模具温度和凸模速度对超高强钢热冲压成形的影响

来源期刊:中国有色金属学报(英文版)2012年第z2期

论文作者:刘 伟 刘红生 邢忠文 刘 钢 包 军

文章页码:534 - 541

关键词:热冲压;超高强钢板;有限元模型;热固耦合;模具温度;凸模速度

Key words:hot stamping; ultra high strength steel; FEM; thermo-mechanical coupling; tool temperature; punch speed

摘 要:高强钢板热冲压作为一种创新工艺逐渐被用于汽车领域制造超高强度的零件。实际上,由于在热冲压过程中材料表现出高度非线性的弹塑性以及热固响应行为,实验很难全面考察热成形过程。因此,有必要建立超高强钢板热冲压三维弹塑性热固耦合的有限元模型。同时,在高温拉伸试验的基础上,测试超高强钢的高温力学性能,并建立和应变、应变速率、温度相关的材料本构模型。此外,采用热冲压试验结合数值模拟研究模具温度和凸模速度对方盒形件超高强钢热冲压的影响规律,在测试热成形零件性能的基础上,得到优化的模具温度和冲压速度。

Abstract: The hot stamping process of ultra high strength (UHS) sheet metal is an innovative way which is used in automobile increasingly for the manufacturing of components with a ultra high ultimate tensile strength (UTS). Due to the high nonlinear elastoplastic and thermo-mechanical responses of material during the hot forming process, practically it is difficult to investigate such hot forming presses only via experiments. Therefore, it is necessary to develop a 3D elastoplastic coupled thermo-mechanical finite element model (FEM) of UHS sheet metal hot forming. Meanwhile, the mechanical properties of UHS steel at elevated temperatures were characterized and the corresponding material constitutive, which is strain, strain rate and temperature dependent, is developed on the basis of unaxial tensile test at elevated temperatures. In addition, hot stamping experiments were conducted and combined with the simulation to investigate the effect of tool temperature and punch speed on the hot stamping of UHS sheet metal for the square-box-shaped (SBS) component. Considering the UTS of hot formed component, the optimum tool temperature and the punch speed are achieved.

Trans. Nonferrous Met. Soc. China 22(2012) s534-s541

LIU Wei1, 2, LIU Hong-sheng3, XING Zhong-wen3, LIU Gang1, 2, BAO Jun3

1 National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

2 .School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

3. School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 28 August 2012; accepted 25 October 2012

Abstract: The hot stamping process of ultra high strength (UHS) sheet metal is an innovative way which is used in automobile increasingly for the manufacturing of components with a ultra high ultimate tensile strength (UTS). Due to the high nonlinear elastoplastic and thermo-mechanical responses of material during the hot forming process, practically it is difficult to investigate such hot forming presses only via experiments. Therefore, it is necessary to develop a 3D elastoplastic coupled thermo-mechanical finite element model (FEM) of UHS sheet metal hot forming. Meanwhile, the mechanical properties of UHS steel at elevated temperatures were characterized and the corresponding material constitutive, which is strain, strain rate and temperature dependent, is developed on the basis of unaxial tensile test at elevated temperatures. In addition, hot stamping experiments were conducted and combined with the simulation to investigate the effect of tool temperature and punch speed on the hot stamping of UHS sheet metal for the square-box-shaped (SBS) component. Considering the UTS of hot formed component, the optimum tool temperature and the punch speed are achieved.

Key words: hot stamping; ultra high strength steel; FEM; thermo-mechanical coupling; tool temperature; punch speed

