非线性油气悬架系统平顺性仿真与参数优化设计

田玲玲,谷正气,李伟平,梁小波,彭国谱

(湖南大学 汽车车身先进设计制造国家重点实验室,湖南 长沙,410082)

摘要:基于油气悬架台架实验,建立工程自卸车八自由度数学模型,该模型包含刚度五次方非线性和阻尼立方非线性。在此基础上利用SIMULINK建立仿真模型,并用实验验证仿真模型的正确性。通过对油气悬架参数的灵敏度分析,确定优化变量,然后以行驶平顺性为优化目标,建立油气悬架参数优化模型,利用SIMULINK、遗传算法对油气悬架参数进行联合优化设计,得到油气悬架理想的非线性刚度和阻尼特性曲线。仿真分析与实验结果表明:油气悬架的减振特性需要进一步优化设计。优化后,各车速下座椅的加权加速度均方根值分别降低了约17.3%,18.8%,25.8%,油气悬架的减振性能和整车行驶平顺性得到明显改善。

关键词:油气悬架;SIMULINK;遗传算法;联合优化设计

中图分类号:TP391.9 文献标志码:A 文章编号:1672-7207(2011)12-3715-07

Ride comfort simulation and parameters optimization design of nonlinear hydro-pneumatic suspension system

TIAN Ling-ling, GU Zheng-qi, LI Wei-ping, LIANG Xiao-bo, PENG Guo-pu

(State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, Hunan University, Changsha 410082, China)

Abstract: Based on the bench test of hydro-pneumatic suspension, the model of engineering dump truck with eight degrees of freedom was set up, including five square stiffness and cubic damping characteristics. The simulation model was established by SIMULINK and validated by test. The most suitable optimized parameters were achieved according to sensitivity analysis, and then the optimal design model was established by taking ride comfort as optimization objective. The optimal stiffness and damping curves were obtained after the combined optimization design between SIMULINK and GA algorithm. The results show that the stiffness and damping characteristics of hydro-pneumatic suspension need to be optimized to improve ride comfort. The root mean square values of different seat accelerations are brought down by 17.3%, 18.8%, 25.8%, and the vehicle ride comfort can be significantly improved.

Key words: hydro-pneumatic suspension; SIMULINK; genetic algorithm; combined optimization design

油气悬架(hydro-pneumatic suspension,HPS)系统多用于非公路车辆,具有非线性特征。理想的油气悬架的非线性刚度特性和阻尼特性能够使车辆具有良好的行驶平顺性[1-2]。国内外对油气悬架系统性能及车辆的平顺性做了大量仿真研究[3-7],但上述研究建立的动力学仿真模型结构简单,一般为二自由度1/4模型,只能反映垂直方向的振动,而且大都只针对油气悬架系统性能及其车辆的平顺性作了仿真,没有进一步对其刚度和阻尼特性进行优化研究。而理想的油气悬架的非线性刚度特性和阻尼特性能够使车辆具有良好的行驶平顺性,在此,本文作者基于整车平顺性实验,建立了整车八自由度数学模型和仿真模型,以行驶平顺性为优化目标,建立了油气悬架优化模型,利用SIMULINK、遗传算法对油气悬架参数进行了联合优化设计,得到了油气悬架理想的非线性刚度和阻尼特性曲线,为进一步优化油气悬架充气高度、充气压力、结构参数等提供了依据。

1 整车八自由度数学模型

1.1 油气悬架非线性力学特性

结合实验数据用最小二乘法对油气悬架的非线性刚度和阻尼特性进行拟合[8-9],得到其非线性刚度特性(去除摩擦力)的表达式:

(1)

(1)

其非线性阻尼特性的表达式:

(2)

(2)

