文章编号:1004-0609(2009)08-1379-06

在AZ91D表面SHS反应热喷涂Al-CuO系

Al2O3基复相陶瓷涂层

马 壮,林 鹏,董世知,李智超

(辽宁工程技术大学 材料科学与工程学院,阜新 123000)

摘 要:采用SHS反应火焰喷涂技术,把Al-CuO系铝热剂引入到喷涂材料中,在AZ91D表面制备了Al2O3基复相陶瓷涂层。结果表明:SHS反应热喷涂层综合性能明显优于传统热喷涂层,传统热喷涂层的热震次数、开气孔率、耐蚀性和耐磨性分别为14次、17.4%、基体的24倍和8.5倍;而反应热喷涂层则分别为40次、15.2%、基体的37倍和10.6倍。若辅以Ni-Al合金打底,喷后重熔工艺可使反应喷涂层的综合性能进一步提高。

关键词:AZ91D镁合金;SHS反应热喷涂;陶瓷涂层

中图分类号:TG 148 文献标识码:A

Al2O3- based multiphase ceramic coating of Al-CuO system prepared by SHS reaction thermal spraying on AZ91D

MA Zhuang, LIN Peng, DONG Shi-zhi, LI Zhi-chao

(College of Materials Science and Engineering, Liaoning Technical University, Fuxin12300, China)

Abstract: With SHS reaction flame spraying, Al2O3-based multiphase ceramic coating was prepared on AZ91D by introducing Al-CuO thermite into spraying materials. The results indicate that, the comprehensive properties of reaction spraying coatings are better than those of traditional ones. The thermal-shock times of traditional spraying coating is 14, the open porosity is 17.4%, the corrosion resistance and wear resistance are 24 and 8.5 times of those of the substrate, respectively, while those of the reaction ones are 40, 15.2%, 37 and 10.6, respectively. If adding Ni-Al alloy as the render and remelting after spraying, the comprehensive properties of reaction spraying coatings can be improved further.

Key words: AZ91D magnesium alloy; SHS reaction thermal spraying; ceramic coating

为解决镁合金耐磨、耐蚀和耐热性差等问题,经常在镁合金表面制备一层陶瓷涂层。常用的制备涂层方法有化学或物理气相沉积、激光熔覆、等离子喷涂等,而采用工艺设备简单、成本较低的氧?乙炔火焰喷涂方法制备涂层在国内外研究很少,只有叶宏等[1]和本文作者的前期工作[2]对此进行了尝试,采用的都是传统的火焰喷涂,虽取得一定进展,但仍存在诸如涂层生粉较多、组织疏松、结合强度差等问题。因为在传统的热喷涂中,陶瓷相常采用外加复合的方式预制在喷涂原材料中,所以涂层中陶瓷相分布不均匀,粒度较大,结合界面易受污染,大大影响涂层的性能[3?6]。而近年来发展起来的反应热喷涂将自蔓延高温合成(SHS)与热喷涂技术相结合,在合成材料的同时将合成材料沉积,涂层中的陶瓷相是原位合成的,结合界面洁净[7],而且反应放出的热量可作为第二热源进一步提高喷涂材料的熔融程度,有助于改善涂层的综合性能。目前,这种方法在钢基体上应用较多[8?10],而在镁合金基体上的应用在国内外文献中还未见报道。本文作者认为,利用SHS反应火焰喷涂技术在镁合金表面制备陶瓷涂层比在钢基体上制备陶瓷涂层更具应用前景,这是因为:1) 在喷涂火焰和SHS反应放出的反应热的双重作用下,由于镁合金熔点比钢低,所以表面更容易发生微熔化,有利于和涂层形成牢固的冶金结合;2) 由于Mg化学活动性比钢强,更容易和喷涂材料发生化学反应,和涂层形成较强的化学结合;3) 镁及其合金质地较软,塑韧性比钢好得多,使得喷涂粒子在喷枪的加速作用下更容易在其表面上沉积并发生嵌合,从而形成更牢固的机械结合。这些因素都将有助于提高涂层的结合强度,改善涂层的综合性能。

本文作者把Al-CuO系铝热剂引入到Al2O3基陶瓷骨料中,采用SHS反应火焰喷涂技术在镁合金表面制备复相陶瓷涂层,并对其结构、抗热震性、致密性、耐蚀性、耐磨性等性能进行研究。

