DOI: 10.11817/j.issn.1672-7207.2018.06.007

拉应力对6N01铝合金蠕变时效组织与性能的影响

邓运来1, 2, 3,单彪1,张劲1,王宇2,张书2

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083;

3. 中南大学 高性能与复杂制造国家重点实验室,湖南 长沙,410083)

摘要:采用单轴蠕变拉伸试验研究6N01铝合金蠕变时效后组织与性能的变化规律,并结合金相(OM)、扫描电镜(SEM)和透射电镜(TEM)的组织分析与维氏硬度、室温拉伸的力学性能分析,研究蠕变过程中加载的拉应力对6N01铝合金组织与性能的影响。研究结果表明:在180 ℃/6 h的蠕变时效条件下,加载60 MPa拉应力的试样室温拉伸抗拉强度最大,为341.6 MPa;蠕变时效处理时,加载应力小于60 MPa的试样抗拉强度略比加载应力为60 MPa的试样抗拉强度低;当加载拉应力大于60 MPa时,合金抗拉强度明显下降;当加载拉应力超过60 MPa时,会引起铝基体中析出相粗化,甚至析出相的分布出现应力位向效应,导致合金性能各向异性严重,综合性能变差。

关键词:6N01铝合金;蠕变时效;析出相;位向效应

中图分类号:TG146.2+1 文献标志码:A 文章编号:1672-7207(2018)06-1358-08

Effect of tensile stress on microstructures and properties of creep aged 6N01 aluminum alloy

DENG Yunlai1, 2, 3, SHAN Biao1, ZHANG Jin1, WANG Yu2, ZHANG Shu2

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. State Key Laboratory of High Performance and Complex Manufacturing,Central South University, Changsha 410083, China)

Abstract: The changing regularity of microstructures and properties of 6N01 aluminum alloys after the uniaxial tensile-creep test were studied. After creep aging under different tensile stresses, the microstructures of samples were analyzed by optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM), while the mechanical properties were tested by Vickers hardness and tensile tests. The results show that the sample with 60 MPa loading creep stress has the highest tensile strength (341.6 MPa) after creep aging at 180 ℃ for 6 h, if the loading creep stress of CA treatment is below 60 MPa, the tensile strength would decreases slightly compared with that of 60 MPa loading creep stress. However, when the creep stress exceeds 60 MPa, tensile strength decreases sharply. This is because a greater creep stress would make precipitates coarsen in the aluminum matrix. What’s more, stress-orienting effect of precipitation may appear, which makes anisotropic performance worse, and therefore, the mechanical properties of the material become worse.

Key words: 6N01 aluminum alloy; creep aging; precipitates; precipitation orientation effect

6N01铝合金是日本在6000系合金基础上研发的新型高速车辆铝合金,属于Al-Mg-Si系铝合金,具有中高强度、优良的成形性能,作为壁板材料被广泛应用于地铁列车、双层列车、高速列车和客货汽车[1]。目前,高速列车的车体壁板材料一般为高强度超薄壁多腔异形空心型材, 具有大型(均有10余m长)、整体、断面形状复杂和壁厚差异大的特点。为了满足车体设计,对成形后型材的尺寸精度以及材料的组织和性能有严格要求。传统成形装配工艺大多采用铆接与焊接,这2种成形方法生产的构件服役性能较差[2-3]。在铝合金结构件中,90%的疲劳断裂是在焊接接头处发生的,并且构件的疲劳失效往往是突发的、灾难性的,是引发安全事故的重要原因[2-3]。铆接技术在构件制造过程中造成的变形不仅在装配体中留下残余应力和挤压裂纹,增加连接结构的脆性,降低构件的疲劳寿命,而且产品的装配性能较差。蠕变时效成形(creep age forming,CAF)已应用于航空航天领域构件的一次成形成性,在保证高成形精度的同时,使可时效强化铝合金材料具有优异性能[4]。CAF工艺是在一定温度和外力同时作用下使铝合金发生蠕变变形,同时进行时效强化,从而得到形状和性能均满足服役条件的构件,能有效提高构件的制造精度,提高整体壁板的使用寿命[5]。由于CAF不需要大吨位专用设备,具有成形质量稳定、成形效果好、人工干预少、生产效率高、工装简单等优点,非常适合应用于型面结构复杂和装配精度高的壁板类零件精密成形[4]。将CAF应用于高速列车壁板材料成形成性制备上,可以减少铆接、焊接等工序,对我国高速列车发展有重要意义。为此,本文作者对蠕变拉伸对6N01铝合金组织与力学性能的影响进行研究,从蠕变时效时间和加载力2个方面研究6N01铝合金的微观组织及其力学性能的变化规律,以便为6N01铝合金的蠕变时效成形提供实验与理论依据。

