文章编号:1004-0609(2008)S1-0053-06

某难选金矿加温化学预氧化浸出技术

邱廷省1, 2,廖德华1,毛仁康3,尹艳芬1

(1. 江西理工大学 资源与环境工程学院,赣州 341000;

2. 北京科技大学 冶金与生态工程学院,北京 100083;

3. 广东高要市 河台金矿,高要 526100)

摘 要:以某实际含铜金矿为研究对象,在氯盐酸性加温体系下,分析浸出温度、时间、矿物粒度、NaCl浓度、H2SO4浓度、氧气流量等因素对化学预氧化浸出除铜和浸出渣氰化浸金的影响过程。结果表明:在90%矿样粒度小于37 μm、浸出温度95 ℃、初始H2SO4浓度0.75 mol/L、起始NaCl浓度0.7 mol/L、液固比5?1、浸出时间24 h、搅拌速度750 r/min的条件下,可使铜的浸出去除率达到80%以上,预氧化渣金的氰化浸出率达98.23%。

关键词:含铜金矿;预处理;化学氧化;浸出工艺

中图分类号:TF 111.31 文献标识码:A

Warming and chemical pre-oxidation leaching of refractory gold ores

QIU Ting-sheng1, 2, LIAO De-hua1, MAO Ren-kang3, YIN Yan-fen1

(1. Faculty of Resource and Environment, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing,Beijing 100083, China;

3. Gold Mining of Hetai, Gaoyao Town in Guangdong Province, Gaoyao 526100, China)

Abstract: A certain refractory copper-bearing gold ores were studied. Under the acid and warming system of chlorine, the influence of some factors on process of chemical pre-oxidation leaching copper and cyanidation leaching gold from residue were researched, such as leaching temperature and time, mineral granularity, NaCl concentration, H2SO4 concentration and flow rate of oxygen. The results show that copper removing ratio is more than 80% and gold leaching ratio is more than 98.23%, under the condition of 90% of mineral granularity 37 μm, leaching temperature 95 ℃, initial NaCl concentration 0.7 mol/L, initial H2SO4 concentration 0.70 mol/L, leaching time 24 h, ratio of liquid to solid 5?1 and stirring rate 750 r/min.

Key words: copper-bearing gold ores; pretreatment; chemical oxidation; leaching

含铜金矿石属于难选金矿石,铜含量低于0.2%的金矿石一般来说可以直接氰化提金[1]。当矿石中的铜含量高于0.5%时,氰耗增加,金的浸出率相当低,直接氰化已变得不经济,因此,对于含铜金矿一般要进行预处理除铜。常用的预处理方法有焙烧氧化法、微生物氧化法、加压氧化法和化学氧化法等[2]。由于化学氧化法预处理含铜金矿具有经营成本低、环境污染小、回收率高等优点,近年来越来越受到人们的重视。

本文作者对广东某典型含黄铜矿的金精矿进行氯盐酸性加温氧化预处理除铜和渣氰化浸金的研究。探讨起始酸浓度、氯化物浓度、浸出温度和磨矿细度等因素对化学氧化预处理浸铜的影响。

1 实验

1.1 实验原料

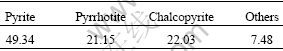

矿样为广东某矿浮选含铜金精矿,矿石中金属矿物主要为黄铁矿、磁黄铁矿、黄铜矿,其次是辉铜矿、铜蓝、黝铜矿、孔雀石、蓝铜矿、方铅矿、闪锌矿、褐铁矿、毒砂;非金属矿物主要为石英,其次为绢云母、绿泥石、长石,少量为方解石、白云石、角闪石等。主要金属矿物含量如表1所列。

表1 含铜金矿中主要金属矿物含量

Table 1 Main metallic mineral contents of copper-bearing gold ores (mass fraction, %)

