TiC颗粒强化Ti-30Fe复合材料的摩擦行为

来源期刊:中国有色金属学报(英文版)2021年第4期

论文作者:徐圣航 邱敬文 张惠斌 曹华珍 郑国渠 刘咏

文章页码:988 - 998

关键词:TiC颗粒;Ti-Fe基复合材料;粉末冶金;显微组织;摩擦行为

Key words:TiC particle; Ti-Fe based composite; powder metallurgy; microstructure; friction behavior

摘 要:将Ti、Fe和TiC粉末进行低温球磨,并结合放电等离子烧结制备Ti-Fe-xTiC (x=0,3,6,9,质量分数%)复合材料。结果表明:该复合材料中含有β-Ti、β-Ti-Fe、η-Ti4Fe2O0.4以及TiC颗粒。显微组织随着TiC添加量的增加而显著细化。粘着磨损是Ti-Fe-xTiC复合材料的主要磨损机制。随着TiC添加量的增加,摩擦因数(COF)减小,硬度增大。其中,由于Ti-Fe-6TiC复合材料中TiC含量较高,TiC颗粒尺寸小,组织细化程度高,因此,具有最佳的耐磨性能,磨损率仅有1.869×10-5 mm3/(N·m),同时,摩擦因数为0.64。由此可见,TiC颗粒增强Ti-Fe基复合材料在耐磨材料领域具有潜在的应用价值。

Abstract: Ti-Fe-xTiC (x=0, 3, 6, 9, wt.%) composites were fabricated through low temperature ball milling of Ti, Fe and TiC powders, followed by spark plasma sintering. The results show that β-Ti, β-Ti-Fe, η-Ti4Fe2O0.4 and TiC particles can be found in the composites. The microstructure can be obviously refined with increasing the content of TiC particles. The coefficient of friction (COF) decreases and the hardness increases with increasing the content of TiC particles. The adhesive wear is the dominant wear mechanism of all the Ti-Fe-xTiC composites. The Ti-Fe-6TiC composite shows the best wear resistance, owing to the small size and high content of TiC particle as well as relatively fine microstructure. The wear rate of the Ti-Fe-6TiC composite is as low as 1.869×10-5 mm3/(N·m) and the COF is only 0.64. Therefore, TiC particle reinforced Ti-Fe based composites may be utilized as potential wear resistant materials.

Trans. Nonferrous Met. Soc. China 31(2021) 988-998

Sheng-hang XU1,2, Jing-wen QIU3, Hui-bin ZHANG1, Hua-zhen CAO1, Guo-qu ZHENG1, Yong LIU2

1. College of Materials Science and Engineering, Zhejiang University of Technology, Hangzhou 310014, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Hunan Provincial Key Laboratory of High Efficiency and Precision Machining of Difficult-to-Cut Material, Hunan University of Science and Technology, Xiangtan 411201, China

Received 14 May 2020; accepted 21 December 2020

Abstract: Ti-Fe-xTiC (x=0, 3, 6, 9, wt.%) composites were fabricated through low temperature ball milling of Ti, Fe and TiC powders, followed by spark plasma sintering. The results show that β-Ti, β-Ti-Fe, η-Ti4Fe2O0.4 and TiC particles can be found in the composites. The microstructure can be obviously refined with increasing the content of TiC particles. The coefficient of friction (COF) decreases and the hardness increases with increasing the content of TiC particles. The adhesive wear is the dominant wear mechanism of all the Ti-Fe-xTiC composites. The Ti-Fe-6TiC composite shows the best wear resistance, owing to the small size and high content of TiC particle as well as relatively fine microstructure. The wear rate of the Ti-Fe-6TiC composite is as low as 1.869×10-5 mm3/(N·m) and the COF is only 0.64. Therefore, TiC particle reinforced Ti-Fe based composites may be utilized as potential wear resistant materials.

Key words: TiC particle; Ti-Fe based composite; powder metallurgy; microstructure; friction behavior

1 Introduction

Ti-Fe based alloys have been widely studied owing to their high strength and low density, which can be applied in the prospect of automotive, aerospace and medical apparatus [1,2]. LOUZGUINE et al [3] reported a Ti65Fe35 alloy with a high ultimate tensile strength of 2200 MPa and a proper ductility of 6.7%. Because of the presence of hard Ti-Fe intermetallic compounds, the Ti-Fe based alloys have potential applications in the field of wear resistant materials. According to the Archard’s equation [4], the wear resistance of material is strongly depended on its hardness, and the Ti-Fe based composite possesses higher hardness than that of other Ti alloy [5]. However, seldom researches have reported the wear behavior of Ti-Fe based alloys.

Composites have been widely fabricated in order to enhance the hardness of matrix [6,7]. Generally, composites can be classified according to the morphological characteristics of their reinforcements, such as fiber [8] and particle reinforcements [9]. Particle reinforcements [10,11] are widely used in the wear resistant materials. The ceramic particles are common reinforcements, which can provide composites for excellent hardness and wear resistance, such as TiC [12], TiB [13], SiC [14], and TiN [15]. Because of the high hardness, high melting point and low density, TiC particle has been considered as an ideal reinforcement in Ti-based [16], Al-based [17] and Fe-based [18] composites. For example, the AlSi10Mg alloys reinforced by TiC were prepared by laser additive manufacturing with high- frequency micro-vibration, and the ultimate tensile strength reached up to 314.7 MPa [19]. Moreover, the TiC particle possesses suitable thermal conductivity and good compatibility with matrix, and thus the connection between TiC particle and matrix is rather perfect, which comes as the basis for satisfactory performance.

