文章编号:1004-0609(2011)06-1415-07

沉积参数对Mo-Re合金基体上沉积金刚石薄膜的影响

王 健,余志明,吴晓斌,刘 倩

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用热丝化学气相沉积法(HFCVD),以甲烷和氢气为反应气体,在综合性能良好的Mo-40%Re(摩尔分数)合金基体上沉积金刚石薄膜。采用X射线衍射仪(XRD)、场发射扫描电子显微镜(FESEM)和显微激光拉曼光谱仪(Raman)分别对金刚石薄膜相组成、表面形貌、晶粒大小和质量等进行检测分析,研究CVD沉积参数,如基体温度(θs)、碳源浓度(R,CH4的体积分数)和沉积压强(p),对金刚石形核、生长和金刚石成膜的影响。结果表明:在合适的基体预处理条件下,当θs=750 ℃,R=3%,p=3.5 kPa时,薄膜平均线生长速率高达1 μm/h,得到的金刚石膜完整致密,晶粒大小均匀,纯度较高,具有明显的(111)织构。

关键词:金刚石薄膜;Mo-Re合金;Raman光谱;阴极材料

中图分类号:TG135.5 文献标志码:A

Effects of deposition parameters on diamond film on

Mo-Re alloy substrate

WANG Jian, YU Zhi-ming, WU Xiao-bin, LIU Qian

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The diamond films were prepared on Mo-40%Re (mole fraction) alloy substrates by hot filament chemical vapor deposition (HFCVD) in a reactor with a background pressure of 10-5 Pa. The interlayer, diamond morphologies and the purity of the film were investigated by X-ray diffractometer (XRD), field emission scanning electron microscope (SEM) and Raman spectroscope (Raman), respectively. Meanwhile, the effects of process parameters, such as substrate temperature, gas composition and reactor pressure, on diamond growth were systematically studied. The results show an optimal growth condition being substrate temperature θs=750 ℃, volume fraction of CH4 R=3%, reaction pressure p=3.5 kPa. Under this condition, a high quality diamond film is obtained with a liner growth rate of 1 μm/h and an obvious (111) texture.

Key words: diamond film; Mo-Re alloy; Raman spectroscope; cathode material

金刚石具有许多材料无与伦比的优异性能,如高硬度、低摩擦因数、高弹性模量、高透光率、高绝缘等特性,被誉为21世纪的新型功能材料。人工合成的金刚石薄膜其{111}面具有负电子亲和势(NAE)、宽禁带(5.5 eV)、低介电常数(5.7)、高热导率(2 000 W/(m?K))、优良抗辐射性能及其稳定的化学性质,呈现出良好的场致发射性能,使其在制作冷阴极和场电子发射器件等领域具有很好的应用前景[1-3]。MADALENO等[4]报道利用微波等离子体化学气相沉积系统在a-SiO2基体上沉积金刚石薄膜,其阀值电压为5.5 V/μm,当测试电压为11 V/μm时,其场发射电流密度高达 10 mA/cm2。

金属钼是一种具有重要战略意义的难熔金属,其力学强度大、硬度高、延展性好,具有良好的导热导电性能和较低的热膨胀系数,是常用的阴极发射材 料[5]。然而,纯金属钼加工性能差、易氧化、具有再结晶脆性,难以用作极端条件下的阴极材料。对于Mo-Re合金,金属铼的加入可显著提高钼的高温强度和低温塑性,改善高温蠕变性能[6]。例如,在1 473 K时,Mo-47.5%Re的抗拉强度为230 MPa,伸长率为8%,而纯钼此时的抗拉强度只有100 MPa[7]。这种综合性能的提高,使得Mo-Re合金可以更好地满足作为阴极发射材料的苛刻要求。同时也可应用在航空航 天、电子学等高端领域,可用作高速旋转的X光管靶材、微波通讯的长寿命栅板、空间反应堆堆芯加热管、高温炉发热体、高温热电偶等器件。

