基于磨粒突出高度为瑞利分布的磨削力模型

郎献军,何玉辉,唐进元,陈海锋

(中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:假设砂轮磨粒形状为圆锥形,其突出高度服从瑞利分布,在磨削过程中均参与切削且切除材料。在此基础上,推导出在平面磨削过程中与磨削参数和砂轮磨粒密度相关的未变形磨屑厚度的计算表达式。磨削力包括磨削变形力和摩擦力2部分。基于未变形磨屑厚度的计算表达式,推出磨削变形力的计算表达式;考虑摩擦系数是关于磨削参数的函数而非某一常值,得到摩擦力的计算表达式。综合上述2种计算表达式,建立磨削力预测模型。然后,通过将预测值与实验数据进行对比分析,得出预测值与实验值的最大相对误差小于25%,平均相对误差小于15%,从而验证了该预测模型能有效地预测磨削力。

关键词:瑞利分布;平面磨削;未变形磨屑厚度;预测模型

中图分类号:TG58 文献标志码:A 文章编号:1672-7207(2014)10-3386-06

Grinding force model based on prominent height of abrasive submitted to Rayleigh distribution

LANG Xianjun, HE Yuhui, TANG Jinyuan, CHEN Haifeng

(State key laboratory of high performance complex manufacturing, Central South University, Changsha 410083)

Abstract: Assume that the shape of abrasive grain is conical and its prominent height submitted to Rayleigh distribution, and all prominent grains are involved in cutting and removal of workpiece materials in the grinding process. On this basis, calculated expression of undeformed grinding thickness during the process of surface grinding associated with the grinding parameters and the abrasive density was deduced. The grinding force comprises two parts, deformation force and friction force. Based on the calculation expression of the thickness of undeformed chip, the deformation force expression was deduced; considering that the friction coefficient was a function about grinding parameters rather than a constant value, the expression of friction was obtained. Taking these two calculated expressions into consideration, the predictive model of grinding force was built. Then, the predicted values and the experimental values were compared and analyzed. The results show that the maximum relative error is less than 25%, and the average relative error is less than 15%, which proves that the predictive model can effectively predict the grinding force.

Key words: Rayleigh distribution; surface grinding; undeformed chip thickness; predicted model

磨削力是在磨削过程中,由砂轮与工件接触后引起的弹性变形、塑性变形、切屑形成以及磨粒和结合剂与工件表面之间的摩擦作用引起的[1],对砂轮的耐用度、磨削比能、工件表面加工质量、工艺系统的变形等均会产生很大的影响。磨削力是评价材料可磨削性的一个重要指标,而在各类零件的磨削加工过程中,磨削大多依赖于操作者的经验。因此,研究磨削机理,建立有效的磨削力预测模型具有很高的理论意义和应用价值。许多学者在磨削力预测模型方面进行了很多研究。Werner[2]从砂轮磨粒的几何分布和磨粒运动学入手,基于单位接触面上的动态磨刃数和磨屑面积建立了单位宽度磨削力计算模型,该模型包括了磨削变形力与摩擦力,但没有从物理意义上清楚地区分磨削变形力和摩擦力,也没有清楚地表达磨削变形力与摩擦力对磨削力的影响程度。Malkin[3]将磨削力划分为磨削变形力和摩擦力两部分,并通过实验建立了磨削力与砂轮磨粒磨损平面面积的关系。李力钧等[4]在此基础上,建立了由磨削变形力和摩擦力2部分组成的单位宽度上的磨削力数学模型,进一步推导了磨削力的数学模型。Hecker等[5]假定磨粒高度服从瑞利分布,推导了未变形磨屑厚度的计算表达式,并基于硬度测试的定义建立了磨削力的预测模型。Chang等[6]考虑了磨粒的随机分布特性,建立了磨削力的统计表达式,分析了磨削力的频谱特性,并提出总磨削力的功率谱密度是由单颗磨粒磨削力的能量谱密度和磨粒密度的功率谱密度决定的。Ren等[7]在断裂力学的基础上建立了与工艺参数和材料物理机械性能相关的磨削力数学模型,该模型可以预测不同晶粒度硬质合金的磨削力。Tang等[8]基于磨削力尺寸效应和磨削比能,建立了磨削力预测模型,并且建立摩擦系数与加工参数之间的关系而不是被认定为某一常值。Patnaik等[9]基于磨削过程的3个阶段,即滑擦、耕犁和切削,将磨削力分为摩擦力、耕犁力和切削变形力,推导了磨削力的数学磨削,并设计实验证明模型的正确性。王君明等[10-11]基于磨粒与工件接触的运动方程建立了未变形磨屑厚度的计算表达式,并在此基础上推导了磨削力的预测模型。本文作者根据砂轮磨粒形状为圆锥形,突出高度服从瑞利分布,在磨削过程中均参与切削且切除材料等假设,推导出了在平面磨削过程中与磨削参数和砂轮磨粒密度相关的未变形磨屑厚度的计算表达式。磨削力分为磨削变形力和摩擦力2部分。根据未变形磨屑厚度的计算表达式,推出了磨削变形力的计算表达式;考虑摩擦因数是关于磨削参数的函数而非某一常值,得到了摩擦力的计算表达式。综合上述2种计算表达式,建立了磨削力预测模型。