1 Introduction

In lightweight construction, besides the conventional lightweight materials, aluminium, magnesium and polymers, high and ultra high strength steels are being increasingly used in the automotive industry [1-3]. Due to their high strength and improved formability, those steels offer some new potentials of weight reduction particularly for the body in white body. However, at room temperature the workability of such UHS steel is low and the relatively large srpingback after cold forming will seriously impair the geometrical shape accuracy of formed components [4,5]. Therefore, to improve the properties of component manufactured from UHS sheet metal, an innovative processing technology was presented [6]. In such hot forming, forming and hardening are combined in one non-isothermal forming process step. After passing through hot forming process, the component finally exhibits a martensitic microstructure with tensile strength of above 1500 MPa [7-9]. Therefore, such forming of UHS sheet metal at elevated temperatures has an obvious advantage over the cold forming in the enhancement of UTS of formed component. For example, with the application of hot forming for the UHS steel 22MnB5 [7-9], the hot formed components like bumpers and pillars have the UTS above 1500 MPa. Further, compared with the cold forming of UHS sheet metal, a less quantity of springback can be achieved and higher shape-accuracy of formed component can be obtained due to low yield strength to elastic modulus ratio for UHS steel in the hot forming process. The mechanism of small springback in hot forming of UHS sheet metal is addressed [10]. However, compared with the cold sheet metal forming, the hot stamping of UHS sheet metal involves a complicated thermo-mechanical process. In the hot forming process, the flow stress of material has an apparent dependence on temperatures, and thus leads to that the ambient temperature and the thermo contact significantly influence the final properties of hot stamped component. In addition, the high strain rate sensitivity of UHS steel flow stress was observed [11-16] and it reveals that the final properties of hot stamped component will be also impaired by punch speed. However, the hot stamping process is a high nonlinear process involving nonlinear material stress response, thermo and geometrical contacts between workpiece, tools and atmosphere [8]. It is not practical to exactly investigate the hot stamping process and understand the deformation mechanism only by experiments.

In the present work, a finite element thermomechanical model is developed to investigate the hot stamping of UHS sheet metal for the SBS component. Two important parameters of tool temperature and punch speed in hot stamping technology have significant effects on the temperature distribution and thus the microstructure and the final properties of hot stamped component. In the present work, we aim at obtaining the effect laws of tool temperature and punch speed on the temperature distributions and final properties of hot stamped component by implementing both the simulations and the experiments of hot stamping for a classical SBS component, and further analyzing the microstructure evolution at the different temperatures with forming process proceeding and the UTS of hot formed component by combining the experimental and simulation results.

2 Thermomechanical FEM and experiments

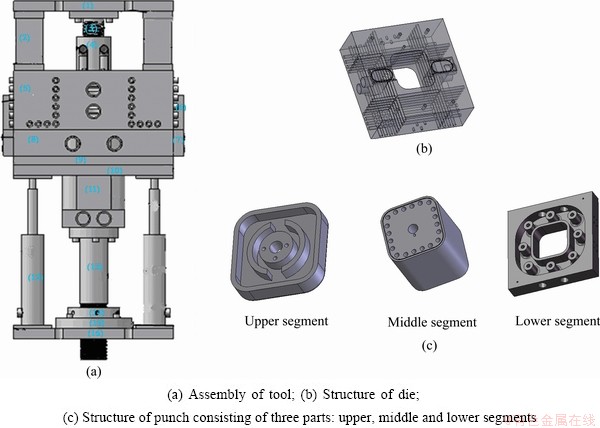

The tools used in the classical UHS sheet metal hot stamping process for SBS component are schematically illustrated in Fig. 1. The hot stamping process mainly consists of four steps: heating of workpiece to austenization temperature, holding, hot forming lasting for about 0.5 s and quenching of hot formed component with water cooled die, and the last step will last for about 6.0 s. Prior to hot forming, the workpiece should be heated to austenitizing temperature and kept at such temperature for about 300 s in the furnance, and then the heated workpiece is transferred on the die and held by blank holder. Afterwards, hot stamping will be performed with the punch moving down for a prescribed displacement and taking the workpiece into die. This step may determine the final properties of hot formed component. In this stage, the convection and, mainly the radiation to its surrounding impose to a workpiece, which leads to that the workpiece is cooled at a low rate of about 10 °C/s and the austenite cannot be fully transformed into martensite due to the fact that the thermal contact conductance between workpiece and die is very low and its contribution to the cooling of the sheet is limited. To improve the UTS of hot formed component, in the last step the formed component remains on die without any applied pressure and is cooled by die. The last step, namely, quenching is crucial for improving the final properties of hot stamped component. The tool temperature is closely related with the quenching effectiveness, lower tool temperature, better quenching effectiveness and more high UTS of hot stamped component. Therefore, to facilitate the martensite phase transformation and improve the UTS of hot stamped component, a cool system containing some channels in tools including die and punch shown in Fig. 1 is designed and the tool can be further cooled by ejecting water into channel when quenching is performed to obtain high cooling rate of hot stamped component. Due to the fact that after the first two steps, the temperature keeps a relatively high temperature about 900 °C and the phase transformation from martensite phase to austenite phase does not take place at such high temperature, the first two steps are not considered in the numerical model in the present work.

