应用振动提高搅拌摩擦加工效率

来源期刊:中国有色金属学报(英文版)2019年第7期

论文作者:M. ABBASI M. GIVI B. BAGHERI

文章页码:1393 - 1400

关键词:振动搅拌摩擦加工;搅拌摩擦加工;显微组织;力学性能

Key words:friction stir vibration processing; friction stir processing; microstructure; mechanical properties

摘 要:搅拌摩擦加工(FSP)是一种处理金属表面的固态改性方法。在此过程中,由于非自耗刀具的旋转和来回移动,使金属表面组织细化、力学性能提升。提高FSP效率的方法较多,本研究中采用的是一种叫振动搅拌摩擦加工(FSVP)的新方法。在此方法中,金属工件在FSP过程中与加工线垂直振动。分析比较FSP法和FSVP法加工的Al5052合金试样的显微组织和力学性能,包括硬度、极限抗拉强度(UTS)和伸长率。结果表明,采用FSVP后,振动可使材料的晶粒尺寸减小约33%,极限抗拉强度和硬度提高约7%。这与振动作用下金属表面材料的应变增强有关。应变增加导致位错密度增加,动态再结晶使大角度晶界进一步发育。结果还表明,FSV加工试样的极限抗拉强度和伸长率均随振动频率的增加而增加。

Abstract: Friction stir processing (FSP) is a solid-state modification method to process the surface of metals. In this process, due to rotation and traverse motions of a non-consumable tool, metal surface microstructure is refined and its mechanical characteristics are improved. Different methods have been applied to improving the efficiency of FSP. In this research, a new method entitled friction stir vibration processing (FSVP) was presented to enhance the efficiency of FSP. In this method, metal workpiece was vibrated normal to processing line during FSP. Microstructure and mechanical properties including hardness, ultimate tensile strength (UTS) and elongation of Al5052 alloy specimens processed using FSP and FSVP methods were analyzed and compared. The results showed that grain size decreased by about 33% as vibration was applied. It was also observed that ultimate tensile strength as well as hardness increased by about 7% as FSVP was applied. This was related to the enhanced straining of metal surface material as vibration was applied. The increase in straining results in the increase of dislocation density. It leads to more development of high angle grain boundaries due to dynamic recrystallization. The results also showed that UTS and elongation of FSV processed specimens increased as vibration frequency increased.

Trans. Nonferrous Met. Soc. China 29(2019) 1393-1400

M. ABBASI1, M. GIVI1, B. BAGHERI2

1. Faculty of Engineering, University of Kashan, Kashan, Iran;

2. Department of Mining and Metallurgy, Amirkabir University of Technology, Tehran, Iran

Received 21 August 2018; accepted 8 January 2019

Abstract: Friction stir processing (FSP) is a solid-state modification method to process the surface of metals. In this process, due to rotation and traverse motions of a non-consumable tool, metal surface microstructure is refined and its mechanical characteristics are improved. Different methods have been applied to improving the efficiency of FSP. In this research, a new method entitled friction stir vibration processing (FSVP) was presented to enhance the efficiency of FSP. In this method, metal workpiece was vibrated normal to processing line during FSP. Microstructure and mechanical properties including hardness, ultimate tensile strength (UTS) and elongation of Al5052 alloy specimens processed using FSP and FSVP methods were analyzed and compared. The results showed that grain size decreased by about 33% as vibration was applied. It was also observed that ultimate tensile strength as well as hardness increased by about 7% as FSVP was applied. This was related to the enhanced straining of metal surface material as vibration was applied. The increase in straining results in the increase of dislocation density. It leads to more development of high angle grain boundaries due to dynamic recrystallization. The results also showed that UTS and elongation of FSV processed specimens increased as vibration frequency increased.

Key words: friction stir vibration processing; friction stir processing; microstructure; mechanical properties

1 Introduction

Friction stir processing (FSP) as a method to manipulate the surface characteristics of a metal was developed based on the concept of friction stir welding method [1,2]. In this process, a non-consumable rotating tool with pin and shoulder is plunged into a workpiece surface and traverses along the process line. Localized heating by the friction between the tool and workpiece surface softens the material around the pin and moves it from the front to the back of the pin which results in microstructural changes on surface [3].

