文章编号:1004-0609(2010)02-0250-07

热连轧Ti-6Al-4V合金的蠕变行为及影响因素

田素贵1,包宪宇1,陈礼清2,刘 洋1,赵忠刚1,刘相华2

(1. 沈阳工业大学 材料科学与工程学院,沈阳 110178;

2. 东北大学 轧制技术及连轧自动化国家重点实验室,沈阳 110004)

摘 要:采用热处理、蠕变性能测试及位错组态的衍衬分析,研究热连轧Ti-6Al-4V合金的蠕变行为及影响因素。结果表明:经低于β相变点的固溶处理,合金的组织结构由高固溶度的等轴α相和网篮组织组成;随着固溶温度提高,网篮组织数量增多;经1 000 ℃固溶处理后合金可获得完全网篮组织;与940 ℃固溶时效合金相比,经 1 000 ℃固溶时效合金在420 ℃、575 MPa条件下具有较低的应变速率和较长的蠕变寿命;在试验的温度和应力范围内,计算出该合金的蠕变激活能为249.8 kJ/mol;在蠕变期间,热连轧合金的变形机制是位错在具HCP结构的α相中发生双取向滑移,940 ℃固溶处理合金的蠕变机制是波浪状áa+c?位错在α相中发生锥面滑移,而经1 000 ℃固溶处理合金的变形机制是(1/2)á111?位错在具BCC结构的β相中发生多系滑移;经1 000 ℃固溶处理合金中所含的高含量富V的β相可提高合金蠕变抗力,这是合金具有较低应变速率和较长蠕变寿命的主要原因。

关键词:Ti-6Al-4V合金;热连轧;固溶处理;蠕变;变形机制

中图分类号:146.2 文献标识码:A

Creep behaviors and effect factors of

hot continuous rolled Ti-6Al-4V alloy

TIAN Su-gui1, BAO Xian-yu1, CHEN Li-qing2, LIU Yang1, ZHAO Zhong-gang1, LIU Xiang-hua2

(1. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110178, China;

2. State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110004, China)

Abstract: By heat treatment, measurement of creep properties and contract analysis of dislocations configuration, the creep behaviors and the effect factors of hot continuous rolled (HCR) Ti-6Al-4V alloy were investigated. The results show that, after the alloy solution treated at temperatures lower than β phase transformation point, the microstructures of the alloy consist of the supersaturation equiaxial α phase and network basket structure. The quantities of the network basket structure increase as the solution temperature increases, and the full network basket structure may be obtained after solution-treated at 1 000 ℃. Compared with the alloy solution treated at 940 ℃, the alloy solution treated at 1 000 ℃ displays a lower strain rate and a longer creep lifetime under the conditions of the applied stress of 575 MPa at 420 ℃. In the range of the applied temperatures and stresses, the creep activation energy of the alloy is calculated to be 249.8 kJ/mol. The deformed mechanism of HCR alloy during creep is double orientation slipping of dislocations activated within α phase with HCP structure, while the deformed feature of the alloy solution treated at 940 ℃ is the wave-like áa+c? dislocations activated on the pyramidal planes in α phase. After solution treated at 1 000 ℃, the deformed mechanism of the alloy is the multiple slipping of (1/2) á111? dislocations activated within β phase with BCC structure. In this alloy, the high volume fraction V-riched β phase may enhance the creep resistance of the alloy. This is the main reason why this alloy possesses relatively low strain rate and long creep lifetime.

Key words: Ti-6Al-4V alloy; hot continuous rolling; solution treatment; creep; deformation mec

由于钛合金具有比强度高、中温力学性能及抗腐蚀性能好等特点,已被广泛用于制作发动机的风扇、压气机盘及其它重要承力构件[1-3]。 采用真空自耗熔炼制备合金锭坯[4],然后进行等温锻造和热处理是钛合金传统的制备工艺[5-9],但由于钛合金的制备工艺复杂、生产成本高等限制了其进一步的应用。采用热连轧技术生产钛合金是一种新工艺的尝试,若能采用该技术制备钛合金,而不降低使用性能,则可达到实现连续性工业化生产、节约能源和降低成本等目的。

