镍红土矿硫酸常压浸出液高温水解除杂

石文堂,李栋,郭学益

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘要:以硫酸常压浸出液为原料,以腐殖土为中和剂,采用高温水解法对其进行净化除杂研究。在探讨除杂原理的基础上,考察水解温度、时间、腐殖土加入量和加入方式对杂质脱除率的影响。研究结果表明:水解反应前每升溶液加入腐殖土100 g,在220 ℃下反应1 h,常压浸出液中的铁、铬、铝的脱除率分别达到96.19%,93.32%和93.99%,同时镍、钴、镁、锰的回收率均在99%以上;水解渣成分以Fe2O3为主,具有良好的过滤性能;高压釜结垢中含有Fe2O3,NaAl3(SO4)2(OH)6和FeOHSO4,结垢方式为沉积式结垢,易清理。

关键词:镍红土矿;常压浸出液;水解;腐殖土;结垢

中图分类号:TF815 文献标志码:A 文章编号:1672-7207(2011)09-2571-06

Removal of impurities in atmosphere leaching liquor of nickel laterite by high temperature hydrolysis

SHI Wen-tang, LI Dong, GUO Xue-yi

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The hydrolysis process at high temperature was adopted to remove the impurities in atmosphere leaching liquor when the saprolite was used as a neutralizer. Based on the hydrolysis principles, the effects of hydrolysis temperature and time, the adding amount and methods of the saprolite on the removal of impurities were investigated. The results show that 96.19% iron, 93.32% chromium and 93.99% aluminum in liquor are removed when the saprolite of 100 g/L solution is added before hydrolysis process at 220 ℃ for 1 h and more than 99% of nickel, cobalt, magnesium and manganese are recovered. The residue with fine filtration performance consists chiefly of Fe2O3. The scale formed as a deposition in hydrolysis process consists of Fe2O3, NaAl3(SO4)2(OH)6 and FeOHSO4 and they are easily removed.

Key words: nickel laterite; atmosphere leaching liquor; hydrolysis; saprolite; scale

镍具有较大的机械强度和较强的延展性,主要用于不锈钢、高温合金、电镀和化工等行业,在国民经济中具有极其重要的地位[1]。据统计,2003年全球陆地镍矿资源中有72%的镍赋存于镍红土矿中,而其产量只占镍总产量的42%[2]。随着镍硫化矿的日益枯竭,镍红土矿资源的开发和利用成为当前研究的重点。镍红土矿处理主要分为火法和湿法:火法处理工艺具有投资成本低、处理量大等优点,但是,该工艺能耗高,一般处理品位较高的腐殖土型镍红土矿,褐铁矿和过渡层矿则适合采用湿法冶金工艺处理[3]。目前,世界上主要采用硫酸加压浸出、硫酸或盐酸常压浸出以及还原焙烧-氨浸等湿法工艺处理镍红土矿,其中还原焙烧-氨浸工艺由于能耗高、金属回收率低等缺点,限制了该工艺的进一步大规模应用[4-5]。硫酸加压浸出工艺和常压浸出工艺被广泛认为是未来低品位镍红土矿处理的主要方法,近年来国际上在这方面的研究较多,并提出了硫酸常压浸出、盐酸常压浸出、还原控电浸出、硫酸熟化—焙烧—浸出、加压—常压联合浸出(AMAX工艺)、BHP-Billiton的EPAL加压浸出等工艺流程[6-11]。其中,常压浸出工艺具有投资省、建设周期短、过程易于控制、维护成本低等优点,但也存在着酸耗高、高含铁浸出液难以处理等不足。加压浸出工艺虽然金属回收率高、酸耗低,但是,由于其反应条件苛刻,造成设备投资大、建设周期长,同时还存在反应釜容易结垢,需定期停产处理等缺点[12-13]。在此,本文作者以镍红土矿硫酸常压浸出液为原料,采用高温水解法对溶液进行净化除杂,研究水解温度、时间以及腐殖土加入量及形式对除杂效果的影响,探讨水解过程各金属的行为。