1 材料制备与实验方法

表1所示为6N01铝合金的化学成分(质量分数)。铝合金构件蠕变时效成形的目的之一是尽量获得时效强化效果。采用显微维氏硬度计测量的方法分析6N01铝合金的普通人工时效硬化规律。在蠕变时效过程中,加载力不超过材料的屈服极限,采用室温拉伸实验测得固溶态6N01铝合金的屈服强度为102.7 MPa,由此确定蠕变时效应力应小于100.0 MPa。

表1 6N01铝合金型材化学成分(质量分数)

Table 1 Chemical composition mass fraction of 6N01 aluminum alloy profile %

图1所示为按GB /T 2039—2012[6]从型材面板上切取的试样结构。试样经过固溶处理(530 ℃/3 h)后立即水淬,装夹在RWS50型电子蠕变松弛实验机上,时效温度为180 ℃,分别加载8组不同的单轴拉伸应力:30,45,55,60,65,70,75和90 MPa;另在恒温干燥箱中取样进行180 ℃普通人工时效,以作为对比。在每组应力水平下分别进行2,4,6,8和10 h时效实验。

图1 6N01铝合金蠕变拉伸试样结构

Fig. 1 Structure of creep tensile test specimen of 6N01 aluminum alloy

采用OLYMPUS DSX500型金相显微镜、Sirion200场发射扫描电镜(SEM)和TECNAIG220型透射电镜(TEM)分析材料的组织变化规律。金相样品经磨制后通过电解抛光,抛光液为高氯酸与乙醇的混合液(体积比1:9),再采用阳极覆膜,覆膜液配比为:1.1 g硼酸+3 mL HL+97 mL H2O。将TEM样品采用电解双喷减薄,电解液为硝酸与甲醇混合液(体积比为3:7),温度为-30 ℃。采用室温拉伸方法分析时效后试样的力学性能变化规律,并对室温拉伸样断口进行SEM分析。按GB/T 288.1—2010[7]切取室温拉伸试样,拉伸试验在CSS-44100电子万能试验机上进行,拉伸速度为2 mm/min。在HV-5型维氏硬度计下测量试样的维氏硬度,试验力为10 N,保持时间为15 s。

2 实验结果

2.1 时效硬化曲线

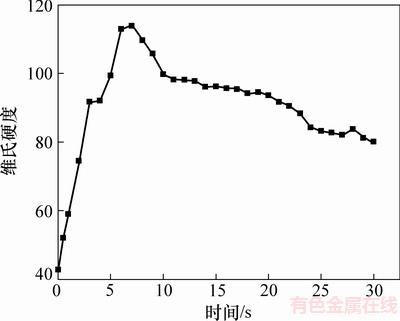

图2所示为6N01铝合金时效硬化曲线。6N01铝合金经530 ℃/3 h固溶-水淬处理的试样于180 ℃进行普通人工时效(artificial aging, AA),测试不同时效时间下样品的硬度并绘制时效硬化曲线,结果见图2。由图2可见:该合金具有明显的时效硬化效应;在人工时效初期,维氏硬度迅速上升,在6 h附近达到峰值;随着时效时间延长,维氏硬度下降,进入过时效阶段。

图2 试验6N01铝合金时效硬化曲线(180 ℃)