钛合金经不同温度热处理,可获得不同的组织结构与蠕变性能[10-11]。经低于β相变点温度进行固溶及时效处理后,可获得等轴α相与网蓝组织并存的双态组织,兼有较好的塑性和抗蠕变能力[12];经高于β相变点温度进行固溶及时效处理,则可明显提高合金的抗蠕变能力[13]。由于不同组织结构合金具有不同的变形机制,且变形机制又与蠕变性能密切相关,因而,探讨合金的蠕变机制,可分析合金的蠕变抗力,为合金的成分设计和制定热处理工艺提供理论依据,但有关钛合金蠕变机制方面的研究很少有文献报道。

因此,本文作者采用热连轧技术制备Ti-6Al-4V合金,通过对合金进行不同工艺热处理、蠕变性能测试、组织形貌观察及位错组态的衍衬分析,研究热连轧Ti-6Al-4V合金的蠕变行为及微观变形机制,试图为热连轧钛合金的发展与应用提供理论依据。

1 实验

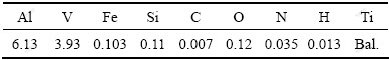

将真空感应熔炼及3次真空自耗熔炼制备的Ti-6Al-4V合金锭坯,在1 100~1 150 ℃范围内进行热连轧,制备出直径为50 mm的棒材,称为热连轧(HCR)合金,该合金的化学成分列于表1。将热连轧Ti-6Al-4V合金棒材分别在940、980和1 000 ℃进行固溶处理,再经480 ℃保温24 h进行时效处理,将不同温度固溶及时效处理后的Ti-6Al-4V合金加工成横断面为4.5 mm×2.5 mm,标距长度为20 mm的片状蠕变试样,分别将其置入GWT504型高温持久/蠕变试验机中,进行不同条件的蠕变性能测试,并绘制蠕变曲线。采用SEM和TEM观察不同工艺处理合金的组织形貌,并对其进行位错组态的衍衬分析,研究热连轧合金的蠕变行为及影响因素,并对不同工艺处理合金进行蠕变机理分析。

表1 Ti-6Al-4V合金的化学成分

Table 1 Chemical compositions of Ti-6Al-4V (mass fraction, %)

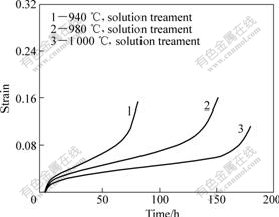

图1 在420 ℃、575 MPa条件下经不同温度固溶处理后合金的蠕变曲线

Fig.1 Creep curves of Ti-6Al-4V alloy after solution treatment at different temperatures measured at 420 ℃ and 575 MPa

2 结果与分析

2.1 合金的蠕变特征

与等温锻造合金相比,热连轧态Ti-6Al-4V合金具有相近的组织结构与蠕变性能,在410 ℃、550 MPa条件下,等温锻造合金的蠕变寿命为66 h,热连轧态合金的蠕变寿命为72 h。热连轧态合金经不同温度固溶及时效处理后,在420 ℃、575 MPa条件下测定的蠕变曲线如图1所示。测定出各自合金在稳态蠕变期间的应变速率分别为2.3×10-7、1.33×10-7和8.89×10-8 s-1,蠕变寿命分别为81、151.5和180 h,与前两者相比,经1 000 ℃固溶及时效处理合金具有较低的稳态期间应变速率和较长的蠕变寿命。

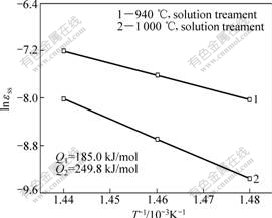

合金经940和1 000 ℃固溶及时效处理后,在400~420 ℃和575 MPa条件下,测定各自合金在稳态蠕变期间的应变速率与温度的关系,结果如图2所示。在试验温度和应力范围内,根据图2可计算出各自合金在稳态蠕变期间的激活能分别为Qa1=185 kJ/mol和Qa2=249.8 kJ/mol。结果表明,经1 000 ℃固溶及时效处理后,合金具有较好的蠕变抗力。

图2 在稳态蠕变期间合金的应变速率与施加温度的关系

Fig.2 Relationship between strain rates and applied temperatures during steady state creep

