激光冲击强化ZCuAl10Fe3Mn2合金的热疲劳裂纹生长行为

来源期刊:中国有色金属学报(英文版)2021年第4期

论文作者:刘光磊 曹宇豪 杨坤 郭伟 孙小轩 赵玲 司乃潮 周建忠

文章页码:1023 - 1030

关键词:铜合金;激光冲击强化;表面形貌;热疲劳性能;裂纹萌生;裂纹扩展

Key words:copper alloy; laser shock strengthening; surface morphology; thermal fatigue properties; crack initiation; crack propagation

摘 要:为了提高高温构件的热疲劳性能、减少表面裂纹,研究激光冲击对ZCuAl10Fe3Mn2合金硬度、表面形貌、残余应力和热疲劳性能的影响。采用扫描电子显微镜(SEM)和能谱仪(EDS)分析合金的显微组织和裂纹形貌。结果表明:在4 J脉冲能量下,激光冲击能显著改善合金的热疲劳性能。在热应力和交变应力的作用下,试样缺口附近组织氧化而变得疏松多孔,促使萌生多条微裂纹。其中,竖直方向的微裂纹变为主裂纹,主要以裂尖前沿空洞连体的形式扩展;其他方向的微裂纹沿晶界生长而发生组织脱落现象。

Abstract: The effect of laser shock processing (LSP) on the hardness, surface morphology, residual stress, and thermal fatigue properties of a ZCuAl10Fe3Mn2 alloy was investigated to improve the thermal fatigue performance and decrease the surface crack of high-temperature components. The microstructure and crack morphology were analyzed by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results showed that laser shock could significantly improve the thermal fatigue performance of the alloy at a pulse energy of 4 J. Under the effect of thermal stress and alternating stress, microstructure around the specimen notch was oxidized and became porous, leading to the formation of multiple micro-cracks. The micro-cracks in the vertical direction became the main cracks, which mainly expanded with the conjoining of contiguous voids at the crack tip front. Micro-cracks in other directions grew along the grain boundaries and led to material shedding.

Trans. Nonferrous Met. Soc. China 31(2021) 1023-1030

Guang-lei LIU1,2, Yu-hao CAO1, Kun YANG1, Wei GUO1, Xiao-xuan SUN1, Ling ZHAO1, Nai-chao SI1, Jian-zhong ZHOU2

1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. School of Mechanical Engineering, Jiangsu University, Zhenjiang 2120013, China

Received 6 May 2020; accepted 28 January 2021

Abstract: The effect of laser shock processing (LSP) on the hardness, surface morphology, residual stress, and thermal fatigue properties of a ZCuAl10Fe3Mn2 alloy was investigated to improve the thermal fatigue performance and decrease the surface crack of high-temperature components. The microstructure and crack morphology were analyzed by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results showed that laser shock could significantly improve the thermal fatigue performance of the alloy at a pulse energy of 4 J. Under the effect of thermal stress and alternating stress, microstructure around the specimen notch was oxidized and became porous, leading to the formation of multiple micro-cracks. The micro-cracks in the vertical direction became the main cracks, which mainly expanded with the conjoining of contiguous voids at the crack tip front. Micro-cracks in other directions grew along the grain boundaries and led to material shedding.

Key words: copper alloy; laser shock strengthening; surface morphology; thermal fatigue properties; crack initiation; crack propagation

1 Introduction

Non-room temperature working equipment undergoes thermal fatigue damage due to the combined effect of alternating temperature and stress during steady-state operation, the starting and stopping of the equipment, or a sudden change in working conditions, leading to poor operation or even equipment damage. The thermal fatigue performance of materials exhibits a direct effect on the long-term service stability of the high- temperature components. Macroscopically, cracks on the material surface reflect a general sign of fatigue failure [1]. To resolve this issue, researchers have proposed laser shock processing (LSP) to strengthen the material surface [2].