1 硫酸浸出液高温水解除杂反应机理

硫酸浸出液高温水解除杂过程以铁的沉淀分离为主要目的,同时涉及铝和铬的沉淀行为[14]。

过渡层红土矿的硫酸常压浸出液中Fe3+质量浓度较高,一般在10~30 g/L之间。赤铁矿(Fe2O3)是Fe3+含高温水解的主要产物,温度和酸浓度是影响赤铁矿形成的主要因素。图1所示为25~200 ℃时lg ρ(Fe3+)- pH关系图,其表明温度越高,越有利于在较高的酸度条件下沉铁。同时,反应过程还必须考虑硫酸盐的影响。当温度高于150 ℃时,硫酸介质中Fe3+的水解随酸度的改变具有不同的反应历程:低酸度时,式(1)为主要反应;高酸度时,式(2)为主要反应。

2Fe3++3H2O=Fe2O3+6H+ (1)

Fe3++SO42-+H2O=Fe(OH)SO4+H+ (2)

在有Na+,K+或NH4+存在的情况下,赤铁矿存在的酸度范围也会缩小。这是由于它们的存在可引起赤铁矿沉淀与黄铁矾沉淀相竞争,反应如下:

3Fe3++M+2SO42-+6H2O=MFe3(SO4)2(OH)6+6H+

(M=Na+,K+或NH4+) (3)

若硫酸浸出液中含有一定量的Al3+,则高温水解过程会生成草明矾或明矾等固体:

3Al3++2SO42-+7H2O=H3O·Al3(SO4)2(OH)6+5H+ (4)

3Al3++2SO42-+M+6H2O=MAl3(SO4)2(OH)6+6H+

(M=Na+,K+或NH4+) (5)

铬在水解过程中以CrO42-形式存在,并部分取代SO42-进入草明矾或明矾晶格,其取代比例可高达30%[15]。

图1 Fe3+水解平衡时lg ρ(Fe3+)-pH关系图

Fig.1 Effect of temperature and pH on ferric ion concentration in solution

2 实验

2.1 原料

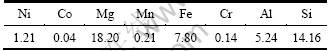

本实验处理的原料为过渡层红土矿的常压硫酸浸出液。该浸出液采用常压硫酸浸出工艺处理菲律宾南部MATI矿区矿床中层的过渡层红土矿而获得,其溶液组成如表1所示。由表1可知:该浸出液中的铁镍质量比约为5:1,远高于高压浸出液中的铁镍质量比(一般为0.1:1~0.5:1),如果采用常规的中和法除铁,将会造成镍的大量损失[16]。因此,该浸出液适合采用高温水解法除铁及其他杂质。

表1 过渡层红土矿常压浸出液的组成(质量浓度)

Fig.1 Assay of atmosphere acid leaching liquor of transition laterite g/L

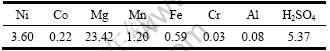

在高温除杂过程中,加入腐殖土层红土矿以中和产生的酸。该腐殖土同样来自菲律宾南部MATI矿区,属于矿床下层红土矿。将腐殖土于110 ℃烘干,细磨至粒度小于150 μm后,其主要化学成分见表2。从表2可以看出:矿中镁含量较高(达到18.2%),说明腐殖土中存在大量的耗酸物质,适宜于作为酸中和剂,同时还可以利用水解产生的酸浸出腐殖土中的有价金属镍和钴,因此,采用腐殖土作为中和剂具有双重效果。腐殖土的物相结构(见图2)分析表明:其主要成分为Mg3Si2O5(OH)4和FeOOH。

表2 腐殖土型红土矿的主要化学成分(质量分数)