2.2 固溶温度对合金组织结构的影响

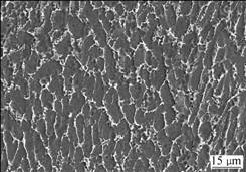

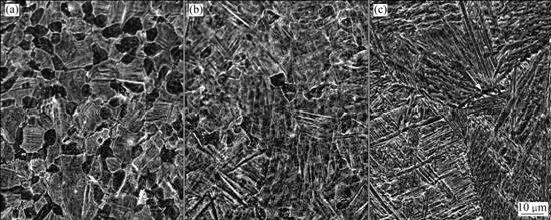

Ti-6Al-4V合金经热连轧后的纵断面组织形貌如图3所示。由图3可知,Ti-6Al-4V合金具有与等温锻造合金相同的组织结构,均由α和β两相组成。图3中暗色区域为α相,白色的网状组织为β相,合金中的α相沿轧制的流变方向呈类条状分布,β相沿条带状α相的边界呈网状分布,其中条带状α相的长度约为15 μm,宽度约为5 μm,且α相中无明显析出物,并均匀分布。

图3 热连轧Ti-6Al-4V合金的组织形貌

Fig.3 Microstructure of hot continuous rolled Ti-6Al-4V alloy

合金经不同温度固溶及时效处理后的组织形貌如图4所示。经940 ℃固溶及时效处理后,合金的组织形貌如图4(a)所示。实验选用合金的β相转变温度为995 ℃[14],由于固溶温度低于β相转变点,在固溶处理期间,合金中大部分α相转变为β相,但仍有部分α相得以保留。高温β相经快速冷却后成为富Al的过饱和固溶体,并有针状相析出,经时效处理后,针状析出物数量增多,形成网篮组织,其形貌如图4(a)中的灰色区域所示。在图4(a)中的暗色区域为固溶处理后仍保留的α相,且数量较多。合金经980 ℃固溶及时效处理后的组织形貌如图4(b)所示,尽管固溶温度有所提高,合金中仍然保留有未溶解的初始α相,但数量明显减少,网篮组织数量增多。当固溶温度提高到1 000 ℃(已高于β相转变点),合金中的α相已完全溶解,均转变成BCC结构的β相,冷却后成为浓度过饱和的β相,经时效处理后,完全转变成网蓝组织,并有针状α相在β相中沿一定取向析出,如图4(c)所示。合金中的晶界如图4(c)中箭头所示,在网篮组织中的不同晶粒内,针状α相具有不同的取向,在同一晶粒内,有多组针状相相互平行或互成一定角度排列。

图4 在不同温度固溶处理后Ti-6Al-4V合金的组织形貌

Fig.4 Microstructures of Ti-6Al-4V alloy after solution treatment at different temperatures: (a) 940 ℃; (b) 980 ℃; (c) 1 000 ℃

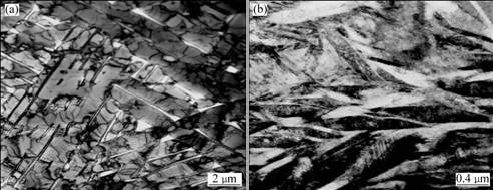

合金中网篮组织的TEM像如图5所示。经电子衍射及微区成分分析表明,在网篮组织中的条束状暗色区域为BCC结构且富含元素V的β相,而β相间的白色针状相为α相,如图5(a)所示。由图5可以看出,条状β相具有多组平行束的特征,且平行束之间互成60?角,并在网篮组织的局部区域存在针状或片状马氏体,如图5(b)所示。

图5 经高温固溶处理后Ti-6Al-4V合金中的网篮组织

Fig.5 Network basket structures of Ti-6Al-4V alloy after solution treatment at 1 000 ℃: (a) Networks basket structure; (b) Slice- like martensite in network-basket structure

2.3 变形合金的位错组态

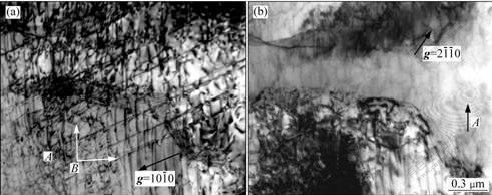

在400 ℃、575 MPa 条件下,热连轧Ti-6Al-4V合金蠕变66 h断裂后,在HCP结构α相中的位错组织如图6所示。由图6可以看出,该合金在蠕变期间的变形特征是α相中发生位错的双取向滑移,其中垂直方向的迹线定义为位错A,近水平方向的迹线定义为位错B,如图6(a)中的箭头标注所示。在 衍射条件下,垂直方向的位错A和近水平方向的位错B均显示衬度,如图6(a)所示。当

