文章编号:1004-0609(2008)07-1261-07

MB8镁合金阴极电沉积Ni-SiC纳米复合镀层

微观结构及性能

李雪松1, 2,吴 化1,杨 友1,江中浩2

(1. 长春工业大学 材料科学与工程学院,长春 130012;

2. 吉林大学 汽车材料教育部重点实验室,长春 130025)

摘 要:采用以硫酸镍为主盐的电沉积技术,在MB8形变镁合金表面制备纳米复合镀层。利用扫描电镜和透射电镜观察复合镀层的显微形貌和微观结构,利用X射线衍射仪和能谱仪对复合镀层进行物相分析,利用显微硬度计测定镀层显微硬度,利用快速磨损试验机测试复合镀层的耐磨性能,利用电化学测试仪测定复合镀层在3.5%NaCl(质量分数)溶液中的极化曲线。结果表明:在MB8形变镁合金表面可以获得结晶均匀、结构致密的纳米复合镀层,该复合镀层的显微硬度最高达HV 682,其耐磨性能超过硬铬镀层,且具有较好的耐蚀性能,自腐蚀电位较镁合金基体提高677 mV。

关键词:MB8镁合金;电沉积;纳米复合镀层;纳米SiC

中图分类号:TG 174.4 文献标识码:A

Microstructure and properties of cathode electrodeposited Ni-SiC nano composite coatings on MB8 magnesium alloy

LI Xue-song1, 2, WU Hua1, YANG You1, JIANG Zhong-hao2

(1. College of Materials Science and Engineering, Changchun University of Technology, Changchun 130012, China;

2. Key Laboratory of Automobile Materials, Ministry of Education, Jilin University, Changchun 130025, China)

Abstract: Nano composite coatings were prepared on MB8 wrought magnesium alloy by electrodeposition with sulfate nickel as main salt. The microstructure of the composite coatings were observed with scanning electron microscopy and transmission electron microscopy, its phase compositions were analyzed with X-ray diffractometry, its microhardness was determined with microhardness meter, its abrasive resistance was tested by rapid abrasive test, and its polarization curve in 3.5% (mass fraction) sodium chloride solution was determined by electrochemical tester. The results show that nano composite coatings with uniform crystalline, dense structure and better corrosion resistance can be obtained on MB8 wrought magnesium alloy and its maximum microhardness reaches HV 682. Moreover, the abrasive resistance of the composite coatings is superior to that of the hard chromium coating, the corrosion potential is increased by 677 mV compared with base Mg alloy.

Key words: MB8 magnesium alloy; electrodeposition; nano composite coating; nano-SiC

镁合金是工业上可供选择的最轻的金属结构材 料[1?2],且具有优良的力学性能,如高比强度和高比刚度,良好的导热性、阻尼减振性能、电磁屏蔽性能、容易切削加工以及易回收利用等优点[3?4]。在减少有限的燃油消耗和降低日益严重的汽车废气污染等问题的迫切要求下,汽车及航空零件的轻量化发展成为趋势,航天航空领域和汽车工业等都越来越多的需要应用镁合金。但镁合金在潮湿环境中极易腐蚀,尤其在氯化盐、硫酸盐等环境下更容易发生腐蚀而破坏[5]。因此,镁合金的防腐蚀问题已经成为镁合金研究的关键课题。

现已有很多镁合金表面防护方法,如表面喷涂、化学氧化、微弧氧化等[6]。近些年也有研究在镁合金表面化学镀镍磷合金效果较好[7?8]。但具有较高的表面显微硬度、耐磨性、自润滑性、耐腐蚀性及特殊功能的复合电镀(Composite plating)正日益引起人们的关 注[9?10]。近几年来,纳米材料的兴起为复合镀层的制备带来新的契机。而在镁合金上进行纳米复合电镀的报道很少,因此,本文作者就此项技术在镁合金表面上的应用进行了较为深入的探讨。

