文章编号:1004-0609(2013)S1-s0494-06

热处理对TC4薄板组织与性能的影响

党 鹏,高维娜,付文杰,李 辉,吕利强

(西部钛业有限责任公司,西安 710201)

摘 要:研究退火温度、保温时间、退火方式及冷却方式等热处理制度对TC4薄板室温力学性能和显微组织的影响。结果表明:在单片式退火方式下,温度从720 ℃升高到820 ℃时,板材的抗拉强度和屈服强度先降低后升高,但其伸长率先升高后降低;退火温度为780~800 ℃时,板材的强度和塑性得到了良好的匹配;当保温时间从30 min增加到120 min时,板材的抗拉强度变化不明显,屈服强度显著下降,但保温时间超过60 min后屈服强度趋于定值。随退火温度的升高和保温时间的延长,初生α和β转变组织的晶粒尺寸都增大,且β转变组织的比例增大。采用真空垛式退火+炉冷方式,退火温度为780 ℃、保温时间为7 h时,板材可获得良好的综合力学性能。

关键词:TC4钛合金;显微组织;退火温度;保温时间;真空退火

中图分类号:TG166.5 文献标志码:A

Influence of heat-treatment process on structure and performance of TC4 alloy sheet

DANG Peng, GAO Wei-na, FU Wen-jie, LI Hui, Lü Li-qiang

(Western Titanium Technologies Co., Ltd., Xi’an 710201, China)

Abstract: The influences of heat treatments, such as annealing temperature, holding time, annealing way and cooling rates on the microstructure and room temperature mechanical properties of TC4 titanium alloy sheet were studied. The results show that the tensile strength and yield strength of the alloy sheet decrease at first and then increase with the annealing temperature rising from 720 ℃ to 820 ℃ under the condition of monolithic annealing, but the elongation has an opposite change. And the strength and elongation get a well match at temperature of 780-800 ℃. When the holding time changes from 30 min to 120 min, the tensile strength has a little change. While the yield strength decreases significantly before 60 min, and then it is up to a fixed value. The grain sizes of primary α and transformed β increase with the annealing temperature and annealing time rising. And the amount of transformed β increases at the same time. The predominant comprehensive mechanical properties of TC4 alloy can be obtained at annealing temperature of 780 ℃ and annealing time of 7 h with vacuum stack annealing and furnace cooling treatment.

Key words: TC4 titanium alloy; microstructure; annealing temperature; holding time; vacuum annealing

TC4钛合金具有极佳的综合力学性能及良好的加工能力,在航空、航天、化工等领域具有广泛的应用。近年来,随着航空工业的发展,对TC4钛合金薄板的需求越来越大,TC4钛合金薄板的应用前景极其广阔。经过冷加工或热加工的TC4板材都需要通过后续热处理来改善加工过程中产生的不良影响,改善其综合性能。目前,关于TC4中厚板热处理的研究较多[1-8],有关热处理对TC4薄板组织和性能的影响方面的研究较少。本文作者研究了不同热处理制度如退火方式、退火温度、保温时间及冷却方式对TC4薄板组织和室温力学性能的影响规律,确定较佳的热处理制度,以便为工业生产中TC4薄板的热处理提供参考。

1 实验

1.1 实验材料

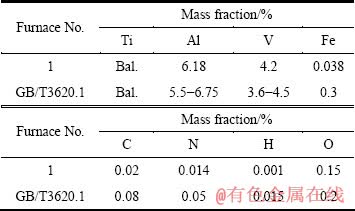

本实验采用的TC4板坯相变点为(980±10) ℃,经过2 800 mm热轧机轧到4 mm,再用1 760 mm冷轧机经2个冷轧程轧到2 mm,板材化学成分如表1所列。