Mo作为一种典型的金刚石薄膜沉积基体,一直是广大学者研究的热点。在金属纯Mo上镀金刚石薄膜,Mo的场发射性能明显提高[8]。LIU等[9]预先在Si基体上镀一层很薄的金属Mo涂层,再沉积金刚石薄膜,相比于直接在Si基体上沉积,金刚石的形核率显著增加,并且场发射性能优异,阀值电压为13 V/μm,场发射电流密度可达55 mA/cm2。而钼铼合金具有比钼更加优异的综合性能,为了利用钼铼合金和金刚石各自在成型和电子发射方面的优势,开发新一代阴极材料,本文作者在Mo-40%Re(摩尔分数)合金基体上,采用热丝化学气相沉积(HFCVD)方法生长金刚石薄膜。研究了CVD金刚石关键工艺参数,如基体温度(θ)、碳源浓度(R)和沉积气压(p)对金刚石在钼铼合金表面形核和生长的影响。采用Raman光谱仪、X射线衍射仪(XRD)和场发射扫描电子显微镜(FESEM)分别对金刚石膜的质量、结构和表面形貌进行了检测分析。并在此基础上,优化本实验条件下金刚石薄膜的沉积工艺。

1 实验

采用超高真空热丝化学气相沉积(HPCVD)系统[10]沉积金刚石薄膜,其背底真空为1.33×10-5 Pa。反应气体流量由质量流量计控制,反应室压强由CMLA-21S08型薄膜电容式真空计监测控制。灯丝温度(θf)设置为2 100~2 300 ℃,用光学高温计测定;基体温度(θs)由灯丝温度和基体与灯丝之间的距离共同调节,θs用置于与基体同一高度的热电偶监控。灯丝是直径为0.5 mm的纯钨丝绕制成d=3 mm共9匝螺旋线圈。沉积前,先将灯丝置于腔体中炭化。反应气体是纯度均为99.999%的H2和CH4的混合气体。

选用Mo-40%Re(摩尔分数)合金作为基体,沉积前先用金相砂纸将其表面抛光;然后置于硫酸与硝酸的混合酸中超声波处理10 min;再用金刚石粉(50~250 nm)-丙酮悬浊液超声波处理20 min;最后在纯丙酮溶液中超声清洗10 min,置于大气中干燥后以备用。金刚石薄膜沉积工艺参数如表1所列。

表1 金刚石薄膜的沉积参数

Table 1 Deposition technology parameters of diamond coating

采用Dmax-2500VBX型X射线衍射仪对金刚石薄膜的成分、晶体结构和生长取向进行分析,实验所采用的X射线源为Cu Kα辐射(λ=0.154 nm,步长为0.02°);采用Sirion200场发射扫描电镜(FESEM)观察金刚石薄膜的截面厚度和表面形貌;利用Dilor Super Labram拉曼光谱仪来检测金刚石薄膜质量和键结构。

2 结果与讨论

2.1 金刚石薄膜的物相分析和截面形貌分析

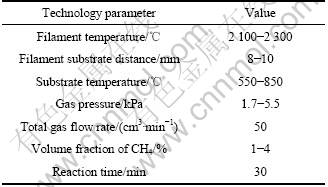

图1所示为基体温度为750 ℃、碳源体积分数为3%、沉积压强为3.5 kPa时Mo-40%Re合金基体上生长金刚石薄膜的XRD谱。由图1可知,在2θ约为43.9°、75.3°和91.5°处出现衍射峰,分别为金刚石的(111)、(220)和(311)晶面衍射峰。在标准PDF卡片中,金刚石(220)峰位于75.372°,Mo2C(112)和(142)峰所对应的2θ值分别为74.745?和75.513?。由此可知,图1中峰A处是金刚石(200)与Mo2C的两个峰共同作用的体现。金刚石位于119.521°的(400)峰被XRD背底掩盖,没有出现。

图1 金刚石样品的XRD谱

Fig.1 XRD pattern of CVD diamond films under condition of θs=750 ℃, R=3% and p=3.5 kPa

参照ASTM数据,用XRD衍射强度比值I(111)/ I(220),I(111)/I(311)来表征薄膜表面织构特征,比值偏离标准样品越大,则织构特征越明显。从图中不难得出,金刚石具有明显的(111)织构。由于沉积时间较短(30 min),金刚石膜比较薄,因此,金刚石峰远低于基体峰(Mo-Re峰)和碳化物过渡层峰(Mo2C峰)。另外,在48.149°和106.182°位置有两个较弱的未知峰,这可能是Mo-Re合金中存在的σ相或χ相的衍射峰[11]。