衍射条件下,垂直方向的位错A和近水平方向的位错B均显示衬度,如图6(a)所示。当 时,位错A显示衬度,位错B消失衬度,如图6(b)所示。根据g?b=0不可见判据,可以确定,近水平方向的位错B是Burgers矢量为b=(1/3)

时,位错A显示衬度,位错B消失衬度,如图6(b)所示。根据g?b=0不可见判据,可以确定,近水平方向的位错B是Burgers矢量为b=(1/3) 的áa+c?位错,且在

的áa+c?位错,且在 发生柱面滑移。

发生柱面滑移。

图6 热连轧Ti-6Al-4V合金在蠕变期间的位错组态

Fig.6 Dislocation configurations of hot continuous rolled Ti-6Al-4V alloy during creep: (a)  ; (b)

; (b)

同样,在 (照片略去)衍射条件下,垂直方向的位错A和近水平方向的位错B均失去衬度,由此可以确定,垂直方向的位错A是Burgers矢量为b=(1/3)[1120]的áa?位错,且在

(照片略去)衍射条件下,垂直方向的位错A和近水平方向的位错B均失去衬度,由此可以确定,垂直方向的位错A是Burgers矢量为b=(1/3)[1120]的áa?位错,且在 锥面发生非基面滑移。

锥面发生非基面滑移。

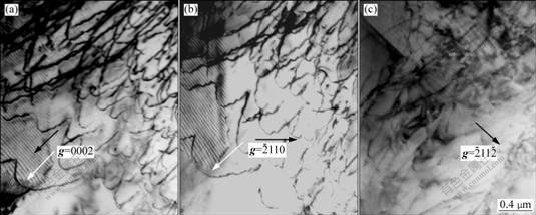

经940 ℃固溶及时效处理合金在400 ℃、575 MPa 条件下蠕变548 h断裂后,在HCP结构α相中的位错组态如图7所示。由图7可以看出,大部分蠕变位错呈现波浪状形貌,其波浪状位错的弓出方向为(0002)取向,如图7(a)中白色箭头所示。由图7(a)可以看出,在g[0002]和 衍射条件下,波浪状位错显示衬度,如图7(a)和(b)所示,而在

衍射条件下,波浪状位错显示衬度,如图7(a)和(b)所示,而在 操作条件下,波浪状位错消失衬度,如图7(c)所示。由此可以确定,该波浪状位错是Burgers矢量为b=(1/3)[0111]的áa+c?位错,并在

操作条件下,波浪状位错消失衬度,如图7(c)所示。由此可以确定,该波浪状位错是Burgers矢量为b=(1/3)[0111]的áa+c?位错,并在 发生锥面滑移。

发生锥面滑移。

图7 在蠕变期间940 ℃固溶及时效处理合金α相中的位错组态

Fig.7 Dislocation configurations in α phase of alloy during creep after heat treatment at 940 ℃: (a) g=0002; (b)  ; (c)

; (c)

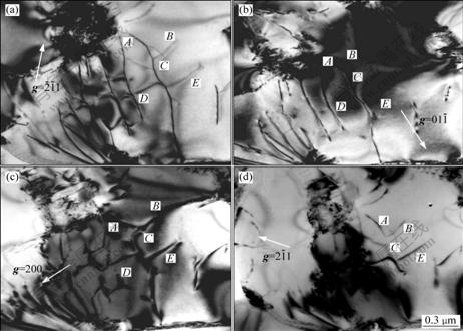

合金经1 000 ℃固溶及时效后,得到完全的网篮组织,如图4(c)所示。在网篮组织中的灰色区域为具有BCC结构的β相,如图5(a)所示。该合金在420 ℃、575 MPa 条件下蠕变180 h断裂后,β相中的位错组态如图8所示。将照片右侧上方近垂直方向的迹线分别标注为位错A和C,将位错A右侧、近水平方向的迹线标注为位错B,其中与位错B相邻的下方迹线为位错C,在位错C下端近水平方向的迹线定义为位错D和位错E,如图8(a)所示。由图8可以看出,在 ,g=200和

