DOI: 10.11817/j.issn.1672-7207.2017.11.006

载重汽车用直齿轮冷挤压组合凹模的优化设计

梁强1,周杰1,何雄1,夏泽雨2,刘正伟2

(1. 重庆大学 材料科学与工程学院,重庆,400044;

2. 重庆众联齿轮传动有限公司,重庆,402247)

摘要:为提高载重汽车用直齿轮冷挤压组合凹模的使用寿命,以组合凹模的齿形腔等效内径、直径比和过盈系数为设计变量,以降低模芯内壁等效应力为优化目标,建立组合凹模结构参数与等效应力的Kriging模型。应用Kriging模型结合粒子群算法,在可行变量空间内寻优,得到组合凹模最佳结构尺寸为:模芯外径D2=107.485 mm,中圈外径D3=187.215 mm,外圈外径D4=274.839 mm,模芯与中圈的单边径向过盈量U1=0.134 mm,中圈与外圈的单边径向过盈量U2=0.253 mm,采用优化后的组合凹模进行数值模拟。研究结果表明:在模芯消气带齿槽处等效应力最大,其值为1 870 MPa。优化方法为齿类零件冷挤压成形组合凹模设计提供了定量的确定方法。

关键词:大模数直齿轮;冷挤压;组合凹模;优化设计

中图分类号:TG316 文献标志码:A 文章编号:1672-7207(2017)11-2881-08

Optimization design of cold extrusion combined die for spur gear of camion

LIANG Qiang1, ZHOU Jie1, HE Xiong1, XIA Zeyu2, LIU Zhengwei2

(1. School of Material Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Chongqing Zhonglian Gear Transmission Co. Ltd., Chongqing 402247, China)

Abstract: In order to improve the service life of cold extrusion combined die for spur gear of camion, the equivalent diameter of tooth shaped cavity, diameter ratio and shrink fitting ratio of combined die were taken as design variables, the Kriging model of effective stress and structure parameters of the combined die was built, which aimed at decreasing the effective stress of the die insert. The Kriging model combined with the particle swarm optimization were used to find the optimal structure size of combined die in the variable space. The optimal structure sizes of the combined die were as follows: die insert diameter D2=107.485 mm, middle layer diameter D3=187.215 mm, stress ring diameter D4=274.839 mm, unilateral radial shrink fitting between die insert and middle layer U1=0.134 mm, unilateral radial shrink fitting between middle layer and stress ring U2=0.253 mm. Meanwhile, the numerical simulation method was also used to simulate the forming process with the optimized combined die. The results show that the maximum effective stress on the inside of die insert is obtained and the value is 1 870 MPa. The optimization method provides a method for the design of cold extrusion combined die for gears.

Key words: spur gear with big modulus; cold extrusion; combined die; optimization design

随着齿轮成形工艺研究的深入和市场需求的不断发展,现代制造业对齿轮产品精度要求不断提高,而齿轮的精密成形一直都是研究的热点[1-2]。大模数直齿轮作为载重汽车轮边减速器中的关键零部件,需求量较大,一般配套厂的年产量为150万件以上。而目前大模数直齿轮主要加工方式有切削加工和“冷挤压+冷整形”复合精密成形,切削加工工时长,材料利用率低,成本较高,因此“冷挤压+冷整形”复合成形成为大模数直齿轮的主要加工工艺。提高冷挤压模具使用寿命是大模数直齿轮精密成形的关键点。冷挤压组合凹模传统的设计方法为结合拉美公式和经验公式确定尺寸参数[3],而对于内圈带有齿形的模具则不宜采用该方法。近年来,为提高模具使用寿命,研究者进行了大量的研究并取得了显著成效。胡成亮等[4-6]利用有限元法和黄金分割迭代法对圆柱直齿轮冷挤压组合凹模进行优化设计。EYERCIOGLU等[7]通过数值模拟和工艺实验研究了2层组合凹模径向过盈量与齿形最大主应力间的关系。LEE等[8]通过实验研究了螺栓冷挤压组合凹模径向过盈量对模具使用寿命的影响规律。以上研究只优化了径向过盈量,并未全部优化组合凹模结构参数。张渝等[9-11]应用Kriging模型结合遗传算法对射孔弹壳预挤压组合凹模进行了优化设计。敖文刚等[12-15]应用统一强度理论考虑抗压异性的情况下计算出筒件冷挤压件组合凹模的结构参数。鲁志兵等[16]采用Lagrange乘子法对筒形件冷挤压组合凹模进行了优化设计。以上研究模芯内壁为圆筒形,对形状复杂的齿形来说过于简单。本文作者以降低模芯内壁处最大等效应力为目标,对某款大模数直齿轮冷挤压组合凹模结构参数进行优化。采用实验设计与数值模拟相结合的方法,构建组合凹模结构参数与模芯最大等效应力的Kriging模型,运用粒子群算法对其进行全局寻优,得出组合凹模最佳直径比和过盈系数,并应用于生产实际。