The microstructure is another important factor for the wear behavior. The combination of mechanical alloying (MA) and spark plasma sintering (SPS) may introduce fine microstructure into the composite. MA process can largely decrease the grain size and improve the sintering activity [20,21]. The microstructure of the materials after sintering is fine with limited porosity, which is extremely beneficial to improving the properties. For example, LUO et al [22] fabricated a bulk of Hf by combination of high-energy ball milling and spark plasma sintering, and the hardness of the bulk reached up to above HV 1200, which was mainly owing to the grain boundary strengthening. LIU et al [23] reported a nanocrystalline CrMnFeCoNi high entropy alloy through MA process followed by SPS. The grain size was completely preserved after sintering, and this alloy presented a high ultimate tensile strength of 1000 MPa and a reasonable ductility. Besides, extra O element can be uniformly dissolved into the matrix during the milling process, which can further enhance the material by the solid solution strengthening effect.

However, the researches about the TiC enhanced Ti-Fe based composites seem quite scarce. In this work, we first fabricated TiC particles reinforced Ti-Fe based composites through spark plasma sintering of Ti-Fe/TiC mechanical alloyed (MAed) powders. The TiC particles inside the Ti-Fe matrix can further enhance the strength and thereby improve the wear behavior. This method provides an effective strategy for designing and fabricating TiC enhanced material for wear resistant application. Besides, the microstructural evolution of the Ti-Fe based composites with different TiC contents was studied, and the wear behavior was also investigated.

2 Experimental

2.1 Material preparation

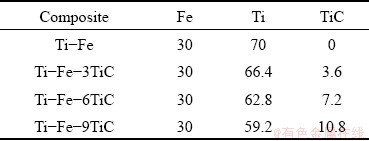

Ti-Fe-xTiC (x=0, 3, 6, 9, wt.%) composites were prepared by the mechanical alloying of Ti (purity >99.9%), Fe (purity >99.8%) and TiC (purity >98.0%) powders. The compositions of Ti-Fe based composites are listed in Table 1. The powders were milled in a low temperature planetary ball-miller for 8 h at -3 °C with the protection of argon atmosphere. The low temperature can prevent the growth of grain size during MA process. The milling speed was 250 r/min and the ball-to-powder mass ratio was 10:1. For simplicity, the composites are named as Ti-Fe, Ti-Fe-3TiC, Ti-Fe-6TiC and Ti-Fe-9TiC according to the content of added TiC particles.

Table 1 Compositions of Ti-Fe-xTiC composites (wt.%)

The SPS process was conducted at 1000 °C and then held for 10 min by using an HP D 25/3 spark plasma sintering system. The pressure was 30 MPa, the heating rate was 200 °C/min and the cooling rate was 50 °C/min. The shape of the as-SPSed samples was cylindrical structure, and the diameter and the height were 40 and 6 mm, respectively. Then, the as-SPSed samples were annealed at 600 °C in a furnace for 30 min followed by water quenching.

2.2 Characterization

The powder morphologies and microstructures were examined by an FEI Nova Nano250 scanning electron microscope (SEM). The phase was identified using a D/MAX-2250 X-ray diffraction (XRD) analyzer with a Cu Kα radiation operated at 45 kV at room temperature. The elemental distribution was investigated by an electron probe micro analysis (EPMA, JEOL-1600).

The hardness of the composites was measured by HV-1000 type Vicker’s hardness instrument at a load of 200 N. Tribological tests were performed by using an HT-1000 friction and wear tester in a ball-on-disc contact configuration at room temperature. The disc samples were made of Ti-Fe based composites with the size of d25 mm × 5 mm. The counterpart ball was made of Si3N4, whose hardness is about HRC 78. Prior to the friction and wear experiments, both the disc-like samples and the Si3N4 balls were ultrasonically cleaned in acetone for 10 min, and then dried in hot air to guarantee the clean surfaces. Fiction and wear tests were conducted at an applied load of 5 N and a sliding speed of 0.28 m/s. The rotation diameter, testing time and sliding distance were 10 mm, 60 min and 1008 m, respectively. The coefficient of friction was recorded automatically, and the tests were repeated at least three times to ensure the accuracy of the data. After tribological tests, the worn volume was measured by a surface profilometer (Keyence VHX-5000). In order to investigate the wear mechanisms of the composites, the worn surfaces were also examined by SEM and EPMA.

