 为最大值。因此,可以辨识出1#~5#槽相对于原液的时滞分别为50、90、140、200和 250 min。

为最大值。因此,可以辨识出1#~5#槽相对于原液的时滞分别为50、90、140、200和 250 min。

为验证改进互相关函数方法辨识时滞的准确性,以2#槽为例辨识单个槽的时滞。分析1#和2#分解槽氧化铝数据之间的关联关系,由图7可知,2#槽的时滞为40 min,而由1#、2#分解槽相对于原液的时滞分别为50和90 min可知,2#槽单个槽的时滞为40 min。由此可见,两者结果一致。

图3 原液和2#分解槽内氧化铝浓度数据的相关性

Fig.3 Correlation of alumina concentration data between stock solution and tank 2

图4 原液和3#分解槽内氧化铝浓度数据的相关性

Fig.4 Correlation of alumina concentration data between stock solution and tank 3

图5 原液和4#分解槽内氧化铝浓度数据的相关性

Fig.5 Correlation of alumina concentration data between stock solution and tank 4

图6 原液和5#分解槽内氧化铝浓度数据的相关性

Fig.6 Correlation of alumina concentration data between stock solution and tank 5

图7 1#和2#分解槽内氧化铝浓度数据的相关性

Fig.7 Correlation of alumina concentration data between tank 1 and tank 2

以上是原液氧化铝取第一组数据时的相关性,当原液依次取1到60组数据时,考查原液和其他分解槽内氧化铝浓度数据最大相关性对应的相对滞后周期数。图8所示为1#分解槽的数据相对于原液数据滞后周期数(D)随原液所取数据组数变化的情况。由图8可以看出,当原液的考查数据组由第1组变化到第60组时,它和1#槽内的氧化铝浓度的相关性最大值,基本上保持在5个周期后取得,进一步验证了1#槽的时滞为50 min。

图8 原液与1#分解槽的相对滞后周期变化曲线

Fig.8 Relatively delay period change curve of stock solution and tank 1

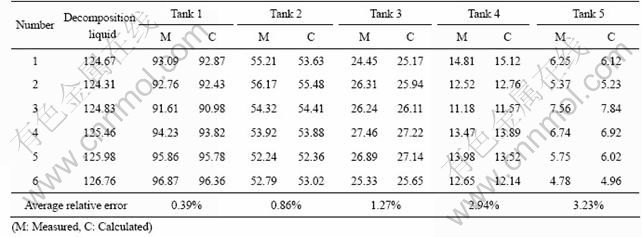

将辨识出来的时滞代入邓燕妮等[15]建立的模型,计算氧化铝浓度值,对比模型估计浓度和实际测量浓度值,验证时滞的精度,其计算值和实际值对比如表1所示。

由表1可以看出,1#~5#槽的氧化铝浓度实际值和计算值之间的平均相对误差最大值为3.23%,表明所辨识的时滞能够较好地反映实际碳分过程,本文作者提出的方法能够较好地应用于复杂工业过程的多重时滞辨识。

表1 连续碳分过程各槽溶液氧化铝浓度的实际测量值与模型计算值

Table 1 Measured values and calculated values of alumina concentration of carbonation decomposition tanks (g/L)

3 结论

1) 类似氧化铝碳分过程的复杂工业生产过程,其多个变量具有多重时滞的特点。改进传统的互相关函数,从多变量中确定一个参考变量,分别考查其他变量与参考变量之间的关联关系,选取变量某段时间内的一组数据作为辨识对象,通过计算数据组之间的互相关矩阵,比较互相关矩阵的奇异值,其最大的奇异值对应的时滞,即为所要辨识值。

2) 基于某铝厂的碳分过程现场数据,分析各分解槽和原液之间氧化铝浓度的关联关系,从而辨识出各个分解槽相对于首槽入口处的多重时滞值。将该多重时滞值代入氧化铝碳分过程横型中,计算各分解槽的氧化铝浓度,计算值和实测值的比较结果表明,计算值的精度较高。

REFERENCES

[1] RAD A B, LO W, TSANG K M. Simultaneous online identification of rational dynamics and time delay: A correlation-based approach[J]. IEEE Transaction on Control Systems Technology, 2003, 11(6): 957-959.

[2] 孙建平, 闫永跃, 于树新, 李庆周. 时滞时变对象参数辨识方法[J]. 电光与控制, 2008, 15(1): 94-96.

SUN Jian-ping, YAN Yong-yue, YU Shu-xin, LI Qing-zhou. A parameter identification algorithm for time-varying/time-delay system[J]. Electronic Optics and Control, 2008, 15(1): 94-96.

