文章编号:1004-0609(2011)09-2209-07

承受扭矩和剪切时开口多孔金属的孔棱失效

刘培生1, 马晓明2

(1. 北京师范大学 核科学与技术学院,北京100875;2. 清华大学 核能与新能源技术研究院,北京100084)

摘 要:以高孔率的三维网状多孔金属(即开口多孔金属)为研究对象,建立其简化结构失效模型。分析多孔构件在扭转和剪切载荷形式作用下由于孔棱发生拉断、剪切和屈曲而引起的失效模式,系统地研究上述两种承载条件下这类多孔体构件受到载荷作用而导致孔棱失效时名义载荷与孔率的数理关系。在此基础上,进一步研究此类材料在不同载荷作用下发生各种孔棱失效模式的载荷条件。结果表明,这些失效模式与多孔金属的材质指标、孔率及承受的载荷大小等因素均有关系,这种关系也可以进行相应的具体数理表征。

关键词:多孔金属;泡沫金属;多孔材料

中图分类号:TB383 文献标志码:A

Possible failure of pore-strut for

open-cell foamed metals under torsion and shearing

LIU Pei-sheng1, MA Xiao-ming2

(1. College of Nuclear Science and Technology, Beijing Normal University, Beijing 100875, China;

2. Institute of Nuclear and New Energy Technology, Tsinghua University, Beijing 100084, China)

Abstract: The simplified structural models of failure were put forward for three-dimensional reticulated porous metals, i.e. open-cell porous metals, with high porosity. The failure modes were then analyzed for porous components under torsional and shearing loads, of which the destruction is caused by the tensile rupture, the shearing fracture and the yield of the pore strut of these porous metals. In addition, the mathematical relationships between the nominal loading and porosity were systemically studied for these failures of the pore strut of these components under loads resulting in the strut failure. On the basis of these works, the loading conditions of these porous materials were further studied for various strut failure modes from different loading. The results show that these failure modes are relative to the material indexes, porosity and loading magnitude, and these relationships can be correspondingly expressed by the specific mathematical equations.

Key words: foamed metal; porous metal; porous material

多孔金属构件作为一种性能优异的工程材料,可用于分离、过滤、布气、消音、吸震、包装、屏蔽、热交换、生物移植、电化学过程和各类轻质结构等诸多方面[1-3]。多孔金属的工程应用对材料的力学性能有相应的要求,尤其是对于作为轻质结构件的场合。因此,国内外研究人员对多孔金属的力学行为开展了大量的研究[1, 4-21]。然而,以往的相关研究工作主要集中于多孔材料的拉压性能[1, 4],国内外对多孔材料承受扭矩和剪切作用的力学行为研究相对少见[1, 8-9, 13-14, 17, 19]。CHEN等[8]对泡沫铝充填薄壁方柱的扭转行为进行了研究,结果发现填充物的存在改变了构件的扭转坍塌机制,即抑制或减少了向内坍塌,并提高了薄壁方柱的扭转抗力。BERNARD等[9]对泡沫铝夹芯结构的扭转实验结果也发现,空心金属方管在充入泡沫铝芯体后,其结构的屈曲变形受到抑制,刚度得到提高。BLAZY等[13]研究了泡沫铝的扭转变形和破坏,发现其剪切应力—应变曲线显示了一个短的弹性区和两个明显的硬化区,但未能解释这两个硬化段出现的原因。除此之外,没有发现最近其他对于泡沫金属在扭转载荷作用下的有关研究。此外,RAKOW和WAAS[14]对泡沫铝剪切响应的尺寸效应进行了实验研究;KOVACIK[17]检测了泡沫铝的剪切模量;WANG等[19]也研究了泡沫铝的剪切行为,发现闭孔泡沫铝的剪切变形和破坏机制有别于压缩机制。可见,对于开口多孔金属及其构件的扭转和剪切行为的研究,至今还是远远不足的。为此,本文作者在文献[22-23]的工作基础上,结合八面体模型[6, 24]的有关计算结果,研究高孔率(孔率大于70%[1])网状开口多孔金属构件在扭矩和剪切载荷作用下产生破坏时其孔棱的可能失效模式,以期为该材料在这些情况下使用时的强度设计提供更全面的依据。