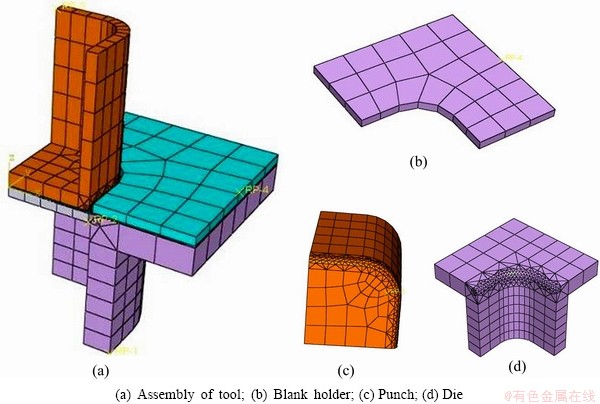

To investigate the complicated hot forming process, considering the thermomechanical characteristic of UHS steel during hot forming, a thermomechanical FE model is developed. In this model, the finite element discretizations of tools used in UHS sheet metal are developed, as shown in Fig. 2. Due to symmetry, a quarter of whole model is adopted. In those finite element models, the element type of C3D8RT is adopted and the finer element is used to describe the geometrical shape of round angle. The heat transfer among workpiece, tools and ambient should be dealt deliberately. The heat is transferred from workpiece in three ways of convection, radiation and contact conductance. Compared with the radiation and the convection, the pressure-dependent contact conductance is the dominant heat transference way during the hot forming and quenching [12].

Another issue involving the development of finite element hot stamping model is to characterize the mechanical properties of UHS sheet metal at elevated temperatures and strain rates. In our previous work [7-9], for a quenchable UHS 22MnB5 sheet metal, a strain, strain rate and temperature dependent material constitutive is developed and adopted at the present work by fitting the strain—stress curves obtained by tensile test at different temperatures and strain rates. The developed material constitutive is expressed as

(1)

(1)

where ε is strain;  is strain rate; σ is the flow stress; T is forming temperature; T0 is room temperature; Ti is constant. K=33.56, n0=0.2236, cn=0.0021, ε0=0.0025, β= 2341.78, m0=0.0756, cm=0.0022.

is strain rate; σ is the flow stress; T is forming temperature; T0 is room temperature; Ti is constant. K=33.56, n0=0.2236, cn=0.0021, ε0=0.0025, β= 2341.78, m0=0.0756, cm=0.0022.

Fig. 1 Assembly of tools used in UHS sheet metal hot stamping for SBS component

Fig. 2 Finite element discretization of tools used in hot stamping of UHS sheet metal

3 Results and discussion

The simulations and experiments of hot stamping of UHS sheet metal are performed to investigate the effects of tool temperature and the punch speed on the temperature distribution and thus the microstructure evolution and the final properties of hot stamped component.