Many researches were carried out to analyze the effect of this process on characteristics of different materials as well as to improve it. SUN and APELIAN [4] studied the effect of FSP on microstructure and mechanical properties of a sand-casted A206 aluminum plate. They analyzed the effect of heat treatment on processed specimens and found that grain size decreased as FSP was applied. Their results also showed that the size and aspect ratio of Al2Cu second phase particles within as-cast microstructure matrix decreased and they were distributed uniformly in aluminum matrix after FSP. They found that dynamic recovery and recrystallization were the main reasons for grain refinement during FSP.

LEAL et al [5] investigated the influence of the tool geometry and FSP parameters on the microstructure, mechanical and electrical properties of the copper alloy C12200. The friction stir (FS) of material processed using two different tools, namely a scrolled and a conical shoulder tool under different tool rotation and traverse speeds. They found that tool geometry had strong influence on characteristics of the processed material and the grain size for the specimen processed using scrolled shoulder tool was smaller than that processed using conical shoulder. They also observed that the average grain size increased exponentially with the increase in tool rotation speed. The results also showed that electrical conductivity of the processed material was lower than that of the unprocessed copper and improvement in the electrical conductivity of the processed material was possible by increasing the tool rotation speed. XUE et al [6] applied friction stir processing technique with additional cooling into Cu pure plates to decreasing the grain size in the stir zone and to increasing the yield strength. The specimens were fixed in water. VENKATESWARLU et al [7] applied Taguchi method to studying the effect of FSP process variables such as tool tilt angle, rotational and traverse speeds on the tensile strength of magnesium alloy AZ31B. They found that rotational speed had the major influence on the tensile strength.

HANNARD et al [8] evaluated the effect of FSP pass number on microstructure of a 6056 rolled Al alloy. They found that the increase of FSP pass number reduced the volume fraction of porosities and decreased the intermetallic particles size. FSP also distributed the particles more homogenously. MISHRA et al [9] found the potential of FSP in fabricating surface composites. They incorporated SiC particles into surface layer of 5083 Al alloy by FSP. This method introduced a new way to improve the surface characteristics of metals such as copper [10], magnesium [11], steel [12] and titanium [13]. In the current research, a new method to improve the efficiency of FSP is presented. The workpiece is vibrated normal to processing line during FSP. This new method is entitled friction stir vibration processing (FSVP).

2 Experimental

Al5052 alloy sheet with thickness of 3 mm was studied in this work. Al5052 alloy is an aluminum magnesium alloy which is not heat treatable and it can be hardened by cold work. The chemical composition of the studied material is presented in Table 1.

Table 1 Chemical composition of studied aluminum alloy (wt.%)

Specimens with dimensions of 150 mm × 100 mm were prepared from the sheet. To omit the effect of rolling process on microstructure, the specimens were heated at 400 °C for 2 h and then cooled in water before processing and then they were cleaned off oil and grease by application of ethanol.

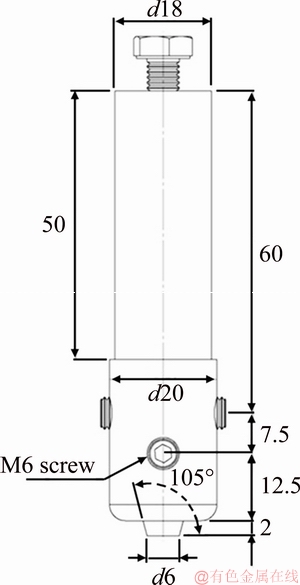

FSP experiments were carried out by a milling machine. Two-pieces tool consisted of a shoulder from M2 steel and a pin from carbide tungsten was utilized for FSP. The geometry of tool is presented in Fig. 1. Shoulder with hardness of HRC 65 had a good durability to wear and heat.

Vibration was applied during FSP by application of camshaft. Rotational movement of an AC motor spindle was transformed into reciprocating and linear motion of a sliding plate through the camshaft. Fixture was mounted on the sliding plate and the specimen was fixed on fixture. The schematic design of machine used for FSVP is presented in Fig. 2. The camshaft was designed in a way that the vibration amplitude for sliding plate was 0.5 mm. The motor was equipped by a driver to get different vibration frequencies.