但是,纳米颗粒在电解液中因纳米作用能而极易发生团聚,因此纳米复合电镀技术的关键问题就是纳米颗粒在电解液中的均匀分散技术及纳米颗粒在镀层中的可控带入技术[11]。且由于镁的化学活性和氧的亲和力,以至于在其表面瞬间产生氧化膜,在电镀时,这层氧化膜的存在影响了镀层与金属之间的结合力,结果会使镀层结合力不好,易产生起泡和脱皮等不良现象,不能起到防护的作用。本文作者采用以硫酸盐为主盐的电镀工艺方法[12],该工艺简单,成本低,可获得高硬度、高耐磨性的纳米复合镀层。为纳米复合镀技术在镁合金耐蚀方面的应用打下良好的研究基础。

1 实验方法

实验试样为MB8形变镁合金,试样规格为30 mm×30 mm×2 mm,用金相砂纸从粗到细(1000#)逐级打磨,纳米复合电镀的工艺流程为:丙酮超声波除油-水洗-铬酸酸洗-水洗-氢氟酸酸洗-水洗-化学预处理-水洗-复合电镀-水洗-烘干,电解镍板为阳极。电镀所用设备为:GDF?50 A/24 V硅整流电镀电源、KQ?100DB型超声波装置、D40?2F型电动搅拌机。预处理液及复合镀液主要成分及工艺参数见表1和2。

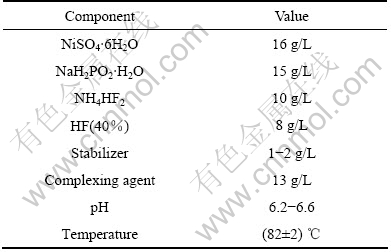

表1 预处理镀液的组成及工艺参数

Table 1 Component and parameter of pretreatment bath

表2 制备Ni-SiC纳米复合镀层工艺参数

Table 2 Electro-co-deposition parameters of preparing Ni-SiC composite coating

由于纳米粒子本身具有非常高的表面活性(作用能)和极大的比表面积,在镀液中极易发生团聚。解决团聚问题是纳米复合电镀的关键。为在镀液中得到高分散度的SiC纳米颗粒,先用少量配制液(含分散剂即阳离子表面活性剂)将SiC纳米颗粒充分润湿,在超声波下振荡分散5~6 h,然后将其加入镀液,而且施镀过程中一直使用超声波分散辅助可变速的机械搅拌。使纳米颗粒充分分散并增加其到达阴极的几率。

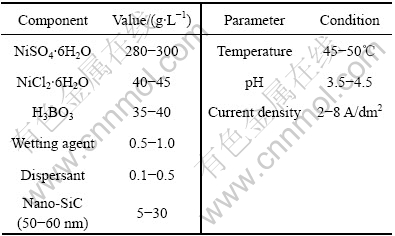

采用透射电子显微镜观察纳米颗粒形貌及显微结构(见图1),JSM?5600LV扫描电镜观察不同工艺条件下获得的复合镀层的微观形貌,利用XRD衍射仪测试镀层相结构及组成。使用HXD?1000显微硬度仪测量复合镀层显微硬度。在磨损实验机上进行复合镀层磨损试验。磨损试样的尺寸为10 mm×10 mm,对磨试样为GCr15淬火钢环。磨损所加载荷为30 N,转速为200 r/min,每磨损5 min取下试样用电子天平称量,总磨损时间为45 min。

图1 纳米SiC颗粒的TEM像

Fig.1 TEM micrograph of nano-SiC particles

采用质量分析法测定镀层中SiC纳米颗粒的含量,其方法如下:将复合镀层置于适量电解液中进行电化学退镀。待镀层全部溶解后用数倍去离子水稀释。然后烘干且精确称量的定量滤纸,质量记为m1。过滤稀释液,将其过滤后用去离子水清洗数次。将带颗粒的滤纸在100 ℃烘干10 min后用高精度电子天平称量,质量记为m2。定量滤纸的两次质量差值(Δm=m2?m1) 为镀层中SiC纳米颗粒的质量。