表1 TC4板材化学成分

Table 1 Chemical compositions of TC4 alloy sheet

1.2 实验设备

本实验用到的热处理设备有辊底式电阻退火炉和3 m真空退火炉。板材经热处理后取样,用微机控制电液伺服万能试验机测试其室温力学性能,用OLYMPUS PMG3倒置式金相显微镜观察其微观组织。

2 结果与分析

2.1 不同热处理制度对力学性能的影响

2.1.1 退火温度对力学性能的影响

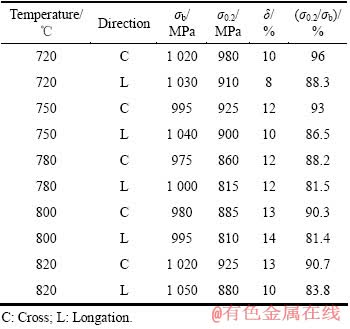

TC4板材在电阻炉中采用单片式退火,分别经过720、750、780、800和820 ℃保温40 min后空冷[9],退火后的室温力学性能见表2。从表2可以看出,该TC4板材的室温抗拉强度在975~1 050 MPa之间,屈服强度在810~980 MPa之间。不同退火温度下,纵向抗拉强度都略高于横向抗拉强度,而纵向屈服强度比横向屈服强度平均要低50 MPa左右,纵向屈强比低于横向屈强比[10]。这主要是由于金属塑性变形时,晶粒会沿着变形方向转动,使各晶粒的晶体位向趋向一致。这种择优取向形成的有序结构称为形变织构。对于钛、锆等密集六方晶格的金属的形变织构具有择优反向的现象,变形使晶格有序化,会使垂直于变形方向的强度(尤其屈服强度)高于变形方向,这就造成了横向屈服强度高于纵向屈服强度,横向屈强比要高于纵向屈强比。

表2 不同退火温度下TC4 薄板室温力学性能

Table 2 Room-temperature mechanical properties of TC4 alloy sheet annealed at various temperatures

不同退火温度下TC4薄板室温力学性能的变化趋势如图1所示。从图1可以看出,随着退火温度的升高,板材的抗拉强度和屈服强度呈现先减小后增大的趋势,但屈服强度下降的幅度大于抗拉强度下降的幅度。板材在780~800 ℃之间的屈服强度和抗拉强度取得最小值。板材的伸长率随退火温度的升高呈现先增大后减小的趋势,在800 ℃时取得最大值。退火温度在720~780 ℃之间时,抗拉强度和屈服点强度都呈下降趋势,伸长率呈现升高趋势,这是由于在相同的退火时间内,随退火温度的升高。再结晶的驱动力增大,再结晶越完全。在780~800 ℃之间,晶粒经历了再结晶和晶粒长大,达到相对稳定的形状和尺寸,强度和塑性得到良好的匹配,使板材获得较好的综合力学性能。

图1 不同退火温度下TC4 薄板室温力学性能

Fig. 1 Room-temperature mechanical properties of TC4 alloy sheet annealed at various temperatures

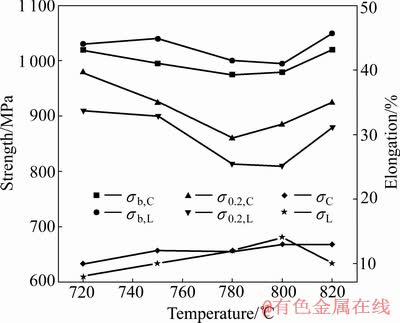

2.1.2 退火时间对力学性能的影响

板材在电阻炉中经过800 ℃退火,分别保温30、40、60和120 min出炉后空冷,其室温力学性能的变化趋势如图2所示。由图2可见,抗拉强度随退火时间的增加先升高后降低,变化幅度不大。屈服强度随退火时间的增加逐渐降低,保温时间从30 min延长到60 min时,横、纵向屈服强度均下降了30 MPa;保温时间从60 min延长到120 min时,屈服强度基本趋于定值。伸长率随退火时间的增加先升高后降低,在保温40 min时取得最大值。