3 Results

3.1 Characterization of MAed powders

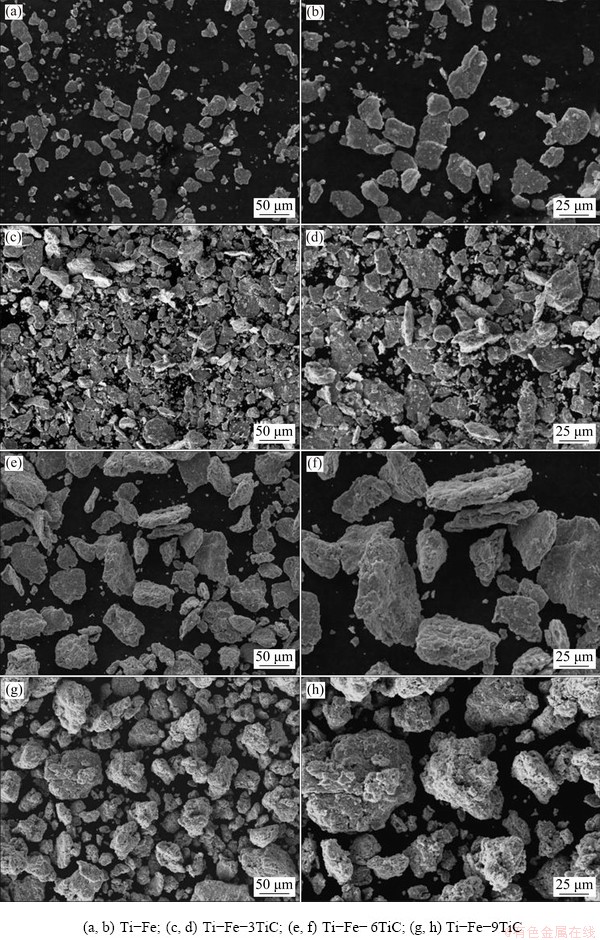

Figure 1 shows the morphologies of as-milled powders of Ti-Fe, Ti-Fe-3TiC, Ti-Fe-6TiC, Ti-Fe-9TiC, respectively. It can be seen that Ti-Fe, Ti-Fe-3TiC and Ti-Fe-6TiC powders present flat-like structure while Ti-Fe-9TiC powder shows the irregular structure. The particle size of the milled powders increases with increasing content of TiC particles. The size of Ti-Fe powder is about 30 μm while that of Ti-Fe-9TiC powder is larger than 80 μm.

Fig. 1 Morphologies of powders after low temperature milling for 4 h

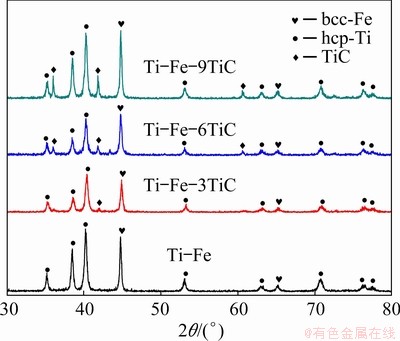

Figure 2 illustrates the XRD patterns of the as-milled Ti-Fe based powders. The index of XRD peaks suggests that both bcc-Fe and hcp-Ti phases occur in all MAed Ti-Fe powders. The weak diffraction peaks of TiC only present at about 42° in the XRD pattern of Ti-Fe-3TiC, owing to the low content of TiC particle (only 3 wt.%). However, the diffraction peaks of TiC can be clearly detected in the XRD patterns of Ti-Fe-6TiC and Ti-Fe-9TiC powders, as shown at 36°, 42° and 63°.

Fig. 2 XRD patterns of Ti-Fe-xTiC powders after low temperature ball milling at -3 °C for 8 h