Fig. 2 Age hardening curve of 6N01 aluminum alloy

2.2 蠕变行为

图3所示为试验6N01铝合金在180 ℃时加载不同拉应力进行蠕变实验所得蠕变曲线。由图3可见:蠕变伸长率随着加载的单轴拉伸应力增大而增大,经过6 h蠕变后,拉应力为30 MPa时的蠕变伸长率达0.009%,60 MPa时的蠕变伸长率达0.033%,75 MPa时的蠕变伸长率达0.048%。拉应力为60 MPa和75 MPa时的蠕变在第1阶段表现明显,有较大的蠕变变形量,而拉应力为30 MPa的蠕变在第1阶段变形不明显,蠕变变形量较小。蠕变第1阶段变形量也随着加载的单轴拉伸应力的增大而增大。

图3 不同拉应力状态下试样在180 ℃时的蠕变曲线

Fig. 3 Creep curves of samples at 180 ℃ under different tensile stresses

2.3 蠕变时效后的力学性能

图4所示为不同加载应力和时效时间下蠕变时效(creep aging, CA)后6N01铝合金的抗拉强度(σb)。由图4(a)可见:σb随时间的变化规律与普通人工时效后硬度随时间的变化规律相似,呈现先升高后下降的趋势,在6 h附近达到峰值;当时效时间超过6 h时,σb随着蠕变时效时间延长而降低。从图4(b)可见:加载60 MPa拉应力时效6 h后试样的σb为8组实验中的最大值;当加载应力为30~65 MPa时,σb变化不显著;当加载应力大于60 MPa时,时效后试样的σb表现出下降趋势,其中,加载90 MPa应力蠕变时效后试样的σb与加载60 MPa应力蠕变时效后试样的σb相比下降27.9 MPa。

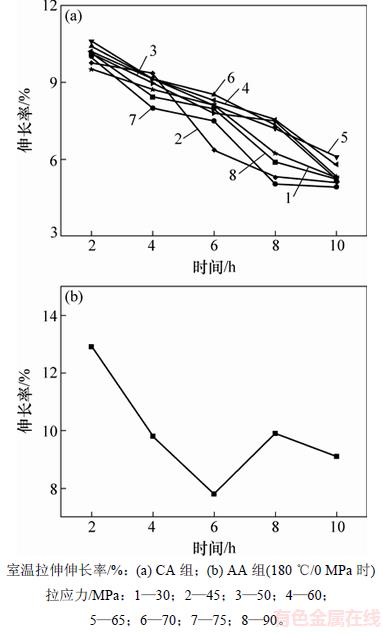

图5所示为不同加载应力和时效时间条件下蠕变时效后6N01铝合金的伸长率。从由图5(a)可见:蠕变时效后(CA组)试样的伸长率均呈现出随时效时间延长而下降的趋势;对于经过6 h蠕变时效处理的试样,当加载应力为60~70 MPa时,伸长率最大,达8.3%。从图5(b)所示的普通人工时效处理后(AA组)试样的伸长率可见:AA组样品伸长率变化趋势与CA组样品有明显区别,经6 h人工时效处理后试样的伸长率为该组实验中的最低值;当人工时效时间小于6 h时,随着时效时间增加,伸长率降低;当人工时效时间超过6 h时,伸长率相对于6 h时有小幅度增大。

图4 不同蠕变时效条件下6N01铝合金的抗拉强度

Fig. 4 Tensile strength of 6N01 aluminum alloy under different creep aging conditions

图5 不同蠕变时效条件下6N01铝合金的伸长率

Fig. 5 Elongation at break of 6N01 aluminum alloy under different creep aging conditions

综合图4和图5可知:在峰时效阶段,拉应力对6N01铝合金蠕变时效后的σb有较大影响;当蠕变拉应力超过65 MPa时,σb呈显著下降趋势;在加载应力30~60 MPa下,于180 ℃时效6 h时,6N01铝合金的抗拉强度最高,达341.6 MPa;而在同样时效温度和时效时间下,当加载的拉伸应力为60~70 MPa时,蠕变时效后的伸长率最大,达8.3%,接近人工时效的伸长率。