Fig. 1 Schematic design of tool used for FSP and FSVP (unit: mm)

Fig. 2 Schematic design of machine designed and manufactured for FSVP

Different rotational (750, 900 and 1150 r/min) and traverse (31.5, 45 and 60 mm/min) speeds were tried to fully reveal the effect of vibration on microstructure and mechanical properties of friction stir vibration (FSV) processed specimens. Vibration frequencies of 20, 35 and 50 Hz were also employed to find the effect of frequency on different characteristics of FSV processed specimens. The tilt angle for all processing conditions was 2°.

FS processed specimens were cross sectioned normal to the processing line to analyze the microstructure. Metallography was carried out according to ASTM-E3-11 [14]. The samples were etched for 10 s with an etchant consisting of 4.2 g picric acid, 10 mL acetic acid, 10 mL water and 70 mL ethanol. Grain size was determined by application of the linear intercept method based on ASTM-E112 [15] standard test.

Mechanical properties of FS processed specimens were assessed using the tensile test. Tensile test specimens, according to standard ASTM-E8 [16], normal to the processing direction were prepared using electro discharge machining (EDM) from the processed specimens. For tensile test specimens, the stir zone was in the middle of the specimens. Uniaxial tensile tests were conducted at cross head speed of 1 mm/min and at room temperature [17]. For each condition, three tensile test specimens were performed. Tensile tests were carried out by application of the Instron 5582 Universal tester with a 100 kN load frame. Vickers microhardness test according to ASTM-E384 [18] was applied to assessing the microhardness. Load was 0.98 N and dwell time was 10 s [19]. For each processing condition, five measurements were obtained.

3 Results and discussion

3.1 Effect of vibration

Analyses showed that the best processing conditions occurred when rotation speed was 1150 r/min and traverse speed was 31.5 mm/min. Voids and porosities were detected in cross section of specimens processed with other speeds. Macrostructures of some processed specimens with the optimum values for processing variables are presented in Fig. 3. Figure 3 shows defect-free sections. The figure also shows that stir zones of FSV processed specimens are larger than those of FS processed specimens. This is related to vibrating motion of specimen during FSVP which leads to larger processing zone.

Fig. 3 Macrostructures of FS (a, c) and FSV (b, d) processed specimens

Microstructures of FS and FSV processed specimens as well as base material are observed in Fig. 4. It is observed that grains for FSV processed specimens are smaller than those for FS processed specimens and both are smaller than those for base material. Grain sizes measured for different specimens using linear intercept method are presented in Table 2.

Fig. 4 Microstructures of FS (a), FSV (b) processed specimens and base metal (c)

Table 2 Grain sizes for FS and FSV processed specimens as well as base material

Researchers [20,21] have found that dynamic recovery and recrystallization are the main mechanisms for grain refinement during FSP. According to KAIBYSHEV et al [22], heat generated during FSP brings the possibility for dynamic recovery. Based on this theory, dislocations arrange themselves at low angle grain boundaries (LABs) during dynamic recovery. As processing continues, dynamic recrystallization occurs and misorientation between the boundaries increases and correspondingly LABs transform to high angle grain boundaries (HABs). In this regard, dynamic recovery and recrystallization are the main mechanisms for grain refinement [23,24].

The authors of this work believe that the presence of vibration increases the straining of material during FSVP. In fact, during FSVP the softened material around the pin is deformed more due to rotational and traverse motions of tool as well as the vibration of workpiece. It is known that dislocation density increases as strain increases [25,26]. More dislocation density in FSV processed specimen with regard to FS processed specimen leads to enhanced dynamic recovery and recrystallization and more refined grains develop. In this regard, the smaller grain size for FSV processed specimens with regard to FS processed ones is reasonable.

Stress-strain curves of FS and FSV processed specimens are presented in Fig. 5. It is observed that UTS and ductility values of the FSV processed specimen are higher than those of the FS processed specimen. This can be related to grain size effect. Grain boundary strengthening is numerated as a strengthening mechanism [27]. It is known that grain boundaries impede the movement of dislocations and increase the strength as the volume fraction of grain boundaries levels up [27]. The decrease in grain size increases the volume fraction of grain boundaries. According to the Hall-Petch equation [28], the strength increases as grain size decreases. Smaller grain size of FSV processed specimen with respect to FS processed specimen is the main reason for higher strength of this specimen.