3.2 Microstructures of composites

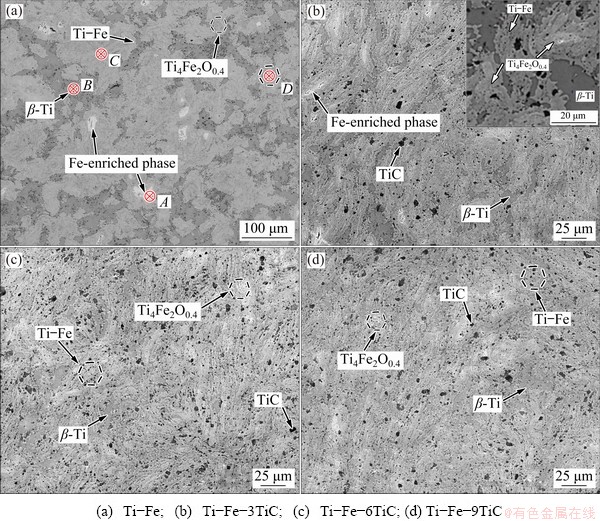

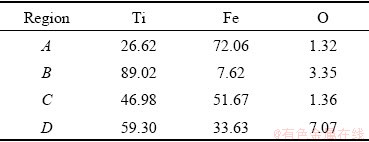

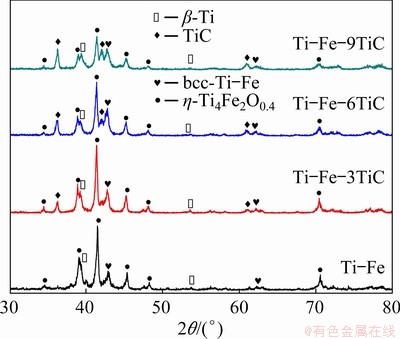

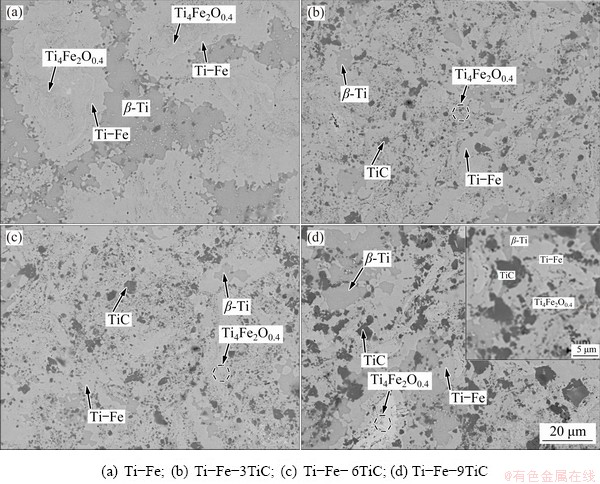

Figure 3 shows the microstructure of the Ti-Fe based composites after SPS. It clearly shows that the TiC particles (black areas) are uniformly distributed inside the composites, as shown in Figs. 3(b-d). The refining efficiency of micro- structure improves with increasing addition of TiC particles. Table 2 shows the chemical compositions of different regions in Fig. 3(a). The grey region (B in Fig. 4(a)) represents β-Ti phase while the relatively bright region (C in Fig. 4(a)) is β-Ti-Fe phase. Ti4Fe2O0.4 phase (D in Fig. 4(a)) can be found inside the β-Ti-Fe phase. The structure of Ti4Fe2O0.4 has been reported in Ref. [24]. Moreover, owing to the short time sintering process, Fe element is distributed unevenly and therefore the Fe-enriched areas can be preserved. The XRD patterns in Fig. 4 show the phase constitution of the Ti-Fe-xTiC composites. It is indicated that only the β-Ti, β-Ti-Fe and Ti4Fe2O0.4 phases can be detected inside the Ti-Fe sample while the obviously individual peaks of TiC can be obtained in Ti-Fe-3TiC, Ti-Fe-6TiC and Ti-Fe-9TiC composites. The content of Fe-enriched phase is relatively limited, and thus, the peaks of Fe-enriched phase cannot be indexed in the XRD patterns.

Fig. 3 Microstructures of Ti-Fe-xTiC composites after SPS

Table 2 Compositions of different regions in Fig. 3(a) (wt.%)

Fig. 4 XRD patterns of Ti-Fe-xTiC after SPS

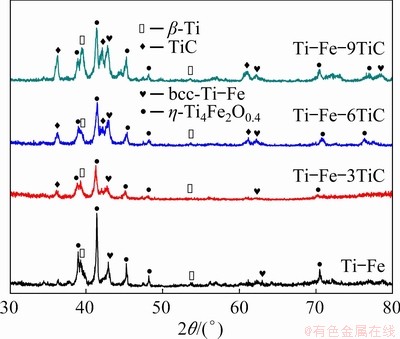

In order to homogenize the microstructure of the Ti-Fe based composites, annealing process was applied after SPS. Figure 5 presents the microstructure after annealing at 600 °C for 1 h. No Fe-enriched phase can be found any more, indicating that Fe element is uniformly distributed in the matrix. The volume fractions of Ti-Fe phase and β-Ti phase both increase after annealing. For one thing, Fe element can diffuse into the Ti matrix and form Ti-Fe intermetallic phase. For another, Fe is a kind of β-stabilizing elements, the dissolved Fe element can boost the formation of β-Ti phase. Besides, the size of TiC particles increases with increasing the TiC content. The sizes of TiC particles in Ti-Fe-3TiC and Ti-Fe-6TiC composites are about 2 and 4 μm while the size of that in Ti-Fe-9TiC composite is about 8 μm. The XRD patterns in Fig. 6 show that no other precipitations appear after annealing.

Fig. 5 Microstructures of Ti-Fe-xTiC composites after SPS and annealing

Fig. 6 XRD patterns of Ti-Fe-xTiC after SPS and annealing

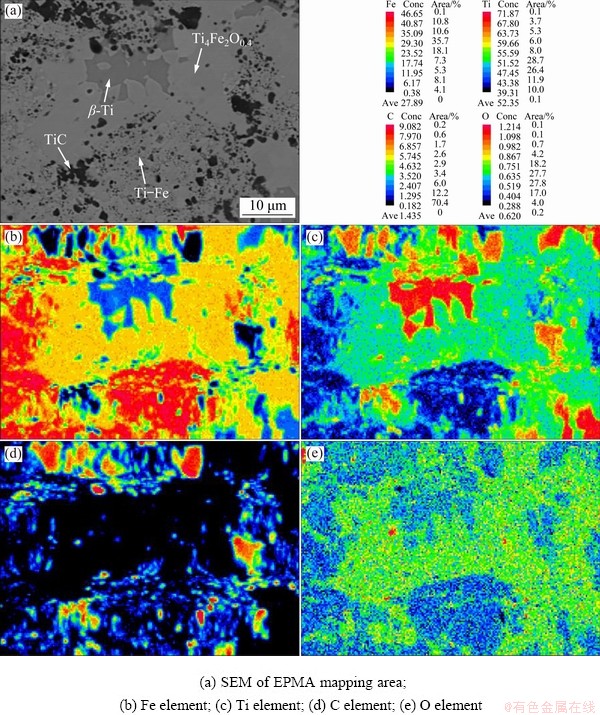

In order to further determine the distribution of different elements, EMPA mapping was utilized, and Fig. 7 shows the compositional profiles of the Ti-Fe-6TiC composite after annealing. It is interesting to note that TiC particles are mainly distributed inside the β-Ti-Fe intermetallics. Besides, almost all C atoms occur in the TiC particles, and few C element can be detected inside the Ti4Fe2O0.4 phase as well as the β-Ti phase, as marked in Fig. 7(a).

3.3 Wear behavior of composites

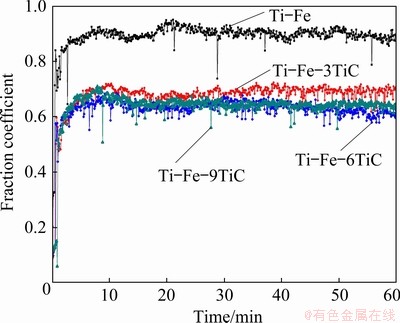

The coefficient of friction (COF) curves of the Ti-Fe-xTiC (x=0, 3, 6, 9) composites are shown in Fig. 8. It can be found that the Ti-Fe composite possesses a high COF value of 0.91. The addition of TiC particles can significantly decrease the COF value of the Ti-Fe based composite. The COF values of the Ti-Fe-3TiC, Ti-Fe-6TiC, Ti-Fe- 9TiC composites are 0.70, 0.64, 0.64, respectively. The obvious decrease of COF value with the addition of TiC particles can be explained by the improved wear resistance, which will be discussed later.