1 分析模型和基本数理关系

1.1 分析模型

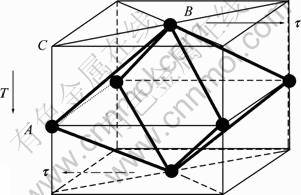

对于结构均匀、各向同性的三维网状多孔金属,可将其结构抽象为金属棱柱(孔棱或孔筋)按立方体对角线方式规则地连接而成的多孔体[6, 24-25],该简化结构模型的体心立方式八面体孔隙单元见图1。由于多孔体中的孔棱结点强度一般高于孔棱本身的,所以,失效、破坏一般优先发生在孔棱上。当多孔体构件承受扭转、剪切载荷时,由其名义扭矩T或名义切应力τ引起的孔棱内部最大拉应力σmax达到对应密实材质的许用正应力或抗拉强度σ0大小,或者最大切应力达到对应密实材质的许用切应力或剪切强度τ0大小,或者孔棱发生屈曲时,都会导致多孔体的整体性失效。

图1 均匀开口网状多孔金属的简化结构模型

Fig.1 Structural unit of octahedron for isotropic open-cell reticulated foamed metals

1.2 基本数理关系

1.2.1 扭矩作用

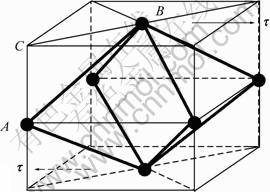

如果有一个竖直方向的扭矩矢量T作用于多孔构件,则产生一个水平方向的剪切作用,参见图2。取扭矩造成最大剪切作用处的八面体单元为研究对象。根据文献[22]的推演结果,如果多孔构件受到扭矩T作用,则多孔体中孔棱出现的由扭矩引起的最大正应力和最大轴应力(它们发生在多孔构件的截面边缘,或者说是多孔构件的表层部分)分别为

(1)

(1)

(2)

(2)

式中:θ是多孔体的孔率(θ >70%);T为扭矩矢量T的标量;WT(下标T为torsion的首写字母,表示“扭转”)为多孔构件的抗扭截面模量。

图2 开口网状多孔金属在扭转载荷作用下发生剪切的分析模型图

Fig.2 Analytical model of open-cell reticulated foamed metals under torsional loading

因此,孔棱中出现的最大正应力为

(3)

(3)

对应孔棱中出现的最大切应力为

(4)

(4)

1.2.2 剪切作用

假定有一个水平方向的剪切力τ作用于多孔构件,参见图3。根据文献[23]的推演结果,类似于本文第1.2.1部分对扭矩作用的处理,如果多孔构件受到名义切应力τ作用,则多孔体中孔棱出现的由剪切载荷引起的最大正应力和轴应力分别为

(5)

(5)

(6)

(6)

式中:τ为τ的标量。

图3 开口网状多孔金属在剪切载荷作用下的分析模型图

Fig.3 Analytical model of open-cell reticulated foamed metals under shearing loading

因此,孔棱中出现的最大正应力为

(7)

(7)

对应孔棱中出现的最大切应力大小为

(8)

(8)

2 失效模式分析

2.1 孔棱拉断和剪切破坏模式

2.1.1 扭矩作用

根据文献[22]的处理方式,可得出扭转载荷作用下多孔体中孔棱发生拉断破坏模式和剪切破坏模式时最大名义扭矩与孔率的数理关系表征分别为

(9)

(9)

(10)

(10)

式中:Tmax为多孔体能够承受的最大名义扭矩;kT为扭转材料常数,取决于多孔体的材质种类和制备工艺条件;m为多孔体对应致密材质的塑脆性指标,介于1~1.5(即3/2)之间[6, 22, 25];σ0和τ0分别为多孔体对应致密材质的抗拉强度和剪切强度。对于对应致密构件的抗扭截面模量为WP的多孔圆轴来说,其抗扭截面模量有如下关系[22]:

(11)

(11)