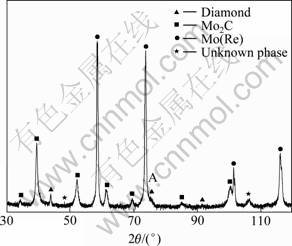

图2(a)所示为θs=750 ℃,R=3%,p=3.5 kPa时厚度约为500 nm的金刚石薄膜截面的SEM像,已知沉积时间为30 min,由此可粗略算出,金刚石薄膜的平均线生长速率高达1 μm/h。由图2(a)可知,此样品截面共有3层,包括Mo-Re基体层、Mo2C过渡层和金刚石薄膜层。薄膜和基体之间的结合十分紧密,过渡自然。其中,在金刚石膜层中,明显观察到金刚石形核层和柱状晶生长层,且晶粒尺寸随着远离形核层的方向逐渐增大。图2(b)为此截面图的模型图,形核初期为粒度较小的颗粒,在金刚石长大的过程中取向有利的晶粒择优生长,不断吞噬掉那些取向不利的晶粒,从而形成粗大的柱状晶[12]。

图2 金刚石薄膜截面的SEM像和模型图

Fig.2 SEM image(a) and model(b) of cross-section of diamond films under condition of θs=750 ℃, R=3% and p=3.5 kPa

2.2 基体温度对金刚石薄膜的影响

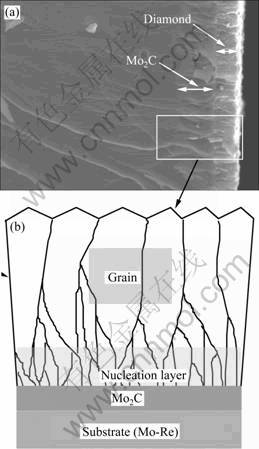

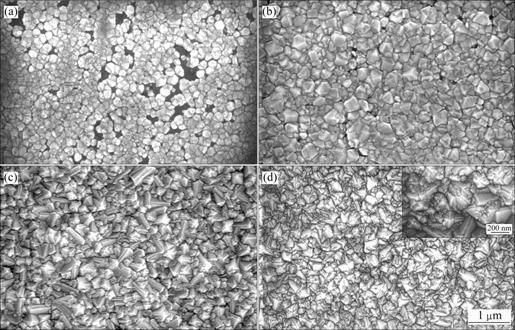

图3所示为甲烷浓度为3%,沉积压强为3.5 kPa,不同基体温度下沉积30 min得到的金刚石薄膜SEM像。由图3可知,θs=550 ℃时,金刚石形核不均匀,晶粒尺寸非常细小,约为20~40 nm,没有形成完整致密的膜(见图3(a));θs=650 ℃时,晶粒尺寸明显增大,约为200 nm,出现了较多的孪晶和带有凹坑的晶型,薄膜表面平整致密(见图3(b));当θs=750 ℃时,得到的晶粒尺寸与图3(b)中的相差不大,晶粒形貌清晰可见,显露面多为{111}面,如图3(c)右上角10万倍插图所示,形成明显的{111}织构,这与图1所示XRD分析结果相符合;当θs升高到850 ℃时,金刚石二次形核严重,且二次形核发生在特定的晶面上,出现了有些晶面光滑(多为{100}面),有些晶面粗糙(多为{111}面)的现象(见图3(d))。

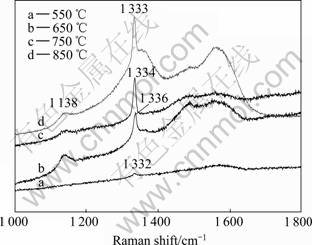

图4所示为不同温度下沉积金刚石薄膜的Raman光谱。由图4可知,当温度为550 ℃时,金刚石拉曼峰的强度很弱;且随着温度的升高,金刚石峰的强度明显增大,曲线b、c和d中金刚石峰的位置相对于金刚石的一阶特征峰1 332.5 cm-1右移,表现为压应 力[13]。近年的研究中,对位于1 140 cm-1和1 485 cm-1的峰产生了争议,这两个峰一般成对出现,有的学者认为是受尺寸限制效应金刚石峰左移的结果,可作为纳米金刚石判据[14];有的学者则通过实验论证它们分别是反式聚乙炔(TPA)C=C和C—C的振动模[15]。目前的主流思想偏向于TPA的振动模,图3(a)所示的纳米尺寸金刚石所对应拉曼光谱图中也并未出现1 140 cm-1和1 485 cm-1峰。石墨或非晶碳的拉曼信号比金刚石相的信号要灵敏得多,一般认为,其拉曼散射因子是金刚石的50~230倍[16],本研究取50来定性分析金刚石薄膜的纯度,计算公式[17]为