,g=200和 衍射条件下,近垂直方向的位错A显示衬度,如图8(a)、(c)和(d)所示,而在

衍射条件下,近垂直方向的位错A显示衬度,如图8(a)、(c)和(d)所示,而在 操作条件下,近垂直方向的位错A消失衬度,如图8(b)所示。由此可以确定,位错A的Burgers矢量为bA=(1/2)

操作条件下,近垂直方向的位错A消失衬度,如图8(b)所示。由此可以确定,位错A的Burgers矢量为bA=(1/2) ,并在

,并在 晶面滑移。在

晶面滑移。在 ,

, 和g=200衍射条件下,近垂直方向的位错C均显示衬度,如图8(a)、(b)和(c)所示。而在

和g=200衍射条件下,近垂直方向的位错C均显示衬度,如图8(a)、(b)和(c)所示。而在 操作条件下,位错C消失衬度,如图8(d)所示,由此可以确定该近垂直方向的位错C是 Burgers矢量为bC=(1/2)

操作条件下,位错C消失衬度,如图8(d)所示,由此可以确定该近垂直方向的位错C是 Burgers矢量为bC=(1/2) 的位错,并在

的位错,并在 晶面滑移。

晶面滑移。

在 ,g=200和

,g=200和 衍射条件下,近水平方向的位错B均显示衬度,如图8 (a)、(c)和(d)所示,而在

衍射条件下,近水平方向的位错B均显示衬度,如图8 (a)、(c)和(d)所示,而在 操作条件下,近水平方向的位错B消失衬度,如图8(b)所示,由此可以确定,该近水平方向的位错B是Burgers矢量为bB=(1/2)[111]的位错,并在

操作条件下,近水平方向的位错B消失衬度,如图8(b)所示,由此可以确定,该近水平方向的位错B是Burgers矢量为bB=(1/2)[111]的位错,并在 晶面滑移。

晶面滑移。

图8 经1 000 ℃固溶及时效处理后合金在蠕变期间β相中的位错组态

Fig.8 Dislocation configuration in β phase of alloy during creep after heat treatment at 1 000 ℃: (a)  ; (b)

; (b)  ; (c) g=200; (d)

; (c) g=200; (d)

由于在 条件下,位错D和位错E的衬度同时消失,如图8(b)所示。由此可以确定,近水平方向的位错D和位错E是Burgers矢量为bD=bE=(1/2)

条件下,位错D和位错E的衬度同时消失,如图8(b)所示。由此可以确定,近水平方向的位错D和位错E是Burgers矢量为bD=bE=(1/2) 的位错,即位错D和位错E具有相同的Burgers矢量,且在

的位错,即位错D和位错E具有相同的Burgers矢量,且在 晶面滑移。可以认为,位错D和位错E原是同一直线上的位错,随蠕变进行,激活的位错C剪切通过原直线位错D、E后,使原直线位错发生扭折,则可形成图8所示的扭折形态的位错D和位错E。

晶面滑移。可以认为,位错D和位错E原是同一直线上的位错,随蠕变进行,激活的位错C剪切通过原直线位错D、E后,使原直线位错发生扭折,则可形成图8所示的扭折形态的位错D和位错E。

3 讨论

由于940 ℃和980 ℃低于β相转变温度,因此,在该温度区间固溶处理后,合金仍保留α相,形成等轴α相和网篮的混合组织,且在网篮组织中存在大量针状马氏体,如图5(b)所示,可提高合金的蠕变抗 力[15]。随蠕变进行,在合金的网篮组织中仅有少量位错[16],表明网篮组织具有较高的蠕变抗力。可以认为,合金在蠕变期间的应变主要来自于α相的贡献,如图6和7所示,则合金的应变量与α相的体积分数密切相关。与980 ℃固溶及时效处理相比较,940 ℃固溶及时效处理合金有较高体积分数的α相,因此,该合金具有较高的应变速率和较大的蠕变应变量,如图1所示。