Compared to traditional shot peening, LSP technology exhibits good control, and the recycling of a medium or a high-level working environment is not required. The residual compressive stress generated by LSP can reach more than 10 times that generally generated by shot peening. In recent years, researchers have mainly examined the effect of laser process parameters on strengthening. The main process parameters include pulse energy [3], overlap ratio [4], spot size and shape [5], absorbent and confinement layers [6], rebound degree [7], thickness [8], and temperature [9]. The above research contents mainly reveal the influence of laser shock processing parameters on the microstructure, strength and hardness of materials, but there is still a lack of research on materials under specific working conditions such as thermal fatigue, friction and wear. Research of the LSP strengthening mechanism generally reveals that [10] the residual compressive stress layer induced by LSP on the alloy surface at room temperature can significantly delay the formation of micro-cracks and move the crack source from the surface to the subsurface, which is beneficial to improving the fatigue life of materials [10,11]. On the other hand, LSP plays an important role in refining coarse grain and reducing average grain size [12]. After the LSP, the surface of the alloy can form micron scaled sub-grain microstructure, which can hinder the movement of dislocation and the initiation of fatigue crack, and play a role of fine grain strengthening [13]. In addition, studies have pointed out that at high temperatures, the residual stress produced by LSP will disappear rapidly [14], and even the refined microstructure will recover and recrystallize [15], which will eventually lead to a significant decrease in the enhancement of LSP on thermal fatigue [16]. In conclusion, LSP has some advantages in improving the fatigue properties of materials. However, there is no consensus on whether LSP still has a good effect on prolonging fatigue life under thermal fatigue conditions, and research on the thermal fatigue crack initiation and propagation behavior after LSP is rarely reported.

In this study, the effect of LSP on the thermal fatigue properties of a ZCuAl10Fe3Mn2 alloy was investigated. The mechanism for extending the fatigue life of copper alloys by LSP was revealed by the comparison and analysis of the mechanical properties, surface morphology, and thermal fatigue properties of LSP samples under different process conditions, providing a theoretical basis for expanding the application range of cast copper alloys and guidance for the industrial production of enterprises.

2 Experimental

A commercially available ZCuAl10Fe3Mn2 alloy used in experiment was cut into thermal fatigue samples by wire-electrode cutting. The sample thickness was 5 mm. Figure 1(a) shows the dimensions of the sample and the oblique line area shows the laser strengthening area. The laser peening path is shown in Fig. 1(b).

A lamp-pumped high-energy solid-state laser system (Thales Laser Inc., France) was used for LSP. The spot diameter was 3 mm, with an overlap ratio of 50% and a pulse width of 20 ns. The K9 glass and a 0.3 mm-thick aluminum foil were used as the confinement and absorbent layers, respectively. Table 1 summarizes process conditions and parameters. The FM-ARS900 automatic micro- hardness tester was employed to test the hardness of the sample, the load was 2.8 N and the loading time was 15 s. MFP-3D scanning probe microscope was used to test the surface morphology and roughness of the sample, and X-350A residual stress tester was used to test the residual stress of the sample.

Fig. 1 Dimensions of sample for thermal fatigue test (a) and schematic diagram of LSP impact path (b) (unit: mm)

Table 1 Process conditions and parameters

The thermal fatigue test was carried out on an LRS1200 thermal fatigue testing machine. Samples for testing were mechanically polished and subsequently observed under an optical microscope, and the samples without defects such as cracks and pores in the notch area were selected for the thermal fatigue test. The sample was put into the thermal fatigue testing machine and heated it together. The circulating temperature was from (20±5) to (450±5) °C, and the temperature was maintained at the desired value for 120 s. Cooling was conducted by circulating water. The sample was placed into water at a depth of (15±1) mm, and its retention time in water was 10 s. Each completed heating and cooling process was defined as a cycle. After 1000 cycles, the sample was removed from the testing machine and examined using a Hitachi S-3400 scanning electron microscope (SEM) for investigating the microstructure and thermal fatigue crack initiation and propagation.