1 未变形磨屑厚度

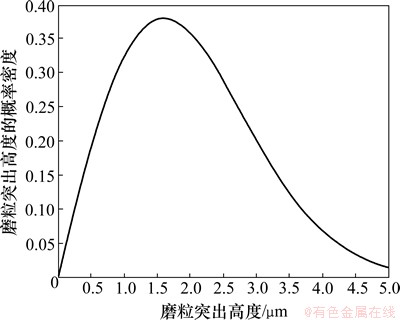

砂轮表面的磨粒突出高度参差不齐,张建华等[12]假设磨粒突出高度的概率分布符合正态分布,而Hecker等[5]和Sanjay等[13-14]假设其服从瑞利分布。其中正态分布由2个参数(μ和σ)决定,而瑞利分布只由1个参数(β)决定,相比较而言,瑞利分布更容易确定,因此在本文中,假设磨粒高度分布的概率密度函数近似为瑞利分布,其分布图如图1所示。

其函数表达式为

图1 磨粒突出高度的概率密度分布函数

Fig. 1 Abrasive grains protruding heights probability density function

式中:β是唯一确定瑞利分布的未知数,只要β已知,则磨粒突出高度的概率密度函数就完全确定了。

瑞利分布的期望值为

(2)

(2)

为了计算未变形磨屑厚度,现作以下两点假设:

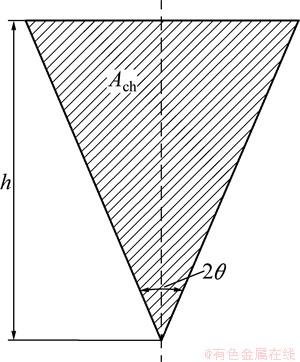

1) 磨粒为圆锥形,并且其平均顶锥角为2θ;

2) 砂轮上所有突出的磨粒都参与切削,并且切除材料。

基于以上假设,磨粒切除的切屑横截面如图2所示,其面积Ach的期望值为

(3)

(3)

则磨粒切除的切屑的总横截面面积Atotal的期望为

(4)

(4)

在磨削接触区域中,Nd=blcC。

其中:C为砂轮中单位面积上的有效磨粒数;lc=  为砂轮与工件接触长度;ap为切削深度;ds为砂轮直径;b为磨削接触宽度。

为砂轮与工件接触长度;ap为切削深度;ds为砂轮直径;b为磨削接触宽度。

磨屑的微观去除体积率应和磨削的宏观材料去除率相等,即

(5)

(5)

其中:vs为砂轮速度;vw为工件进给速度。

图2 切屑横截面示意图

Fig. 2 Schematic diagram of chip cross section

将式(4)代入式(5)中,得

(6)

(6)

而

(7)

(7)

将式(1)代入式(7)中,得

(8)