1 实验

1.1 试验材料

基体材料为AZ91D,喷涂材料由陶瓷骨料Al2O3-20%TiO2复合粉末和由Al、CuO组成的铝热剂粉末两部分组成,Al和CuO质量比为3?1,喷涂材料粉末粒度为44~74 μm。为更好地探讨反应热喷涂中铝热剂对涂层质量和性能的作用机理,本试验也制备了喷涂材料为Al2O3-20%TiO2纯陶瓷粉末和喷涂材料为Al+(Al2O3-20%TiO2)的两种传统喷涂试样以进行对比。试样编号及喷涂材料配比如表1所列。

表1 喷涂材料

Table 1 Spraying materials components

1.2 涂层制备

本研究采用QT-E2000?7/H型两用火焰喷枪进行喷涂,工艺参数如表2所列。由于喷涂材料在空中飞行的时间极短,其中的铝热剂可能来不及反应或反应不充分就沉积到基体上,不能充分发挥作用。而喷后重熔处理则可以使铝热剂喷到基体上后继续发生反应,并可提高涂层的致密性和结合强度。但由于镁合金熔点过低,重熔过度,会使基体熔化甚至点燃,因此,在喷前先喷一层Ni-Al过渡层,既可起到防止基体熔化的作用,还可降低因镁合金基体与涂层热膨胀系数差异而引起的热应力。本研究在反应热喷涂工艺C1的基础上制备了喷前Ni-Al合金打底、喷后重熔的试样(编号为C2,Ni-Al过渡层厚度约为100 μm)。为探讨孔隙率对涂层耐蚀性影响,还制备了喷后清漆封孔的试样(编号为C3)。

表2 喷涂工艺参数

Table 2 Parameters of spraying process

1.3 涂层性能结构测试

采用日本理学D/MAX-RB型X射线衍射仪对涂层进行物相分析;采用SSX?550型扫描电镜进行形貌分析;将试样在400 ℃箱式电阻炉中恒温加热15 min,然后取出迅速淬入室温水中,如此循环进行,直至涂层出现裂纹或剥落,用循环次数表征涂层的抗热震性和结合强度[11?12];用浮力法测试涂层开气孔率以评定其致密性;将各试样在浓度为3.5%的醋酸溶液中浸泡,每隔10 min中称一次质量,用质量损失评定其耐蚀性。磨损在M?200磨损实验机上进行,其工艺参数为:外加载荷300 N,磨损时间10 min,转速180 r/min,采用环块式滑动磨损方式,对磨环尺寸为d40 mm×5 mm,用读数显微镜测量磨痕尺寸并根据下式换算成磨损体积:

2 结果与分析

2.1 反应热喷涂层物相分析

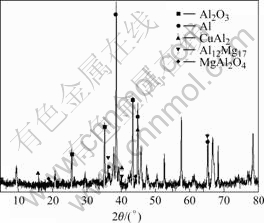

对反应热喷涂试样C1进行X射线物相分析结果如图1所示,采用X′Pert High Score分析软件对涂层物相组成进行半定量分析,结果如表3所列。由表1可以看出,涂层中Al2O3含量已由喷涂材料中的40%增至55%,Al和 CuO分别由原来的37.5%和12.5%减至10%和不到1%,说明Al和 CuO大部分发生了铝热反应原位生成Al2O3,并且涂层中还有CuAl2、MgAl2O4、Al12Mg17等其他新相生成。由于铝热反应生成的产物及产生的新相都是在喷涂过程中原位合成,因而具有洁净界面,容易和基体及周围粒子形成化学、冶金结合,有利于提高涂层与基体的结合强度以及涂层中陶瓷粒子间的聚合强度[7, 13]。另外,铝热反应生成的产物及产生的新相呈熔融状态,沉积到涂层中,一方面起粘结剂的作用,一方面对涂层沉积时产生的孔隙具有一定填充作用,使涂层致密度明显上升[14],从而提高涂层耐蚀性及界面抗氧化性。

图1 反应喷涂层X射线物相分析结果

Fig.1 XRD pattern of reaction spraying coatings

表3 涂层物相组成

Table 3 Phase composition of coatings (mass fraction, %)