3 Results and discussion

3.1 Microhardness

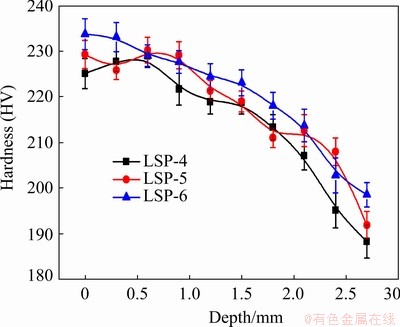

The microhardness of the as-cast alloy is HV 167.88. Figure 2 shows the microhardness of ZCuAl10Fe3Mn2 alloys after the LSP. LSP can significantly increase the surface hardness of the alloy, and the higher the pulse energy, the greater the hardness. At pulse energies of 4, 5, and 6 J, the alloy hardness values are increased by 34.10%, 36.58%, and 39.24%, respectively, compared with that of the as-cast alloy, and strengthening decreases as the depth from the peening surface increases. Moreover, when the depth exceeds 2.75 mm, the hardness improvement of the alloy affected by LSP is marginal.

Fig. 2 Microhardness curves in depth direction of ZCuAl10Fe3Mn2 alloys after laser shock strengthening

3.2 Surface morphology and roughness

Figure 3 shows the three-dimensional (3D) morphology of the peening surface of the alloys under four processing conditions. For the as-cast sample (Fig. 3(a)), the average height variation is between -0.28 and 0.265 μm due to the effect of wire-electrode cutting and sand paper grinding. After LSP treatment, the height variation range of the sample surface increases. At a pulse energy of 4 J (Fig. 3(b)), the average height variation is between -0.41 and 0.29 μm, while at a pulse energy of 6 J (Fig. 3(d)), the average height variation increases from -0.9 to 0.8 μm.

Figure 4 shows the surface roughness of the alloys under four processing conditions. The surface roughness increases with the increase of laser shock energy. The surface roughness of the as-cast sample is 0.151 μm. At laser pulse energies of 4, 5, and 6 J, the roughness values for the LSP samples are increased by 17.88%, 74.83%, and 124.50%, respectively.

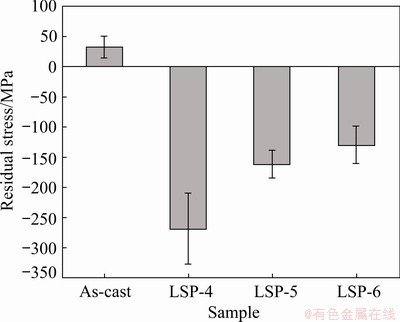

3.3 Residual stress

Figure 5 shows the effect of LSP on the residual stress on the alloy surface under four processing conditions. The as-cast sample surface exhibits a tensile stress of 32 MPa, corresponding to the micro-cutting effect during wire-electrode cutting and grinding on the sample surface. After LSP, the residual stress on the alloy surface becomes compressive. At a pulse energy of 4 J, the residual compressive stress of the sample surface reaches the maximum value of 268.5 MPa. Moreover, with the increase in the pulse energy, the residual compressive stress tends to decrease instead. Combined with the sample roughness results, the high pulse energy can cause melting or even ablation on the sample surface (especially the overlap area), leading to the release of stress and reduction of the residual stress.

Fig. 3 3D surface topographys of ZCuAl10Fe3Mn2 alloy before and after laser shock strengthening

Fig. 4 Surface roughness of ZCuAl10Fe3Mn2 alloys before and after laser shock strengthening

Fig. 5 Surface residual stress of ZCuAl10Fe3Mn2 alloys before and after laser shock strengthening