Fig. 7 EPMA mapping of Ti-Fe-6TiC composite showing distribution of elements

Fig. 8 Typical evolution curves of friction coefficients of Ti-Fe-xTiC composites with sliding time after annealing

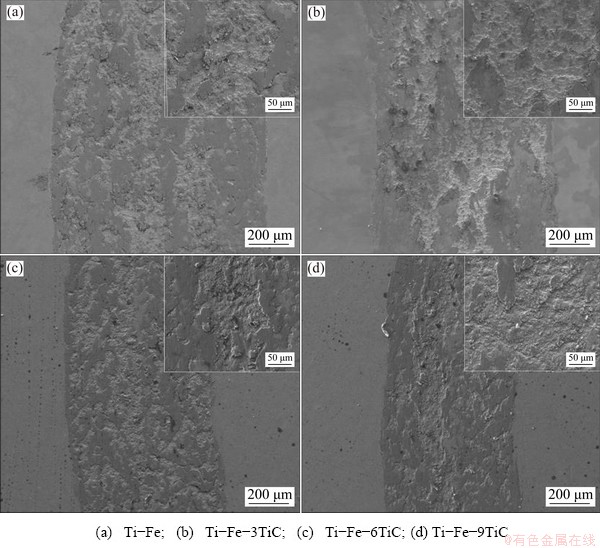

Figure 9 shows the SEM morphologies of the worn surfaces of the Ti-Fe-xTiC (x=0, 3, 6, 9) composites. All the worn surfaces present considerable flattened patches and significant surface damage, indicating that the dominate wear mechanism of the Ti-Fe-xTiC composites is adhesive wear. The micro plowing structure can also be detected in the Ti-Fe-6TiC composite. For the Ti-Fe, Ti-Fe-3TiC and Ti-Fe-6TiC composites, increasing content of TiC particles can obviously decrease the occurrence of flattened patches. However, the surface damage turns severer when added more TiC particles (Ti-Fe-9TiC composite), which can be attributed to the large size of the TiC particles. The connection between TiC particle and matrix is weak when the size of TiC particle is rather large. Therefore, the particle is easy to be peeled off from the matrix during the friction and wear process.

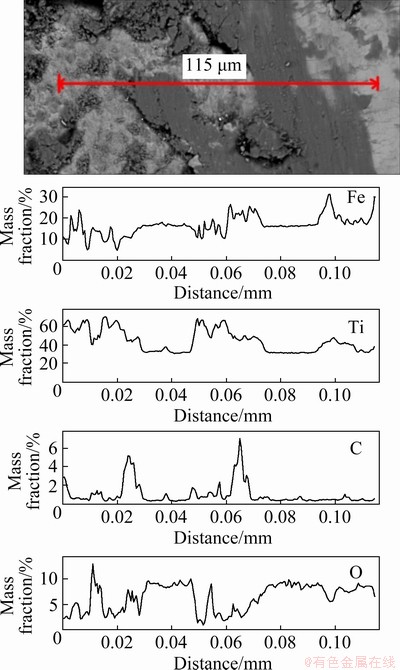

In order to investigate the chemical composition of the worn surfaces, EPMA line scanning was applied on the Ti-Fe-6TiC composite, as shown in Fig. 10. The results show that the Ti-Fe intermetallics are severely peeled off while the Ti4Fe2O0.4 phase and partial TiC particles can remain unbroken inside the frictional surface during wear process, and therefore support the applied loads.

Fig. 9 Typical worn surfaces morphologies of composites

Fig. 10 EPMA line scanning of worn surface of Ti-Fe-6TiC composite

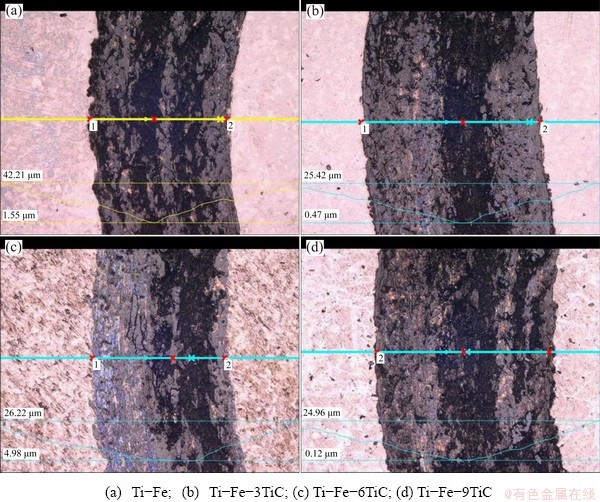

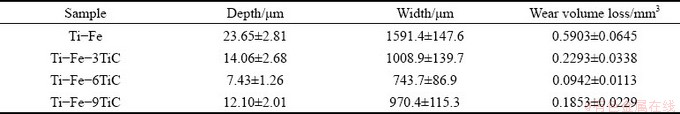

Figure 11 shows the OM morphologies of the worn surfaces of the Ti-Fe-xTiC (x=0, 3, 6, 9) composites. The measured worn groove depth and width are presented in Table 3. The results show that with increasing the TiC content, the worn groove depth and width decreased obviously except the Ti-Fe-9TiC composite.