(1)

(1)

式中:ID和IC分别为分峰拟合后金刚石峰和G峰强 度。PI(Purity index)值为金刚石薄膜的纯度指数。PI值越大,代表金刚石的纯度越高。研究中也可用金刚石Raman峰的半高宽(HNHM)来表征其质量,半高宽与金刚石晶体中的晶界、位错、微孪晶等晶体缺陷有关,一般来说,半高宽越小,金刚石薄膜的质量就越好。

图3 不同沉积温度下金刚石薄膜的表面形貌

Fig.3 Surface morphologies of diamond films deposited under different substrate temperatures: (a) 550 ℃; (b) 650 ℃; (c) 750 ℃; (d) 850 ℃

图4 不同温度下金刚石薄膜的拉曼光谱

Fig.4 Raman spectra of diamond film obtained at different temperatures

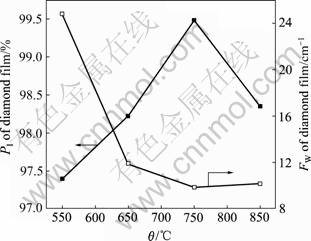

图5所示为不同基体温度下沉积金刚石薄膜的PI值和半高宽值。由图5可知,当θs=550 ℃时,PI= 97.3%,FW=24.8 cm-1;当θs=650 ℃时,金刚石纯度约为98.2%,半高宽为11.9 cm-1。从曲线变化趋势可以很明显的看出,当沉积温度为750 ℃时,金刚石薄膜的PI值最大,约为99.5%,质量最好,半高宽为 9.9 cm-1;若温度继续升高至850 ℃,PI值又下降到98.3%,半高宽值稍有上升。

图5 不同基体温度下沉积金刚石薄膜的PI和FW的变化

Fig.5 Change of PI and Fw of diamond films prepared under different substrate temperatures

上述结果表明,基体温度的变化对于金刚石薄膜的晶型、晶粒尺寸大小和二次形核有较大的影响,这是由于基体温度影响着基体表面的微观过程如原子迁移、原子凝结系数、形核的临界尺寸、H原子与CH3自由基的置换速率等参数的变化[18]。当沉积温度较低时(550 ℃),甲烷和氢气的离解较少,能量来源不足,从而使金刚石形核困难,长大速率也不高,得到纳米金刚石颗粒(见图4(a)),同时,由于金刚石处于亚稳态,石墨相处于稳态,H原子对石墨的刻蚀作用不足,造成金刚石薄膜的纯度很低。随着基体温度的逐渐升 高,原子迁移速率增加,基体表面吸附的碳原子能够以体扩散的方式进入基体晶格点阵中,形成碳化物过渡层(Mo2C),易于形核生成金刚石。当沉积温度过高时(850 ℃),最先形核的金刚石晶核在高温下迅速长大,得到的晶粒尺寸较大。已知{111}面生长速率受C2H2和CH3浓度的控制,而{100}面生长速率只由CH3来决定[19]。因此,当沉积温度较高时,衬底表面附近的碳氢基团的迁移速率增加,相互碰撞反应的几率增加,使得C2H2浓度增加,CH3的浓度相对降低,最终导致{111}面生长活性大,其上有大量的二次形核;而显露面{100}面不易二次形核,多为光滑面。