(8)

将式(6)代入式(8)中,得

(9)

(9)

将式(9)代入式(2)中,得磨粒平均突出高度即未变形磨屑厚度为

(10)

(10)

2 建立磨削力模型

李力均等[4]将磨削力分为切屑变形力和摩擦力2部分,建立了如下磨削力模型:

(11)

(11)

式中: 为法向力;

为法向力; 为切向力;

为切向力; 为由于磨削变形引起的法向力;

为由于磨削变形引起的法向力; 为由于摩擦力引起的法向力;

为由于摩擦力引起的法向力; 为由于磨削变形引起的切向力;

为由于磨削变形引起的切向力; 为由于摩擦力引起的切向力。

为由于摩擦力引起的切向力。

2.1 磨削变形力的数学模型

在不考虑摩擦作用的情况下,将磨粒简化为圆锥形,并假设其平均顶锥角为2θ,对于单颗磨粒,由磨削变形引起的切向磨削力为[1]

(12)

(12)

式中:Fp为单位磨削力, 为未变形平均磨屑厚度。

为未变形平均磨屑厚度。

将式(12)乘以磨削接触区内的总磨粒数,便可得到由磨削变形力引起的切向磨削力为

(13)

(13)

将 代入式(13)得

代入式(13)得

(14)

(14)

在平面磨削中,由磨削变形引起的切向磨削力和法向磨削力之间存在一定的比例关系[1]

(15)

(15)

式中: 。

。

则得由磨削变形引起的法向磨削力为

(16)

(16)

2.2 摩擦力的数学模型

在平面磨削过程中,由摩擦引起的磨削力为[1]

(17)

(17)

式中:△为单颗工作磨粒顶面积,即工件与工作磨粒的实际接触面积; 为磨粒实际磨损表面与工件间的平均接触压力;μ为摩擦因数。

为磨粒实际磨损表面与工件间的平均接触压力;μ为摩擦因数。

在平面磨削中,工件与砂轮磨粒磨损平面间的平均接触压力 随曲率半径差值△的增加而近似成线性关系增大,其关系可用下式表示[15]:

随曲率半径差值△的增加而近似成线性关系增大,其关系可用下式表示[15]:

(18)

(18)

式中:p0为一常数,可通过试验确定;△=4vw/(dsvs)是当用抛物线函数近似切削轨迹时的曲率半径与砂轮半径的差值。

根据摩擦二项式定律,摩擦因数为

(19)

(19)

式中:α和β分别为由摩擦表面的物理和机械性质决定的系数;W为法向载荷;A0为接触面积。

将式(18)代入式(19),摩擦因数μ为

(20)

(20)

将式(20)代入式(17),可以得在平面磨削中由摩擦引起的法向和切向磨削力为

(21)

(21)

2.3 磨削力的数学模型

综合磨削变形力和摩擦力,便可得到磨削力的表达式。即将式(14),(16)及(21)代入式(11)中,就得到在平面磨削中的法向磨削力和切向磨削力分别为

(22)

(22)

将式(22)简化为

(23)

(23)

式中: ,

, ,

, ,

, ,

, ,均可由实验得出。

,均可由实验得出。

3 磨削力模型的验证及分析

现用文献[16]的磨削力试验数据对该模型进行验证,其实验条件为:磨床为MM132A精密卧轴钜台平面磨床,工件为钛合金TC4,其长×宽×高为100 mm×20 mm×20 mm,砂轮型号为CBN100/120S75%P300×20×75×5,磨削液为10%乳化液。其实验数据见表1,根据表1中带*号的数据分别计算式(23)中的参数,得K1=2 849.013,K2=43 304.134,K3=5 064.732,K4=0.309,K5=29 300.565,并将其代入式(23),得到在该磨削条件下的磨削力的计算公式为:

(24)

(24)