图2 TC4薄板在800 ℃退火不同保温时间的室温力学性能

Fig. 2 Room-temperature mechanical properties of TC4 alloy sheet annealed at 800 ℃ for various holding times

2.1.3 退火方式对力学性能的影响

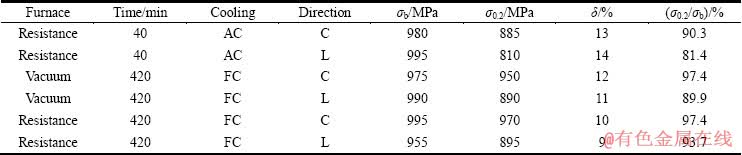

工业生产中,生产的板材数量较多,往往采用整垛叠放退火+炉冷方式,这种方式要将整垛料加热透,需要的保温时间较长。表3列出了在800 ℃不同退火方式下的室温力学性能。真空退火+炉冷与电阻炉退火+炉冷相比较,其各个方向的抗拉强度和屈服强度相当,但采用真空退火的伸长率要略高于电阻炉退火的伸长率。单片式退火+空冷方式与真空退火+炉冷相比较,各方向的抗拉强度相当,但其屈服强度比真空退火方式的低60~80 MPa,而伸长率要略高[11]。由此可知,TC4薄板的抗拉强度对退火方式不敏感,但屈服强度对退火方式比较敏感,采用真空退火+炉冷方式可以获得良好的综合力学性能。同时,真空退火还可以避免板材表面氧化,简化了后续处理工序。

2.2 不同热处理制度对显微组织的影响

2.2.1 退火温度对显微组织的影响

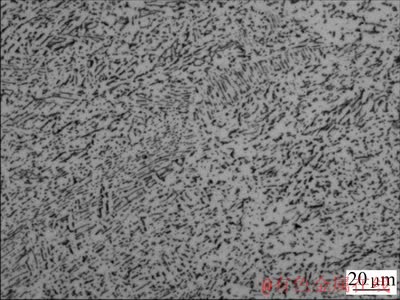

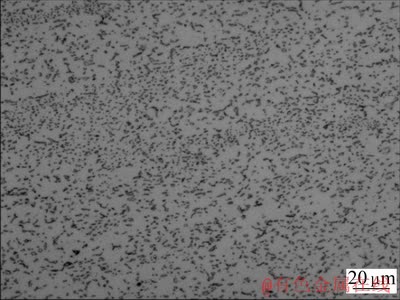

图3所示为未经热处理的TC4冷加工态的横向组织,其为拉长变形的条状α+β,两相杂乱排列。

图3 TC4薄板冷加工态组织

Fig. 3 Microstructure of TC4 alloy sheet after cold rolling

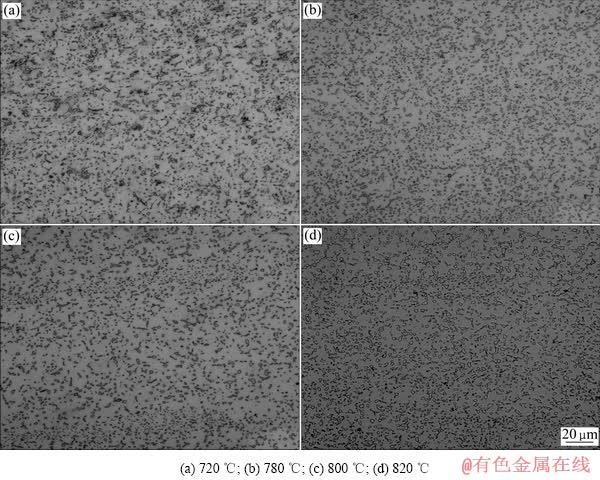

图4所示为TC4薄板分别在720、780、800和820 ℃退火保温40 min后的横向显微组织。由图4可见,板材经过不同温度退火后都发生了再结晶,晶粒明显球化,形成全新的等轴晶粒。随着加热温度的升高,组织形态和数量发生了一定变化。板材经过720 ℃保温40 min后,其组织为初生的等轴α+β转变组织,但再结晶不完全,还存在部分未再结晶区域,此时板材的强度较高,伸长率较低。板材经过780、800和820 ℃退火保温40 min后,已完全再结晶,其组织都为初生的等轴α+β转变组织。随退火温度的升高,晶粒尺寸明显增大,初生α的比例减小,β转变组织的比例增大[12-15]。