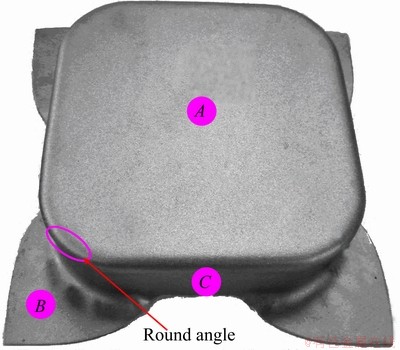

3.1 Effect of tool temperature

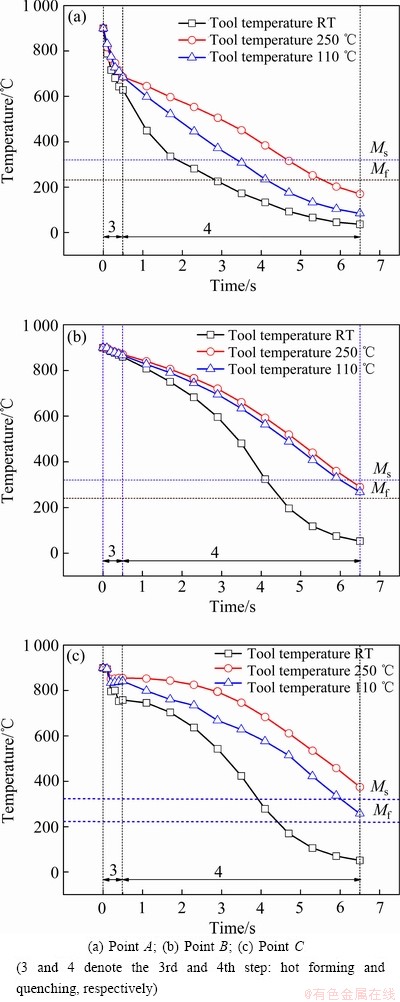

From the view of heat conduction, the higher temperature difference between workpiece and tools results in a higher cooling rate of workpiece and better quenching effectiveness. In experiments, prior to the hot forming the various tool temperatures can be obtained simply by contact conductance between tools and hot metal bulk which is heated and then placed on tools several times. To investigate the effect of tool temperature on the final microstructure of hot formed component, the temperature and microstructure evolutions of three material points A, B and C on SBS hot formed part shown in Fig. 3 were investigated by simulations. Figures 4(a), (b) and (c) show the temperature history of points A, B and C at different tool temperatures for the steps: hot stamping (the third step) and quenching (the forth step), respectively.

Fig. 3 Square-box-shaped component by hot stamping

As seen in Fig. 4, the tool temperature has a significant effect on the temperature evolution of workpiece during hot forming and quenching, the temperature of workpiece decreases dramatically regardless of points A, B and C as the tool temperature decreases from 250 °C to room temperature. The point A can be fully cooled even at the tool temperature of 250 °C, while the point C is cooled to the temperature above the martensite transformation start point (Ms) at the same tool temperature. This means that at the end of quenching, actually the martensite transformation does not start due to the fact that the temperature of point C is above the Ms. At a lower tool temperature of 110 °C, the martensite transformation takes place partially at the point C. When the tool temperature reduces to room temperature (RT), the austenite phase can be totally transformed into martensite phase, as shown in Fig. 4(c), due to the fact that the temperature of point C is below martensite transformation finish point (Mf) at the end of quenching. One important reason for the above results is that compared with the contact condition between the tools, the bottom of SBS component has better contact conditions with the tools. In addition, the bottom is exerted with a relatively high pressure while the side wall is pressure free. Better contact conditions and higher applied pressure lead to better heat conductance between the tool and workpiece because of the pressure dependent heat conductance [13,14].

Fig. 4 Temperature history during hot forming and quenching for three material points