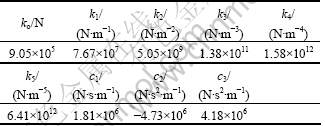

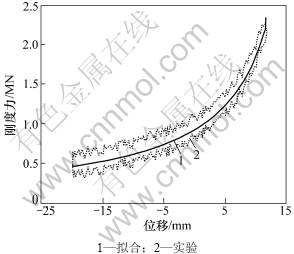

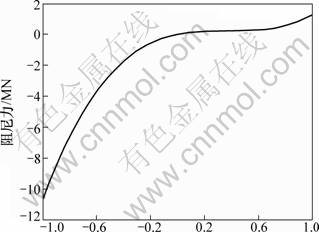

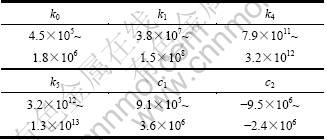

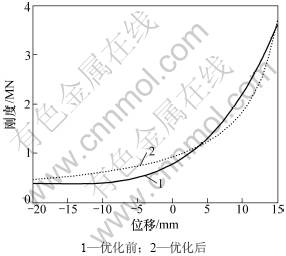

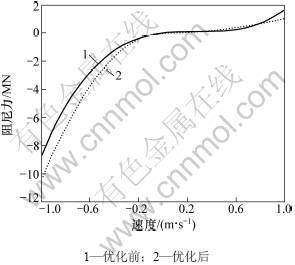

式中:ki(i=1,…,5)和ci(i=1,2,3)为油气悬架力学性能参数;Δz和 分别为悬架活塞行程和速度。表1所示为油气悬架力学特性参数。油气悬架多项式模型表示结果和实验结果对比如图1和2所示,从图1和2可以看出:二者基本吻合,说明拟合得到的油气悬架多项式模型,能够准确预测油气悬架的力学特性。

分别为悬架活塞行程和速度。表1所示为油气悬架力学特性参数。油气悬架多项式模型表示结果和实验结果对比如图1和2所示,从图1和2可以看出:二者基本吻合,说明拟合得到的油气悬架多项式模型,能够准确预测油气悬架的力学特性。

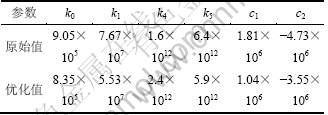

表1 油气悬架力学特性参数

Table 1 Mechanical properties of HPS

图1 油气悬架拟合刚度曲线

Fig.1 Stiffness curves of HPS

图2 油气悬架拟合阻尼曲线

Fig.2 Damping curve of HPS

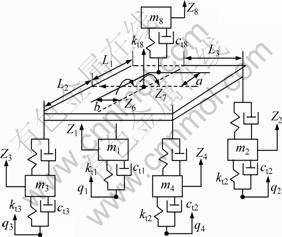

1.2 非线性油气悬架整车八自由度数学模型

本文研究的自卸车是两轴矿用重载运输车辆,综合考虑仿真精度和参数测量准确度,采用集中质量法将自卸车简化为八自由度(Degree of freedom,DOF)三维空间模型,如图3所示。根据牛顿第二定律,以车身静平衡位置为坐标原点建立车辆运动的数学模型,即式(3)~(10)。

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

其中:S1=z1-(z5-L1z6+L3z7),S2=z2-(z5-L1z6-L3z7),S3=z3-(z5+L2z6+L3z7),S4=z4-(z5+L2z6-L3z7)分别为左前、右前、左后、右后油气悬挂上下测点相对位移;m1,m2,m3,m4为前后非悬挂质量;m5,I6,I7为车身质量、车身绕其质心的转动惯量;m8为人椅系统的质量;kt1,kt2,kt3,kt4为前后轮胎的刚度;ct1,ct2,ct3,ct4为前后轮胎的阻尼;kj(j=0,1,2,3,4,5)为油气弹簧非线性刚度特性表达式系数;cj(j=1,2,3)为油气悬架非线性阻尼特性表达式系数;k8,c8为座椅的支撑刚度和阻尼;L1,L2,L3分别为各支撑点到车身质心的距离;a,b分别为座椅支撑点到车身质心的距离;Zi(i=1,2,3,4,5,8)分别为各集中质量的垂直位移;Zi(i=6,7)为车身的转角位移;qi(i=1,2,3,4)分别为前后轮路面激励。

图3 自卸车八自由度三维空间模型

Fig.3 3D model of dump truck with 8 DOF

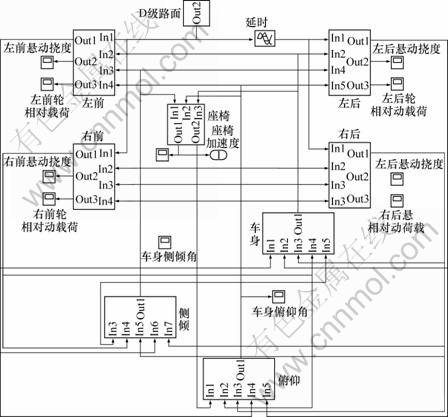

2 整车SIMULINK可视化仿真建模

由于式(3)~(10)是强非线性微分方程组,包含非线性项、互相耦合的8个自由度,自由度多且方程组复杂,采用解析法难以求解。本文采用SIMULINK将非线性动力学微分方程组转化成仿真模型进行求解和仿真研究,仿真模型如图4所示。