将式(11)代入式(9)和(10),得

(12)

(12)

(13)

(13)

根据上文可以知道,当多孔金属在扭矩载荷作用下满足

(14)

(14)

时,多孔体将发生由孔棱最大正应力引起孔棱拉断的破坏;而满足关系

(15)

(15)

时,多孔体将发生由孔棱最大切应力引起孔棱剪断的破坏。

当多孔金属由相同材质并通过相同工艺方式制备时,则有相同的材料常数kT和相同的塑脆性指标m。根据式(14)和(15),由于脆性材质的剪切强度与抗拉强度大小相当,即τ0≈σ0 [26],因此,式(14)条件比较容易满足,所以此时多孔体的孔棱将为拉断破坏;而韧性材质的剪切强度略高于其抗拉强度的半值,即τ0≈(0.5~0.577)σ0 [26],因此,式(14)和(15)的条件相当,当材质的τ0为其σ0的半值或接近半值时,多孔体的孔棱趋向于剪切断裂破坏;当材质的τ0超过其σ0/2一定程度时,多孔体的孔棱将趋向于拉断破坏。

2.1.2 剪切作用

根据文献[23]的处理方式,类似于本文第2.1.1部分对扭矩作用的处理,可得出剪切载荷作用下,多孔体中孔棱发生拉断破坏模式和剪切破坏模式时,最大名义切应力与孔率的数理关系表征分别为

(16)

(16)

(17)

(17)

式中:τN(下标N为nominal的首写字母,表示“名义上的”)为多孔体能够承受的最大名义切应力;kS(下标S为shearing的首写字母,表示“剪切”)为剪切材料常数,类似于本文第2.1.1部分的扭转材料常数kT。

根据以上所述可知,当多孔金属在扭矩载荷作用下满足

(18)

(18)

时,多孔体将发生由孔棱最大正应力引起孔棱拉断的破坏;而满足关系

(19)

(19)

时,多孔体将发生由孔棱最大切应力引起孔棱剪断的破坏。

类似于本文第2.1.1部分的对应分析,当多孔金属由相同材质并通过相同工艺方式制备时,有相同的材料常数kS和相同的塑脆性指标m。根据式(18)和(19),由于脆性材质的剪切强度与抗拉强度大小相当,即τ0≈σ0 [26],因此,式(18)条件比较容易满足,此时多孔体的孔棱将为拉断破坏。而韧性材质的剪切强度略高于其抗拉强度的半值,即τ0≈(0.5~0.577)σ0 [26],因此,式(18)和(19)的条件相当,当材质的τ0为其σ0的半值或接近半值时,多孔体的孔棱趋向于剪切断裂破坏;当材质的τ0超过其σ0/2一定程度时多孔体的孔棱将趋向于拉断破坏。

2.2 孔棱屈曲破坏模式

2.2.1 扭矩作用

由式(2)和(11),得出此时多孔体孔棱的最大压缩轴应力σA(下标A为axial的首写字母,表示“轴的”)可进一步表示为

(20)

(20)

根据文献[27]可知,多孔体孔棱的长细比为

(21)

(21)

1)细长杆情形

如果以E表示对应致密材质的弹性模量,sp表示对应致密材料的比例极限,则当多孔体的孔率

(22)

(22)

时,孔棱即为细长杆。此时,对于对应致密材质若有工作安全因数nw大于规定的稳定安全因数[n]st

(23)

(23)

则承载系统不会发生屈曲。这里,scr为对应致密材质的欧拉临界应力;s为对应致密材质的工作应力,亦即孔棱的压缩轴应力σA。

将式(23)中的s用式(20)中的σA代替,并按照文 献[27]的方式进行处理,可得多孔体中孔棱发生临界弹性屈曲时名义扭矩与孔率的数理关系

(24)

(24)

式中:kTT(下标第一个符号T为torsion的首写字母,表示“扭转”;第二个符号T为thin的首写字母,表示“细长”)是由修正正应力大小而引入的材料常数,且kTT≈kT。

根据上式可直接得到此时多孔体孔棱发生弹性屈曲的载荷条件为

(25)