2 结果与讨论

2.1 复合镀层的显微形貌

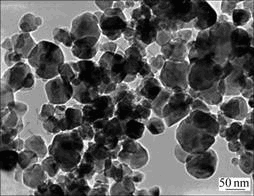

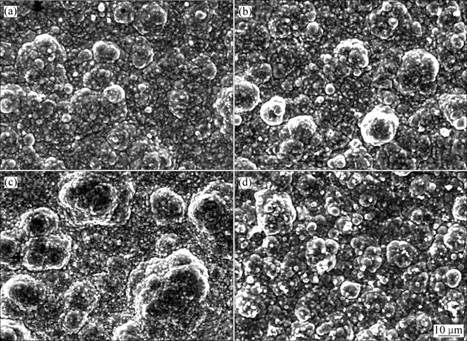

图2所示为镁合金表面预处理化学镀镍层表面显微形貌。预镀镍条件为:硫酸镍为主盐、温度(82±2) ℃,时间 20 min。由SEM像可以看出:在酸性(pH<6.5)条件下化学镍层较碱性(pH>8)条件下更为均匀、致密及光亮。

10?m

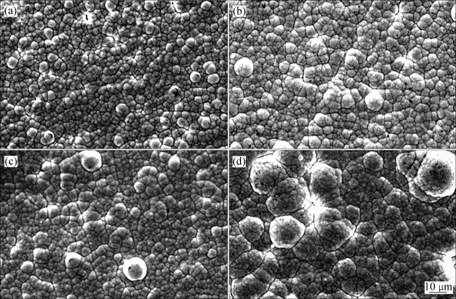

图3所示为不同电流密度下镁合金表面Ni-SiC纳米复合镀层表面显微形貌。电沉积工艺条件为:温度(50±2) ℃、pH 4、超声波分散加慢速机械搅拌、镀液中SiC含量10 g/L、电流密度2~8 A/dm

2。由SEM像可以看出,随着电流密度的增大,晶粒团簇的尺寸呈明显增大的趋势。这是因为电流密度增大,晶粒形核及长大的速度都增大,从而使镀层宏观表面变得粗糙。当电流密度过大,即金属离子沉积的速度远超过纳米颗粒在阴极表面发生吸附的速度时,纳米颗粒在镀层中的复合量将大大减少,不利于复合镀层的形成。而电流密度太小,沉积的金属离子不能将在阴极表面发生强吸附的纳米颗粒迅速包裹嵌入时,也不利于复合镀层的形成。所以,实验得出的最佳电流密度为2~4 A/dm

2。

图2 不同pH值时镁合金表面化学预镀镍层的SEM形貌

Fig.2 SEM micrographs of electroless nickel coating on magnesium alloy surface prepared at different pH values: (a) pH 5.5; (b) pH 6.5; (c) pH 8; (d) pH 9

图3 不同电流密度时镁合金表面Ni-SiC纳米复合镀层SEM形貌

Fig.3 SEM micrographs of Ni-SiC composite coating on magnesium alloy surface prepared at different current densities: (a) 2 A/dm2; (b) 4 A/dm2; (c) 6 A/dm2; (d) 8 A/dm2

并且离子减薄时离子束还可能打掉一部分纳米颗粒,最终出现图6所示的微观结构。

2.2 复合镀层成分分析

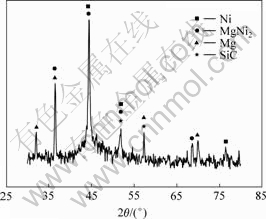

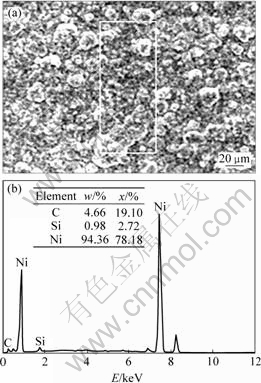

图4所示为温度50 ℃、pH 4、电流密度4 A/dm2、经超声波加慢速机械搅拌分散时得到复合镀层的XRD谱。可以看出,在此条件下,纳米复合镀层为多晶Ni中含有SiC颗粒。SiC颗粒的加入并没有改变多晶Ni衍射峰的位置,但Ni衍射峰明显宽化,说明SiC颗粒的加入起到了细化镀层晶粒尺寸的作 用[13]。对同一个试样进行能谱测试(见图5),可以看出,镀层微区内含有0.98%Si和4.66%C元素,进一步证明镀层中含有一定量的纳米SiC颗粒。