The wear rate can directly show the wear resistance of the materials, which can be explained by [25]

K=V/ws

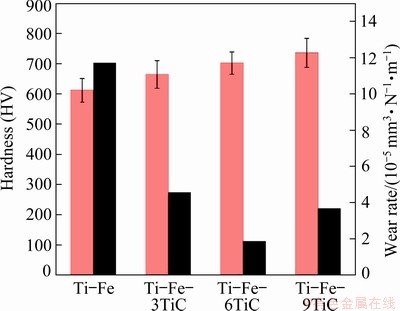

where V is the worn volume (mm3), w is the normal load (N) and s is the totally sliding distance (m). Figure 12 shows the wear rate of the Ti-Fe-xTiC composites at a speed of 0.28 m/s. It can be found that all the wear rates are located in the magnitude of 10-5-10-4 mm3/(N·m). The Ti-Fe-6TiC composite shows the lowest wear rate of only 1.869×10-5 mm3/(N·m).

4 Discussion

4.1 Microstructural evolution

After mechanical alloying and spark plasma sintering, fine scale β-Ti, β-Ti-Fe intermetallics and Ti4Fe2O0.4 phase are obtained, and the TiC particles are uniformly distributed inside the matrix. The microstructure becomes finer with higher content of TiC particles. This can be explained by the following reasons. For one thing, the TiC particles possess much higher hardness than that of Ti and Fe powders [2]. Therefore, they can effectively refine the grain size during MA process. For another, the TiC particles in the matrix can hinder the growth of grain during sintering and annealing processes. Many studies [26,27] have shown that the grain size decreased obviously with increasing addition of TiC particles. Therefore, the microstructure of the Ti-Fe-xTiC composites turns fine with increasing addition of TiC particles.

Fig. 11 OM morphologies of worn surface to groove bottom after wear tests

Table 3 Worn groove dimensions of Ti-Fe-xTiC composites

Fig. 12 Hardness and wear rate of Ti-Fe-xTiC composites

The microstructure of the Ti-Fe-xTiC composites changes largely after annealing at 600 °C for 1 h. The TiC particles grow obviously, especially for the Ti-Fe-9TiC composites. Because of the small atom size, C atoms can diffuse through the crystal lattices easily. TiC particles are stable, and therefore, C atoms, solid solute element in the composite, tend to form and enlarge TiC particles during annealing process. Owing to the highest content of C element in the Ti-Fe-9TiC composite, the TiC particles become the largest after annealing. The improved volume fraction of TiC particles during annealing process by diffusion of C atoms has been reported by other research [28].

4.2 Wear behavior

Generally, the property of wear resistance is strongly depended on the content and the size of TiC particle, as well as the microstructure, hardness and ductility of composites [4]. The hardness of the Ti-Fe based composites increases obviously with increasing the TiC content. Besides, as mentioned above, the refinement of microstructure occurs when added TiC particles during the MA process, which can also improve the hardness. Therefore, the better property of wear resistance can be achieved with increasing content of TiC particles. Moreover, ZHANG et al [29] indicated that the ductility is also an important parameter governing tribological behaviors of materials, although the hardness plays a vital role in wear rate. As discussed above, relatively large size of TiC particle can weaken the bonding between the particle and matrix, especially for the Ti-Fe-9TiC composite. During the friction and wear process, TiC particles are easy to be pulled out when applied the shear stress. Thus, the wear resistance is bad for Ti-Fe-9TiC composite, because the removed TiC particles cannot support the applied loads any more. The similar phenomenon is also reported in Ti-Mo-TiC composites that the TiC particles tend to be pulled out from the matrix during the tensile deformation owing to the weak bonding [30].

According to Fig. 12, the worn volume of the Ti-Fe-xTiC composites decreases with increasing content of TiC particles except Ti-Fe-9TiC composite. The EPMA line scanning in Fig. 10 shows that the Ti-Fe phase can be pulled out while Ti4Fe2O0.4 phase remains unbroken under the repeated shear stress. Besides, partial TiC particles can also be preserved in the matrix. The Ti4Fe2O0.4 phase and the remained TiC particles can support the applied loads and act as load-bearing roles. Although the Ti-Fe-9TiC composite possesses the highest hardness, the large-scale TiC particles are easy to be pulled out and thus deteriorate the wear rate. Besides, the depth and width of worn groove decrease with increasing the TiC content except Ti-Fe-9TiC composite. The obviously decreasing of COF value with increasing the TiC particles in Ti-Fe composite can be attributed to the reduction of friction contact region. Certainly, a small amount of TiC particles can be brought out from the Ti-Fe phase during the friction and wear process. As hard abrasives, the detached TiC particles may cause plowing grooves when move to the friction surfaces. Thus, the micro-plowings can be detected on the worn surfaces. As mentioned above, the size of TiC is relatively large in Ti-Fe-9TiC composite. Therefore, higher density of heavily flattened patches can be found on the worn surface of Ti-Fe-9TiC composite than that of Ti-Fe-6TiC composite. Besides, the worn groove depth and width both increase, reflecting the deterioration of wear resistance. Overall, the Ti-Fe-6TiC composite possesses the best property of wear resistance.

5 Conclusions

(1) Ti-Fe-xTiC (x=3, 6, 9, wt.%) based composites possess β-Ti, β-Ti-Fe, Ti4Fe2O0.4 phase as well as TiC particles after sintering and annealing. With increasing TiC content, the size of TiC particles increases.