Fig. 5 Stress-strain curves of base material as well as FS and FSV processed specimens

Figure 5 shows that ductility of base material is lower than those of both processed specimens and FSV processed specimen has higher ductility with respect to FS processed specimen. Higher ductility of FSV processed specimen with respect to FS processed specimen can also be related to grain size effect. Microstructural analyses by TEM [29,30] have shown that grain boundaries increase the dislocation density through the generation of dislocations called geometrically necessity dislocations (GNDs). Investigations reveal that GNDs can provide displacement compatibility by accommodating each strain gradient of crystal and ductility increases as grain size decreases [30]. Higher ductility of small grains can also be assigned to higher resistance of these grains to crack propagation [31]. Small grains have a higher resistance to crack propagation due to strain distribution between grain boundaries. ESTRIN et al [32] also studied the effect of grain size on fracture mechanism of AZ31 magnesium alloy and found that ductility is enhanced as grain size decreases. They attributed this to fracture mechanism shift from intergranular to transgranular as grain size decreases.

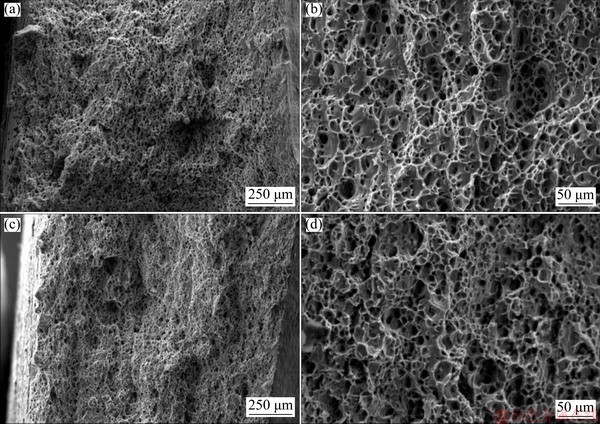

Fracture surfaces of FS and FSV processed tensile test specimens are shown in Fig. 6. Both samples fractured from stir zones and according to Fig. 6, both show a porous fracture surface which is a characteristic of ductile fracture surface of metals. It has been known that ductile metals exhibit massive amounts of plastic deformation prior to fracture in comparison to brittle metals [28]. During loading of ductile metals voids form at different sites where these voids grow and coalesce as loading continues. This results in a dimpled fracture surface [33,34]. Particles and precipitations are primary sites for void formation although the voids can be generated where special jogs or dislocations locks are forced to move. However, the voids form on particles and participations are larger than those form on jogs and dislocation locks [34,35].

The presence of large cavities in Figs. 6(a) and (b) indicates the presence of larger inclusions and particles in microstructure of FS processed specimen with respect to FSV processed specimen (Figs. 6(c) and (d)). It has been known that FSP modifies the microstructure of parent metal and leads to breakdown of large particles and inclusions in microstructure [36]. Less extent of large cavities in microstructure of FSV processed specimen (Fig. 6(b)) is respected to larger extent of straining during FSVP, which results in more breakdown of large particles and inclusions. This may increase the strength and ductility of FSV processed specimen with regard to FS processed one.

Hardness distribution curves of the studied specimens are shown in Fig. 7. Hardness curves relate to hardness data measured on a line 1 mm beneath the surface on cross section of processed specimens. The measured data relate to various zones of processed specimens, namely base material, heat affected zone, thermo-mechanically affected zone and stir zone. The curves show that hardness values of stir zones are higher than those in other zones and hardness values of FSV processed specimens are higher than those relating to processed specimens without vibration. These can be related to grain size effect. It is known that grains in the stir zone are excessively fine and they are co-axial due to severe plastic deformation which occurs in the stir zone [37,38]. The grains in TMAZ deform less than grains in stir zone and the grains within the HAZ do not deform. However, these both regions experience heat during FSP. In this regard, the grains in stir zone are smaller than those in other zones and the presence of vibration also decreases the size of grains. Impediment to dislocations movement increases as grain size decreases and correspondingly, hardness increases.

Fig. 6 Fracture surfaces of FS (a, b) and FSV (c, d) processed specimens for different magnifications

Fig. 7 Hardness distribution with respect to distance from stir zone center

3.2 Effect of frequency

Microstructures of processed specimens with different vibration frequencies are shown in Fig. 8. According to Fig. 8, grain size decreases as frequency is enhanced. The more vibration frequency during FSVP leads to the more straining of material [39]. Increment of straining results in more generation of dislocations, and correspondingly, dynamic recovery and recrystallization are enhanced and more refined grains are developed. Correspondingly, smaller grains are obtained as vibration increases.