图4 镁合金表面Ni-SiC纳米复合镀层的XRD谱

Fig.4 XRD pattern of Ni-SiC nano-composite coating on magnesium alloy surface

图5 Ni-SiC纳米复合镀层表面形貌能谱分析

Fig.5 SEM image and EDS pattern of Ni-SiC composite coating

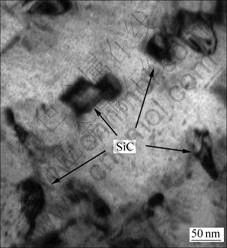

复合镀层的TEM像如图6所示。从图中可以看出,在镍层中分布着纳米颗粒,这与图4所示的XRD谱及图5所示的能谱分析结果相同。只是因为镀液中纳米颗粒极易发生团聚,使镀层中的颗粒也不能很好的均匀分布,并且离子减薄时离子束还可能打掉一部分纳米颗粒,最终出现6所示的微观结构。

图6 复合镀层微观结构的TEM像

Fig.6 TEM image of composite coating

2.3 复合镀层表面的磨损性能

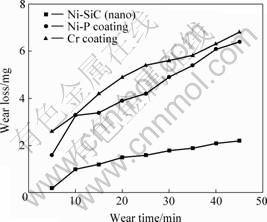

图7 所示为Ni-SiC纳米复合镀层时间磨损量曲线。可以看出,Ni-SiC纳米复合镀层的磨损率远小于纯铬镀层的磨损率。铬是一种面心立方结构的金属,在与金属接触时不是理想的耐磨材料,容易出现粘着磨损。当纯镍层中加入硬质颗粒SiC形成复合镀层后,会使镀层具有一定的韧性外,且有高的硬度及强的耐磨性能。在磨擦接触时,由于颗粒是均匀分散在基质金属中,并且在磨擦表面上形成微弱的突起,从而使润滑油膜易于保持在磨损面上,可以预防粘着磨损的发生,当镀层表面的基质受到磨损,使嵌镶在基质金属中的固体颗粒得以凸出,充当主滑动面参与磨损,颗粒的高强度和高硬度特点在磨擦过程中支撑载荷,使突起处不易引起切削、破碎等塑性变形,而在颗粒周围稍远些的位置,部分基体金属被磨损掉,形成凹槽,它也可以储存润滑剂,从而减轻磨损,使复合镀层整具有良好的耐磨性能,在复合镀层中基质金属为连续相形成骨架,若使固体颗粒牢固地嵌入,不致剥落下来,这就要求基质金属必须有一点的塑性和韧性,不发生脆性破坏,同时还要有一定的强度和硬度,以保证对颗粒的牢固支撑作用,两者配合方能使颗粒的特性得以发挥,Ni-SiC(纳米)复合镀层具有高的耐磨性能。

图7 Ni-SiC纳米复合镀层的时间—磨损量曲线

Fig.7 Curves of time—wear loss of Ni-SiC composite coating

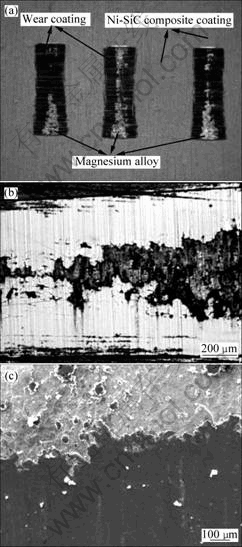

图8所示为复合镀层表面磨损的显微形貌。从图中可以看出,在与摩擦副淬火钢环对磨时,没有产生严重的粘着磨损。同时镶嵌在镀层中均匀分布的第二相颗粒质点会起到支撑载荷的作用,并依靠其高硬度特性降低镀层磨损率,从而表现出较高的磨损抗力[14]。

图8 Ni-SiC纳米复合镀层磨损层形貌

Fig.8 Wear micrographs of Ni-SiC composite coating: (a) Whole wear micrograph; (b) , (c) Part amplifying micrographs of (a)