Table 2 Assay of saprolitic laterite ore %

图2 腐殖土型红土矿的XRD图

Fig.2 XRD analysis of saprolitic laterite

2.2 装置与设备

实验主要装置与设备有:GSH-5L-TA2型磁力旋转搅拌高压釜及配套加热控制器(威海坤昌制造);SHZ-D(III)型真空抽滤机(上海大研制造);GZX-9030型真空干燥箱(上海博讯制造)。

2.3 工艺流程

浸出液的高温水解过程是在密闭的加压釜中进行。将3 L浸出液加入到加压釜中,覆盖密封后升温到指定温度,反应一定时间;反应结束后,通冷却水将反应釜内溶液温度迅速降至85 ℃以下;将矿浆转移至外置容器并进行真空抽滤,滤液直接送化学分析;滤渣经洗涤、烘干,并分析其化学成分和物相结构。

2.4 分析检测

采用D/Max-2550型X线衍射仪(XRD,日本JEOL制造)分析固体原料及产物的物相结构;采用Varian 720-ES型电感耦合等离子光谱发生仪(ICP,美国VARIAN制造)测定原浸出液及反应后溶液中金属离子浓度;采用PHB-3型酸度计(上海雷磁制造)测定反应后溶液的pH。

3 结果与讨论

实验主要考察水解温度、水解时间、腐殖土加入量及加入形式等因素对杂质脱除率的影响。

3.1 水解温度的影响

在水解时间为1 h,不添加任何试剂的情况下,控制水解温度为180~250 ℃,获得溶液中各元素的沉淀率如图3所示。

图3 水解温度对各金属沉淀率的影响

Fig.3 Effect of hydrolysis temperature on metals precipitation efficiencies

由图3可知:在高温水解过程中,溶液中的镍、钴、镁和锰基本不被沉淀,不受温度变化的影响;同时,随着水解温度的提高,溶液中金属杂质元素铁、铬和铝的含量明显下降,说明水解温度越高,杂质元素铁、铝和铬水解沉淀越高。水解温度从180 ℃上升到230 ℃过程中,其杂质脱除率明显提高,但是,在水解温度230~250 ℃时,其变化趋缓。这是由于230 ℃时水的饱和蒸汽压为2.79 MPa,而220 ℃时水的饱和蒸汽压仅为2.31 MPa。考虑到操作的经济性,选择220 ℃为最佳反应温度。

红土镍矿硫酸高压浸出过程中温度一般高于250 ℃,其操作压力大于4.0 MPa。与其相比,高温水解过程虽然温度仅降低30 ℃,但是,实际生产中加压釜的壁厚将减少一半以上,从而大大降低了投资,同时也大大降低实际生产中的能耗。

3.2 水解时间的影响

在水解温度为220 ℃,不添加任何试剂的情况下,控制反应时间为0.5~2 h,获得溶液中各金属元素的回收率如图4所示。

由图4可见:220 ℃下水解时间对溶液中镍、钴、镁和锰含量基本没有影响,而铁、铬和铝则快速沉淀,1 h后即达到平衡,浸出率分别为87.35%、58.82%和44.96%。同时随着水解时间从30 min增加至60 min,溶液的pH从0.78下降到0.45;继续增加水解时间,pH基本不变。因此,选择水解时间为1 h。

图4 水解时间对各金属沉淀率的影响

Fig.4 Effect of hydrolysis time on metals precipitation efficiencies

3.3 腐殖土加入量及加入方式的影响

水解温度的升高以及水解时间的延长会使溶液的pH逐渐降低,使Fe3+的水解程度受到限制,致使溶液中剩余的Fe3+质量浓度仍然较高,基本维持在2 g/L左右,因此,必须降低溶液酸度才能够进一步降低溶液中Fe3+的质量浓度。

本实验中采用腐殖土来中和溶液中的酸。腐殖土加入方式有2种:一是在高温水解除铁完成后,再进行常压腐殖土中和;二是在高温水解前加入一定量的腐殖土,再进行水解除铁。各金属沉淀率按以下公式计算:

WA=[mp/(ml+ms)] ×100%

式中:Wa表示金属A的沉淀率;mp表示沉淀固体中的金属A质量;ml表示硫酸常压浸出液中的金属A质量;ms表示加入腐殖土中的金属A质量。

对水解温度220 ℃、水解时间1 h条件下得到的水解后液进行腐殖土常压中和,考察腐殖土加入量对溶液中各杂质元素脱除率的影响。腐殖土中和过程条件如下:中和温度为85 ℃,时间为2 h,每升溶液腐殖土加入量为50~130 g。

图5所示为水解过程后腐殖土加入量对各金属沉淀率的影响。由图5可知:随着腐殖土加入量的增加,溶液中铁、铬和铝的沉淀率逐渐升高。但是,在中和浸出过程中,腐殖土中的铁、铝、镁、锰和铬等杂质也被浸出,使得溶液中的杂质含量升高。同时,随着腐殖土加入量的增加,腐殖土中镍和钴的浸出率也随之下降,从而造成镍和钴的损失。因此,采用水解反应后加入腐殖土的方式虽然可以达到中和水解产生的游离酸以及浸出腐殖土中部分镍钴的目的,但是,该中和方式还容易造成溶液中杂质离子含量上升,不利于溶液的除杂,同时,中和渣中镍和钴的含量较高,镍和钴的回收率较低。

由于腐殖土矿的主要组成为Mg3Si2O5(OH)4和FeOOH,其中和浸出过程的实质是氧化镁和氧化铁发生酸溶解,从本质上破坏硅酸盐矿和针铁矿物质。其主要反应如下:

Mg3Si2O5(OH)4+6H+=3Mg2++2SiO2+5H2O (6)

FeOOH+3H+=Fe3++2H2O (7)

图5 水解过程后腐殖土加入量对各金属沉淀率的影响

Fig.5 Effect of saprolitic laterite addition on metals precipitation efficiencies after hydrolysis process

采用第2种方式进行中和浸出:在水解反应前将腐殖土加入到硫酸常压浸出液中,并在温度为220 ℃、时间为1 h条件下进行水解,考察腐殖土加入量对溶液中各杂质元素脱除率的影响。

图6所示为水解过程前腐殖土加入量对各金属沉淀率的影响。从图6可知:随着腐殖土加入量的增加,溶液中的铁、铬和铝沉淀率不断升高,并在每升溶液加入量为100 g时达到最大,分别为96.19%,93.32%和93.99%;继续增加腐殖土加入量,铁、铬、铝沉淀率出现小幅下降的趋势,这主要是由于腐殖土中的存在一定量的Fe2+,并随着加入量的增加而不断累积(经分析,除杂后液中60%的残留铁离子为Fe2+)。同时,随着腐殖土加入量从每升50 g增加到130 g,溶液pH由0.53上升到1.05,与未加入腐殖土的情况相比,溶液中的铁、铝、铬沉淀率大幅度提高。溶液中镍、钴、镁和锰沉淀率随腐殖土加入量增加而逐渐升高,但升高幅度不大,其沉淀率维持在4%以下,这主要是因为腐殖土的逐渐增加不断降低水解过程溶液的H+浓度,腐殖土中的镍、钴、镁和锰等金属浸出率逐渐降低。因此,选择每升溶液腐殖土加入量为100 g。

图6 水解过程前腐殖土加入量对各金属沉淀率的影响

Fig.6 Effect of saprolitic laterite addition on metals precipitation efficiencies before hydrolysis process

表3 水解后液的组成(质量浓度)

Table 3 Assay of liquor produced in hydrolysis process g/L

通过以上研究,确定硫酸常压浸出液水解过程最优条件为:水解温度220 ℃,水解时间1 h,在水解反应前每升溶液加入腐殖土100 g。在此条件下,获得水解后液的组成如表3所示。对比表1和表3可知:溶液中铁、铬和铝的质量温度分别由最初的15.7,0.47和1.40 g/L下降到了0.59,0.03和0.08 g/L,除杂效果十分明显。