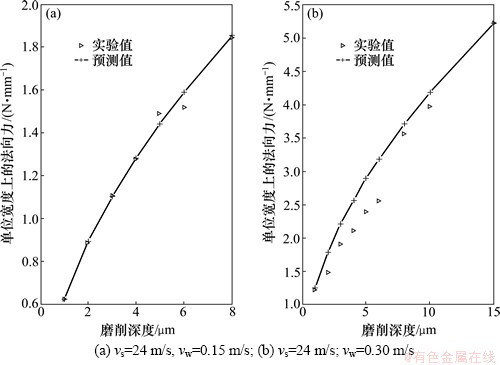

根据上式计算其他参数条件下的磨削力,并与实验数据进行对比,结果如图3和图4所示。

表1 实验数据[16]

Table 1 Experimental data

由图3可见:当vs=24 m/s,vw=0.15 m/s时,单位宽度上的切向磨削力的预测值与实验值的最大相对误差为20.61%,平均相对误差为9.46%;而在vs=24 m/s,vw=0.30 m/s时,其最大相对误差为11.58%,平均相对误差为3.96%。由图4可见:当vs=24 m/s,vw=0.15 m/s时,单位宽度上的法向磨削力的预测值与实验值的最大相对误差为4.63%,平均相对误差为1.41%;而在vs=24 m/s,vw=0.30 m/s时,其最大相对误差为24.65%,平均相对误差为12.92%。误差产生原因分析:1)在推导磨削力计算表达式的过程中,将磨粒简化为圆锥形,而实际的磨粒并不是标准的圆锥形;2)在计算动态磨粒数时,用几何接触长度而不是工件与砂轮的实际接触长度;3)在磨削中,并非所有磨粒都产生磨屑,而有的只发生滑擦。张建华等[12]基于砂轮表面磨粒服从正态分布的假设,对磨削弧区内的磨粒进行统计,得出了滑擦磨粒和切削磨粒的数目,建立了磨削力的理论计算模型。其切向磨削力的预测值与实验值的最大相对误差为15.00%,而平均相对误差为8.82%。经比较可知,在一定条件下,本文建立的模型的误差相对较小,表明该模型能够有效的预测磨削力。

图3 单位宽度切向磨削力与磨削深度的关系

Fig. 3 Relationship between tangential grinding forces per unite width and grinding depth

图4 单位宽度法向磨削力与磨削深度的关系

Fig. 4 Relationship between normal grinding forces per unite width and grinding depth

4 结论

1) 假定磨粒为平均锥度为2θ的圆锥形,在砂轮上的突出高度服从瑞利分布,在平面磨削过程中均参与切削且切除材料,进而推出未变形磨屑厚度的数学模型。在该过程中,通过分析砂轮的微观结构和磨粒的静态分布密度,使未变形磨屑厚度的计算表达式得到进一步完善。

2) 根据可分为磨削变形力和摩擦力2个部分的磨削力,分别推导出了磨削变形力的计算表达式和摩擦力的计算表达式。在该模型中,基于未变形磨屑厚度的计算表达式,分析了磨削变形力与磨削参数和砂轮磨粒密度的相互作用,得出磨削变形力的计算表达式;通过探究加工参数(如工件速度、磨削深度等)对摩擦因数的影响,确定摩擦因数是关于磨削参数的函数关系式,而非某一常值,推出摩擦力的计算表达式。综合这2种计算表达式,建立了磨削力预测模型。然后用实验数据对该模型进行了验证,结果表明该模型能有效地预测磨削力。

参考文献:

[1] 李伯民, 赵波. 现代磨削技术[M]. 北京: 机械工业出版社, 2003: 29-34.

LI Bomin, ZHAO Bo. Modern grinding technology[M]. Beijing: China Machine Press, 2003: 29-34.

[2] Werner G. Influence of work material on grinding force[J]. Annals of CIRP, 1978, 27(1): 243-248.

[3] Malkin S. 磨削技术理论与应用[M]. 蔡光起, 巩亚东, 宋贵亮, 译. 沈阳: 东北大学出版社, 2002: 88-94.

Malkin S. Grinding technology theory and application of machining with abrasives[M]. CAI Guangqi, GONG Yadong, SONG Guiliang, transl. Shenyang: Northeastern University Press, 2002: 88-94.