矿石中金矿物主要为自然金,少量为金银矿。金矿物表面清洁,嵌布粒度较细,主要为尖角粒状和枝叉状。金矿物与脉石关系密切,少量与黄铜矿和磁黄铁矿有关。依其嵌布部位的不同可划分为粒间金、裂隙金和包裹金。

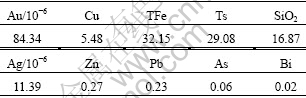

含铜金精矿多元素化学分析结果如表2所列。结果表明该矿中金和铜含量较高,应该作为有价金属进行综合回收,而且该矿样硫含量较高。

表2 含铜金矿的多元素分析结果

Table 2 Multi-element analysis results of copper-bearing gold ores (mass fraction, %)

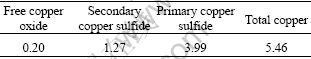

含铜金矿的铜矿物物相分析结果如表3所列。自由氧化铜包括孔雀石、蓝铜矿、赤铜矿和黑黝铜矿等,这类矿石易于酸浸出;次生硫化铜主要指斑铜矿、辉铜矿和铜蓝等;原生硫化铜是指黄铜矿和方黄铜矿。从岩矿鉴定和铜的物相分析可知,该含铜金矿中铜主要以黄铜矿形式存在。因此,化学氧化预处理的矿物主要是黄铜矿。

表3 铜矿物中铜的物相分析结果

Table 3 Copper phase analysis results of copper minerals (mass fraction, %)

1.2 实验方法

1) 加温化学预氧化浸出

加温常压化学氧化预处理实验在可调控温的数显恒温水浴箱中进行。矿石在球磨机中磨到合适粒度,在烧杯中按实验条件调浆后,放入水浴恒温控制箱中。根据实验条件要求,需控制好搅拌速度、温度等条件,同时预处理过程中一直保持充入氧气。化学氧化预处理后,用真空过滤机过滤,液体送化验,渣洗涤干燥后,一部分制样送化验分析,一部分用于测试,其它样进行氰化浸出实验和备用。

2) 氰化浸金研究方法

氰化浸金实验在锥型瓶中进行。取100 g金矿样和300 g水加入锥型瓶中,用烧碱调浆到pH为10~12后,加入NaCN,NaCN用量为4 kg/t处理矿样,在HY-8型调速震荡机上摇瓶浸出,氰化24 h。浸出液送化验,渣淋洗烘干制样送化验。

2 结果与讨论

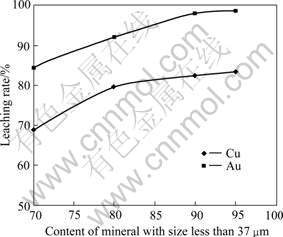

2.1 粒度对含铜金矿预处理过程及金浸出率的影响

加温氧化预处理过程中,氧化过程是溶液与固体之间的多相过程,氧化浸出速度与固体与液相接触表面关系密切,因此必须考虑矿物粒度对预处理过程及金浸出率的影响。在浸出温度95 ℃,初始酸度[H2SO4]=0.75 mol/L,初始[NaCl]=0.7 mol/L,氧气流量150 mL/min,液固比4/1,浸出时间24 h,搅拌速度750 r/min的条件下,考察粒度对含铜金矿预处理过程及金浸出率的影响,结果如图1所示。由图1可以看出,矿样粒度对预处理过程影响较大,粒度减小,铜浸出率显著提高,同时金的浸出率也相应提高。粒度越细,预处理效果越好,越有利于金的浸出。另外,矿物粒度越细,固体与液体的接触面积越大,对反应动力学过程就越有利。粒度小于37 μm的矿样达到90%以上时,金的浸出率上升较缓,考虑到磨矿成本等因素,实验选用90%矿样粒度小于37 μm的为最佳。