表2所示为6N01铝合金人工时效与蠕变时效后的力学性能。从表2可知:CA态样品的σb均比AA态的小,相对人工时效6 h的状态而言,60 MPa/6 h(CA态σb峰值)下σb下降2.8%,90 MPa/6 h下σb下降10.7%,这表明蠕变时效加载的单轴拉伸应力会影响6N01铝合金的抗拉强度;当拉应力超过60 MPa时,单轴拉伸应力影响效果更加明显;当蠕变时效时间超过6 h时,伸长率明显下降,当时效时间达到10 h时,拉应力为60 MPa时的伸长率与人工时效的伸长率相比下降36.3%,拉应力为90 MPa时的伸长率与人工时效的伸长率相比下降43.6%。

2.4 蠕变时效后的微观组织

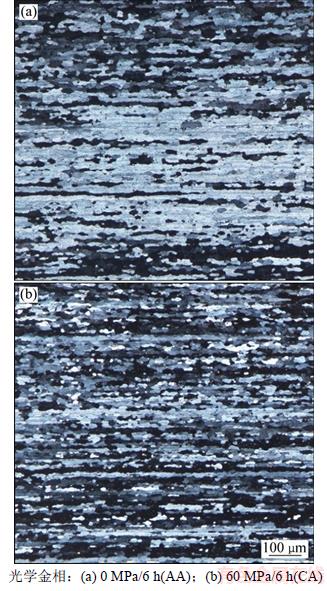

图6所示为经AA和CA时效处理(180 ℃/6 h)后6N01铝合金的金相组织。从图6可见:金相组织保持原型材挤压态组织,晶粒有明显拉伸变形,呈现出拉长的长条形纤维组织;AA与CA这2种状态试样的金相组织差别不大。要得到蠕变拉应力对该合金组织的影响,必须对样品微观组织进行更小分辨率研究。

对3种加载应力下蠕变时效6 h后试样的室温拉伸断口进行SEM分析,结果见图7。从图7可见:拉应力为30 MPa和60 MPa时的断裂方式主要为韧窝型穿晶断裂,分布大量等轴韧窝,韧窝直径相差不大;而拉应力为90 MPa时的断口只有少量韧窝,在韧窝周边出现大量呈台阶状撕裂棱。利用Nano Measurer软件统计得出:拉应力为30 MPa的韧窝平均直径为5.80 μm,拉应力为60 MPa的韧窝平均直径为5.72 μm,拉应力为90 MPa的韧窝平均直径为3.72 μm。可见:在峰值时效(180 ℃/6 h)条件下,随着蠕变拉应力增大,断口的微观组织也发生变化,韧窝的直径不断变小,并且伴随着愈发严重的呈层状分布的沿晶断裂[8]。这表明在本实验条件下,随着蠕变拉应力增大,6N01铝合金的塑性和伸长率都有所下降。

表2 试样6N01铝合金人工时效(AA)与蠕变时效(CA)后的力学性能

Table 2 Mechanical properties of the tested 6N01 alloy samples after creep aging (CA) and artificial aging (AA)

图6 不同时效状态下的金相组织

Fig. 6 Metallographic structures under different aging conditions

当加载拉应力为60 MPa时,蠕变时效2,6和10 h后试样的TEM明场相见图8,晶带轴(Zone axis)为[001]Al。从图8(a)可见:对于CA态、于60 MPa时效2 h后的样品,晶内均匀弥散地析出细小的强化相粒子pre-β″相,使6N01铝合金产生初始强化效果。从图8(b)可见:大量析出由GP区经过固态相变形成的pre-β″/β″相,这种相与基体呈共格关系,沿6N01铝合金的<001>晶向族析出,并在这3个晶向上相互垂直。从图8(c)可见:衍射斑纹为“十字型”,析出相为大量杆状β′相和少量β″相。由于受单轴拉伸应力的影响,图8(b)和图8(c)中的析出相有明显应力位向效应[9-10]。