(25)

2)中长杆情形

当多孔体的孔率符合条件

(26)

(26)

时,孔棱即为中长杆。此时若有

(27)

(27)

则承载系统不会发生屈曲。这里的a和b均为与对应致密材料有关的常数(单位为MPa),其他符号意义同前。

将式(27)中的s用式(20)中的σA代替,并按照文 献[27]的方式进行处理,可得多孔体中孔棱发生临界弹塑性屈曲时名义扭矩与孔率的数理关系

(28)

(28)

式中:kTM(下标第二个符号M为middle的首写字母,表示“中长”)是类似于前述kTT的材料常数。

根据式(28)可直接得到此时多孔体孔棱发生弹塑性屈曲的载荷条件为

(29)

(29)

3)粗短杆情形

当多孔体的孔率符合条件

(30)

(30)

时,孔棱即为粗短杆。此时若有

(31)

(31)

则承载系统不会发生屈服。这里的ss为对应致密材料的屈服应力,smax为杆件中的最大压应力(出现在孔棱截面的边缘[27])。

将式(3)中的smax代入式(31),并考虑到式(11)的关系,同时按照文献[27]的方式进行处理,即得多孔体中孔棱发生临界边缘屈服时名义扭矩与孔率的数理关系

(32)

(32)

式中:kTS(下标第二个符号S为stocky的首写字母,表示“粗短”)是类似于前述kTT和kTM的材料常数。

按照文献[27]的方式对式(32)进行作进一步的修正,并令常数项

即得到

(33)

(33)

式中:m的意义同前,是对应致密材料的塑脆性指标(介于1~1.5之间)。

根据式(33)可直接得到此时多孔体孔棱发生边缘屈服的载荷条件为

(34)

(34)

2.2.2 剪切作用

根据式(6)可知,此时多孔体孔棱的最大压缩轴应力σA为

(35)

(35)

承本文第2.2.1部分,当多孔体的孔率满足式(22)的关系时,孔棱即属于细长杆的情形。将式(23)中的s用式(35)中的σA代替,并按照文献[27]的方式进行处理,即可得多孔体中孔棱发生临界弹性屈曲时名义切应力与孔率的数理关系

(36)

(36)

式中:kST(注:下标第一个符号S为shearing的首写字母,表示“剪切”,下同;第二个符号T为thin的首写字母,表示“细长”)是由修正正应力大小而引入的材料常数,类似于本文第2.2.1部分的kTT。

根据式(36)可直接得到此时多孔体孔棱发生弹性屈曲的载荷条件为

(37)

(37)

当多孔体的孔率符合式(26)的关系时,孔棱即属于中长杆的情形。将式(27)中的s用式(35)中的σA代替,并按照文献[27]的方式进行处理,即可得多孔体中孔棱发生临界弹塑性屈曲时名义切应力与孔率的数理关系

(38)

(38)

式中:kSM(下标第二个符号M为middle的首写字母,表示“中长”)是类似于前述kST的材料常数。

根据式(38)可直接得到此时多孔体孔棱发生弹塑性屈曲的载荷条件为

(39)

(39)

当多孔体的孔率满足式(30)的条件时,孔棱即属于粗短杆的情形。将式(31)中的smax用式(7)代替,并按照文献[27]的方式进行处理,即可得此时多孔体中孔棱发生临界边缘屈服时名义切应力与孔率的数理关系

(40)

(40)

式中:kSS(下标第二个符号S为stocky的首写字母,表示“粗短”)是类似于前述kST和kSM的材料常数。

按照文献[27]的方式对式(40)进行作进一步的修正,并令常数项

即得到

(41)

(41)

式中:m的意义同前,是对应致密材料的塑脆性指标(介于1~1.5之间)。

根据式(41)可直接得到此时多孔体孔棱发生边缘屈服的载荷条件为

(42)

(42)