图1 矿样粒度对金属浸出率的影响

Fig.1 Effect of sample size on metal leaching rate

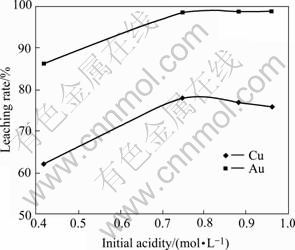

2.2 起始酸度对含铜金矿预处理过程及金浸出率的影响

加温氧化预处理过程中,硫酸不仅是硫化矿的溶解剂,同时它直接影响预处理产物及过程,是影响预处理效果的重要因素之一。为了考察其影响效果,在90%试样的粒度小于37 μm,浸出温度95 ℃,起始[NaCl]=0.7 mol/L,氧气流量为150 mL/min,液固比4?1,浸出时间24 h,搅拌速度750 r/min的条件下,考察了起始酸度对预处理效果及金浸出的影响。实验结果如图2所示。

图2 起始酸度对金属浸出率的影响

Table 2 Effect of initial acidity on metal leaching rate

由图2可以看出,随着硫酸用量的提高,在氧化浸出的开始阶段有利于浸出速度的提高,但浸出速度不与硫酸用量成正比,当起始硫酸用量大于0.75 mol/L时,金的浸出率随酸度增加提高较小,而铜的浸出速度反而减小。此外,提高酸度对设备的要求也更高,同时浸出液的酸度也相应提高,对后续处理不利。所以酸度不宜过高,否则不仅会增大处理成本,而且增加浸出液处理的难度。因此,起始酸度确定为0.75 mol/L较为合适。

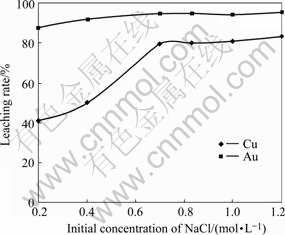

2.3 NaCl浓度对含铜金矿预处理过程及金浸出率的影响

加温氧化预处理过程中,Cl-与金属离子形成较稳定的络合物,使铜溶解加速、加大,是很好的硫化矿溶解剂,在90%试样粒度小于37 μm,浸出温度95 ℃,初始酸度[H2SO4]=0.75 mol/L, 氧气流量150 mL/min,液固比4?1,浸出时间24 h,搅拌速度750 r/min的条件下,考察其对预处理效果及金浸出的影响。实验结果如图3所示。

图3 NaCl起始浓度对金属浸出率的影响

Fig.3 Effect of NaCl initial concentration on metal leaching rate

从图3可以看出,当氯化钠浓度低时,铜预处理去除率及预处理渣金浸出率很低。NaCl浓度增大,金、铜的浸出率迅速增加。因此,在浸出液中保持适当的氯化钠浓度,有利于氧化浸金的效果,但当氯化钠浓度大于0.7 mol/L,其用量继续扩大,对金、铜的浸出影响不大。因此,NaCl起始浓度确定为0.7 mol/L较为合适。

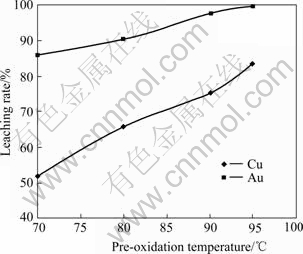

2.4 温度对含铜金矿预处理过程及金浸出率的影响

加温氧化预处理过程中,温度对化学速度影响很大,温度的升高能大大加快氧化反应速度。本研究是要实现较低温度下预处理浸金,因此,在90%粒度小于37 μm,初始酸度[H2SO4]=0.75 mol/L,起始[NaCl]=0.7 mol/L,氧气流量150 mL/min,液固比4?1,浸出时间24 h,搅拌速度750 r/min的条件下,在温度60~100 ℃范围内,考察其对预处理效果及金浸出的影响。实验结果如图4所示。