蠕变期间,热连轧合金的α相中发生直线位错的双取向滑移,如图6所示。而经940 ℃固溶及时效处理合金中α相的位错组态呈波浪状特征,如图7所示。由图6和7可知,两合金中的α相具有不同的蠕变抗力。分析认为,在恒定载荷的蠕变期间,若基体组织具有较低的蠕变抗力,则位错运动阻力小,易发生直线位错的多取向滑移(见图6)。经940 ℃固溶处理,合金中大部分α相已经溶解,其未溶解的α相中也溶入较多的溶质原子,使其过饱和程度增加,该过饱和的溶质元素可阻碍位错运动,使运动位错呈现弯曲形状(见图7)。这表明浓度过饱和的α相具有较高的固溶强化程度及较好的蠕变抗力。

衬度分析表明,热连轧合金中α相的变形机制是类直线的áa?位错和áa+c?位错在HCP结构的柱面和锥面发生双取向滑移,如图6所示。这表明热连轧合金的蠕变抗力较低,在蠕变期间易开动的滑移系较多,随蠕变进行位错易于滑移,故致使合金具有较高的应变速率和较短的蠕变寿命。而940 ℃固溶及时效处理合金在蠕变期间的位错组态是áa+c?位错在HCP结构的锥面滑移,如图7所示。这表明固溶及时效态合金中易开动的滑移系较少,蠕变抗力较高,由于溶质原子的强化作用,使蠕变位错呈现波浪状特征,故该合金具有较低的应变速率和较长的蠕变寿命。

经1 000 ℃固溶及时效处理后,合金中存在高体积分数的条束状β相,其α相体积分数较小,且呈针状存在于β相中,如图5(a)所示。故合金在蠕变期间的应变主要发生在条束状β相内,其变形机制是(1/2) á111?位错在{110}和{112}晶面滑移(见图8)。由于β相中富含元素V,具有较高的强度及蠕变抗力,故在β相中激活的位错数量较少。因此,在蠕变期间合金具有较低的应变速率和应变量(如图1所示)。

上述分析表明:合金经不同温度固溶处理,具有不同的组织结构,因而具有不同的蠕变机制及蠕变寿命。经940 ℃固溶处理后,在试验条件下,合金的蠕变应变较大,且主要发生在HCP结构的α相中,其蠕变激活能为185 kJ/mol;而经1 000 ℃固溶处理合金具有高体积分数,且富含元素V的β相,在同样条件下合金的应变主要发生在BCC结构的β相中,且应变量较小,其蠕变激活能为249.8 kJ/mol。与HCP结构的α相比较,BCC结构的β相具有较好的蠕变抗力。因此,经1 000 ℃固溶处理后,合金获得高体积分数的β相,是使其具有较低应变速率和较长蠕变寿命的主要原因。

4 结论

1) 经低于β相变点温度固溶处理后,Ti-6Al-4V合金的组织结构由高固溶度的等轴α相和网篮组织组成,随固溶温度提高,网篮组织数量增多,经1 000 ℃固溶处理后,合金可获完全网篮组织,且网篮组织中弥散分布针状和片状马氏体。

2) 在420 ℃、575 MPa条件下,不同温度固溶及时效处理合金具有不同的蠕变特征,经1 000 ℃固溶及时效处理合金具有较低的应变速率和较长的蠕变寿命;在试验的温度和应力范围内,计算出该状态合金的蠕变激活能为Qa=249.8 kJ/mol。

3) 在蠕变期间,不同状态合金具有不同的变形机制,热连轧合金的变形机制是位错在α相中发生双取向滑移;940 ℃固溶及时效处理合金的蠕变机制是波浪状áa+c?位错发生锥面滑移,而1 000℃固溶及时效处理合金的蠕变机制是(1/2) á111?位错在BCC结构的β相中发生多系滑移;其中,后者具有高体积分数富含元素V的β相,可提高蠕变抗力,是使合金具有较低应变速率和较长蠕变寿命的主要原因。

REFERENCES

[1] 钱九红. 航空航天用新型钛合金的研究发展及应用[J]. 稀有金属, 2000, 24(3): 218-220.

QIAN Jiu-gong, Application and development of new titanium alloys for aerospace[J]. Chinese Journal of Rare Metals, 2000, 24(3): 218-220.