3.4 Thermal fatigue properties

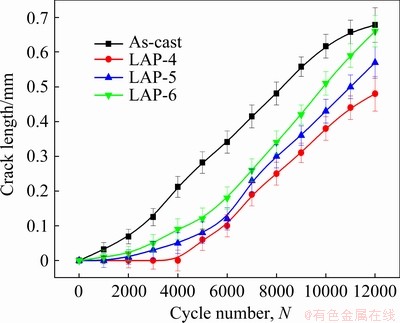

Figure 6 shows the thermal fatigue crack length curves of the four alloys versus the number of cooling and heating cycles. LSP treatment can effectively improve the thermal fatigue performance of the ZCuAl10Fe3Mn2 alloy, and the strengthening effect is directly related to the laser pulse energy. At a pulse energy of 4 J, the maximum improvement is observed, while it decreases with the continuous increase in the pulse energy. Thermal fatigue life is increased by 120% as the crack length is 0.1 mm, compared with that of the as-cast alloy. Considering the thermal fatigue conditions, thermal fatigue cracks usually initiate on the surface of materials. Further improvement in the thermal fatigue performance of materials rendered by LSP depends on not only the high- energy laser peening but also the comprehensive effect of the laser peening on the surface morphology, roughness, and stress state of materials.

Fig. 6 Thermal fatigue crack length of ZCuAl10Fe3Mn2 alloys versus number of cooling and heating cycles

3.5 Crack initiation and propagation

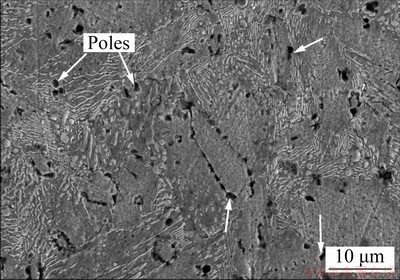

Figure 7 shows the microstructures and crack growth morphology at the notches of the as-cast and LSP-4 samples under cycling at 20-450 °C. Owing to the stress concentration of the notch, oxygen diffuses into the microstructure near the notch to form an oxidized region under the effect of alternating temperature and stress (Figs. 7(a) and (e)). With the increase in the stress state and oxidation, the microstructure becomes porous, and micro-cracks begin to form. During the thermal fatigue test, the sample vertically moves with the notch facing down; hence, the micro-cracks in this direction are subjected to the maximum stress and continue to grow into the main crack.

Although the growth of the main crack inhibits the growth of micro-cracks in other directions at the notch, plastic deformation still occurs and accumulates at the grain boundary due to the mismatch of the expansion coefficients between the matrix and grain boundary, leading to the growth of micro-cracks along the grain boundary and subsequent shedding (Fig. 8).

Fig. 7 Microstructures and thermal fatigue crack growth near gap of samples

Fig. 8 Microstructure exfoliation near gap of sample

In addition, in the late stage of thermal fatigue crack growth, when the thermal stress accumulated between the second phase and matrix is greater than the binding stress at the interface, micro-cracks emerge at locations far away from the notch and cause the second phase of the shedding of the alloy from the matrix. A large number of pores are formed in the matrix (Fig. 9). When the main crack grows here, it initiates and accelerates crack propagation.

It was pointed out that two forms of thermal fatigue crack growth existed [17]: the first was caused by passivation-sharpening at the crack tip, and the second was caused by the conjoining of voids at the front of the crack tip. From the above analysis, the alloy is strengthened by LSP, and the crack growth is mainly conducted by the second route. Compared with the as-cast sample, the main reasons why laser shock can improve the thermal fatigue properties of the ZCuAl10Fe3Mn2 alloy are as follows. On one hand, the residual compressive stress generated on the sample surface can consume the effect of alternating stress, thereby inhibiting the initiation of crack sources on the sample surface; on the other hand, the grain refinement of the alloy surface, rendering high hardness and a dense structure, can improve the oxidation resistance of the alloy and suppress from the shedding of materials.

Fig. 9 SEM micrograph of second phase abscission

4 Discussion

4.1 Microstructure strengthening

Figure 10 shows the microstructure of the LSP-4 sample. Clear grain refinement is observed in the impact area. By utilizing Image-Pro Plus image analysis software, the average grain size of the ɑ matrix phase is 93 μm, and the average grain size in the LSP-affected area is 57 μm, with a grain refinement of 38.7%. During LSP, high-energy plasma shock waves are transmitted into the material, causing atomic movement to form a large number of dislocations; macroscopically, this phenomenon is plastic deformation. According to the Orowan equation [18], there exists

ε=Kρχb (1)

where ε is the plastic deformation, K is the dislocation coefficient, ρ is the dislocation density, χ is the dislocation distance and b is the Burgers vector.