2.3 碳源浓度对金刚石薄膜的影响

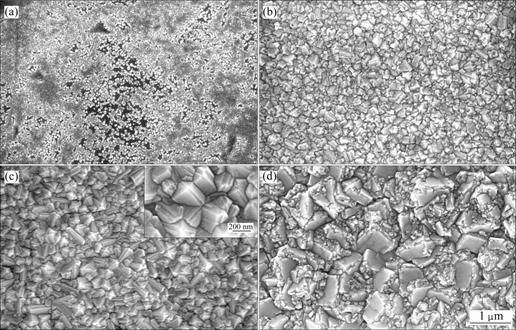

图6所示为基体温度为750 ℃,沉积压强3.5 kPa,不同气体组分下沉积30 min得到的金刚石薄膜SEM像。由图6可知,当碳源浓度为1%时,金刚石形核率相对较低,约为3.1×109 cm-2,薄膜到处可见孔洞;当甲烷浓度增大到2%时,金刚石形核率增加1倍,约为6.0×109 cm-2,晶粒形貌清晰,但大小不太均匀,在50~400 nm之间,某些地方仍然存在微小的孔洞;当碳源浓度为3%时,形核率大小变化不大,但薄膜更加完整、致密,晶粒大小更为均匀;当碳源浓度增大到4%时,形核率增大至1010 cm-2,晶体生长中存在大量的缺陷,二次形核较为严重,如图6(d)右上角10万倍插图所示。

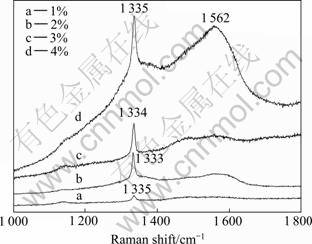

图7所示为不同碳源浓度下沉积金刚石薄膜的Raman光谱。由图7可知,随着甲烷浓度的增加,金刚石峰的强度逐渐增加,但当浓度增大至4%时,杂质石墨G峰的强度也急剧增加,导致金刚石薄膜质量最差。通过计算其PI值和测量金刚石峰的半高宽可知:当甲烷浓度为1%~3%之间时,其PI值和半高宽变化不大,PI>99.2%,FW≤10 cm-1; 而当甲烷浓度为4%时,PI值显著降低,约为96%,半高宽增加,约为 14 cm-1。

甲烷浓度的变化影响着基体表面的碳原子和氢原子浓度之比。当甲烷浓度较低(1%)时,活性H原子的浓度相对较高,对石墨碳的刻蚀作用非常明显,得到的金刚石晶界分明、棱角清晰,同时,由于甲基等活性基团的浓度较低,化学吸附在基体表面的C很容易与H原子反应生成碳氢化合物又回到气氛中,金刚石形核率低,沉积速度慢,薄膜孔洞较多。而当甲烷浓度偏高(4%)时,活性碳原子的浓度增加,H原子的刻蚀作用下降,导致金刚石薄膜中非金刚石相含量增加,二次形核增多,金刚石薄膜结晶性能和质量降低。因此,在沉积过程中选用合适的碳源浓度是得到高质量金刚石薄膜的关键因素之一。

2.4 沉积压强对金刚石薄膜的影响

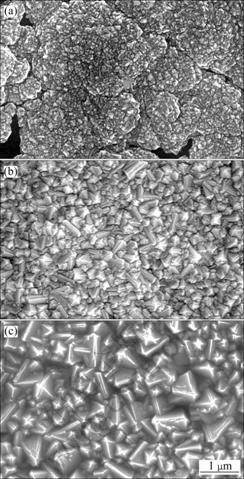

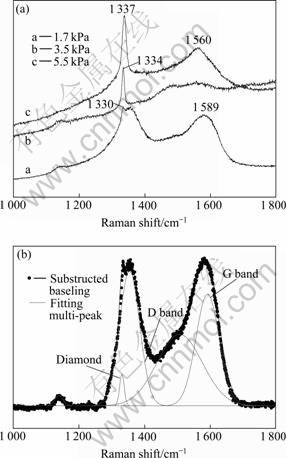

图8和9所示分别为基体温度为750 ℃,甲烷浓度为3%,不同沉积压强时沉积30 min对金刚石薄膜形貌和Raman光谱的影响。由图8和9可知,随着腔体压强的增大,金刚石晶粒尺寸也逐渐增大。当沉积压强p≈1.7 kPa时,金刚石薄膜形核很不均匀,出现了严重的团聚生长,由高斯函数分峰拟合后的拉曼光谱图可知(如图9(b)),薄膜中sp3键的金刚石相含量很少,多为sp2键的石墨相,金刚石薄膜质量很差;当沉积压强为3.5 kPa时,薄膜质量明显提高;而当沉积压强增大至5.5 kPa时,金刚石晶型清晰可见,变化不大,但薄膜表面较为粗糙。由对应的拉曼光谱可知,其金刚石峰位为1 337 cm-1,相对于标准峰位1 333 cm-1偏移较大,表明膜基之间的压应力也较大,且1 560 cm-1处的石墨峰也明显高于沉积压强为3.5 kPa时的石墨峰。由Raman光谱图计算金刚石薄膜的PI值和半高宽值可知:压强为1.7 kPa时,金刚石薄膜的纯度最低,约为93.4%,随着腔体压强的增加,纯度也逐渐增加,p=3.5 kPa和5.5 kPa时,纯度均为99%左右,其半高宽也随着沉积压强的变化呈先减小后升高的趋势。