2.2 反应热喷涂层形貌分析

样品C1的反应热喷涂层表面及截面SEM像如图2所示。由图2(a)可以看出,反应火焰喷涂涂层的形貌具有在大气中热喷涂涂层的典型特征:涂层主要由大小不一的扁平颗粒组成(即片层结构),说明喷涂材料在沉积过程中熔融较为充分。由图2(b)可以看出,涂层均匀致密,只存在少量夹杂和孔隙,涂层与基体之间界线不明显,说明涂层与基体已融为一体,呈现出一定的冶金结合。

图2 样品C1的反应热喷涂层SEM形貌

Fig.2 SEM images of coatings of sample Cl: (a) Surface; (b) Cross section

2.3 反应热喷涂层抗热震性

传统热喷涂(样品B1和B2)和反应热喷涂(样品C1和C2)试样在同等热震条件下的热震结果如表4所列。样品B1的喷涂材料为纯陶瓷粉末,只热震一次,涂层就完全脱落并破碎。样品B2由于铝粉的加入,其热震性能有所改善。Al的热膨胀系数和Mg相差不大,它的引入可减小涂层与基体热膨胀系数差异,降低热循环过程中产生的热应力[15]。但由于传统火焰喷涂火焰温度较低,粉末飞行速度较小,涂层与基体之间以机械结合为主,其结合强度不够高,所以只热震14次便有大块脱落。样品C1为反应热喷涂试样,其抗热震性明显提高,热震次数可达到40次。因为除了过剩相Al可减小涂层与基体热膨胀系数差异和降低热应力外,Al-CuO系铝热剂在喷涂过程中引燃,放出大量反应热能进一步提高喷涂材料的熔融程度,有利于与基体形成化学冶金结合,涂层的结合强度明显提高。样品C2为在样品C1工艺基础上,喷前先喷Ni-Al底层,喷后进行重熔处理,这样可使工作层、Ni-Al底层和基体表面发生熔化,使涂层和基体间产生焊合的冶金结合面,从而大幅度提高涂层致密性和结合强度[16],所以其抗热震性能达到最好,热震到50次时,仍完好无损。

表4 热震试验结果

Table 4 Results of thermal-shock experiment

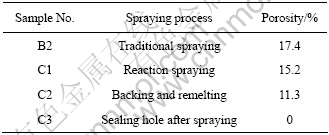

2.4 反应热喷涂层致密性

不同工艺热喷涂层孔隙率如表5所列。由表5可以看出,不经封孔的试样涂层孔隙率都比较大,主要因为传统火焰喷枪火焰温度不够高,喷射速率不够大。但相比而言,反应热喷涂层由于铝热反应能够放出大量反应热可进一步提高喷涂材料的熔融程度,使得致密度比传统喷层稍好。Ni-Al打底并轻度重熔工艺可明显降低涂层孔隙率。理论上,喷后重熔处理可以更大幅度的降低孔隙率,但限于本试验所用试样尺寸较小,且镁合金熔点过低,所以只能轻度重熔,重熔过度,会使基体熔化甚至点燃。样品C3为清漆封孔试样,由于清漆在液态时可完全渗入涂层孔隙中,因此固化后可使涂层孔隙率降至为0%。

表5 涂层孔隙率

Table 5 Porosity of coatings

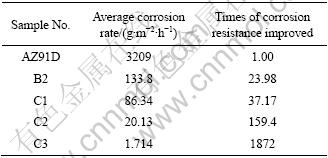

2.5 反应热喷涂层耐蚀性

各种试样的腐蚀质量损失曲线如图3所示,计算所得平均腐蚀速率如表6所列。由图3(a)可看出,AZ91D基体在醋酸中腐蚀速率远远高于喷涂试样的,这使得喷涂试样腐蚀曲线在相同坐标下无法标明,只得另建坐标系才能标明,如图3(b)所示。由图3可看出,喷涂试样耐蚀性由样品B2到样品C2逐渐提高,样品C3几乎未发生腐蚀。结合表5中的致密性数据可发现,涂层耐蚀性随着孔隙率的降低而提高。因此,本试验条件下,涂层致密性成为影响涂层耐蚀性的主要因素。另外,各喷涂试样中都有过剩相Al存在,可形成Al2O3致密保护膜,也可提高涂层耐蚀性。但过剩相Al不宜太多,因为Mg的电极电位比Al低,可以和Al构成原电池,加速Mg腐蚀,这也正是样品B2在腐蚀后期,腐蚀速率迅速上升的原因之一。对于样品C2,Ni-Al打底并重熔不但能大幅度降低孔隙率,而且Ni、Al之间还能形成一系列耐蚀性优良的金属间化合物和致密的腐蚀产物膜,可阻止腐蚀进一步扩 展[17]。由图3(b)中的曲线可知,腐蚀过程中样品C2质量增加和减少交替出现,可能就是腐蚀产物膜的形成和脱落造成的。对于样品C3,由于用聚氨酯清漆封孔,可使涂层孔隙率降低为零,阻止腐蚀介质透过涂层孔隙形成穿孔腐蚀,同时还会覆盖在涂层上,使涂层与基体之间不能构成腐蚀电池,因此耐蚀性能最好。但聚氨酯清漆不耐高温,若在高温下使用,可考虑水玻璃等其他无机封孔剂。