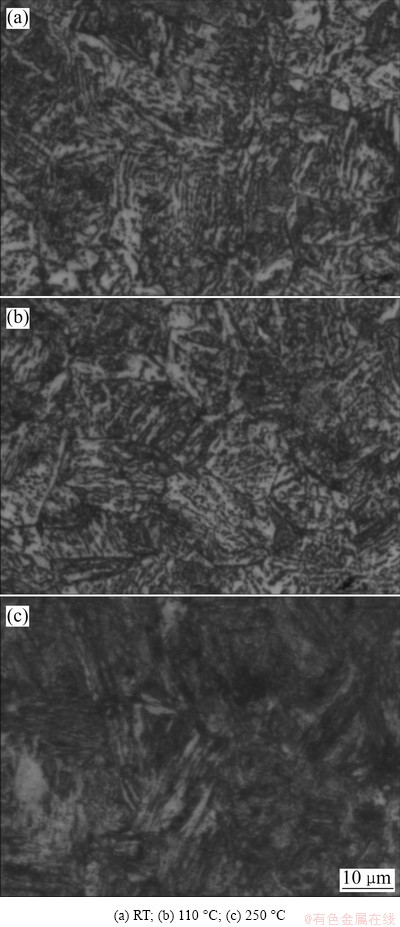

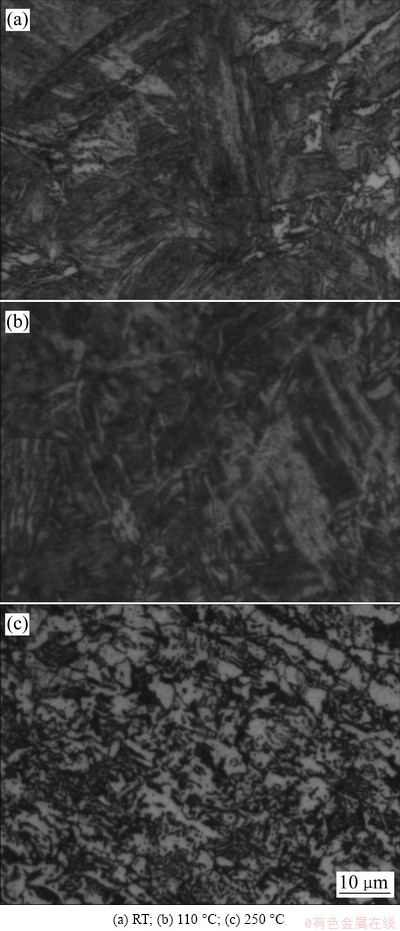

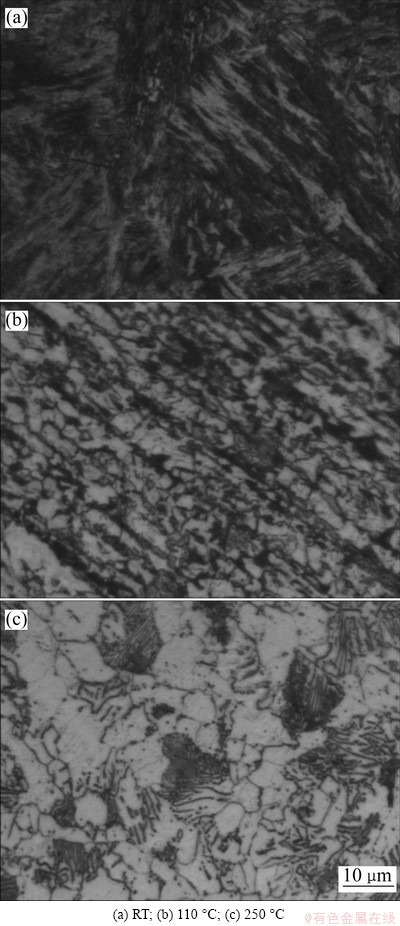

The different final microstructures of points A, B and C for tool temperatures of RT, 110 °C and 250 °C as shown in Figs. 5, 6 and 7, respectively, are observed by SEM. Figures 5-7 show that the tool temperature also has a significant effect on the microstructure. Austenite phase is completely transformed into martensite as shown in Fig. 5 regardless of the tool temperature from 250 °C to RT. The plate martensite becomes finer as the tool temperature decreases from 250 °C to RT. Due to the little bad contact condition between the tool and the flange of SBS component, the point B cannot be cooled fully at tool temperature of 250 °C and the microstructure is the mixture of martensite and pearlite at point B, as shown in Fig. 6. Even at the tool temperature of 110 °C the pearlite has a high proportion for the microstructure at point C as shown in Fig. 7.

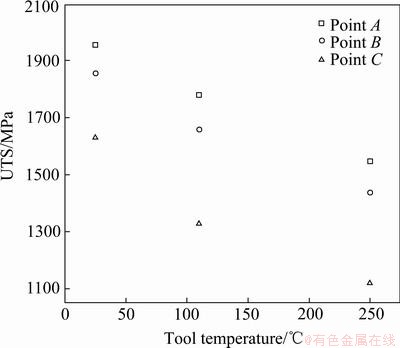

Tensile tests are conducted to investigate the effect of tool temperature on the UTS of hot stamped component. Figure 8 shows the UTS of material points A, B and C at different tool temperatures. The point C in the flange of SBS component formed at tool temperature 250 °C is the weakest, and the highest UTS of 1954 MPa is obtained for the point A at tool temperature of RT. The UTSs of the points A, B and C are consistent with the microstructures as shown in Figs. 5, 6 and 7, respectively.