图6 不同甲烷浓度下金刚石薄膜的表面形貌

Fig.6 Surface morphologies of diamond films deposited under different methane concentrations: (a) 1%; (b) 2%; (c) 3%; (d) 4%

图7 不同甲烷浓度下金刚石薄膜的拉曼光谱图

Fig.7 Raman spectra of diamond films deposited under different CH4 concentrations

图8 不同沉积压强下金刚石薄膜的表面形貌

Fig.8 Surface morphologies of diamond films prepared under different deposition pressures: (a) 1.7 kPa; (b) 3.5 kPa; (c) 5.5 kPa

图9 不同沉积压强下金刚石薄膜的拉曼光谱和沉积压强为1.7 kPa时金刚石薄膜Raman光谱的分峰拟合图

Fig.9 Raman spectra of diamond films deposited under different chamber pressures(a) and Gauss fitting plot for Raman spectra of diamond film at 1.7 kPa(b)

反应室的气体压强决定着各种粒子的重组时间、寿命、自由程以及气体间的碰撞几率。当沉积压强较低时,分子的平均自由程大,活性基团碰撞复合的几率低,到达基体时能量高,而高的反应速率一方面造成基体表面的活性粒子不能及时扩散到合适的位置,得到的膜致密度低,团簇生长严重[20];一方面使氢原子来不及刻蚀sp2石墨相,金刚石薄膜质量很低,易发生二次形核,且晶粒细小。当气体压强过高时,气体分子原子之间的碰撞过于频繁,有效的活性基团密度反而降低,金刚石形核密度和质量都有所下降。

3 结论

1) 利用合适的基体表面预处理和薄膜生长工艺,在Mo-40%Re合金基体上沉积金刚石薄膜,其生长速率可达1 μm/h,膜基之间结合良好,薄膜具有明显的(111)织构,形成清晰的Mo2C过渡层。

2) 基体温度、碳源浓度和沉积压强对金刚石薄膜的形核率、晶粒尺寸、二次形核、生长取向和杂质碳含量均有较大的影响。结合SEM图和Raman光谱分析,得到一个最优沉积工艺,即当基体温度为750 ℃,甲烷浓度为3%,沉积压强为3.5 kPa,得到的金刚石膜完整、致密,晶粒大小均匀,晶形清晰,纯度最高。

REFERENCES

[1] YAMAGUCHI1 H, MASUZAWA T, NOZUE S, KUDO Y, YAMADA T, OKANO K. Electron emission from conduction band of diamond with negative electron affinity[J]. Physical Review B, 2009, 80(16): 165321-165326.

[2] 董建会. 金刚石薄膜场发射述评[J]. 中北大学学报: 自然科学版, 2007, 28: 155-158.

DONG Jian-hui. Reviews on the field emission of diamond thin films[J]. Journal of North University of China: Natural Science Edition, 2007, 28: 155-158.

[3] ARORA S, VANKAR V D. Field emission characteristics of microcrystalline diamond films: Effect of surface coverage and thickness[J]. Thin Solid Films, 2006, 515: 1963-1969.

[4] MADALENO J C, SINGH M K, TITUS E, CABRAL G, GRACIO J, PEREIRA L. Electron field emission from patterned nanocrystalline diamond coated α-SiO2 micrometer-tip arrays[J]. Applied Physics Letters, 2008,92(2): 023113-1-3.

[5] 冯进军, 丁明清, 张甫权, 李兴辉, 白国栋, 彭自安, 廖复疆. 钼尖场致发射阵列阴极的性能研究[J]. 液晶与显示, 2002, 17(1): 39-43.

FENG Jin-jun, DING Ming-qing, ZHANG Fu-quan, LI Xing-hui, BAI Guo-dong, PENG Zi-an, LIAO Fu-jiang. Properties of Mo field emission arrays[J]. Chinese Journal of Liquid Crystals and Display, 2002, 17(1): 39-43.