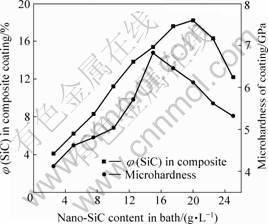

2.4 复合镀层表面显微硬度

图9所示为镀液中纳米颗粒含量与镀层中颗粒含量及镀层表面显微硬度的关系曲线。由图可知,基本上说明硬度值是随着纳米颗粒在镀液中含量的增加而增大,出现极值后下降,这是因为镀液中的纳米粒子的浓度对颗粒在镀层中的共析量也有很大的影响。浓度过低,颗粒到达阴极的几率就会减小,当然被吸附的几率也会很小。但如果浓度过大,则由于纳米颗粒的细小,在溶液中悬浮过程易使镀液变得粘稠,颗粒向阴极传输过程纳米粒子间也会发生相互阻碍作用。并且纳米颗粒浓度过大,在阴极表面吸附的颗粒也会增多,这样将覆盖一些阴极表面上的活化点,也不利于金属离子的沉积。而颗粒进入镀层的量较多时,均匀弥散在金属中的硬质颗粒会对晶粒间的位错滑移产生很大的阻碍作用,引起弥散强化[11],最终在颗粒周围留下一个位错环。颗粒上积累的位错环越多,位错再次通过颗粒的阻力也越大。同时纳米颗粒嵌入基质金属镍的晶体点阵之中引起晶体结构的畸变,使晶格扭曲产生位错强化,也使镀层内产生较大的应力,引起应变强化作用。但如果颗粒过多,在共沉积时极易发生聚积而形成松散的团聚体,反而会降低镀层的硬度。

图9 镀液中纳米颗粒含量对镀层中颗粒含量及表面显微硬度的影响

Fig.9 Effects of nano particle content in bath on particle content of coating and microhardness of nano-composite coatings

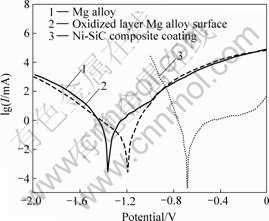

2.5 复合镀层的电化学腐蚀行为

图10所示为镁合金基体、镁合金氧化层、复合镀层在3.5% NaCl溶液中的腐蚀电位与腐蚀电流的关系。实验条件为:初始电位?2.0 V,终止电位为0 V,扫描速度为0.01 V/s,阴极极化曲线和阳极极化曲线的Tafel直线段的交点所对应的电位值为该试样的自腐蚀电位,即达到自腐蚀电位值,腐蚀开始进行。同样腐蚀条件下,自腐蚀电位越低,越容易腐蚀。在此实验中复合镀层耐蚀性较镁合金基体及镁合金氧化层都有较大的提高,其自腐蚀电位较镁合金基体提高677 mV。从曲线还可看到在阳极极化曲线中出现水平台阶,这是因为镀层出现钝化现象,表面生成的腐蚀产物在基体与腐蚀介质之间起到一定的阻碍作用,从而减缓腐蚀的进行[15]。

图10 不同镀层在3.5% NaCl溶液中的Tafel曲线

Fig.10 Tafel curves of different coatings in 3.5% NaCl

3 结论

1) 采用以硫酸镍为主盐的电沉积技术可以在MB8形变镁合金表面获得结晶均匀、结构致密的纳米复合镀层。电沉积最佳工艺条件为:温度(50±2) ℃、电流密度2~4 A/dm2、pH 3.8~4.2、超声波分散加慢速机械搅拌、镀液中SiC含量10 g/L。

2) 复合镀层与镁合金基体具有较好的结合力,使镁合金表面的显微硬度及耐磨、耐蚀性能都有很大的提高,镀层显微硬度最高达HV 682,自腐蚀电位较镁合金基体提高677 mV,耐磨性能超过硬铬镀层。

REFERENCES

[1] 张新明, 陈健美, 邓运来, 肖 阳, 蒋 浩. Mg-Gd-Y-Zr耐热镁合金的压缩变形行为[J]. 中国有色金属学报, 2005, 15(12): 1925?1932.

ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai, XIAO Yang, JIANG Hao. Deformation behavior of Mg-Gd-Y-Zr heat resistant magnesium alloy during hot-compression[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1925?1932.

[2] ANYANWU I A, KAMADO S, KOJIMA Y. Creep properties of Mg-Gd-Y-Zr alloy[J]. Materials Transactions, 2001, 42(1): 1212?1218.

[3] LUO ALAN A. Recent magnesium alloy development for automotive power train application[J]. Material Science Forum, 2003, 419/422(1): 56?57.