表3 TC4薄板在不同冷却方式下的室温力学性能

Table 3 Room-temperature mechanical properties of TC4 alloy sheet at different cooling rates

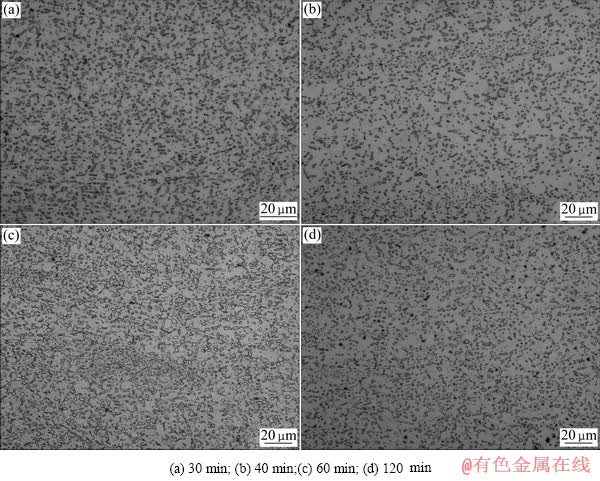

2.2.2 退火时间对显微组织的影响

图5所示为TC4冷轧板经过800 ℃退火分别保温30、40、60和120 min的横向显微组织。由图5可见,在不同保温时间内其组织均为初生的等轴α+β转变组织,其组织形态基本不发生变化,但晶粒尺寸的大小发生了一定改变。随着保温时间的延长,初生α相和β转变组织通过相界的迁移发生合并长大,初生α相的比例减小,β转变组织的比例增大[12-15],板材的屈服强度降低。但初生α相和β转变组织增大到一定程度时,两相比例趋于平衡,屈服强度也趋于一定值。

图4 不同退火温度下TC4薄板的显微组织

Fig. 4 Microstructures of TC4 alloy sheets annealed at various temperatures

图5 TC4薄板在800 ℃退火保温不同时间的显微组织

Fig. 5 Microstructures of TC4 alloy sheets annealed at 800 ℃ for various holding times

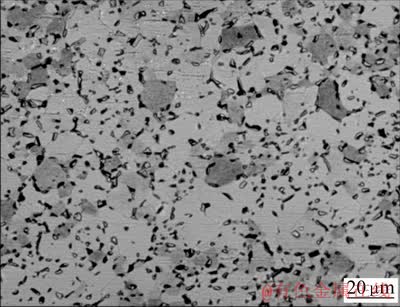

2.2.3 退火方式对显微组织的影响

图6所示为板材经过780 ℃真空退火保温7 h后炉冷的显微组织。由图6可见,板材组织为等轴α+晶间β,晶间β在α晶粒之间呈连续或不连续的网状薄层,也有一部分以粒状的形式弥散分布在等轴α的基体上。

图7所示为板材经过780 ℃电阻炉垛式退火保温7 h后炉冷的显微组织。由图7可见,板材组织也是等轴α+晶间β,同真空退火组织相比较可以发现,等轴α和晶间β的晶粒尺寸都明显增大,这是因为电阻炉垛式退火冷却速率比真空退火冷却速率慢,不仅α相明显长大,晶间β相随着保温时间的增加而通过相界的迁移发生合并长大。与真空退火方式不同,板材采用单片式退火经过780 ℃保温40 min空冷后,其组织主要为初生的等轴α+β转变组织,如图4(b)所示。由于β转变组织的存在使板材的屈服强度较真空退火方式下的屈服强度要低60~80 MPa,说明板材的屈服强度对组织较敏感。