[6] AGNEW S R, LEONHARDT T. The low-temperature mechanical behavior of molybdenum-rhenium[J]. JOM, 2003, 55(10): 25-29.

[7] 谭拴斌, 郭让民, 杨升红, 张廷杰. 钼铼合金的结构和性能[J]. 稀有金属, 2005, 27(6): 788-793.

TAN Shuan-bin, GUO Rang-min, YANG Sheng-hong, ZHANG Ting-jie. Structure and properties of molybdenum-rhenium alloys[J]. Chinese Journal of Rare Metals, 2005, 27(6): 788-793.

[8] GONZALEZ-BERRIOS A, WEINER B R, GUPTA S. Synthesis, structure, and field emission properties of sulfur-doped nanocrystalline diamond[J]. Journal of Materials Science- Materials in Electronics, 2006, 17(6): 443-451.

[9] LIU Keng-fu, CHEN Li-ju, TAI Nyan-hua, LIN I-nan. Effect of Mo-buffer layer on the growth behavior and the electron field emission properties of UNCD films[J]. Diamond and Related Materials, 2009, 18(2/3): 181-185.

[10] 余志明, 魏秋平, 叶 俊, FLODRSTR?M A. 正二十面体金刚石的形成及其计算机模拟[J]. 新型炭材料, 2009, 24(2): 102-108.

YU Zhi-ming, WEI Qiu-ping, YE Jun, FLODRSTR?M A. Formation of an icosahedral diamond crystal and its computer simulation[J]. New Carbon Materials, 2009, 24(2): 102-108.

[11] MANNHEIM R L, GARIN J L. Structural identi?cation of phases in Mo-Re alloys within the range from 5 to 95% Re[J]. Journal of Materials Processing Technology, 2003, 143/144: 533-538.

[12] REICHART P, DATZMANN G, HAUPTNER A, HERTENBERGER R, WILD C, DOLLINGER G. Three- dimensional hydrogen microscopy in diamond[J]. Science, 2004, 306(26): 1537-1539.

[13] GRIES T, VANDENBULCKE L, SIMON P, CANIZARES A. Stresses in textured and polycrystalline cubic ?lms by Raman spectroscopy: Application to diamond[J]. Journal of Applied Physics, 2007, 102(8): 083519-1-11.

[14] YARBROUGH W A, MESSIER R. Current issues and problems in the chemical vapor deposition of diamond[J]. Science, 1990, 247: 688-696.

[15] FERRARI A C, ROBERTSON J. Origin of the 1 150 cm-1 Raman mode in nanocrystalline diamond[J]. Physical Review B, 2001, 63: 121405-121410.

[16] KNIGHT D S, WHITE W B, MATER J. Disorder-induced line broadening in first-order Raman scattering from graphite[J]. Physical Review B, 1990, 41(17): 12260-12263.

[17] GUO Liang, CHEN Guo-hua. High-quality diamond film deposition on a titanium substrate using the hot-filament chemical vapor deposition method[J]. Diamond & Related Materials, 2007, 16: 1530-1540.

[18] 李建国, 刘 实, 李依依, 胡东平, 李 军, 周德惠. 热丝法气相沉积金刚石薄膜的影响因素[J]. 金刚石与磨料磨具工程, 2004, 139(1): 41-44.

LI Jian-guo, LIU Shi, LI Yi-yi, HU Dong-ping, LI Jun, ZHOU De-hui. Hot filament chemical vapor deposition diamond film and its influence factors[J]. Diamond & Abrasives Engineering, 2004, 139(1): 41-44.

[19] SUN Bi-wu, ZHANG Xiao-pin, LIN Zhang-da. Growth mechanism and the order of appearance of diamond (111) and (100) facets[J]. Physical Review B, 1993, 47(15): 9816-9824.

[20] WU Nan-chun, XIA Yi-ben, TAN Shou-hong, WANG Lin-jun. Effect of gas pressure on nanocrystalline diamond films prepared by electron-assisted chemical vapor deposition[J]. Chinese Phys Lett, 2005, 22(11): 2969-2972.

(编辑 李艳红)

收稿日期:2010-06-28;修订日期:2010-09-28

通信作者:余志明,教授;电话:0731-88830335;E-mail: zhiming@csu.edu.cn