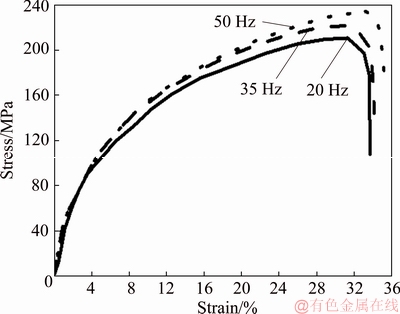

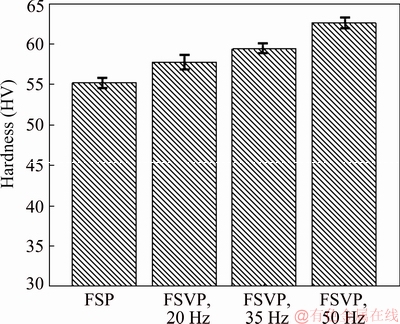

Stress-strain curves of FSV processed specimens with different vibration frequencies are observed in Fig. 9. Based on data in Fig. 9, the UTS and ductility increase as vibration frequency increases. It was observed in Fig. 8, that grain size decreased as vibration frequency increased. Lower grain size of FSV processed specimen results in higher volume fraction of grain boundaries and according to the Hall-Petch equation [28], more strength is obtained. Hardness values of stir zone center for specimens FSV processed with different frequencies are presented in Fig. 10. It is observed that hardness as well as strength increases as vibration frequency is enhanced.

Formability indexes of FSV processed specimens with three vibration frequencies are compared in Fig. 11. Formability index which is defined as the ability of substance to absorb energy before failure was introduced by GHEYSARIAN et al [40] and is denoted by UTS×EL, where UTS and EL indicate ultimate tensile strength and elongation, respectively. It is observed that formability index of FSV processed specimens increases as vibration frequency increases. This relates to UTS and elongation increase as vibration frequency increases (Fig. 9). This indicates that FSVP with high vibration frequency might be a good candidate for the increase of FSP efficiency.

Fig. 8 Stir zone microstructures of FSV specimens processed with different frequencies

Fig. 9 Stress-strain curves of FSV processed specimens with various frequencies

Fig. 10 Hardness values of stir zone centers for FS and FSV processed specimens

Fig. 11 Formability index of specimens processed with different frequencies during FSVP

4 Conclusions

(1) The presence of vibration during FSP resulted in more straining of material in the processed zone and enhanced the dynamic recovery and recrystallization and correspondingly increased the grain refinement.

(2) The results also showed that grain refinement improved and additionally, UTS, elongation and hardness increased as vibration frequency during FSVP increased. This new method can enhance the efficiency of FSP and it is advised for application in industry.

References

[1] MA Z Y. Friction stir processing technology: A review [J]. Metallurgical and Materials Transactions A, 2008, 39: 642-658.

[2] GAN W Y, ZHOU Z, ZHANG H, PENG T. Evolution of microstructure and hardness of aluminum after friction stir processing [J]. The International Journal of Advanced Manufacturing Technology, 2014, 24: 975-981.

[3] GHOLAMI S, EMADODDIN E, TAJALLY M, BORHANI E. Friction stir processing of 7075 Al alloy and subsequent aging treatment [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2847-2855.

[4] SUN N, APELIAN D. Friction stir processing of aluminum cast alloys for high performance applications [J]. JOM, 2011, 63(11): 44-50.

[5] LEAL R M, GALVAO I, LOUREIRO A, RODRIGUES D M. Effect of friction stir processing parameters on the microstructural and electrical properties of copper [J]. International Journal of Advanced Manufacturing Technology, 2015, 80: 1-9.

[6] XUE P, XIAO B L, MA Z Y. High tensile ductility via enhanced strain hardening in ultrafine-grained Cu [J]. Materials Science and Engineering A, 2012, 532: 106-110.

[7] VENKATESWARLU G, DAVIDSON M J, TAGORE G R N. Taguchi optimization of friction stir processing parameters to achieve maximum tensile strength of MG AZ31B alloy [J]. Transactions of the Indian Institute of Metals, 2012, 65: 4911-496.