Al-Mg-Si合金的时效析出序列为:α过饱和固溶体→团簇/GP区→pre-β″/β″相针→β′相杆→β相(平衡Mg2Si相) [11]。在蠕变时效初期,主要析出大量球状的GP (Guinier Preston zone) 区,这种原子团簇的强化效果有限,可随着时效时间延长,通过固态相变形成新的强化相。固态相变一般先析出亚稳相,然后向平衡相过渡。也有一些固态相变由于受动力学条件的限制,始终产生亚稳相,而不产生平衡相[12]。由于受时效时间限制,6N01铝合金在蠕变时效6 h后析出大量β″相,而并非平衡相(β相)[11-14]。因为β″相为共格针状相,强化效果最好[11],所以,当蠕变时效6 h时合金抗拉强度达到峰值;蠕变时效进行10 h后,在热力学条件允许下,共格的β″相向半共格的β′相过渡,最终在蠕变时效10 h的样品中发现大量β′相和少量β″相。很多实验都在过时效样品中发现了杆状β′相,由于β′相为六方结构且比较粗大,强化效果较差[11],所以,蠕变时效10 h后的6N01铝合金综合力学性能比蠕变时效6 h的综合力学性能差。

图7 不同时效状态下的室温拉伸断口SEM图像

Fig. 7 SEM images of tensile fracture at room temperature after different aging conditions

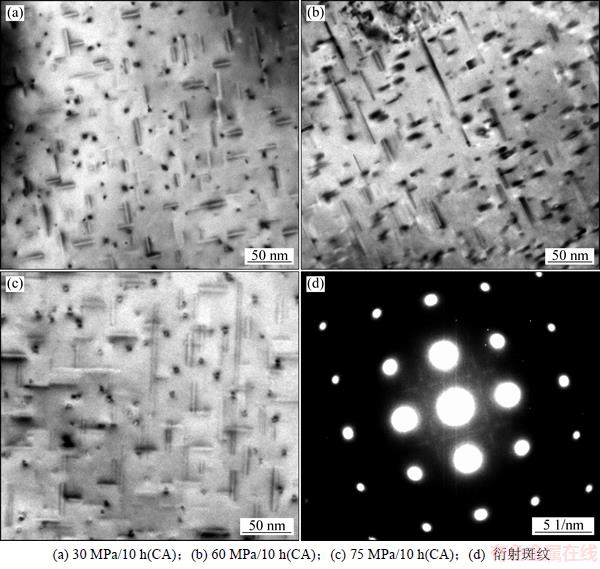

图9所示为加载不同单轴拉伸应力蠕变时效10 h后6N01铝合金的TEM明场相,晶带轴为Z=[001]Al。从图9(d)可见:衍射斑纹为“十字型”,说明10 h后的析出相主要为β′相[11]。对比图9(a),(b)和(c)可见:经过10 h时效后,单轴拉伸应力对析出相的影响主要体现在β′相杆的长度和分布情况2个方面。对于β′相在[100]和[010]方向的析出情况,利用Nano Measurer软件统计β′相得出:当拉应力为30 MPa时,β′相平均长度为16.4 nm,最大长度为34.8 nm,在2个方向上的析出数量分别为64个和56个;当拉应力为60 MPa时,β′相平均长度为34.6 nm,最大长度为98.5 nm,在2个方向上的析出数量分别为36个和25个;当拉应力为75 MPa时,β′相平均长度为32.7 nm,最大长度为101.7 nm,在2个方向上的析出数量分别为39个和26个。这表明当拉应力增加时,β′相长度变长,且应力位向效应更加严重,这必然会影响材料的综合力学性能。对表2可见:就抗拉强度而言,当时效时间为10 h时,AA样品的抗拉强度相对于6 h时下降7.46%,CA样品(60 MPa)下降9.69%,CA样品(90 MPa)下降12.15%。就伸长率而言,在时效时间为10 h时,AA样品的伸长率相对于6 h时上升16.67%,CA样品(60 MPa)则下降30.12%,CA样品(90 MPa)下降36.67%。AA样品在抗拉强度为峰值时伸长率最低,过时效后,随着抗拉强度降低,伸长率会有所升高。CA样品则不同,过时效后,抗拉强度下降,伸长率也有一定程度下降。