图6 TC4薄板780 ℃真空退火7 h的显微组织

Fig. 6 Microstructure of TC4 alloy sheet after vacuum heat treatment at 780 ℃ for 7 h

图7 TC4薄板780 ℃电阻炉退火7 h的显微组织

Fig. 7 Microstructure of TC4 alloy sheet annealed at 780 ℃ for 7 h

3 结论

1) 在单片式退火方式下,随退火温度的升高,板材的抗拉强度和屈服强度呈现先减小后增大的趋势,伸长率呈现先增大后减小的趋势。在780~800 ℃时,强度和塑性得到了良好的匹配。随退火温度的升高,初生α和β转变组织的晶粒尺寸都增大,且β转变组织的比例增大。

2) 在单片式退火方式下,随退火保温时间的延长,屈服强度逐渐降低。当保温时间大于60 min时,屈服强度趋于一定值。随退火时间的延长,初生α和β转变组织的晶粒尺寸都增大,且β转变组织的比例增大。

3) TC4板材的屈服强度对显微组织比较敏感,冷却方式对显微组织形态的影响较大。

4) TC4板材横向屈强比高于纵向屈强比,横向屈服强度比纵向屈服强度高50 MPa左右。

5) 采用真空垛式退火+炉冷方式,在退火温度为780 ℃、保温7 h时,可使板材获得良好的综合力学性能。

REFERENCES

[1] 黄利军, 王庆如, 马济民, 王韦琪. TC4钛合金厚板的组织与性能术[J]. 金属学报, 2002, 38(1): 188-190.

HUANG Li-jun, WANG Qing-ru, MA Ji-min, WANG Wei-qi. Structure and mechanical properties of TC4 plate [J]. Acta Metallurgica Sinica, 2002, 38(1): 188-190.

[2] 祝力伟, 王新南, 朱知寿. 不同热处理工艺下TC4-DT钛合金的显微组织及力学性能[J]. 钛工业进展, 2012, 29(1): 9-12.

ZHU Li-wei, WANG Xin-nan, ZHU Zhi-shou. Effect of heat treatment on microstructure and mechanical properties of TC4-DT alloy [J]. Titanium Industry Progress, 2012, 29(1): 9-12.

[3] 马英杰, 刘建荣, 雷家峰, 杨 锐. 多重热处理对TC4合金的组织和力学性能的影响[J]. 材料研究学报, 2008, 22(5): 555-560.

MA Ying-jie, LIU Jian-rong, LEI Jia-feng, YANG Rui. The influence of multi heat-treatment on microstructure and mechanical properties of TC4 alloy [J]. Chinese Journal of Materials Research, 2008, 22(5): 555-560.

[4] 白新房, 赵永庆, 郑翠萍, 曾卫东. 不同组织形态TC4钛合金力学性能研究[J]. 钛工业进展, 2011, 28(3): 26-29.

BAI Xin-fang, ZHAO Yong-qing, ZHENG Cui-ping, ZENG Wei-dong. Research on mechanical properties of titanium alloys with different microstructures[J]. Titanium Industry Progress, 2011, 28(3): 26-29.

[5] 袁清华, 张文明, 黄重国, 任学平. 工业TC4板材热变形性能及微观组织研究[J]. 锻压技术, 2008, 33(6): 120-124.

YUAN Qing-hua, ZHANG Wen-ming, HUANG Zhong-guo, REN Xue-ping. Study of TC4 sheet elevated temperature deformation behavior and its microstructure evolution [J]. Forging & Stamping Technology, 2008, 33(6): 120-124.

[6] 周 伟, 曲恒磊, 赵永庆, 李 辉. 热处理对TC4合金组织与性能的影响[J]. 热加工工艺, 2005(8): 26-27.