[3] SVANTE B, LENNART L. An improved phase method for time delay estimation[J]. Automatic, 2009, 45(10): 2467-2470.

[4] RAMES C P. Estimation of parameters of under-damped second order plus dead time processes using relay feedback[J]. Computers and Chemical Engineering, 2006, 30(5): 832-837.

[5] LIU Tao, GAO Fu-rong. A generalized relay identification method for time delay and non-minimum phase processes[J]. Automatic, 2009, 45(4): 1072-1079.

[6] NI B Y, XIAO D Y, SHAH S L. Time delay estimation for MIMO dynamical systems—With time-frequency domain analysis[J]. Journal of Process Control, 2010, 20(1): 83-94.

[7] 孟昕元, 薛东亮. 大滞后控制系统性能的小波变换分析方法研究[J]. 机电工程技术, 2006, 35(3): 47-50.

MENG Xin-yuan, XUE Dong-liang. A study of the performance of long time-delayed control system using wavelet transform analysis method[J]. Mechanical & Electrical Engineering Technology, 2006, 35(3): 47-50.

[8] 陆 燕, 杜继红, 李春文. 延迟时间未知的时延系统神经网络补偿控制[J]. 清华大学学报, 1998, 38(9): 67-69.

LU Yan, DU Ji-hong, LI Chun-wen. Neural networks compensate control for unknown systems with time delay[J]. Journal of Tsinghua University: Sci & Tech, 1998, 38(9): 67-69.

[9] 赵仕俊, 李 逊, 左光远. 灰色预估神经网络在时滞系统控制中的应用[J]. 微电子学与计算机, 2008, 25(2): 25-27.

ZHAO Shi-jun, LI Xun, ZUO Guang-yuan. Research on neural network controller with grey-model prediction applied in controlling systems with uncertain time delay[J]. Microelectronics & Computer, 2008, 25(2): 25-27.

[10] YADAIAH N, DEEKSHATULU B L, SIVAKUMAR L, RAO V S H. Neural network algorithm for parameter identification of dynamical systems involving time delays[J]. Applied Soft Computing, 2007, 7(3): 1084-1091.

[11] 王 志, 杨毅宏, 毕诗文, 谢雁丽. 铝酸钠溶液碳酸化分解过程的影响因素[J]. 有色金属, 2002, 54(1): 43-45.

WANG Zhi, YANG Yi-hong, BI Shi-wen, XIE Yan-li. Influencing factors of sodium aluminate solution carbonation decomposition[J]. Nonferrous Metals, 2002, 54(1): 43-45.

[12] 彭志宏, 李小斌, 苟中入, 刘桂华, 周秋生, 丁安平, 李光柱, 李 明. 铝酸钠溶液碳酸化分解产品中的Na2O[J]. 中国有色金属学报, 2002, 12(6): 1285-1289.

PENG Zhi-hong, LI Xiao-bin, GOU Zhong-ru, LIU Gui-hua, ZHOU Qiu-sheng, DING An-ping, LI Guang-zhu, LI Ming. Impurity Na2O in carbonization precipitation from sodium aluminate solution with high Al2O3 concentration[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1285-1289.

[13] 李小斌, 陈 滨, 周秋生, 刘桂华, 彭志宏, 刘祥民. 铝酸钠溶液碳酸化分解过程动力学[J]. 中国有色金属学报, 2004, 14(5): 848-853.

LI Xiao-bin, CHEN Bin, ZHOU Qiu-sheng, LIU Gui-hua, PENG Zhi-hong, LIU Xiang-min. Kinetics of carbonation decomposition of sodium aluminate solution[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 848-853.

[14] 胡志坤, 桂卫华, 阳春华. 基于遗传算法的连续碳酸化分解过程模糊优化[J]. 金属材料与冶金工程, 2007, 35(5): 34-37.

HU Zhi-kun, GUI Wei-hua, YANG Chun-hua. Fuzzy optimization for the process of continuous carbonation decomposition based on genetic algorithm[J]. Metal Materials and Metallurgy Engineering, 2007, 35(5): 34-37.

[15] 邓燕妮, 桂卫华, 阳春华, 谢永芳. 氧化铝碳酸化分解动态过程建模及非线性分析[J]. 中国有色金属学报, 2008, 18(9): 1736-1741.

DENG Yan-ni, GUI Wei-hua, YANG Chun-hua, XIE Yong-fang. Dynamic process modeling and nonlinear analysis for alumina carbonation decomposition[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1736-1741.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(60634020, 61074117)

收稿日期:2010-11-22;修订日期:2011-03-15

通信作者:桂卫华,教授,博士;电话:0731-88830765;E-mail: gwh@mail.csu.edu.cn