图4 预氧化温度对金属浸出率的影响

Fig.4 Effect of pre-oxidation temperature on metal leaching rate

从图4可以看出,温度是影响预处理过程及金浸出率的重要因素,对铜的预处理去除率及金浸出率影响很大。当浸出温度低于80 ℃时,金、铜浸出率较低;在90~100 ℃时,金属浸出率变化最为强烈,金、铜浸出率急剧上升;预氧化温度95 ℃时,铜的去除率和金浸出率都较高。因此温度确定为95 ℃较为合适。

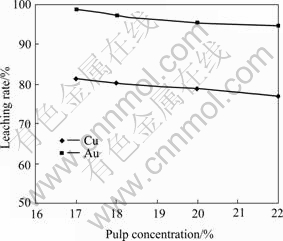

2.5 矿浆浓度对含铜金矿预处理过程及金浸出率的影响

加温氧化预处理过程中,低矿浆浓度能提供更多溶解剂和更多的阴阳离子,能加快氧化速度及加深氧化程度,而低矿浆浓度不利于提高生产效率,合适的矿浆浓度应由实验决定。在90%粒度小于37 μm,初始酸度[H2SO4]=0.75 mol/L,起始[NaCl]=0.7 mol/L,氧气流量150 mL/min,预氧化时间24 h,浸出温度95 ℃,搅拌速度750 r/min的条件下,考察了其对预处理效果及金浸出的影响,结果如图5所示。

图5 矿浆浓度对金属浸出率的影响

Fig.5 Effect of pulp concentration on metal leaching rate

由图5可以看出,矿浆浓度在实验范围内,对预氧化金属浸出影响很小。但矿浆浓度较低,铜的浸出率有所提高,降低矿浆浓度,将使处理量降低,增加成本;提高矿浆浓度,将使搅拌器磨损增加,搅拌阻力增大。为此,实验矿浆浓度定为20%,即液固比为4?1。

2.6 搅拌强度对含铜金矿预处理过程及金浸出率的影响

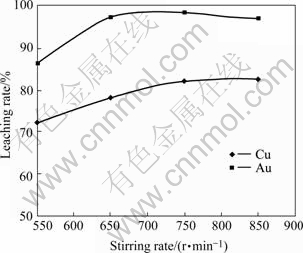

加温氧化预处理过程中,提高搅拌速度,使矿粒扩散层厚度减少,增加氧化速度,但速度达到一定值,再进一步提高速度,并不能加快离子或分子的扩散速度。为了考察其影响效果,在90%粒度小于37 μm,初始酸度[H2SO4]=0.75 mol/L,起始[NaCl]=0.7 mol/L,氧气流量150 mL/min,预氧化时间24 h,浸出温度95 ℃,液固比4?1的条件下,考察了其对预处理效果及金浸出的影响。结果如图6所示。

图6 搅拌速度对金属浸出率的影响

Fig.6 Effects of stirring rate on metal leaching rate

由图6可以看出,速度的提高有利于有价金属的浸出,但在角速度为750 r/min(线速度为1.88 m/s)时就有较好的金浸出率。另外,过快的转速加快了设备的磨损,因此本实验选角速度为750 r/min。

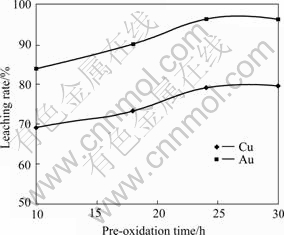

2.7 时间对含铜金矿预处理过程及金浸出率的影响

加温氧化预处理过程中,时间关系到生产效率,是决定预处理效果的重要因素之一,在90%粒度小于37 μm,初始酸度[H2SO4]=0.75 mol/L,起始[NaCl]=0.7 mol/L,浸出温度95 ℃,氧气流量150 mL/min,液固比4?1,搅拌速度750 r/min的条件下,考察预氧化时间对预处理效果及金浸出的影响。结果如图7所示。