Fig. 5 Final microstructures of material point A at different tool temperatures

Fig. 6 Final microstructures of material point B at different tool temperatures

Therefore, to improve the final properties of hot formed SBS component the optimum way is to optimize the tool design and thus guarantee high cooling rate of the flange of SBS component during quenching step.

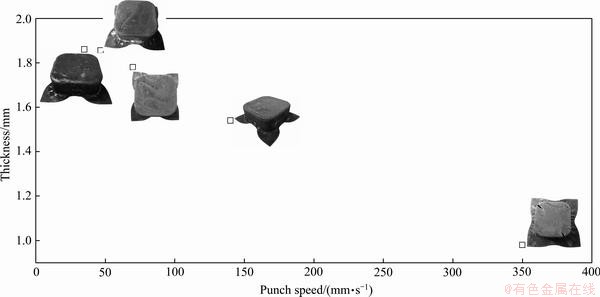

3.2 Effect of punch speed

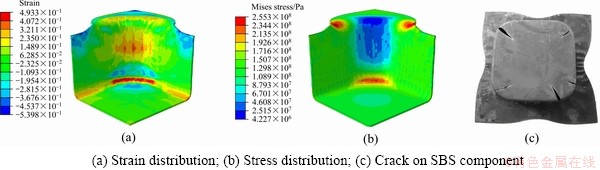

In numerical model, the different punch speeds from 35 mm/s to 350 mm/s can be obtained by varying the hot forming time from 0.1 s to 1.0 s at the same punch stroke of 35.0 mm. The punch speed seriously affects the final properties of hot formed part. Possibly crack will occur with punch speed increasing due to the non-uniform material flow and the non-uniform material shrink during hot stamping. Figure 9 shows thickness of the round angle material of the hot formed SBS component at different punch speeds. The material of the round angle is damaged as shown in Fig. 9 when the workpiece is hot stamped with punch speed of 350 mm/s. The non-uniform material flow resulted from high punch speeds and the low flow stresses of UHS steel at a elevated temperature is the main reason for the crack. Figure 10 shows the Mises stress and equivalent strain distributions. The stress and the strain concentrations produced by the non-uniform material flow are located at the round angle of the SBS component shown in Fig. 10. Therefore, synthetically considering the final properties of hot formed and the practical hot stamping efficiency, the punch speed of 46.7 mm/s, namely, the prescribed punch stroke is finished in the prescribed hot stamping time 0.75 s for the punch stroke of 35 mm, is the optimum one in the present work.

Fig. 7 Final microstructures of material point C at different tool temperatures

Fig. 8 UTS of material points A, B and C at tool temperatures of RT, 110 °C and 250 °C

Fig. 9 Thickness variation of round angle material at different punch speeds

Fig. 10 Stress and strain distributions of SBS component

4 Conclusions

1) Hot stamping experimental apparatus with a cooling system is built up. Subsequently, a thermomechanical-based 3D-FE numerical model of hot stamping for SBS component is developed by deliberately treating contact conditions, i.e., thermal contact and geometrical contact conditions.

2) The developed 3D-FE model is combined with experiments to investigate the effect of two processing parameters of tool temperature and punch speed on the final properties of hot stamped SBS component.

3) The microstructure of hot stamped SBS component can be fully transformed into martensite phase for the tool temperature of RT, while for the tool temperature of 250 °C such transformation can partially take place for the material of the flange and the sidewall SBS component.

4) Compared with other material domains of the SBS component, UTS of the flange is the lowest under the same hot stamping conditions. In addition, the higher punch speed will lead to higher tendency of crack despite, and the high punch speed facilitates the practical production efficiency. Considering the final properties of hot formed and the practical hot stamping efficiency, the punch speed of 46.7 mm/s is the optimum one.

References

[1] HOFFMANN H, SO H, STEINBEISS H. Design of hot stamping tools with cooling system [J]. Annals-Manufacturing Technology, 2007, 56(1): 269-272.

[2] NADERI M, DURRENBERGER L, MOLINARI A, BLECK W. Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperature [J]. Materials Science and Engineering A, 2008, 478(1-2): 130-139.