3.4 水解渣和加压釜结垢分析

对最优条件下的水解渣进行化学成分分析和XRD分析,其结果分别见表4和图7(a)。

从表4可知:水解渣中Fe和Si的含量较高,分别达到40%和10%以上,其中Fe主要来自常压浸出液,而Si则全部来自于腐殖土。由图7可见:水解渣中的物相主要以Fe2O3为主,还含有少量SiO2和NaAl3(SO4)2(OH)6,说明在水解条件下,腐殖土中的FeOOH转变成了Fe2O3,Mg3Si2O5(OH)4中的MgO发生溶解,SiO2被残留在水解渣中。该渣具有良好的过滤性能。

表4 水解渣的化学成分分析(质量分数)

Table 4 Assay of residue produced in hydrolysis process %

图7 水解渣(a)和结垢(b)的XRD分析

Fig.7 XRD analysis of residue and scale produced in hydrolysis process

图7(b)所示为水解过程中加压釜结垢的XRD图。与水解渣相比,结垢中不存在SiO2,除含有Fe2O3和NaAl3(SO4)2(OH)6外,还存在碱式硫酸铁(FeOHSO4)。实验过程表明:常压浸出液高温水解过程中的结垢现象并不严重,其结垢速率远比镍红土矿直接高压浸出过程的结垢速率低,可以大大延长加压釜的操作周期;同时,该结垢为沉积式结垢,易清理,可以通过加强搅拌强度消除或减轻该结垢的形成。

4 结论

(1) 采用高温水解法直接对红土矿硫酸常压浸出液进行除杂,确定最佳水解温度和时间分别为220 ℃和1 h,杂质Fe,Cr和Al的脱除率分别为87.35%,58.82%和44.96%。

(2) 在水解反应前加入腐殖土进行中和,浸出液除杂深度大幅提高;每升溶液最佳加入量为100 g,Fe,Cr和Al的脱除率分别达到96.19%,93.32%和93.99%,而水解过程中镍、钴、镁和锰几乎不被沉淀,其回收率均达到99%以上。

(3) 水解渣主要成分为Fe2O3, 还含有少量SiO2和NaAl3(SO4)2(OH)6;加压釜结垢中主要含Fe2O3,NaAl3(SO4)2(OH)6和FeOHSO4,为沉积式结垢,容易清理。

(4) 与常规的镍红土矿常压浸出-中和除杂工艺相比,该工艺具有镍和钴回收率高、酸耗低、渣量小等优点。同时,由于水解温度(220 ℃)低于加压浸出工艺所需温度(>250 ℃),其投资成本和生产运行成本大大降低。

参考文献:

[1] 张友平, 周渝生, 李肇毅, 等. 红土矿资源特点和火法冶金工艺分析[J]. 铁合金, 2007(6): 18-21.

ZHANG You-ping, ZHOU Yu-sheng, LI Zhao-yi, et al. Characteristics of laterite resource and analysis on its pyrometallurgy process[J]. Ferro-Alloys, 2007(6): 18-21.

[2] Guo X, Li D, Park K H, et al. Leaching behavior of metals from a limonitic nickel laterite using a sulfation-roasting-leaching process[J]. Hydrometallurgy, 2009, 99(3/4): 144-150.

[3] 刘大星. 从镍红土矿中回收镍、钴技术的进展[J]. 有色金属, 2002(3): 6-10.

LIU Da-xing. Recent development in nickel and cobalt recovery technologies from laterite[J]. Nonferrous Metals, 2002(3): 6-10.

[4] 徐庆新. 红土矿的过去与未来[J]. 中国有色冶金, 2005, 12(6): 1-8.

XU Qing-xin. The past and the future of nickel laterites[J]. China Nonferrous Metallurgy, 2005, 12(6): 1-8.

[5] 周晓文, 张建春, 罗仙平. 从红土镍矿中提取镍的技术研究现状及展望[J]. 四川有色金属, 2008(1): 18-22.