1 冷挤压工艺分析

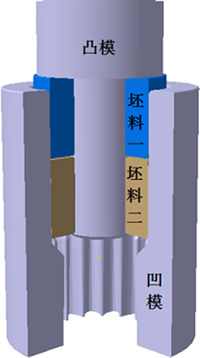

图1所示为本文研究的大模数直齿轮,模数m=4,齿数Z=16,压力角α=20°,变位系数x=0.45。其冷挤压成形工艺为:热锻制坯→球化退火→抛丸→车削制坯→磷化、皂化→冷挤压,并采用“件压件”的形式通过齿形凹模,如图2所示。

2 模型建立和优化设计

2.1 设计变量和目标函数的选择

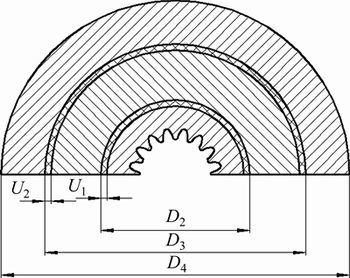

大模数直齿轮冷挤压成形时凹模型腔承受很大的工作压力,型腔内壁处易产生纵向开裂而导致模具失效,因此,大模数直齿轮冷挤压凹模通常采用3层组合式凹模结构,如图3所示。分别选择模芯齿形腔的等效内径D1,直径比n2,n3和n4以及过盈系数β2和β3作为优化的设计变量,取值范围如表1所示,其中n2=D2/D1,n3=D3/D1,n4=D4/D1,β2=2U1/D2,β3=2U2/D3,D2,D3和D4分别为模芯外径、中圈外径和外圈外径, U1和U2分别为模芯与中圈、中圈与外圈的单边径向过盈量。