Fig. 10 Microstructure of LSP-4 sample

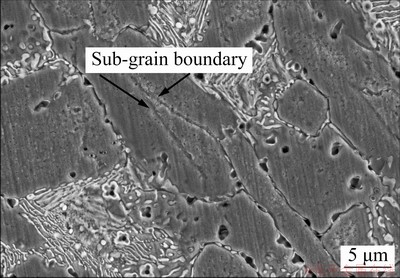

Large deformation induces a high dislocation density. When the plastic deformation reaches a certain level, dislocations align as walls and rings by gliding, multiplication, and such interactions to balance the system’s energy, dividing the original coarse strip grains into subgrains. The subgrain boundaries continue to develop into new grain boundaries, thus refining grains (Fig. 11).

Fig. 11 Microstructure of sub-grain

According to the Hall-Petch formula, there exists

(2)

(2)

where Hv is the hardness of the impact zone,  is the matrix hardness,

is the matrix hardness,  is the Hall-Petch constant and d is the grain size. After LSP, d decreases, Hv increases, and the mechanical properties of the alloy are improved.

is the Hall-Petch constant and d is the grain size. After LSP, d decreases, Hv increases, and the mechanical properties of the alloy are improved.

According to classic dislocation theory [19], there exists

(3)

(3)

where τp is the shear stress, α reflects the dislocation characteristics of the ratio between the dislocation length and the grain size, μ is the shear modulus, bp is the shockley local dislocation Burgers vector, d is the grain size, and r is the stacking fault energy.  is the stress generated at the subgrain boundary, and r/bp is the stacking fault energy. When the grains are refined, the grain size d is reduced, then increasing the shear stress τp and the resistance of dislocation movement. Both of the above points indicate that laser impact can strengthen the microstructure and properties of the alloy.

is the stress generated at the subgrain boundary, and r/bp is the stacking fault energy. When the grains are refined, the grain size d is reduced, then increasing the shear stress τp and the resistance of dislocation movement. Both of the above points indicate that laser impact can strengthen the microstructure and properties of the alloy.

4.2 Reserved compressive stress

The equivalent stress of the alloy’s thermal fatigue crack growth (σeff) can be expressed as

σeff=σf+σr (4)

where σr is the preset residual stress, and σf is the stress generated by the cooling and heating cycle. When σr is equal to σf, the equivalent stress σeff and the driving force for thermal fatigue crack growth decrease.

When the crack is initiated, the relationship between the critical stress of the fatigue crack σk and the stress intensity factor Kth is expressed as follows [20]:

(5)

(5)

where y is the specimen geometric constant, and a0 is the critical crack length. The threshold stress intensity factor of the crack growth is proportional to the fatigue limit, that is, the higher the fatigue limit of the material is, the greater the stress required for the thermal fatigue crack growth is.

According to the Goodman equation, the average stress (σm) at an alloy fatigue limit  can be expressed as follows:

can be expressed as follows:

(6)

(6)

where  is the standard fatigue limit of materials under symmetrical alternating loads, and σb is the tensile limit of material.

is the standard fatigue limit of materials under symmetrical alternating loads, and σb is the tensile limit of material.

When there is residual stress σr inside the alloy, there exists

(7)

(7)

From Eqs. (4)-(7), the fatigue limit increases with the increase in the residual compressive stress. Therefore, the preset compressive stress can effectively improve the thermal fatigue performance of the material.

In summary, after LSP treatment, plastic deformation occurs on the alloy surface, grains on the surface structure are refined, and residual compressive stress occurs. Under a combined effect, the thermal fatigue performance of the alloy is improved.

5 Conclusions

(1) Compared with the as-cast ZCuAl10Fe3Mn2 alloy, at laser pulse energies of 4, 5, and 6 J, the ZCuAl10Fe3Mn2 alloy hardness values are increased by 34.10%, 36.58%, and 39.24%, respectively; while the ZCuAl10Fe3Mn2 alloy roughness values are increased by 17.88%, 74.83%, and 124.50%, respectively.