(2) The coefficient of friction is obviously related to the TiC content. Ti-Fe alloy shows a high COF of 0.91 while Ti-Fe-3TiC composite presents a COF of 0.70. With the further increasing of TiC content, the COFs of Ti-Fe-6TiC and Ti-Fe-9TiC become steady at about 0.64.

(3) The adhesive wear is the dominant worn mechanism of Ti-Fe based composites, while the abrasive wear only occurs in Ti-Fe-6TiC and Ti-Fe-9TiC composites.

(4) The hardness increases with increasing the TiC content, and the Ti-Fe-9TiC composite possesses the highest hardness of HV 736. However, the Ti-Fe-6TiC composite shows the best property of wear resistance, with the lowest worn rate of 1.869×10-5 mm3/(N·m).

Acknowledgments

The authors gratefully acknowledge the financial support from the National Key Fundamental Research and Development Project of China (2014CB644002).

References

[1] LI Pei-you, ZHANG Hui, TONG Ting, HE Zhi-rong. The rapidly solidified β-type Ti-Fe-Sn alloys with high specific strength and low elastic modulus [J]. Journal of Alloys and Compounds, 2019, 786: 986-994.

[2] ZHOU Sheng-feng, XU Yong-bo, LIAO Bang-quan, SUN Ya-juan, DAI Xiao-qin, PAN Hong-bo. In-situ synthesis of Ti-Fe-based alloys prepared by the combination of mechanical alloying and laser melting deposition: Microstructure and corrosion resistance [J]. Journal of Alloys and Compounds, 2018, 768: 697-706.

[3] LOUZGUINE D V, KATO H, INOUE A. High strength and ductile binary Ti-Fe composite alloy [J]. Journal of Alloys and Compounds, 2004, 384: L1-L3.

[4] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics, 1953, 24: 981-988.

[5] RAFIEI M, ENAYATI M H, KARIMZADEH F. Kinetic analysis of thermite reaction in Al-Ti-Fe2O3 system to produce (Fe,Ti)3Al-Al2O3 nanocomposite [J]. Powder Technology, 2014, 253: 553-560.

[6] XU Sheng-hang, DU Meng, LI Jia, YAN Kun, CAI Biao, HE Quan-feng, FANG Qi-hong, MAGDYSYUK O, LIU Bin, YANG Yong, LIU Yong. Bio-mimic Ti-Ta composite with hierarchical “Brick-and-Mortar” microstructure [J]. Materialia, 2019, 8: 100463.

[7] DONG Cui-ge, CUI Rui, WANG Ri-chu, PENG Chao-qun, CAI Zhi-yong. Microstructures and mechanical properties of Al 2519 matrix composites reinforced with Ti-coated SiC particles [J]. Transactions of Nonferrous Metals Society of China, 2020, 30: 863-871.

[8] VASANTHAKUMAR K, KARTHISELVA N S, CHAWAKE N M, BAKSHI S R. Formation of TiCx during reactive spark plasma sintering of mechanically milled Ti/carbon nanotube mixtures [J]. Journal of Alloys and Compounds, 2017, 709: 829-841.

[9] MA Feng-cang, ZHOU Jian-jie, LIU Ping, LI Wei, LIU Xin-kuan, PAN Deng, LU Wei-jie, ZHANG Di, WU Lai-zhi, WEI Xing-qiao. Strengthening effects of TiC particles and microstructure refinement in situ TiC-reinforced Ti matrix composites [J]. Materials Characterization, 2017, 127: 27-34.

[10] HUANG Long, DENG Xiang-tao, JIA Ye, LI Cheng-ru, WANG Zhao-dong. Effects of using (Ti,Mo)C particles to reduce the three-body abrasive wear of a low alloy steel [J]. Wear, 2018, 410-411: 119-126.

[11] NIETO A, YANG H, JIANG L, SCHOENUNG J M. Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites [J]. Wear, 2017, 390-391: 228-235.

[12] SUN Xiang-long, HAN Yuan-fei, CAO San-chen, QIU Pei-kun, LU Wei-jie. Rapid in-situ reaction synthesis of novel TiC and carbon nanotubes reinforced titanium matrix composites [J]. Journal of Materials Science & Technology, 2017, 33: 1165-1171.

[13] BAO Yang, HUANG Lu-jun, AN Qi, JIANG Shan, GENG Lin, MA Xin-xin. Wire-feed deposition TiB reinforced Ti composite coating: Formation mechanism and tribological properties [J]. Materials Letters, 2018, 229: 221-224.

[14] SUN Yan, ZHANG Jie, YUAN Ming-liang, BAI Di-xing, LIU Chun-feng. In-situ stabilized β-Ti in Ti-base alloys to enhance Cf/SiC-Nb heterogenous joint [J]. Journal of Alloys and Compounds, 2019, 773: 217-226.

[15] YANG Wei, AYOUB G, SALEHINIA I, MANSOOR B, ZBIB H. The effect of layer thickness ratio on the plastic deformation mechanisms of nanoindented Ti/TiN nanolayered composite [J]. Computational Materials Science, 2018, 154: 488-498.

[16] OCHONOGOR O F, MEACOCK C, ABDULWAHAB M, PITYANA S, POPOOLA A P I. Effects of Ti and TiC ceramic powder on laser-cladded Ti-6Al-4V in situ intermetallic composite [J]. Applied Surface Science, 2012, 263: 591-596.