图1 大模数直齿轮零件图

Fig. 1 Parts drawing of spur gear with big modulus

图2 冷挤压工艺示意图

Fig. 2 Diagram of cold extrusion process

图3 组合凹模结构

Fig. 3 Structure of combined die

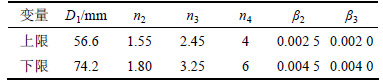

表1 设计变量取值范围

Table 1 Range of design variables

为避免模芯内壁开裂和提高模具使用寿命[17],以降低模芯最大等效应力Y作为目标,对组合凹模的结构参数进行优化设计。

2.2 拉丁超立方抽样

采用拉丁超立方抽样进行实验设计,以上述m=6个变量抽样的最小样本容量N [18-20]为

N=(m+1)(m+2)/2=28

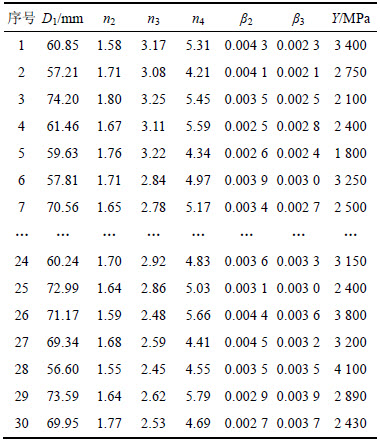

抽样得到的样本数据如表2所示(序号为1~28),另外在设计空间随机抽取2个样本点(序号29与30)用于检验模型的精度。

表2 部分实验方案及结果

Table 2 Parts of test program and results

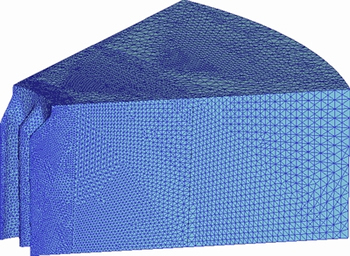

2.3 有限元模型的建立

选择齿轮稳定成形阶段即成形力最大的阶段,如图4所示,用于映射坯料与凹模接触表面的载荷分布实验。选择模芯与中圈、中圈与外圈的接触面设置过盈配合对模芯进行预紧,建立如图5所示的组合凹模有限元模型。为提高计算效率,取1/8模型进行模拟,3层模具均定义为弹性体,其他模拟参数见表3。

图4 行程载荷曲线

Fig. 4 Curve of stroke and load

图5 组合凹模有限元模型

Fig. 5 FE model of combined die

表3 模拟参数

Table 3 Parameters in simulation

2.4 近似模型建立与寻优

将表2所列尺寸的组合凹模进行数值模拟,由模拟结果得到模芯的最大等效应力,并作为响应值。利用MATLAB的DACE工具箱[21],选择高斯函数作为核函数,建立基于28组实验数据的Kriging近似模型。

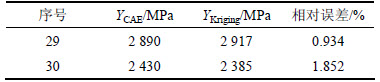

为了检验Kriging近似模型的预测精度,将第29组和第30组样本的数值模拟结果与近似模型的预测值进行比较,相对误差如表4所示。由表4可知:Kriging模型预测值YKriging与有限元仿真值YCAE的相对误差分别为0.934%和1.852%,Kriging模型具有较强的预测能力,可作为下一步优化计算的模型。

表4 拟合所得Kriging模型的精度检验

Table 4 Accuracy test for Kriging model

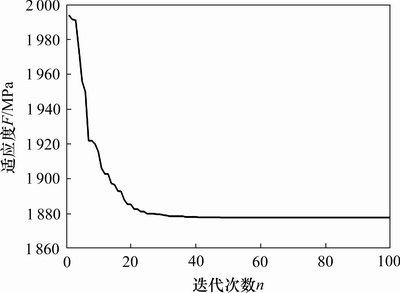

将Kriging近似模型作为适应度函数[22],采用粒子群算法在可行解空间内对模型进行寻优,优化变量及可行解空间见表1。粒子群优化参数设置如下:粒子数目为30个,惯性权重系数w为0.7,学习因子c1和c2均为2,迭代次数为100,优化过程如图6所示。在迭代57次后收敛,最大等效应力为1 877.9 MPa,优化结果为:D1=61.581 7 mm,n2=1.745 4,n3=3.040 1,n4=4.463 0,β2=0.002 5,β3=0.002 7;对应组合凹模各尺寸为:D2=107.485 mm,D3=187.215 mm,D4=274.839 mm,U1=0.134 mm,U2=0.253 mm。

图6 优化过程

Fig. 6 Optimization process

3 分析与讨论

优化设计的组合凹模是否满足设计要求并且有效降低模芯内壁最大等效应力,为此通过对比分析采用传统经验法设计的组合凹模进行说明。采用经验法设计组合凹模根据冷挤压齿轮外径决定模芯型腔D1,即D1=74.2 mm。3层组合凹模的各圈直径如下:

D4=(4~6)D1=296.8~445.2 mm,取D4=400 mm,总直径比n4=D4/D1=400/74.2=5.39;

D2≥1.6D1即D2≥118.72 mm,取D2=120 mm,直径比n2=D2/D1=120/74.2=1.617;