图8 不同时效状态下的TEM图像

Fig. 8 TEM images under different aging conditions

图9 不同CA状态下的TEM图

Fig. 9 TEM images under different CA states

分析图9可知:单轴拉伸应力对蠕变时效后6N01铝合金的微观组织有较大影响。因为蠕变时效虽然有时效强化效果,但同时会伴随着蠕变损伤,使材料组织劣化。对于6N01铝合金这种金属间化合物强化的合金来说,组织劣化主要表现为析出相粒子粗化[15]。在粗化过程中,不可能每个粒子都长大(因为这将导致粒子总量增加),只能通过小粒子不断缩小以致溶解,大粒子不断长大的方式使粒子平均直径增大[12,15]。这种粒子粗化称为Ostwald熟化[16]。粒子粗化使粒子间距增大,必然导致材料蠕变抗力降低,蠕变加速,所以,粒子粗化是一种蠕变损伤,这种损伤对6N01铝合金蠕变时效后的力学性能有一定影响[15]。而在粗化的同时,还伴随析出相的应力位向效应,这种现象使析出相数量多的方向得到较好强化,但粒子总量数不变,使另外方向上析出相的数量减少[17-19],导致这些方向的强化效果变差。材料在这些方向的力学性能变差,导致材料力学性能不均匀效果加重[15],从而使材料的整体性能下降。

3 结论

1) 6N01铝合金具有明显的时效硬化效应,在经过530 ℃/3 h固溶处理后进行180 ℃人工时效实验,维氏硬度在6 h附近达到峰值;维氏硬度达到峰值后,随着时效时间延长,迅速进入过时效阶段,维氏硬度显著下降。

2) 6N01铝合金在蠕变时效后的综合力学性能在60 MPa/6 h时最好,此时,抗拉强度为341.6 MPa,伸长率为8.3%。

3) 蠕变拉应力会影响6N01铝合金杆状析出相的长度、数量及分布,当拉应力达到60 MPa时会引起析出相粗化,并出现应力位向效应,从而使6N01铝合金强度下降。

参考文献:

[1] 桑益. Al-Mg-Si多级时效硬化特性和析出行为[D]. 长沙: 湖南大学材料科学与工程学院, 2012: 1-13.

SANG Yi. The hardening behaviors and precipitation in the Al-Mg-Si alloys during multi-step aging[D]. Changsha: Hunan University. School of Materials Science and Engineering, 2012: 1-13.

[2] 杨志斌. 铝合金机身壁板结构双侧激光焊接特征及熔池行为研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2013: 1-9.

YANG Zhibin. Study on double-sided laser beam welding characteristics and weld pool behavior for aluminum alloy fuselage panel structure[D]. Harbin: Harbin Institute of Technology. School of Materials Science and Engineering, 2013: 1-9.

[3] 张国春. 高强钢双金属焊接疲劳裂纹扩展机理及组织演化规律研究[D]. 西安: 长安大学工程机械学院, 2013: 1-9.

ZHANG Guochun. Study on crack growth mechanism and microstructure variation low of welded high-strength steel with a bi-metal weld seam[D]. Xi’an: Chang’an University, School of Construction Machinery, 2013: 1-9.

[4] 邓运来, 周亮, 晋坤, 等. 2124铝合金蠕变时效的微结构与性能[J]. 中国有色金属学报, 2010, 20(11): 2107-2111.

DENG Yunlai, ZHOU Liang, JIN Kun, et al. Microstructure and properties of creep aged 2124 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2107-2111.

[5] 晋坤, 邓运来, 周亮, 等. 6156 铝合金的人工时效与蠕变时效研究[J]. 航空材料学报, 2011, 31(5): 18-22.

JIN Kun, DENG Yunlai, ZHOU Liang, et al. Investigation on artificial aging and creep aging of 6156 aluminum alloy[J]. Journal of Aeronautical Materials, 2011, 31(5): 18-22.