3 结论

1) 对于结构均匀、各向同性的三维网状高孔率多孔金属,在扭转载荷作用下满足

或者

时,多孔体都将产生破坏:前者源于孔棱最大拉应力造成的孔棱拉断,后者则源于孔棱最大切应力造成的孔棱剪切断裂。

2) 上述多孔材料在剪切载荷作用下若满足

或者

时,多孔体都将产生破坏:前者源于孔棱最大拉应力造成的孔棱拉断,后者则源于孔棱最大切应力造成的孔棱剪切断裂。

3) 当上述多孔体的孔率θ与其对应致密材质的弹性模量E、比例极限sp和屈服应力ss之间的关系分别满足

,

,

,

,

且多孔体构件承受的名义扭矩T与对应致密材质的稳定安全因数[n]st、对应致密构件的抗扭截面模量WP和对应致密材质的屈服应力ss之间的关系依次达到如下条件

,

,

,

,

或者多孔体构件承受的名义切应力τ与对应致密材质的稳定安全因数[n]st和对应致密材质的屈服应力ss之间的关系依次符合如下条件

时,多孔体孔棱都将对应呈现弹性屈曲、弹塑性屈曲和边缘屈服的失效形式。

4) 在扭转和剪切载荷的作用下,脆性材质的多孔构件其孔棱多呈拉断破坏模式,韧性材质的多孔构件当其材质的τ0为其σ0的半值或接近半值时,孔棱趋向于剪切断裂破坏;而当τ0超过其σ0/2一定程度时,孔棱将趋向于拉断破坏。可见,所论多孔构件在上述载荷作用的多数情况下都是孔棱拉断破坏模式,较少出现孔棱的剪切断裂破坏模式,当满足一定条件时还可能出现孔棱弹性屈曲、弹塑性屈曲以及边缘屈服等 情况。

REFERENCES

[1] GIBSON L J, ASHBY M F. Cellular solids: Structure and properties [M]. Cambridge: Cambridge Press, 1999.

[2] 刘培生. 多孔材料引论[M]. 北京: 清华大学出版社, 2004.

LIU Pei-sheng. Introduction to porous materials [M]. Beijing: Tsinghua University Press, 2004.

[3] LIU P S, LIANG K M. Functional materials of porous metals made by P/M, electroplating and some other techniques [J]. J Meter Sci, 2001, 36(21): 5059-5072.

[4] ASHBY M F, EVANS A, FLECK N A, GIBSON L J, HUTCHINSON J W, WADLEY H N G. Metal foams: A design guide [M]. Boston: Elsevier Science, 2000.

[5] NAGAKI S, SOWERBY R, GOYA M. An anisotropic yield function for porous metal [J]. Mater sci Eng A, 1991, 142(1): 163-168.

[6] LIU p s. The tensile strength of porous metals with high porosity [J]. J Adv Mater, 2000, 32(2): 9-16.

[7] BADICHE X, FOREST S, GUIBERT T, BIENVENU Y, BARTOUT J D, IENNY P, CROSET M, BERNET H. Mechanical properties and non-homogeneous deformation of open-cell nickel foams: Application of the mechanics of cellular solids and of porous materials [J]. Mater Sci Eng A, 2000, 289(1): 276-288.

[8] CHEN W G, WIERZBICKI T, BREUER O, KRISTIANSEN K. Torsional crushing of foam-filled thin-walled square columns [J]. inter J mech sci, 2001, 43(10): 2297-2317.

[9] BERNARD T, BERGMANN H W, HABERLING C, HALDENWANGER H G. Joining technologies for Al-foam-Al-sheet compound structures[J]. Advanced engineering materials, 2002, 4(10): 798-802.

[10] BENOUALI A H, FROYEN L, DELERUE J F, WEVERS M. Mechanical analysis and microstructural characterisation of metal foams [J]. Mater sci technol, 2002, 18(5): 489-494.

[11] KWON Y W, COOKE R E, PARK c. Representative unite-cell models for open-cell metal foams with or without elastic filler [J]. Mater Sci Eng A, 2003, 343(1): 63-70.

[12] CHOE H, DUNAND d c. Mechanical properties of oxidation-resistant Ni-Cr foams [J] Mater Sci Eng A, 2004, 384(1/2): 184-193.