D3≥2.56D1即D3≥189.952 mm,取D3=190 mm,直径比n3= D3/D1=190/74.2=2.560。

模芯外壁与中圈内壁、中圈外壁与外圈内壁间的过盈量一般选择D2或D3的0.2%~0.45%,即过盈系数β2和β3在0.20~0.45之间选择,本文中β2和β3均选择0.4。因此,D2处的单边径向过盈量为:U1=β2D2/2= 0.240 mm,D3处的单边径向过盈量为:U2=β3D3/2= 0.380 mm。

图7所示为经验法设计的组合凹模在工作状态下模芯应力分布图。由图7可知:等效应力最大值出现在模芯消气带的齿槽处(位置1),最大值为3 300 MPa。坯料被入模角劈分时变形程度大,在入模角区齿槽处(位置2)承受坯料挤压变形产生的径向压应力,而预紧产生的周向压应力抵消成形时的周向拉应力,因此,该处仍处于受压状态,最小周向压应力为1 300 MPa。坯料经入模角劈分进入定径带和消气带,坯料变形程度减小并逐渐与模具脱离接触,对模具的作用力减弱。

图7 经验法设计组合凹模在工作状态下模芯应力分布图

Fig. 7 Stress distributions of die insert under working condition before optimization

由数值模拟结果可看出:采用经验法设计的组合凹模可以达到工艺设计的要求,但由于组合凹模结构尺寸和过盈量的选取偏保守,使模芯处于很大的压应力状态,虽然可以保证正常工作,但是模具结构偏大,造成昂贵模具材料的浪费。

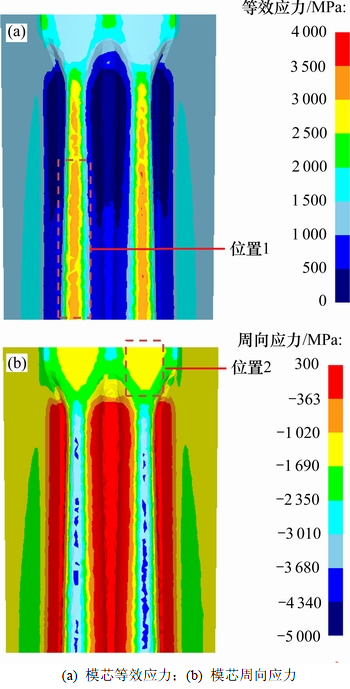

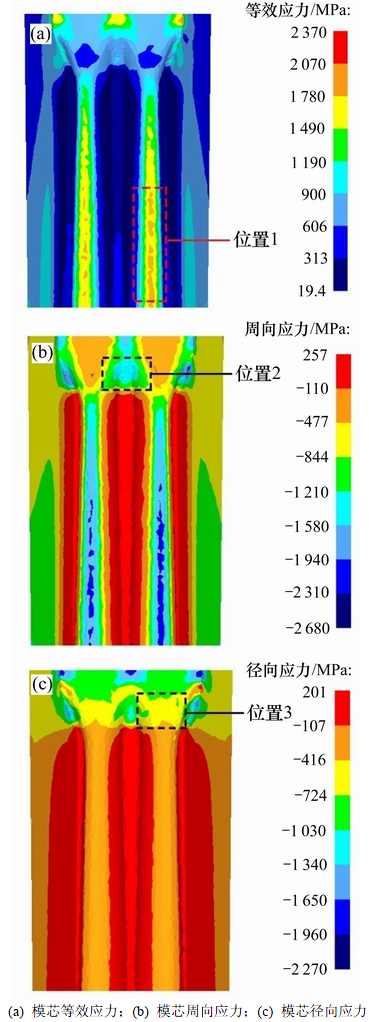

采用优化后的组合凹模尺寸对工作状态下的模具进行数值模拟,图8所示为工作状态下模芯应力分布图。由图8可知:等效应力最大值出现在模芯消气带的齿槽处(位置1),最大值为1 870 MPa;坯料被入模角劈分时变形程度大,入模角(位置2)受坯料挤压而承受较大的压应力;在入模角区齿槽处(位置3),受坯料挤压,该处承受成形产生的较大的径向压应力,而预紧产生的周向压应力抵消成形时的周向拉应力,因此,该处仍处于受压状态,最小周向压应力为120 MPa;坯料经入模角劈分进入定径带和消气带,坯料变形程度减小并逐渐与模具脱离接触,对模具的作用力减弱。