(2) At a pulse energy of 4 J, ZCuAl10Fe3Mn2 alloy exhibits the best thermal fatigue performance, the average grain size of α phase is refined by 38.7%, the residual compressive stress reaches the maximum value of 268.5 MPa and thermal fatigue life is increased by 120% as the crack length is 0.1 mm compared with those of the as-cast alloy.

(3) The thermal fatigue crack of ZCuAl10- Fe3Mn2 alloy after laser shock strengthening mainly grows with the conjoining of contiguous voids at the crack tip front. The strengthening mechanism is fine grain strengthening and residual compressive stress strengthening.

Acknowledgments

The authors are grateful for the financial supports from the National Natural Science Foundation of China—Youth Project (51801076), the Provincial Colleges and Universities Natural Science Research Project of Jiangsu Province (18KJB430009), China, the Postdoctoral Research Support Project of Jiangsu Province (1601055C), China, and the Senior Talents Research Startup of Jiangsu University (14JDG126), China.

References

[1] LIU Ting, SI Nai-chao, LIU Guang-lei, ZHANG Rui, QI Chang-yang. Effects of Si addition on microstructure, mechanical and thermal fatigue properties of Zn-38Al- 2.5Cu alloys [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(7): 1775-1782.

[2] TAN Qing, YAN Zhi-ran, HUANG Hua, LI Shi-lei, WANG Yan-dong, FENG Ye-fei, ZHOU Xin, LI Ying-hong, REN Yang, ANTONOV S. Surface integrity and oxidation of a powder metallurgy Ni-based superalloy treated by laser shock peening [J]. Journal of Metals, 2020, 72(5): 1803-1810.

[3] GLODEZ S, KLEMENC J, ZUPANIC F, VESENJAK M. High-cycle fatigue and fracture behaviours of SLM AlSi10Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(10): 2577-2589.

[4] PARK J, YEO I, JANG I, JEONG S. Improvement of friction characteristics of cast aluminum-silicon alloy by laser shock peening [J]. Journal of Materials Processing Technology, 2019, 266: 283-291.

[5] LU Ying, LI Song-xia, QIAO Hong-chao, QU Nan, ZHAO Ji-bing, HU Tai-you. Surface microstructure evolution analysis of TiAl alloy by laser shock peening [J]. Rare Metal Materials and Engineering, 2019, 48(3): 841-846.

[6] LU Jin-zhong, LU Hai-fei, XU Xiang, YAO Jian-hua, CAI Jie, LUO Kai-yu. High-performance integrated additive manufacturing with laser shock peening-induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components [J]. International Journal of Machine Tools & Manufacture, 2019, 148: 10347.

[7] HU Yong-xiang, YANG Ruo-yu, WANG Dong-yu, YAO Zhen-qiang. Geometry distortion and residual stress of alternate double-sided laser peening of thin section component [J]. Journal of Materials Processing Technology, 2018, 251: 197-204.

[8] YIN Mei-gui, CAI Zhen-bing, LI Zhen-yang, ZHOU Zhong-rong, WANG Wen-jian, HE Wei-feng. Improving impact wear resistance of Ti-6Al-4V alloy treated by laser shock peening [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(7): 1439-1448.

[9] CUI C Y, WAN T Y, SHU Y X, MENG S, CUI X G, LU J Z, LU Y F. Microstructure evolution and mechanical properties of aging 6061 Al alloy via laser shock processing [J]. Journal of Alloys and Compounds, 2019, 803: 1112-1118.

[10] MENG Xian-kai, ZHOU Jian-zhong, SU Chun, HUANG Shu, LUO Kai-Yu, SHENG Jie, TAN Wen-sheng. Residual stress relaxation and its effects on the fatigue properties of Ti6Al4V alloy strengthened by warm laser peening [J]. Materials Science and Engineering A, 2017, 680: 297-304.

[11] GUO Kuai-kuai, LIU Chang-sheng, CHEN Sui-yuan, DONG Huan-huan, WANG Si-yu. High pressure EIGA preparation and 3D printing capability of Ti-6Al-4V powder [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(1): 147-159.