[8] HANNARD F, CASTIN S, MAIRE E, MOKSO R, PARDOEN T, SIMAR A. Ductilization of aluminum alloy 6056 by friction stir processing [J]. Acta Materialia, 2017, 130: 121-136.

[9] MISHRA R S, MA Z Y, CHARIT I. Friction stir processing: A novel technique for fabrication of surface composite [J]. Materials Science and Engineering A, 2003, 341: 307-310.

[10] BARMOUZ M, ASADI P, BESHARATI GIVI M K, TAHERISHARGH M. Investigation of mechanical properties of Cu/SiC composite fabricated by FSP: Effect of SiC particles’ size and volume fraction [J]. Materials Science and Engineering A, 2011, 528: 1740-1749.

[11] DADAEI M, OMIDVAR H, BAGHERI B, JAHAZI M, ABBASI M. The effect of SiC/Al2O3 particles used during FSP on mechanical properties of AZ91 magnesium alloy [J]. International Journal of Materials Research, 2014, 105: 369-374.

[12] GHASEMI-KAHRIZSANGI A, KASHANI BOZORG S F, MOSHREF JAVADI M. Effect of friction stir processing on the tribological performance of steel/Al2O3 nanocomposites [J]. Surface and Coatings Technology, 2015, 276: 507-515.

[13] SHAMSIPUR A, KASHANI BOZORG S F, ZAREI HANZAKI A. Surface modification of titanium by producing Ti/TiN surface composite layers via FSP [J]. Acta Metallurgical Sinica, 2017, 30: 550-557.

[14] ASTM E3-11. Standard guide for preparation of metallographic specimens [S]. West Conshohocken, PA: ASTM International, 2011.

[15] ASTM-E112-13. Standard test methods for determining average grain size [S]. West Conshohocken, PA: ASTM International, 2013.

[16] ASTM-E8. Standard test methods of tension testing of metallic materials [S]. West Conshohocken, Pa: ASTM International, 2016.

[17] SHARMA C, UPADHYAY V, DWIVEDI D K, KUMAR P. Mechanical properties of friction stir welded armor grade Al-Zn-Mg alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 493-506.

[18] ASTM E384-11. Standard test method for Knoop and Vickers hardness of materials [S]. West Conshohocken, PA: ASTM International, 2011.

[19] CHOI D H, KIN Y H, AHN B W, KIM Y I, JUNG S B. Microstructure and mechanical property of A356 based composite by friction stir processing [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 335-340.

[20] ABBASI M, BAGHERI B, DADAEI M, OMIDVAR H, REZAEI M. The effect of FSP on mechanical, tribological and corrosion behavior of composite layer developed on magnesium AZ91 alloy surface [J]. The International Journal of Advanced Manufacturing Technology, 2015, 77: 2051-2058.

[21] MISHRA R S, MA Z Y. Friction stir welding and processing [J]. Materials Science and Engineering R, 2005, 50: 1-78.

[22] KAIBYSHEV R, SHIPILOVA K, MUSIN F, MOTOHASHI Y. Continuous dynamic recrystallization in an Al-Li-Mg-Sc alloy during equal-channel angular extrusion [J]. Materials Science and Engineering A, 2005, 396: 341-351.

[23] FOULADI S, GHASEMI A H, ABBASI M, ABEDINI M, KHORASANI A M, GIBSON I. The effect of vibration during friction stir welding on corrosion behavior, mechanical properties and machining characteristics of stir zone [J]. Metals, 2017, 7(10): 421-433.

[24] BAROONI O, ABBASI M, GIVI M, BAGHERI B. New method to improve the microstructure and mechanical properties of joint obtained using FSW [J]. International Journal of Advanced Manufacturing Technology, 2017, 93(9-12): 4371-4378.

[25] HULL D, BACON D J. Introduction to dislocations [M]. 5th ed. USA: Elsevier, 2011.

[26] FOULADI S, ABBASI M. The effect of friction stir vibration welding process on characteristics of SiO2 incorporated joint [J]. Journal of Materials Processing Technology, 2017, 243: 23-30.

[27] CALLISTER W D. Materials science and engineering: An introduction [M]. USA: Wiley, 2007.