图8 优化后组合凹模在工作状态下模芯应力分布图

Fig. 8 Stress distributions of die insert under working condition after optimization

综上所述,采用优化设计的组合凹模尺寸小于经验法的设计尺寸,优化后的整体尺寸仅为经验法设计尺寸的68.75%。优化设计的模芯内壁最大等效应力小于经验法所得等效应力,并且未出现周向拉应力,可以避免硬质合金模芯因出现拉应力而开裂失效的问题。

坯料被劈分时模芯内壁处应力分布较为复杂,采用点跟踪的方法,获取预紧状态和工作状态下模芯入模角内壁处的应力,图9所示为不同状态下跟踪点应力分布曲线。由图9可知:在预紧状态下,模芯内壁未承受工作压力,模芯主要承受中圈和外圈预紧产生的周向压应力,因此,入模角内壁处径向应力为0 MPa,周向压应力为1 080 MPa。在工作状态下,预应力与工作应力叠加,在入模角劈分坯料的相应内壁处(点1、点6、点11)和入模角齿槽相应的内壁处(点4、点8),等效应力、径向压应力和周向压应力分别达到最大值和最小值。

为了分析2层预应力圈在预紧和工作状态下的应力分布情况,采用点跟踪法获取沿壁厚方向应力分布情况。图10所示为2种状态下沿壁厚方向应力分布曲线。由图10可知:在预紧状态下,模芯、中圈和外圈等效应力最大值均在各层的内壁处,并且沿壁厚方向等效应力逐渐减小;预紧后模芯为周向压应力状态,中圈和外圈为周向拉应力状态,其数值均在各层内壁处得到最大值且沿着壁厚方向减小;预紧后组合凹模均处于径向压应力状态,并且在整个组合凹模内外壁处应力为0 MPa。在工作状态下,模芯承受的工作应力抵消部分预紧产生的周向压应力,模芯内壁处仍为周向压应力,中圈和外圈的周向拉应力相对增大;径向最大压应力在模芯内壁处,且沿着壁厚方向呈现减小的趋势。

4 工艺实验

采用优化后的组合凹模尺寸进行模具加工,为加工方便在保持过盈量不变的前提下,对优化尺寸进行圆整:D2=105 mm,D3=180 mm,D4=275 mm。

图9 模芯内壁处应力的分布曲线

Fig. 9 Distribution curve of stress on inside of die insert

图10 应力沿壁厚方向的分布曲线

Fig. 10 Distribution curve of stress along thickness direction

采用优化后的模具进行实际生产并对模具使用寿命进行跟踪,模具使用寿命约15万次。在使用过程中,模具不断齿、不开裂,挤压15万次后磨损量约0.03 mm。

5 结论

1) 以载重汽车用直齿轮冷挤压组合凹模为研究对象,降低模芯内壁等效应力为优化目标,采用Kriging模型建立了组合凹模结构参数与模芯最大等效应力的近似模型,并采用粒子群算法寻找最优解,得出组合凹模最佳直径比和过盈系数。

2) 在工作状态下,模芯最大等效应力分布在模芯消气带的齿槽处,模芯内壁不会出现周向拉应力,在入模角区齿槽处模芯周向压应力最小。

3) 采用优化后的组合凹模进行实际生产,模具使用寿命约15万次,在使用过程中未出现断齿、开裂的情况。采用优化后的组合凹模能有效减小组合模具的整体尺寸,节约模具材料,为齿类零件冷挤压成形组合凹模设计提供了定量的确定方法。

参考文献:

[1] 冯再新, 周贤宾, 张治民, 等. 齿轮精密成形精整毛坯设计[J]. 塑性工程学报, 2006, 13(1): 67-70.