ZHOU Wei, QU Heng-lei, ZHAO Yong-qing, LI Hui. Effect of heat treatment on mechanical properties and microstructure of TC4 alloy [J]. Hot Working Technology, 2005(8): 26-27.

[7] 王 新, 雷家峰, 马英杰, 李晓艳, 王 俭, 王红武. 热处理对Ti-6Al-4V ELI钛合金厚板显微组织和力学性能的影响[C]//钛锆铪分会2011年年会论文集. 2011: 137-141.

WANG Xin, LEI Jia-feng, MA Ying-jie, LI Xiao-yan, WANG Jian, WANG Hong-wu. Influence of heat-treatment on microstructure and mechanical Properties of Ti-6Al-4V ELI plate [C]// Proceedings of the 2011 Annual Meeting of the Titanium Zirconium and Hafnium. 2011: 137-141.

[8] 李 辉, 曲恒磊, 赵永庆, 冯 亮, 叶红川, 周 伟. 热处理对Ti-6Al-4V ELI 合金厚板组织与性能的影响[J]. 稀有金属, 2005, 29(6): 841-844.

LI Hui, QU Heng-lei, ZHAO Yong-qing, FENG Liang, YE Hong-chuan, ZHOU Wei. Effect of heat treatment on microstructure and mechanical properties of Ti-6Al-4V ELI alloy plate [J]. Chinese Journal of Rare Metals, 2005, 29(6): 841-844.

[9] 黄伯云, 李成功, 石力开, 邱冠周, 左铁镛. 中国材料工程大典(第4卷)[M]. 北京: 化学工业出版社, 2006: 585-593.

HUANG Bai-yun, LI Cheng-gong, SHI Li-kai, QIU Guan-zhou, ZUO Tie-yong. Chinese material engineering dictionary (Volume 4th) [M]. Beijing: Chemical Industry Press, 2006: 585-593.

[10] FRANCILLETTE H, BENMAOUCHE M, GAUQUELIN N. Anisotropic behavior of a Ti-6Al-4V sheet during cold rolling: Evidence of macroscopic shearing [J]. Journal of Materials Processing Technology, 2008, 198: 86-92.

[11] 王小翔, 王 俭, 史正敏, 樊柯利, 魏寿庸. 真空热处理对Ti-230合金薄板的氢含量及组织与性能的影响[J]. 稀有金属材料与工程, 2005, 34(3): 247-248.

WANG Xiao-xiang, WANG Jian, SHI Zheng-min, FAN Ke-li, WEI Shou-yong. Effect of vacuum heat treatment on hydrogen content, microstructure and properties of Ti-230 alloy sheet [J]. Rare Metal Materials and Engineering, 2005, 34(3): 247-248.

[12] 莫 畏. 钛[M]. 北京: 冶金工业出版社, 2008: 295-306.

MO Wei. Titanium [M]. Beijing: Metallurgical Industry Press, 2008: 295-306.

[13] 王金友. 航空用钛合金[M]. 上海: 上海科学技术出版社, 1985: 199-227.

WANG Jin-you. Titanium alloy for aerospace [M]. Shanghai: Shanghai Scientific & Technical Publishers, 1985: 199-227.

[14] C. 莱茵斯, M. 皮特尔斯. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 11-14.

LEYENS C, PETERS M. Titanium and titanium alloy [M]. CHEN Zhen-hua, transl. Beijing: Chemical Industry Press, 2005: 11-14.

[15] E.A.鲍利索娃. 钛合金金相学[M]. 陈石卿, 译. 北京: 国防工业出版社, 1986: 195-203.

БОРИСОВА E A. Titanium alloy metallography [M]. CHEN Shi-qing, transl. Beijing: National Defence Industry Press, 1986: 195-203.

(编辑 何学锋)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:党 鹏,工程师,硕士;电话:029-86968383-8048;E-mail: dpengg@aliyun.com