[4] 李力钧, 付杰才. 磨削力的数学模型的研究[J]. 机械工程学报, 1981, 17(4): 31-41.

LI Lijun, FU Jiecai. Research on mathematical model of grinding force[J]. Chinese Journal of Mechanical Engineering, 1981, 17(4): 31-41.

[5] Hecker R L, Liang S Y, WU Xiaojian, et al. Grinding force and power modeling based on chip thickness analysis[J]. International Journal of Advanced Manufacturing Technology, 2007, 33(5/6): 449-459.

[6] CHANG Huangcheng, Wang J J J. A stochastic grinding force model considering random grit distribution[J]. International Journal of Machine Tools & Manufacture, 2008, 48: 1335-1344.

[7] REN Yinhui, ZHANG Bi, ZHOU Zhixiong. Grinding force prediction for Tungsten Carbides with various grain sizes[J]. Nanotechnology and Precision Engineering, 2008, 6(6): 415- 423.

[8] TANG Jinyuan, DU Jin, CHEN Yongping. Modeling and experimental study of grinding forces in surface grinding[J]. Journal of Materials Processing Technology, 2008, 209: 2847- 2854.

[9] Patnaik D, Singh V, Rao P V. A new model for grinding force prediction and analysis[J]. International Journal of Machine Tools & Manufacture, 2010, 50: 231-240.

[10] 王君明, 汤漾平, 宾鸿赞, 等. 55钢平面磨削中未变形磨屑厚度及单位磨削力的研究[J]. 中国机械工程, 2009, 20(10): 1176-1179.

WANG Junming, TANG Yangping, BIN Hongzan,et al. Research on undeformed chip thickness and unit grinding force during surface grinding of 55 steel[J]. Chinese Journal of Mechanical Engineering, 2009, 20(10): 1176-1179.

[11] 王君明, 叶人珍, 汤漾平, 等. 55钢CBN砂轮平面磨削的磨削力模型研究[J]. 金刚石与磨料磨具工程, 2010, 30(1): 67-70, 79.

WANG Junming, YE Renzhen, TANG Yangping, et al. Research on the grinding force model of steel 55 during surface grinding with CBN wheel[J]. Diamond and Abrasive Engineering, 2010, 30(1): 67-70, 69.

[12] 张建华, 葛培琪, 张磊. 基于概率统计的磨削力研究[J]. 中国机械工程, 2007, 18(20): 2399-2402.

ZHANG Jianhua, GE Peiqi, ZHANG Lei. Research on the grinding force based on the probability statistics[J]. Chinese Journal of Mechanical Engineering, 2007, 18(20): 2399-2402.

[13] Sanjay A, Rao P V. A probabilistic approach to predict surface roughness in ceramic grinding[J]. International Journal of Machine Tools & Manufacture, 2005, 45: 609-616.

[14] Sanjay A, Rao P V. Predictive modeling of force and power based on a new analytical undeformed chip thickness model in ceramic grinding[J]. International Journal of Machine Tools & Manufacture, 2013, 65: 68-78.

[15] 陈勇平. 平面磨削力建模及其应用研究[D]. 长沙: 中南大学机电工程学院, 2007: 19.

CHEN Yongping. Research on surface grinding force model and its application [D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 19.

[16] 杨海, 程耀东, 孙月明. 钛合金磨削中的磨削力研究[J]. 磨床与磨削, 1993(2): 36-38.

YANG Hai, CHENG Yaodong, SUN Yueming. Research on the grinding force during grinding titanium alloy[J]. Grinding Machine and Grinding, 1993(2): 36-38.

(编辑 杨幼平)

收稿日期:2013-10-20;修回日期:2013-12-22

基金项目(Foundation item):国家自然科学基金资助项目(51275530)(Project (51275530) supported by Natonal Natural Science Foundation of China)

通信作者:何玉辉(1974-),男,湖南新化人,博士,副教授,从事机械设计及理论研究;电话:18975837931;E-mail: csuhyh@163.com