FENG Zaixin, ZHOU Xianbin, ZHANG Zhimin, et al. Designing of semifinished product for spur gear precision forming[J]. Journal of Plasticity Engineering, 2006, 13(1): 67-70.

[2] 周瑞, 陈文琳, 李亨, 等. 基于弹性变形行为的冷精整直齿轮尺寸预测[J]. 塑性工程学报, 2013, 20(5): 27-32.

ZHOU Rui, CHEN Wenlin, LI Heng, et al. Dimension prediction of spur gear in cold precision sizing based on elastic deformation behavior[J]. Journal of Plasticity Engineering, 2013, 20(5): 27-32.

[3] 洪慎章. 冷挤压实用技术[M]. 北京: 机械工业出版社, 2005: 324-342.

HONG Shenzhang. Cold extrusion technology[M]. Beijing: China Machine Press, 2005: 324-342.

[4] 胡成亮, 袁兆峰, 蔡冰, 等. 齿形组合凹模弹性变形规律分析[J]. 锻压装备与制作技术, 2008, 43(5): 84-87.

HU Chengliang, YUAN Zhaofeng, CAI Bing, et al. Elastic deformation rules of gear-shape combination die[J]. China Metalforming Equipment & Manufacturing Technology, 2008, 43(5): 84-87.

[5] 胡成亮. 直齿轮冷精锻成形数值模拟分析与实验研究[D]. 合肥: 合肥工业大学材料科学与工程学院, 2005: 43-45.

HU Chengliang. Numerical simulation and experimental research of cold net-shape forming of spur gear[D]. Hefei: Hefei University of Technology. School of Material Science and Engineering, 2005: 43-45.

[6] 王强, 昌木松, 陈忠家, 等. 圆柱直齿轮挤压组合凹模的优化设计[J]. 合肥工业大学学报(自然科学版), 2008, 31(9): 1415-1418.

WANG Qiang, CHANG Musong, CHEN Zhongjia, et al. Optimum design of combined extrusion die for cylindrical spur gear[J]. Journal of Heifei of Technology (Natural Science), 2008, 31(9): 1415-1418.

[7] EYERCIOGLU O, KUTUK M A, YILMAZ N F. Shrink fit design for precision gear forging dies[J]. Journal of Materials Processing Technology, 2009, 209(4): 2186-2194.

[8] LEE H C, SAROOSH M A, SONG J H, et al. The effect of shrink fitting ratios on tool life in bolt forming processes[J]. Journal of Materials Processing Technology, 2009, 209(8): 3766-3775.

[9] 张渝, 胡启国, 张甫仁. 基于粒子群算法的冷挤压模具结构参数优化设计[J]. 中国机械工程, 2010, 21(8): 1003-1007.

ZHANG Yu, HU Qiguo, ZHANG Furen. Optimum design of structural parameters of cold extrusion dies based on particle swarm optimization[J]. China Mechanical Engineering, 2010, 21(8): 1003-1007.

[10] 张渝, 周杰, 胡启国. 基于粒子群算法的预挤压组合凹模优化设计[J]. 热加工工艺, 2010, 39(3): 95-97.

ZHANG Yu, ZHOU Jie, HU Qiguo. Optimization design of combined die for cold extrusion based on particle swarm optimization[J]. Hot Working Technology, 2010, 39(3): 95-97.

[11] 张渝. 基于代理模型的锻造模具结构智能优化研究[D]. 重庆: 重庆大学材料科学与工程学院, 2009: 77-93.

ZHANG Yu. Forging-die structure intelligent optimization research based on surrogate model[D]. Chongqing: Chongqing University. School of Material Science and Engineering, 2009: 77-93.

[12] 敖文刚, 唐全波, 黄勇刚. 用统一强度理论的多层预应力组合凹模强度设计和应用[J]. 塑性工程学报, 2011, 18(6): 31-35.