[2] LUTZ K. Dynamic strength and failure behavior of Ti-6Al-4V alloy for a variation of heat treatment[J]. Mechanics of Time-Dependent Materials, 2008, 12(3): 237-247.

[3] BOURGEOIS M. Creep mechanisms of Ti-6246 alloy at 773 K[J]. Science and Technology, 1995, 24(5): 1083-1090.

[4] 张英明. 钛合金真空自耗电弧熔炼技术发展[J]. 稀有金属快报, 2008, 27(5): 9-13.

ZHANG Ying-min. Progress of vacuum arc remelting technology of titanium alloys[J]. Rare Metals Letters, 2008, 27(5): 9-13.

[5] MA Z Y. Creep behavior of TiBw/Ti in-situ composite fabricated by reactive hot pressing[J]. Metall Mater Trans A, 2001, 32(4): 1019-1022.

[6] 王敏敏. Ti40阻燃钛合金的高温蠕变行为[J]. 稀有金属材料与工程, 2003, 32(2): 117-118.

WANG Min-min. High temperature creep behavior of Ti40 alloys[J]. Rare Metal Materials and Engineering, 2003, 32(2): 117-120.

[7] GAO G.Y, Effect of hydrogen on creep behaviour of Ti-6Al-4V alloy at room temperature[J]. Metall Mater Trans A, 1991, 22(1): 1125-1130.

[8] 周 伟. 热处理对TC4合金组织与性能的影响[J]. 热加工工艺, 2005, 8: 26-28.

ZHOU Wei. Effect of heat treatment on microstructure and mechanical properties of TC4 alloy[J]. Heat Treatment of Metals, 2005, 8: 26-28.

[9] 张延生. 热处理对Ti-6Al-4V 棒材固溶时效性能的影响[J]. 钛工业进展, 2005, 22(6): 18-22.

ZHANG Yan-sheng. Effects of heat treatment of Ti-6Al-4V alloy bars on solution aging performance[J]. Titanium Industry Progress, 2005, 22(6): 18-22.

[10] LI Xiao-li. Deformation behavior of TC6 alloy in isothermal forging[J]. Journal of Materials Engineering and Performance, 2007, 14(5): 671-676.

[11] CHEN CC. Deformation characteristics of Ti-6Al-4V alloy under isothermal forging conditions[J]. Journal of Materials Engineering and Performance, 2007, 11(7): 1931-1941.

[12] KIM Ji-sik. Quantitative analysis on boundary sliding and its accommodation mode during superplastic deformation of two-phase Ti-6Al-4V alloy[J]. Metall Mater Trans A, 1998, 29(1): 217-226.

[13] 王敏敏, 赵永庆, 周 廉. 钛合金蠕变行为的影响因素分析[J]. 稀有金属材料与工程, 2002, 31(2): 135-138.

WANG Min-min, ZHAO Yong-qing, ZHOU Lian. Effect factor and analysis of creep behaviours of Ti alloy[J]. Rare Metal Materials and Engineering, 2002, 31(2): 135-138.

[14] 熊振国. TC4钛合金汽车连杆的精密模锻[J]. 钛工业进展, 2004, 21(1): 19-21.

XIONG Zhen-guo. Precision forging of TC4 titanium alloy connecting rod for motorcar[J]. Titanium Industry Progress, 2004, 21(1): 19-21.

MISHRA R S. High-temperature creep behavior of TiC particulate reinforced Ti-6Al-4V alloy composite[J]. Acta Materialia, 2002, 50(17): 4293-4302.

[15] 张廷杰. 钛合金相变的电子显微镜研究(Ⅲ)—钛合金中的马氏体相变[J]. 稀有金属材料与工程, 1989, 18(4): 71-77.

ZHANG Ting-jie. Electron microscope investigation of phase transformation in titanium alloys(Ⅲ): Martensite phase transformation in titanium alloys[J]. Rare Metal Materials and Engineering, 1989, 18(4): 71-77.

基金项目:国家自然科学基金重点资助项目(50634030)

收稿日期:2009-03-13;修订日期:2009-06-26

通信作者:田素贵,教授,博士;电话:024-25494089;E-mail:tiansugui2003@163.com

(编辑 龙怀中)