[12] CHEN Lan, REN Xu-dong, ZHOU Wang-fan, TONG Zhao-peng, ADU G S, YE Yun-xia, REN Yun-peng. Evolution of microstructure and grain refinement mechanism of pure nickel induced by laser shock peening [J]. Materials Science and Engineering A, 2018, 728: 20-29.

[13] LUO Si-hai, HE Wei-feng, ZHOU Liu-cheng, NIE Xiang-fan, LI Ying-hong. Aluminizing mechanism on a nickel-based alloy with surface nanostructure produced by laser shock peening and its effect on fatigue strength [J]. Surface and Coatings Technology, 2018, 342: 29-36.

[14] REN Xu-dong, TONG Zhao-peng, ZHOU Wang-fan, CHEN Lan, REN Yun-peng, DAI Feng-ze, YE Yun-xia, ADU G S, YANG Jin-de, LI Lin. High temperature wear performance of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy subjected to laser shock peening [J]. Materials Science and Technology, 2018, 34(18): 2294-2304.

[15] LU H F, LUO K Y, WU L J, CUI C Y, LU J Z. Effects of service temperature on tensile properties and microstructural evolution of CP titanium subjected to laser shock peening [J]. Journal of Alloys and Compounds, 2019, 770: 732-741.

[16] CAO Jiang-dong, ZHANG Jun-song, HUA Yin-qun, CHEN Rui-fang, YE Yun-xia. Improving the high temperature oxidation resistance of Ni-based superalloy GH202 induced by laser shock processing [J]. Journal of Materials Processing Technology, 2017, 243: 31-39.

[17] CHEN Kui-wa, PAN Su-ping, LIU Hui-qun, JIANG Yong. Effect of alpha phase morphology on fatigue crack growth behavior of Ti-5Al-5Mo-5V-1Cr-1Fe alloy [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(9): 2459-2471.

[18] HUANG Rui, LI Qing-jie, WANG Zhang-jie, HUANG Ling, LI Ju, MA E, SHAN Zhi-wei. Flow stress in submicron BCC iron single crystals: sample-size-dependent strain-rate sensitivity and rate-dependent size strengthening [J]. Materials Research Letters, 2015, 3(3): 121-127.

[19] LI Y, BUSHBY A J, DUNSTA D J. The Hall-Petch effect as a manifestation of the general size effect [J]. Proceedings of the Royal Society A: Mathematical Physical and Engineering Sciences, 2016, 472(2190): 20150890.

[20] FERREIRA S E, de CASTRO J T P, MEGGIOLARO M A, MIRANDA A C D. Crack closure effects on fatigue damage ahead of crack tips [J]. International Journal of Fatigue, 2019, 125: 187-198.

刘光磊1,2,曹宇豪1,杨 坤1,郭 伟1,孙小轩1,赵 玲1,司乃潮1,周建忠2

1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 江苏大学 机械工程学院,镇江 212013

摘 要:为了提高高温构件的热疲劳性能、减少表面裂纹,研究激光冲击对ZCuAl10Fe3Mn2合金硬度、表面形貌、残余应力和热疲劳性能的影响。采用扫描电子显微镜(SEM)和能谱仪(EDS)分析合金的显微组织和裂纹形貌。结果表明:在4 J脉冲能量下,激光冲击能显著改善合金的热疲劳性能。在热应力和交变应力的作用下,试样缺口附近组织氧化而变得疏松多孔,促使萌生多条微裂纹。其中,竖直方向的微裂纹变为主裂纹,主要以裂尖前沿空洞连体的形式扩展;其他方向的微裂纹沿晶界生长而发生组织脱落现象。

关键词:铜合金;激光冲击强化;表面形貌;热疲劳性能;裂纹萌生;裂纹扩展

(Edited by Wei-ping CHEN)

Corresponding author: Guang-lei LIU; Tel: +86-13861393054; E-mail: liugl@ujs.edu.cn

DOI: 10.1016/S1003-6326(21)65558-9

1003-6326/ 2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press