图7 预氧化时间对金属浸出率的影响

Fig.7 Effect of pre-oxidation time on metal leaching rate

从图7可以看出,在预氧化24 h后,金、铜的浸出率变化不大,已经达到较高值。所以,预氧化时间必须长于24 h,但再增加浸出时间,对预氧化效果影响不大,考虑预氧化工艺经济因素,氧化时间不宜过长。故确定氧化时间为24 h。

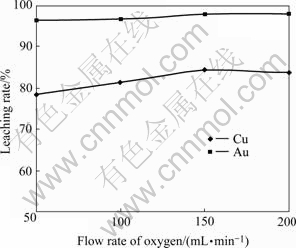

2.8 氧气流量对含铜金矿预处理过程及金浸出率的影响

氧气作为浸出反应的氧化剂,通过将反应生成的Cu+氧化成Cu2+而间接参与硫化物的氧化反应,其流量的增加有利于铜的浸出。图8所示为在90%粒度小于37 μm,初始酸度[H2SO4]=0.75 mol/L,起始[NaCl]=0.7 mol/L,浸出温度95 ℃,液固比4?1,预氧化时间24 h,搅拌速度为750 r/min的条件下,考察氧气流量对预处理效果及金浸出的影响。

图8 氧气流量对金属浸出率的影响

Fig.8 Effect of oxygen flow rate on metal leaching rate

由图8可以看出, 氧气流量对铜、金的浸出都有影响;但在铜氧化阶段, 液相中Cu+比铜蓝更易被O2氧化,此时影响铜氧化的主要因素是氯离子。实验还发现:在同样的反应条件(包括氧流量)下, 改善充气管的气体分布, 使氧气更均匀地弥散在矿浆中,可大幅度提高铜的浸出率。在充气良好的情况下,24 h左右即可将铜较好地浸出。说明改善氧的分散即增加氧气与溶液的接触面积,比简单地增加氧气流量更有效。值得注意的是,铜浸出率在氧气流量为150 mL/min时达到最大,氧气流量继续增大,铜的浸出率反而有所降低。这可能与氧气过量对某种铜化合物的溶解不利有关。文献[3-4]中指出,有还原性物质如Cu(Ⅰ)或Sn(Ⅱ)存在时,铁酸镍在2 mol/L HCl 溶液中的溶解比没有它们或有氧化性物质存在时快得多。在本体系中, 浸出的铜最初是以Cu (Ⅰ)进入溶液,然后再被氧化成Cu(Ⅱ),而过量的氧气显然不利于Cu (Ⅰ)的存在。

3 结论

1) 粒度和温度对含铜金矿预氧化过程影响较大。粒度减小,铜浸出率显著提高,同时金的浸出率也相应提高。粒度越细,预处理效果越好,越有利于金的浸出。当浸出温度低于80 ℃时,金、铜浸出率较低,在90~100 ℃时,金属浸出率变化最为强烈,金、铜浸出率急剧上升。

2) 硫酸用量、氯化钠浓度是影响加温预氧化过程的主要因素。随着硫酸用量的提高,在氧化浸出的开始阶段有利于浸出速度的提高,但浸出速度不与硫酸用量成正比,当起始硫酸用量大于0.75 mol/L时,金的浸出率随酸度增加提高较小,而铜的浸出速度反而减小。氯化钠浓度低时,铜预处理去除率及预处理渣金浸出率很低,氯化钠浓度增大,金、铜的浸出率迅速增加。因此,在浸出液中保持适当的氯化钠浓度,有利于氧化浸金的效果。

3) 氧气作为浸出反应的氧化剂, 通过将反应生成的Cu+氧化成Cu2+而间接参与硫化物的氧化反应,其流量的增加有利于铜的浸出,但改善氧的分散即增加氧气与溶液的接触面积, 比简单地增加氧气流量更有效。

REFERENCES

[1] 王周潭. 含铜难选冶金矿氰化法提金技术在我国的研究现状[J]. 黄金科学技术, 1995(6): 10-12.

WANG Zhou-tan. Cyanide-extraction of gold from copper-gold- bearing ores with and present study situation in China [J]. Gold Science and Technology, 1995(6): 10-12.