图4 整车8自由度仿真模型

Fig.4 Simulation model of full vehicle with 8 DOF

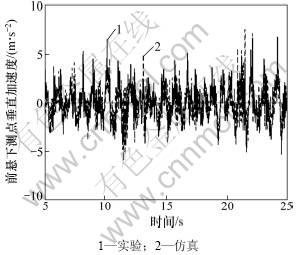

3 平顺性仿真与实验结果比较分析

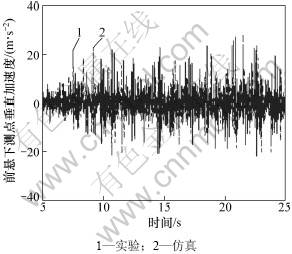

为了评价自卸车的行驶平顺性以及对整车八自由度动力学模型进行验证,对自卸车在ISO D级路面上进行了整车满载道路试验。车速为40 km/h时,前悬上测点垂直加速度仿真结果与实验结果对比如图5和6所示。表2所示为前悬测点垂向加速度均方根值及座椅测点总加权加速度均方根(Root mean square,RMS)仿真结果与实验结果对比分析。从图5和6可看出,前悬上测点垂直加速度仿真结果与实验结果基本吻合。表2中各测点的总加权加速度均方根仿真结果与实验结果的相对误差都在10%之内,以上分析表明:所建仿真模型具有较高的可信度。

图5 前悬上测点垂直加速度实验与仿真结果对比

Fig.5 Comparison of vertical acceleration test and simulation results at upper measuring point of front suspension

图6 前悬下测点垂直加速度实验与仿真对比

Fig.6 Comparison of vertical acceleration test and simulation results at lower measuring point of front suspension

表2 前悬垂向及座椅总加权加速度均方根实验与仿真结果对比

Table 2 Comparison of RMS test and simulation results of front suspension and seat acceleration m/s2

分析仿真和实验数据,采用基本评价方法评价其平顺性,得到座椅测点总的加权加速度超过了0.8 m/s2,在此加权加速度下人会有不舒适的感觉[10],因此需要对悬架系统进行优化,得到悬架许用范围内更为理想的非线性刚度和阻尼特性,以改进整车行驶平顺性能。

4 非线性油气悬架参数优化设计

4.1 优化模型的建立

在仿真模型的基础上,以提高自卸车行驶平顺性为目标,对油气悬架的减振性能进行优化设计。

4.1.1 目标函数

ISO2631-1:1997(E)标准中规定,当评价振动对人体健康的影响时,就考虑座椅平面3个轴向的振动,且2个水平轴向的轴向加权系数取k=1.4,比垂直轴向更敏感,因此将总加权加速度确定为目标函数,目标值越小,其平顺性越好,即:

(11)

(11)

其中:αv为3个轴向的总加权加速度均方根, ;αxw,αyw,αzw分别为纵向、侧向、垂向加权加速度均方根。

;αxw,αyw,αzw分别为纵向、侧向、垂向加权加速度均方根。

4.1.2 参数灵敏度分析确定优化变量

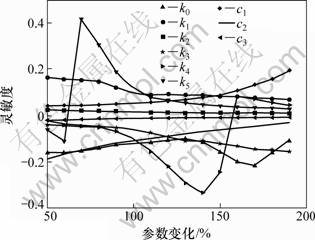

为了选择合理的油气悬架优化参数,对前后油气悬架刚度和阻尼参数进行了灵敏度研究,仿真得到各参数对座椅总加权加速度均方根的灵敏度如图7所示。从图7可知:各参数对座椅总加权加速度均方根影响的显著程度不一样,参数k0,k1,k4,k5,c1和c2的改变对座椅加速度均方根值的影响较大,而参数k2,k3和c3的改变对座椅加速度均方根值的影响很小。因此,选择参数k0,k1,k4,k5,c1,c2作为油气悬架的优化变量。考虑整车行驶平顺性和操纵稳定性对油气悬架刚度和阻尼特性的要求,得到优化变量的范围如表3所示。

图7 各参数对座椅加速度均方根的灵敏度曲线

Fig.7 Sensitivity curves of parameters on seat acceleration RMS

表3 各优化变量取值范围

Table 3 Range of optimization variables

4.1.3 约束条件[10-14]