图3 试样的腐蚀质量损失曲线

Fig.3 Mass loss curves of samples

表6 试样平均腐蚀速率

Table 6 Average corrosion rate of samples

2.6 反应热喷涂层耐磨性

耐磨性是衡量涂层质量的一种重要的力学性能指标,与涂层的结构、结合强度、致密性及涂层中硬质相的含量与分布都有关系。AZ91D基体及各喷涂试样的磨损体积损失及相对耐磨性如表7所列,由表7可看出,各种喷涂试样的耐磨性比AZ91D基体的有大幅度提高,反应热喷涂层(样品C1)的耐磨性好于传统热喷涂层(样品B2)的。这主要因为前者由于Al和CuO的SHS反应而使涂层具有更高的结合强度、致密性和更多的硬质相,而重熔工艺则进一步强化了这种效果,因此,涂层耐磨性得到了进一步提高。

表7 试样磨损体积及相对耐磨性

Table 7 Wear volume and relative wear resistance of samples

3 结论

1) 采用SHS反应火焰喷涂技术,把Al-CuO系铝热剂引入到喷涂材料中,可成功制备AZ91D表面Al2O3基复相陶瓷涂层。Al-CuO系铝热剂不但可直接原位合成Al2O3涂层,还会产生CuAl2、MgAl2O4、Al12Mg17等其他新相。

2) SHS反应热喷涂层抗热震性明显优于传统热喷涂层,热震次数可达到40次,若辅以Ni-Al打底,喷后重熔工艺可使涂层热震到50次时仍完好无损。

3) 反应热喷涂层致密性好于传统热喷涂层,Ni-Al打底并轻度重熔可使涂层致密性大幅度提高,清漆封孔可使涂层孔隙率降低为0,致密性达到最好。

4) 喷涂试样耐蚀性随着致密性的增大而提高,反应热喷涂层的耐蚀性比基体的提高了36倍;Ni-Al打底并喷后重熔后涂层的耐蚀性可提高至基体的160倍;清漆封孔后几乎不发生腐蚀,耐蚀性最好。

5) 传统热喷涂层和反应热喷涂层的耐磨性分别为AZ91D基体的耐磨性的8.5倍和10.6倍,Ni-Al打底并喷后重熔后,反应热喷涂层的耐磨性可增至AZ91D基体的14.3倍。

REFERENCES

[1] 叶 宏, 孙智富, 吴超云. 镁合金表面热喷涂 A1-Al2O3/TiO2梯度涂层研究[J]. 武汉理工大学学报, 2006, 28(7): 9?11.

YE Hong, SUN Zhi-fu, WU Chao-yun. Research on thermal spraying Al-A1203/TiO2 gradient coating on the surface of magnesium alloy[J]. Journal of Wuhan University of Technology, 2006, 28(7): 9?11.

[2] 马壮, 曲文超, 李智超. AZ91D 热化学反应热喷涂陶瓷涂层耐蚀性研究[J]. 热加工工艺, 2007, 36(23): 37?39.

MA Zhuang, QU Wen-chao, LI Zhi-chao. Research on corrosion resistance of thermo-chemical reaction flame spraying ceramic coatings on AZ91D[J]. Hot Working Technology, 2007, 36(23): 37?39.

[3] 胡正前, 张文华, 孙文华. 离子喷涂TiC-Ni-Mo金属陶瓷涂层成分对组织与性能影响的研究[J]. 复合材料学报, 1999, 16(3): 87?92.