[17] YANG Hua-bing, GAO Tong, WU Yu-ying, ZHANG Hua-ning, NIE Jin-feng, LIU Xiang-fa. Microstructure and mechanical properties at both room and high temperature of in-situ TiC reinforced Al-4.5Cu matrix nanocomposite [J]. Journal of Alloys and Compounds, 2018, 767: 606-616.

[18] MOJISOLA T, RAMAKOKOVHU M M, RAETHEL J, OLUBAMBI P A, MATIZAMHUKA W R. In-situ synthesis and characterization of Fe-TiC based cermet produced from enhanced carbothermally reduced ilmenite [J]. International Journal of Refractory Metals and Hard Materials, 2019, 78: 92-99.

[19] LI Chong-gui, SUN Shuai, LIU Chuan-ming, LU Qing-hua, MA Pan, WANG You. Microstructure and mechanical properties of TiC/AlSi10Mg alloy fabricated by laser additive manufacturing under high-frequency micro- vibration [J]. Journal of Alloys and Compounds, 2019, 794: 236-246.

[20] XU Xue-xia, LI Wen-bin, WANG Yong, DONG Guo-zhen, JING Shang-qian, WANG Qing, FENG Yan-ting, FAN Xiao-liang, DING Hai-min. Study of the preparation of Cu-TiC composites by reaction of soluble Ti and ball-milled carbon coating TiC [J]. Results in Physics, 2018, 9: 486-492.

[21] OLESZAK D, ANTOLAK-DUDKA A, KULOK T. High entropy multicomponent WMoNbZrV alloy processed by mechanical alloying [J]. Materials Letters, 2018, 232: 160-162.

[22] LUO Kun, NI Song, SONG Min. Fabricating a bulk FCC Hf by a combination of high-energy ball milling and spark plasma sintering [J]. International Journal of Refractory Metals and Hard Materials, 2018, 75: 107-110.

[23] LIU Yong, WANG Jing-shi, FANG Qi-hong, LIU Bin, WU Yuan, CHEN Shi-qi. Preparation of superfine-grained high entropy alloy by spark plasma sintering gas atomized powder [J]. Intermetallics, 2016, 68: 16-22.

[24] RUPP B, FISCHER P. Reinvestigation of the oxygen stabilized Ti2Ni-type phase Ti4Fe2O0.4 by neutron diffraction [J]. Journal of the Less Common Metals, 1988, 144: 275-281.

[25] ZHANG Ai-jun, HAN Jie-sheng, SU Bo, MENG Jun-hu. A novel CoCrFeNi high entropy alloy matrix self-lubricating composite [J]. Journal of Alloys and Compounds, 2017, 725: 700-710.

[26] TAN You-de, CAI Hong-nian, CHENG Xing-wang, MA Zhao-long, XU Zi-qi, ZHOU Zhi-fang. Microstructural and mechanical properties of in-situ micro-laminated TiC/Ti composite synthesised [J]. Materials Letters, 2018, 228: 1-4.

[27] SHIAL S R, MASANTA M, CHAIRA D. Recycling of waste Ti machining chips by planetary milling: Generation of Ti powder and development of in situ TiC reinforced Ti-TiC composite powder mixture [J]. Powder Technology, 2018, 329: 232-240.

[28] FARLAS I, OLMOS L, JIMENEZ O, FLORES M, BRAEM A, VLEUGELS J. Wear modes in open porosity titanium matrix composites with TiC addition processed by spark plasma sintering [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 1653-1664.

[29] ZHANG You-jing, CHENG Xing-wang, CAI Hong-nian. Fabrication, characterization and tensile property of a novel Ti2Ni/TiNi micro-laminated composite [J]. Materials & Design, 2016, 92: 486-493.

[30] XU Sheng-hang, ZHOU Cheng-shang, LIU Yong, LIU Bin, LI Kai-yang. Microstructure and mechanical properties of Ti-15Mo-xTiC composites fabricated by in-situ reactive sintering and hot swaging [J]. Journal of Alloys and Compounds, 2018, 738: 188-196.

徐圣航1,2,邱敬文3,张惠斌1,曹华珍1,郑国渠1,刘 咏2

1. 浙江工业大学 材料科学与工程学院,杭州 310014;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083;

3. 湖南科技大学 难加工材料高效精密加工湖南省重点实验室,湘潭 411201

摘 要:将Ti、Fe和TiC粉末进行低温球磨,并结合放电等离子烧结制备Ti-Fe-xTiC (x=0,3,6,9,质量分数%)复合材料。结果表明:该复合材料中含有β-Ti、β-Ti-Fe、η-Ti4Fe2O0.4以及TiC颗粒。显微组织随着TiC添加量的增加而显著细化。粘着磨损是Ti-Fe-xTiC复合材料的主要磨损机制。随着TiC添加量的增加,摩擦因数(COF)减小,硬度增大。其中,由于Ti-Fe-6TiC复合材料中TiC含量较高,TiC颗粒尺寸小,组织细化程度高,因此,具有最佳的耐磨性能,磨损率仅有1.869×10-5 mm3/(N·m),同时,摩擦因数为0.64。由此可见,TiC颗粒增强Ti-Fe基复合材料在耐磨材料领域具有潜在的应用价值。

关键词:TiC颗粒;Ti-Fe基复合材料;粉末冶金;显微组织;摩擦行为

(Edited by Xiang-qun LI)

Corresponding author: Sheng-hang XU; Tel: +86-570-88320429; E-mail: shenghangxu@zjut.edu.cn

DOI: 10.1016/S1003-6326(21)65555-3

1003-6326/ 2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press