AO Wengang, TANG Quanbo, HUANG Yonggang. Strength design of multi-layer pre-stressed combination die by unified strength theory[J]. Journal of Plasticity Engineering, 2011, 18(6): 31-35.

[13] 敖文刚, 唐全波, 黄勇刚. 挤压预应力组合凹模强度分析及设计[J]. 特种铸造及有色合金, 2013, 33(5): 405-409.

AO Wengang, TANG Quanbo, HUANG Yonggang. Strength analysis and design of cold extrusion prestressed combination female die[J]. Special Casting & Nonferrous Alloys, 2013, 33(5): 405-409.

[14] 敖文刚, 张贤明, 伍太宾. 考虑材料抗压异性的三层预应力组合凹模设计[J]. 塑性工程学报, 2011, 18(1): 72-76.

AO Wengang, ZHANG Xianming, WU Taibin. Design of three-layer prestressed combination dies considering diversity in tensile and compressive strength of material[J]. Journal of Plasticity Engineering, 2011, 18(1): 72-76.

[15] 敖文刚, 王歆. 统一强度理论在预应力组合凹模设计中的应用[J]. 锻压技术, 2010, 35(6): 124-127.

AO Wengang, WANG Xin. Application of unified strength theory in design of prestressed combination die[J]. Forging & Stamping Technology, 2010, 35(6): 124-127.

[16] 鲁志兵, 王成勇, 张心怡, 等. 筒形件冷挤压凹模强度设计及结构优化[J]. 中国机械工程, 2015, 26(23): 3228-3233.

LU Zhibing, WANG Chengyong, ZHANG Xinyi, et al. Strength design and structural optimization of cold extrusion die for cylindrical workpieces[J]. China Mechanical Engineering, 2015, 26(23): 3228-3233.

[17] 曹金豆. 直齿圆柱齿轮连续冷挤压工艺及模具技术研究[D]. 重庆: 重庆大学材料科学与工程学院, 2016: 57-63.

CAO Jindou. Research on the continuous cold extrusion process and mold technology of spur gear[D]. Chongqing: Chongqing University. School of Material Science and Engineering, 2016: 57-63.

[18] LIU Wei, YAN Yuying. Multi-objective optimization of sheet metal forming process using Pareto based genetic algorithm[J]. Journal of Materials Processing Technology, 2008, 208(1): 499-506.

[19] ZHOU Jie, ZHUO Fang, HUANG Lei. Multi-objective optimization of stamping forming process of head using Pareto-based genetic algorithm[J]. Journal of Central South University, 2015, 22(9): 3287-3295.

[20] PALANIVEL R, MATHEWS P K. Prediction and optimization of process parameter of friction stir welded AA5083-H111 aluminum alloy using response surface methodology[J]. Journal of Central South University, 2012, 19(1): 1-8.

[21] LOPHAVEN S N, NIELSEN H B, SONDERGAARD J. DACE a matlab Kriging toolbox[EB/OL]. [2007-11-07]. http://www. imm.dtu.dk/~hbn/dace/.

[22] 阎长罡, 李松, 刘宇. 基于粒子群优化算法的圆锥刀侧铣刀轴轨迹规划[J]. 计算机集成制造系统, 2016, 22(10): 2380-2388.

YAN Changgang, LI Song, LIU Yu. Tool axis trajectory planning for flank milling with conical tools based on particle swarm optimization[J]. Computer Integrated Manufacturing Systems, 2016, 22(10): 2380-2388.

(编辑 刘锦伟)

收稿日期:2016-11-23;修回日期:2016-12-17

基金项目(Foundation item):国家自然科学基金资助项目(51275543);重庆市科委应用开发项目(cstc2014yykfC70003) (Project(51275543) supported by the National Natural Science Foundation of China; Project(cstc2014yykfC70003) supported by the Science and Technology Application Development Program of Chongqing)

通信作者:周杰,博士,教授,从事模具技术及模具CAD/CAM/CAE研究;E-mail: woliangniliu@163.com