ZHOU Xiao-wen, ZHANG Jian-chun, LUO Xian-ping. The current situation and prospects of the process and technology of nickel extraction from laterite-nickel ore[J]. Sichuan Nonferrous Metals, 2008(1): 18-22.

[6] 刘瑶, 丛自范, 王德全. 对低品位镍红土矿常压浸出的初步探讨[J]. 有色矿冶, 2007, 23(5): 28-30.

LIU Yao, CONG Zi-fan, WANG De-quan. Primary probe into normal atmospheric leaching of low-nickel laterites[J]. Nonferrous Mining and Metallurgy, 2007, 23(5): 28-30.

[7] Geogiou D, Papangelakis V G. Sulphuric acid pressure leaching of a limonitic laterite: Chemistry and kinetics[J]. Hydrometallurgy, 1998, 49(1/2): 23-46.

[8] Kar B B, Swamy Y V. Some aspects of nickel extraction from chromitiferous overburden by sulphatization roasting[J]. Minerals Engineering, 2000, 13(14/15): 1635-1640.

[9] 畅永锋, 翟秀静, 符岩, 等. 稀酸浸出还原焙烧红土矿时铁还原度对浸出的影响[J]. 东北大学学报: 自然科学版, 2008, 29(12): 1738-1741.

CHANG Yong-feng, ZHAI Xiu-jing, FU Yan, et al. Effect of iron reduction degree on leaching results of pre-reduced laterites ores with thin acid[J]. Journal of Northeastern University: Natural Science, 2008, 29(12): 1738-1741.

[10] Lee H Y, Kim S G, Oh J K. Electrochemical leaching of nickel from low grade laterites[J]. Hydrometallurgy, 2005, 77(3/4): 263-268.

[11] Duyvesteyn W P, Lastra M R, Liu H. Method for recovering nickel from high magnesium-containing Ni-Fe-Mg lateritic ore. US, 5571308[P]. 1996-11-05.

[12] 翟秀静, 符岩, 畅永锋, 等. 表面活性剂在红土镍矿高压酸浸中的抑垢作用[J]. 化工学报, 2008, 59(10): 2573-2576.

ZHAI Xiu-jing, FU Yan, CAHNG Yong-feng, et al. Effect of surfactant on laterite ore slurry properties and scale formation in high pressure acid leaching[J]. Journal of Chemical Industry and Engineering, 2008, 59(10): 2573-2576.

[13] 李建华, 程威, 肖志海. 红土镍矿处理工艺综述[J]. 湿法冶金, 2004, 23(4): 191-194.

LI Jian-hua, CHENG Wei, XIAO Zhi-hai. Review on process technologies of laterite -nickel ore[J]. Hydrometallurgy of China, 2004, 23(4): 191-194.

[14] 陈家镛, 于淑秋, 伍志春. 湿法冶金中铁的分离与利用[M]. 北京: 冶金工业出版社, 1991: 164-170.

CHEN Jia-yong, YU Shu-qiu, WU Zhi-chun. Separation and utilization of iron in hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 1991: 164-170.

[15] Mcdonald R G, Whittington B I. Atmospheric acid leaching of nickel laterites review Part I. Sulfuric acid technologies[J]. Hydrometallurgy, 2008, 91(1/2/3/4): 35-55.

[16] Senanayake G, Das G K. A comparative study of leaching kinetics of limonitic laterite and synthetic iron oxides in sulfuric acid containing sulfur dioxide[J]. Hydrometallurgy, 2004, 72(1/2): 59-72.

(编辑 杨幼平)

收稿日期:2010-08-11;修回日期:2010-10-13

基金项目:湖南省科技计划重点项目(2009GK2010)

通信作者:郭学益(1966-),男,湖南长沙人,教授,博士生导师,从事有色金属资源循环与环境材料研究;电话:0731-88877863;E-mail: xyguo@csu.edu.cn