(1) 对悬架动挠度fd的约束。悬架动挠度和其限位行程[fd]有关,若配合不当会增加撞击限位的概率,使平顺性变坏,悬架动挠度均方根σfd应限制在[fd]的1/3之内,这时撞击限位的概率小于0.3%。根据相关标准及油气悬架实际结构,在这里[fd]取15~25 cm。

(2) 对轮胎与地面动载荷Fd的约束。当Fd大于车轮作用于路面的静载G时,车轮会跳离地面,将失去纵向和侧向附着力,使行驶安全性恶化。轮胎相对动载荷均方根σFd小于G/3时,车轮跳离地面的概率小于0.15%。

(3) 对车身侧倾角的约束。侧倾角过大过小都不好,一般要求在0.4g侧向加速度下,车身侧倾角不超过6°。

(4) 对车身俯仰角的约束。汽车在行驶过程中会发生俯仰运动,一般要求车身的俯仰角小于1°。

上述约束的数学模型如下:

(12)

(12)

4.2 油气悬架参数优化设计的实现

本文在SIMULINK建立的仿真模型的基础上,借助遗传算法,以式(11)为目标函数,式(12)为约束条件,对油气悬架参数进行联合优化设计。经过多次试验,优化时遗传算法采用的操作参数如下:种群数30,代数200,交叉概率0.8,变异概率0.04,每隔10代进行一次迁移,迁移概率取0.2。经优化得到油气悬架最佳刚度和阻尼参数如表4所示,与其对应的油气悬架最佳刚度和阻尼特性曲线,如图8和9所示。

4.3 优化结果分析

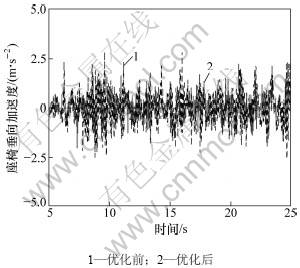

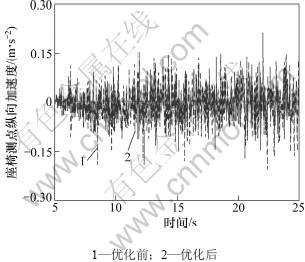

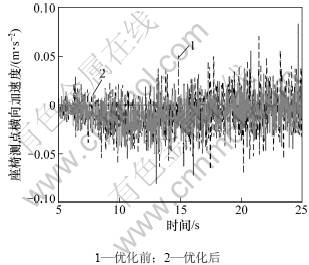

为检验优化后的刚度和阻尼特性曲线对油气悬架减振性能的影响,对优化前后悬架的减振性能进行了仿真分析和对比。表5所示为GB D级路面满载、各车速下目标函数优化前后结果对比分析;图10~12所示为40 km/h座椅各向加速度优化前后结果对比。由表5可以看出:优化后各车速下座椅的加权加速度均方根分别降低了约17.3%,18.8%,25.8%,极大的提高了自卸车的整车行驶平顺性。

表4 油气悬架最佳刚度和阻尼参数

Table 4 Most suitable optimized parameters of HPS

图8 油气悬架优化前后刚度对比曲线

Fig.8 Stiffness curves of HPS before and after optimization

图9 油气悬架优化前后阻尼对比曲线

Fig.9 Damping curves of HPS before and after optimization

表5 各车速下目标函数优化前后对比

Table 5 Comparison of objective functions before and after optimization at different speeds

图10 椅测点垂向加速度优化前后对比曲线

Fig.10 Seat vertical acceleration before and after optimization

图11 座椅测点纵向加速度优化前后对比曲线

Fig.11 Seat longitudinal acceleration before and after optimization

图12 座椅测点横向加速度优化前后对比曲线

Fig.12 Seat lateral acceleration before and after optimization

5 结论

(1) 基于油气悬架台架试验,建立了工程自卸车八自由度非线性动力学模型,该模型可有效模拟油气悬架的动力学响应特性。用SIMULINK建立仿真模型对其进行了仿真研究,与实验结果比较,验证了模型的正确性。

(2) 需要进一步对油气悬架参数进行优化设计。利用SIMULINK、遗传算法对油气悬架参数进行了联合优化设计,得到了油气悬架理想的非线性刚度和阻尼特性曲线,为进一步优化油气悬架充气高度、充气压力、结构参数等提供了依据。

参考文献:

[1] 邹游, 喻凡, 孙涛. 非线性油气悬架的平顺性仿真研究[J]. 计算机仿真, 2004, 21(10): 157-159.