[13] BLAZY J S, MARIE-LOUISE A, FOREST S, CHASTELB Y, PINEAUA A, AWADEC A, GROLLERONC C, MOUSSYC F. Deformation and fracture of aluminium foams under proportional and non proportional multi-axial loading: Statistical analysis and size effect [J]. Inter J Mech Sci, 2004, 46(2): 217-244.

[14] RAKOW J F, WAAS A M. Size effects and the shear response of aluminum foam [J]. Mechanics of Materials, 2005, 32(1): 69-82.

[15] LIU P S. Mechanical behaviors of porous metals under biaxial tensile loads [J]. Mater Sci Eng A, 2006, 422(1/2): 176-183.

[16] 刘培生. 泡沫金属双向承载的力学模型[J]. 中国有色金属学报, 2006, 16(4): 567-574.

Liu Pei-sheng. Mechanical model for metallic foams under biaxial loads [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 567-574.

[17] KOVACIK J. Correlation between elastic modulus, shear modulus, Poisson’s ratio and porosity in porous materials [J]. Advanced Engineering Materials, 2008, 10(3): 250-252.

[18] 刘培生. 泡沫金属在单双向拉压载荷作用下的表征分析[J]. 中国有色金属学报, 2008, 18(11): 2062-2067.

Liu Pei-sheng. Analysis of porous open-cell metal foams under uniaxial and biaxial loadings [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 2062-2067.

[19] WANG X Z, WU L Z, WANG S X. Tensile and shear properties of aluminium foam [J]. Materials Technology, 2009, 24(3): 161-165.

[20] LIU P S, CHEN G F, CHEN Y M. Mechanical model of porous metal foams under multiaxial tensile loads [J]. Philosophical Magazine Letters, 2009, 89(10): 655-663.

[21] LIU P S. Mechanical relation for porous metal foams under complex loads of triaxial tension and compression [J]. Materials and Design, 2010, 31(4): 2264-2269.

[22] 刘培生, 罗 军, 陈一鸣. 泡沫金属多孔体在扭矩作用下的分析表征[J]. 清华大学学报: 自然科学版, 2010, 50(6): 932-935.

Liu Pei-sheng, LUO Jun, CHEN Yi-ming. Characterization of porous open-cell metal foams under torsion[J]. Journal of Tsinghua University: Science and Technology, 2010, 50(6): 932-935.

[23] 刘培生. 泡沫材料在剪切载荷作用下的力学关系推演和分析[J]. 稀有金属材料与工程, 2010, 39(3): 457-459.

Liu Pei-sheng. Deduction and analysis on mechanical relationship of porous open-cell metal foams under shearing loads [J]. Rare Metal Materials and Engineering, 2010, 39(3): 457-459.

[24] LIU Pei-sheng. Chapter 3: Porous materials: The mathematical expressions for some properties of three-dimensional reticulated porous metallic materials in the same analytical model system. Materials Science Research Horizon[M]. New York: Nova Science Publishers, 2007.

[25] 刘培生. 多孔材料在压缩载荷作用下的剪切破坏模式分析[J]. 物理学报, 2010, 59(7): 4849-4856.

Liu Pei-sheng. analyses of shearing failure mode for porous materials under compression [J]. Acta Physica Sinica, 2010, 59(7): 4849-4856.

[26] 范钦珊. 工程力学[M]. 北京: 机械工业出版社, 2008.

FAN Qin-shan. Engineering mechanics[M]. Beijing: China Machine Industry Press, 2008.

[27] 刘培生. 多孔材料在压缩载荷作用下的屈曲破坏模式分析[J]. 物理学报, 2010, 59(12): 8801-8806.

Liu Pei-sheng. Analyses of buckling failure mode for porous materials under compression [J]. Acta Physica Sinica, 2010, 59(12): 8801-8806.

(编辑 何学锋)

基金项目:中央高校基本科研业务费专项基金资助项目(2009SD-26);北京师范大学测试基金资助项目(C10)

收稿日期:2010-09-23;修订日期:2011-02-25

通信作者:刘培生,教授,博士;电话:010-62206024;E-mail: liu996@263.net