[28] DIETER G E. Mechanical metallurgy [M]. Singapore: McGraw-Hill Book Company, 1988.

[29] SCHEMPP P, CROSS C E, HACKER R, PITTNER A, RETHMEIER M. Influence of grain size on mechanical properties of aluminum GTA weld metal [J]. Weld World, 2013, 57: 293-304.

[30] HANSEN N. The effect of grain size and strain on the tensile flow stress of aluminum at room temperature [J]. Acta Metallurgica, 1977, 25: 863-869.

[31] SPITTLE J A, CUSHWAY A A. Influence of superheat and grain structure on hot-tearing susceptibilities of Al-Cu alloy castings [J]. Metals Technology, 1983, 10: 6-13.

[32] ESTRIN Y Z, ZABRODIN P A, BRAUDE I S, GRIGOROVA T V, IASEV N V, PUSTOVALOV V V, FOMENKO V S, SHUMILIN S E. Low temperature plastic deformation of AZ31 magnesium alloy with different microstructures [J]. Low Temperature Physics, 2010, 36: 1100-1112.

[33] ZHANG W W, CONG S. Failure analysis of SUS304 sheet during hydro-bulging based on GTN ductile damage model [J]. The International Journal of Advanced Manufacturing Technology, 2016, 86: 427-435.

[34] UTHAISANGSUK V. Microstructure based formability modeling of multiphase steels [D]. Aachen: RWTH Achen University, 2009.

[35] ABBASI M, SHAFAAT M A, KETABCHI M, HAGHSHENAS D, ABBASI M. Application of the GTN model to predict the forming limit diagram of IF-steel [J]. Journal of Mechanical Science and Technology, 2012, 26: 345-352.

[36] AZIZIEH M, BAHADORI R, ABBASI M, YOON E Y, KIM H S. Effect of friction stir processing on the microstructure of pure magnesium castings [J]. International Journal of Cast Metals Research, 2015, 28: 345-351.

[37] GHANBARI D, KASIRI ASGARANI M, AMINI K, GHARAVI F. Influence of heat treatment on mechanical properties and microstructure of the Al2024/SiC composite produced by multi-pass friction processing [J]. Measurement, 2017, 104: 151-158.

[38] JAFARI M, ABBASI M, POURSINA D, GHEYSARIAN A, BAGHERI B. Microstructure and mechanical properties of friction stir welded dissimilar steel-copper joints [J]. Journal of Mechanical Science and Technology, 2017, 31: 1135-1142.

[39] RAHMI M, ABBASI M. Friction stir vibration welding process: Modified version of friction stir welding process [J]. The International Journal of Advanced Manufacturing Technology, 2017, 90: 141-151.

[40] GHEYSARIAN A, ABBASI M. The effect of aging on microstructure, formability and springback of Ti-6Al-4V titanium alloy [J]. Journal of Materials Engineering and Performance, 2017, 26: 374-382.

M. ABBASI1, M. GIVI1, B. BAGHERI2

1. Faculty of Engineering, University of Kashan, Kashan, Iran;

2. Department of Mining and Metallurgy, Amirkabir University of Technology, Tehran, Iran

摘 要:搅拌摩擦加工(FSP)是一种处理金属表面的固态改性方法。在此过程中,由于非自耗刀具的旋转和来回移动,使金属表面组织细化、力学性能提升。提高FSP效率的方法较多,本研究中采用的是一种叫振动搅拌摩擦加工(FSVP)的新方法。在此方法中,金属工件在FSP过程中与加工线垂直振动。分析比较FSP法和FSVP法加工的Al5052合金试样的显微组织和力学性能,包括硬度、极限抗拉强度(UTS)和伸长率。结果表明,采用FSVP后,振动可使材料的晶粒尺寸减小约33%,极限抗拉强度和硬度提高约7%。这与振动作用下金属表面材料的应变增强有关。应变增加导致位错密度增加,动态再结晶使大角度晶界进一步发育。结果还表明,FSV加工试样的极限抗拉强度和伸长率均随振动频率的增加而增加。

关键词:振动搅拌摩擦加工;搅拌摩擦加工;显微组织;力学性能

(Edited by Xiang-qun LI)

Corresponding author: B. BAGHERI; Tel: +98-383346602; E-mail: b.bagheri@aut.ac.ir

DOI: 10.1016/S1003-6326(19)65046-6