ZOU You, YU Fan, SUN Tao. Simulation of nonlinear hydro-pneumatic suspension for comfort[J]. Computer Simulation, 2004, 21(10): 157-159.

[2] 仝军令, 李威. 非确定性参数对油气悬架系统性能的影响[J]. 起重运输机械, 2007(11): 49-52.

TONG Jun-ling, LI Wei. The effect of Non-deterministic parameters of hydro-pneumatic spring on suspension system performances[J]. Hoisting and Conveying Machinery, 2007(11): 49-52.

[3] 向华荣. 基于油气悬架的车辆平顺性研究[D]. 南京: 江苏大学汽车交通工程学院, 2005: 20-28.

XIANG Hua-rong. The research of comfort based on hydro-pneumatic suspension[D]. Nanjing: Jiangsu University. College of Vehicle and Transportation Engineering, 2005: 20-28.

[4] 张太平. 非线性油气悬架振动系统研究[D]. 大连: 大连理工大学机械工程学院, 2007: 24-31.

ZHANG Tai-ping. The vibrational characteristic research of nonlinear HPS[D]. Dalian: Dalian University of Technology. College of Mechanical Engineering, 2007: 24-31.

[5] 仝军令, 李威, 傅双玲. 油气弹簧主要参数对悬架系统性能的影响分析[J]. 系统仿真学报, 2008(9): 2271-2274.

TONG Jun-ling, LI Wei, FU Shuang-ling. Effect analysis of main parameters of hydro-pneumatic spring on suspension system performances[J]. Journal of System Simulation, 2008(9): 2271-2274.

[6] Burton A W, Truscott A J, Welistead P E. Analysis, modeling and control of an advanced automotive self-leveling suspension system[J]. IEEE, 1995: 1061-1063.

[7] 戴清桥. 油气弹簧及其悬架系统的特性研究[D]. 武汉: 华中科技大学机械科学与工程学院, 2003: 21-62.

DAI Qing-qiao. The characteristic research of hydro-pneumatic spring on suspension system[D]. Wuhan: Huazhong University of Science and Technology. School of Mechanical Science and Engineering, 2003: 21-62.

[8] 杨杰, 陈思忠, 刘昭度. 油气悬架台架试验中的数据处理[J]. 科学技术与工程, 2008(3): 709-713.

YANG Jie, CHEN Si-zhong, LIU Zhao-du. Data processing in the bench test of oil-gas spring[J]. Science Technology and Engineering, 2008(3): 709-713.

[9] 黄贤广. 油气悬架台架试验中的数据处理[J]. 汽车技术, 2008(7): 48-51.

HUANG Xian-guang. Data processing in the bench test of oil-gas spring[J]. Automobile Technology, 2008(7): 48-51.

[10] 余志生. 汽车理论[M]. 北京: 机械工业出版社, 2000: 204-250.

YU Zhi-sheng. Automotive theory[M]. Beijing: China Machine Press, 2000: 204-250.

[11] 卢剑伟, 陈解, 王其东. 平顺性仿真驱动的板簧承载式悬架参数优化[J]. 系统仿真学报, 2007, 19(21): 5025-5029.

LU Jian-wei, CHEN Jie, WANG Qi-dong. Optimization of leaf-spring suspension parameters based on ride comfort simulation[J]. Journal of System Simulation, 2007, 19(21): 5025-5029.

[12] 王飞. 油气悬架系统动力学建模仿真和实验研究[D]. 吉林: 吉林大学机械学院, 2005: 29-39.

WANG Fei. Simulation for the dynamic characteristic of hydro-pneumatic suspension[D]. Jilin: Jilin University. School of Mechanical Engineering, 2005: 29-39.

[13] LU Sun. Optimum design of “road-friendly” vehicle suspension systems subjected to rough pavement surfaces[J]. Applied Mathematical Modeling, 2002, 26(5): 635-652.

[14] 王望予. 汽车设计[M]. 北京: 机械工业出版社, 2004: 174-218.

WANG Wang-yu. Automotive design[M]. Beijing: China Machine Press, 2004: 174-218.

(编辑 赵俊)

收稿日期:2011-01-05;修回日期:2011-05-07

基金项目:国家高技术研究发展计划(“863”计划)项目(2007AA04Z122)

通信作者:谷正气(1963-),男,湖南长沙人,教授,从事空气动力学、整车性能仿真与优化研究;电话:0731-88823055;E-mail:guzhengqi63@sohu.com