HU Zheng-qian, ZHANG Wen-hua, SUN Wen-hua. Effect of the ingredient of plasma spraying TiC-Ni-Mo cermets coating on the microstructure and properties[J]. Acta Materiae Compositae Sinica, 1999, 16(3): 87?92.

[4] 胡正前, 张文华, 汪晓霞. 离子喷涂TiC-Ni-Mo金属陶瓷涂层结构与性能的研究[J].金属热处理, 1998, 23(9): 1?3.

HU Zheng-qian, ZHANG Wen-hua, WANG Xiao-xia. Study on microstructure and properties of TiC-Ni-Mo cermets coatings by plasma spraying[J]. Heat Treatment of Metal, 1998, 23(9): 1?3.

[5] ECONOMOU S, BONTE M D, CELIS J P. Processing, structure and tribological behaviour of TiC-reinforced plasma sprayed coatings[J]. Wear, 1998, 220(1): 34?50.

[6] ECONOMOU S, BONTE M D, CELIS J P. Tribological behaviour at room temperature and at 550 ℃ of TiC-based plasma sprayed coatings in fretting gross slip conditions[J]. Wear, 2000, 244(1): 165?179.

[7] 刘长松, 殷声.反应热喷涂的发展[J]. 材料保护, 2000, 33(1): 83?85.

LIU Chang-song, YIN Sheng. Advance of reactive thermal spraying[J]. Materials Protection, 2000, 33(1): 83?85.

[8] DALLAIRE S, LEVERT H. Synthesis and deposition of TiB2 containing materials by arc spraying[J]. Surface Technology, 1992(50): 241?248.

[9] KODAMA T. Reactive thermal spray by high velocityceramic jet and characterization of the coatings[J]. Journal of Thermal Spray Technology, 1999, 8(4): 537?544.

[10] FAUCHAIS P. Reactive thermal plasma: Ultrafine particle synthesis and coating deposition[J]. Surface Coatings Technology, 1977, 97: 66?78.

[11] FUNKE C, MAILAND J C. Characterization of ZrO2-7%Y2O3 thermal barrier coatings and FEM analysis of stress redistribution during thermal cycling of TBCS[J]. Surface and Coatings Technology 1997, 94/95: 106?111.

[12] RAMASWANY A, SEETHARAMU S, VARMA K B R. Al2O3-ZrO2 composite coatings for thermal barrier application[J]. Compo Sci Tech, 1997, 57: 81?89.

[13] 刘慧渊, 黄继华, 张建纲. 反应火焰喷涂的TiC/Fe金属陶瓷复合涂层[J]. 中国有色金属学报, 2004, 14(8): 1389?1393.

LIU Hui-yuan, HUANG Ji-hua, ZHANG Jian-gang. TiC/Fe metal ceramic composite coating by reactive flame spray[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1389?1393.

[14] WU B C, CHANG E, CHANG S F. Degradation mechanisms of ZrO2-8at%Y2O3/Ni-22Cr-10Al-1Y thermal barrier coatings[J]. J Am Ceram Soc, 1989, 72: 212?218.

[15] 王建江, 杜心康, 刘宏伟.Al对反应火焰喷涂TiC-TiB2复相陶瓷涂层的影响[J]. 无机材料学报, 2007, 22(3): 550?554.

WANG Jian-jiang, DU Xin-kang, LIU Hong-wei. Influence of Al on reaction flame sprayed TiC-TiB2 multiphased ceramic coatings[J]. Journal of Inorganic Materials, 2007, 22(3): 550?554.

[16] ANANTHAPADMANABHAN P V, TAYLOR P R. Titanium car-bide-iron composite coating by reactive plasma spraying of ilmenite[J]. Journal of Alloys and Compounds, 1999, 287(6): 121?125.

[17] 李淑华, 邵德春. 稀土与激光表面重熔对喷涂层耐蚀性的影响[J]. 材料科学与工艺, 1994, 2(2): 91?96.

LI Shu-hua, SHAO De-chun. The effect of rare earths and laser remelting on the corrosion resistance of coatings[J]. Material Science & Technology, 1994, 2(2): 91?96.

基金项目:辽宁省自然科学基金资助项目(20062203)

收稿日期:2008-09-22;修订日期:2008-12-31

通讯作者:马 壮,教授,博士;电话:13941824669;E-mail: linpong1234@163.com

(编辑 何学锋)