[2] 邱廷省, 聂光华, 张 强. 难处理含铜金矿石预处理与浸出技术现状及进展[J]. 黄金, 2005, 8(26): 30-33.

QIU Ting-sheng, NIE Guang-hua, ZHANG Qiang. Present situation and developmental trend of pretreatment and leaching technology for refractory copper-bearing gold ores [J]. Gold, 2005, 8(26): 30-33.

[3] LU Z Y, MUIR D M. Dissolution of metal ferrite and iron oxides by HCl under oxidising and reducing conditions [J]. Hydrometallurgy, 1988, 21(1): 9-21.

[4] 王文潜, 王喜良. 难浸金矿预处理方法评价及新进展[J]. 云南冶金, 1997, 26(6): 30-34.

WANG Wen-qian, WANG Xi-liang. Evaluation and new progress of pretreatment process for refractory leaching gold ores [J]. Yunnan Metallurgy, 1997, 26(6): 30-34.

[5] 印万忠. 黄金选矿评述[J]. 有色金属, 2001(s): 35-38.

YIN Wang-zhong. Review of gold mineral processing [J]. 2001(s): 35-38.

[6] 王力平, 刘春谦. 难处理金矿石预处理技术综述[J]. 黄金, 2000(1): 38-45.

WANG Li-ping, LIU Chun-qian. Summary of pretreatment process for refractory gold ores [J]. Gold, 2000(1): 38-45.

[7] 孙春宝, 魏德州. 国外难处理金矿资源的开发利用[J].黄金, 2001(8): 27.

SUN Chun-bao, WEI De-zhou. Development and utilization of foreign refractory gold resources [J]. Gold, 2000(1): 38-45.

[8] 孙全庆. 难处理金矿石的碱法加压氧化预处理[J]. 湿法冶金, 1999, 2(70): 14-18.

SUN Quan-qing. Alkaline and pre-oxidation pretreatment process for refractory gold ores [J]. Hydrometallurgy of China, 1999, 2(70): 14-18.

[9] 《铅锌冶金学》编委会. 铅锌冶金学[M]. 北京: 科学出版社, 2003.

Lead and Zinc Metallurgy Editorial Board. Lead and zinc metallurgy [M]. Beijing: Science Press, 2003.

[10] 李民权, 关玉蓉. 氯化浸金机理研讨[J]. 黄金, 2003, 24(2): 35-38.

LI Min-quan, GUAN Yu-rong. Study on leaching gold mechanism by chlorination method [J]. Gold, 2003, 24(2): 35-38.

[11] KAMBEOVIC Z J, SOKIC M, KORAC M. Physicochemical Problems of Mineral Processing, 2003(37): 107-114.

[12] D.德赖辛格, 李长根, 雨 田. 贱金属和贵金属矿石和精矿浸出的新进展[J]. 国外金属矿选矿, 2004, 41(1): 19-22.

REISINGER D, LI Chang-gen, YU Tian. New progress of concentrates leaching for base and precious metal ores [J]. Metallic Ore Dressing Abroad, 2004, 41(1): 19-22.

[13] 郑存江. 含砷难浸金矿的研究及应用[J]. 陕西地质, 2003(6): 80-98.

ZHENG Cun-jiang. The study and application of leaching for refractory in arsenic-bearing gold ores [J]. Geology of Shaanxi, 2003(6): 80-98.

[14] 周 军. ML浸金系及其反应器研究[D]. 西安: 西安建筑科技大学, 2003.

ZHUO Jun. Study on ML gold leaching system and reactor [D]. Xi’an: Xi’an University of Architecture and Technology, 2003.

________________________

基金项目:江西省自然科学基金资助项目(0650043)

通讯作者:邱廷省,教授;电话:0797-8312143;E-mail: qiutingsheng@163.com

(编辑 李向群)