[4] DRITS M E, SVIDERKAYA Z A, ROKHLIN L L. Effect of alloying on properties of Mg-Gd alloys[J]. Metallovedenic i Termicheskaya, 1979, 11: 62?64.

[5] GUANG L S, ANDREJ A. The electrochemical corrosion of pure magnesium in 1 N NaCl[J]. Corrosion Science, 1997, 39(5): 855?875.

[6] 孙 颖, 李燕青, 魏晓伟, 慕 东. 镁合金表面防护研究进展[J]. 四川工业学院学报, 2004, 23(4): 4?6.

SUN Ying, LI Yan-qing, WEI Xiao-wei, MU Dong. Advance in the research on magnesium alloy surface’s protection[J]. Journal of Sichuan University of Science and Technology, 2004, 23(4): 4?6.

[7] 霍宏伟, 李 瑛, 王福会. AZ91D镁合金化学镀镍[J]. 中国腐蚀与防护学报, 2002, 22(1): 14?17.

HUO Hong-wei, LI Ying, WANG Fu-hui. Electroless nickel plating on AZ91D magnesium alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2002, 22(1): 14?17.

[8] 胡文彬, 向阳辉, 刘新宽, 刘 磊. 镁合金化学镀镍预处理过程表面状况的研究[J]. 中国腐蚀与防护学报, 2001, 21(6): 340?344.

HU Wen-bin, XIANG Yang-hui, LIU Xin-kuan, LIU Lei. A study on surface state during the pretreatment of electroless nickel plating on magnesium alloy[J]. Journal of Chinese Society for Corrosion and Protection, 2001, 21(6): 340?344.

[9] LEKKA M, KOULOUMBI N, GAJO M, BONORA P L. Corrosion and wear resistant electrodeposited composite coatings[J]. Electrochemica Acta, 2005, 50: 4551?4556.

[10] KUO S L, CHEN Y C, GER M D, HWU W H. Nano-particles dispersion effect on Ni/Al2O3 composite coatings[J]. Materials Chemistry and Physics, 2004, 86: 5?10.

[11] 郭鹤桐, 张三元. 复合镀层[M]. 天津: 天津大学出版社, 1991.

GUO He-tong, ZHANG San-yuan. Composite coatings[M]. Tianjing: Tianjing University Press, 1991.

[12] 李 瑛, 余 刚, 刘跃龙, 叶立元, 郭小华, 雷细平. 镁合金上硫酸镍体系化学镀镍工艺研究[J]. 材料保护, 2003, 36(10): 32?34.

LI Ying, YU Gang, LIU Yue-long, YE Li-yuan, GUO Xiao-hua, LEI Xi-ping. Electroless nickel plating technology of AZ91D magnesium alloy in nickel sulfate bath[J]. Materials Protection, 2003, 36(10): 32?34.

[13] 李光玉, 牛丽媛, 江中浩, 孙丽萍, 连建设. 电流密度对纳米锌镍合金镀层显微组织的影响[J]. 吉林大学学报: 工学版, 2006, 36(6): 835?840.

LI Guang-yu, NIU Li-yuan, JIANG Zhong-hao, SUN Li-ping, LIAN Jian-she. Influence of current density on microstructure of nanocrystalline zinc nickel alloy deposition[J]. Journal of Jilin University: Engineering and Technology Edition, 2006, 36(6): 835?840.

[14] LEKKA M, KOULOUMBI N, GAJO M, BONORA P L. Corrosion and wear resistant electrodeposited composite coatings[J]. Electrochemical Acta, 2005, 50: 4551?4556.

[15] ZHANG W X, HUANG N, HE J G, JIANG Z H, JIANG Q, LIAN J S. Electroless deposition of Ni-W-P coating on AZ91D magnesium alloy[J]. Applied Surface Science, 2007, 253: 5116?5121.

基金项目:吉林省教育厅科技攻关资助项目(2005025);长春工业大学科技发展基金资助项目(2006001)

收稿日期:2007-06-04;修订日期:2008-04-14

通讯作者:吴 化,教授,博士;电话:0431-85716426;E-mail: wuhua57@163.com

(编辑 龙怀中)