[6] GB/T 2039—2012, 金属材料单轴拉伸蠕变试验方法[S].

GB/T 2039—2012, Uniaxial creep testing method of metallic materials in tension[S].

[7] GB/T 288.1—2010, 金属材料拉伸试验第1部分: 室温试验方法[S].

GB/T 288.1—2010, Tensile testing of metallic materials,part 1:method of test at room temperature[S].

[8] 宋满新. 汽车车身板用含锗Al-Mg-Si-Cu系铝合金组织与性能的研究[D]. 长沙: 中南大学材料科学与工程学院, 2012: 44-45.

SONG Manxin. The research of microstructure and properties of properties of Al-Mg-Si-Cu alloy with germanium for automobile panel[D]. Changsha: Central South University. School of Materials Science and Engineering, 2012: 44-45.

[9] CHEN Yuqiang, YI Danqing, PAN Suping, et al. Effect of temperature on creep behavior of 2024 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 632-639.

[10] Guo X, Deng Y, Zhang J, et al. A crystallographic orientation based model for describing the precipitation strengthening of stress-aged Al-Cu alloy[J]. Materials Science and Engineering: A, 2015, 644: 358-364..

[11] 陈江华, 刘春辉. Al-Mg-Si(Cu)合金中纳米析出相的结构演变[J]. 中国有色金属学报, 2011, 21(10): 2352-2359.

CHEN Jianghua, LIU Chunhui, et al. Microstructure evolution of precipitates in Al-Mg-Si(Cu)alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2352-2359.

[12] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 309-408.

ZHENG Ziqiao. Material science foundation[M]. Changsha: Central South University Press, 2007: 365-376.

[13] VISSERS R, VAN HUIS M A, JANSEN J, et al. The crystal structure of the β′ phase in Al-Mg-Si alloys[J]. Acta Materialia, 2007, 55: 3815-3823.

[14] YASSAR R S, FIELD D P, WEILAND H, et al. The effect of pre-deformation on the β″ and β′ precipitates and the role of Q’ phase in an Al-Mg-Si alloy[J]. Scripta Materialia, 2005, 53(3): 299-303.

[15] 张俊善. 材料的高温变形与断裂[M]. 北京: 科学出版社, 2007: 365-376.

ZHANG Junshan. High temperature deformation and fracture of materials[M]. Beijing: Science Press, 2007: 365-376.

[16] 朱甜霞. 相场方法模拟Ostwald熟化演变[D]. 南宁: 广西大学物理科学与工程技术学院, 2014: 1-6.

ZHU Tianxia. Phase field formulations for modeling the evolution of the Ostwald ripening[D].Nanning: Guangxi University. School of Physical Science and Technology, 2014: 1-6.

[17] XU Fushun, ZHANG Jin, DENG Yunlai, et al. Precipitation orientation effect of 2124 aluminum alloy in creep aging[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2067-2071.

[18] Chen J, Chen Z, Guo X, et al. Changing distribution and geometry of S′ in Al-Cu-Mg single crystals during stress aging by controlling the loading orientation[J]. Materials Science and Engineering: A, 2016, 650: 154-160.

[19] Guo X, Deng Y, Zhang J, et al. The inhibiting effect of dislocation helices on the stress-induced orientation of S' precipitates in Al-Cu-Mg alloy[J]. Materials Characterization, 2015, 107: 197-201.

(编辑 陈灿华)

收稿日期:2017-06-10;修回日期:2017-08-15

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2012CB619500);国家重点研发计划项目(2016YFB0300901);国家自然科学基金资助项目(51375503);广西重大专项计划项目(14122001-5)(Project(2012CB619500) supported by the National Basic Research Program(973 Program) of China; Project(2016YFB0300901) supported by the Major State Research Program of China; Project(51375503) supported by the National Natural Science Foundation of China; Project(1412001-5) supported by the Major Science and Technology Project of the Guangxi Zhuang Autonomous Region)

通信作者:张劲,博士,从事高性能铝合金时效成形与组织调控研究;E-mail:zhangjin19861003@126.com