[3] NADERI M, KETABCHI M, ABBASI M. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping [J]. Journal of Materials Processing Technology, 2011, 211(6): 1117-1125.

[4] BARIANI P F, BRUCHI S, GHIOTTI A. Critical issues in the simulation of hot forming operations [J]. Prod Eng Res Devel, 2010, 4(4): 407-411.

[5] KATSUYOSHI I, JUN Y. Valuation method for effects of hot stamping process parameters on product properties using hot forming simulator [J]. Journal of Materials Processing Technology, 2011, 211(8): 1441-1447.

[6] XING Z W, CUI J J, LIU H S, LI C F. Numerical and experiment investigation into hot stamping of high strength steel sheet for auto B pillar reinforced panel [J]. Advanced Materials Research, 2010, 129-131: 322-327.

[7] LIU H S, XING Z W, BAO J. Investigation of the hot-stamping process for advanced high-strength steel sheet by numerical simulation [J]. Journal of Materials Engineering and Performance, 2010, 19(3): 325-334.

[8] LIU H S, BAO J, XING Z W. Modeling and FE simulation of quenchable high strength steels sheet metal hot forming process [J]. Journal of Materials Engineering and Performance, 2011, 20(6): 894-902.

[9] LIU H S, LIU W, BAO J, XING Z W. Numerical and experimental investigation into hot forming of ultra high strength steel sheet [J]. Journal of Materials Engineering and Performance, 2011, 20(1): 1-10.

[10] LIU Hong-sheng, BAO Jun, XING Zhong-wen. Analysis of mechanism of springback in 22MnB5 super-high strength steel forming[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(4): 865-870. (in Chinese)

[11] MERKLEIN M, LECHLER J. Investigation of the thermo- mechanical properties of hot stamping steels [J]. Journal of Materials Processing Technology, 2006, 177: 452-455.

[12] ABDULHAY B, BOUROUGA B, DESSAIN C. Experimental and theoretical study of aspect of the hot stamping process [J]. Applied Thermal Engineering, 2011, 31: 674-685.

[13] MCADAMS W H. Heat transmission[M]. 3rd ed. New York: McGraw Hill, 1954: 180.

[14] SELLERS L. Modeling of metals rolling processes [C]// Proc of 2nd Int Conf. London: The Institute of Materials, 1996.

[15] KARBASIAN H, TEKKAYA A E. A review on hot stamping [J]. Journal of Materials Processing Technology, 2010, 210(5): 2103-2118.

[16] HYUN H B, MYOUNG G L, PAVLINA E J. Comparative study of the prediction of microstructure and mechanical properties for a hot stamped B-pillar reinforcing part [J]. Internationals Journal of Mechanical Sciences, 2011, 53(9): 744-752.

刘 伟1, 2,刘红生3,邢忠文3,刘 钢1, 2,包 军3

1. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

3. 哈尔滨工业大学 机电工程学院,哈尔滨 150001

摘 要:高强钢板热冲压作为一种创新工艺逐渐被用于汽车领域制造超高强度的零件。实际上,由于在热冲压过程中材料表现出高度非线性的弹塑性以及热固响应行为,实验很难全面考察热成形过程。因此,有必要建立超高强钢板热冲压三维弹塑性热固耦合的有限元模型。同时,在高温拉伸试验的基础上,测试超高强钢的高温力学性能,并建立和应变、应变速率、温度相关的材料本构模型。此外,采用热冲压试验结合数值模拟研究模具温度和凸模速度对方盒形件超高强钢热冲压的影响规律,在测试热成形零件性能的基础上,得到优化的模具温度和冲压速度。

关键词:热冲压;超高强钢板;有限元模型;热固耦合;模具温度;凸模速度

(Edited by LI Xiang-qun)

Foundation item: Project (50905041) supported by the National Natural Science Foundation of China; Project (20092302120079) supported by the Specialized Research Fund for the Doctroal Program of Higer Education, China; Project (09JD18) supported by Key Laboratory of Ministry Education for Conveyance and Equipment, East China Jiaotong University, China

Corresponding author: LIU Hong-sheng; Tel: +86-451-86418631; E-mail: hs_liu_hit@163.com

DOI: 10.1016/S1003-6326(12)61757-9