DOI:10.19476/j.ysxb.1004.0609.2017.12.02

HCCM水平连铸黄铜管坯表面点状缺陷的形成机理与控制

莫永达1,姜雁斌1, 2,刘新华1, 2,谢建新1, 2

(1. 北京科技大学 材料先进制备技术教育部重点实验室,北京 100083;

2. 北京科技大学 现代交通金属材料与加工技术北京实验室,北京 100083)

摘 要:研究热冷组合铸型(HCCM)水平连铸H62 (UNS C27400)黄铜管坯外表面点状缺陷的特点和形成机理,提出消除点状缺陷的措施。结果表明:管坯外表面点状缺陷主要为富锌低熔点物质,其锌含量达80%(质量分数);点状缺陷的出现沿连铸方向呈周期性特征,管坯上部的点状缺陷数量明显多于下部的;连铸过程中,挥发的锌在冷型内表面形成的锌液滴与管坯外表面接触后发生熔蚀反应,使管坯外表面形成富锌的点状缺陷;通过快速降低冷型段内管坯温度,减少锌元素挥发及石墨铸型内表面锌液滴的形成,可有效消除点状缺陷。

关键词:HCCM水平连铸;黄铜管坯;富锌物质;表面缺陷;形成机理

文章编号:1004-0609(2017)-12-2408-12 中图分类号:TG245;TG290 文献标志码:A

黄铜合金管材具有较高的强度、优良的导热性能和耐腐蚀性能,在石油化工、海洋工程、建筑装饰等行业应用广泛[1-2]。目前,工业上主要采用传统的“半连铸实心铸锭→热挤压管材→冷轧→拉拔”工艺(简称“挤轧法”)生产黄铜管材,存在工艺流程长、能耗大、成材率低、生产成本高等问题[3]。为了解决上述问题,本文作者等开发了一种黄铜管材短流程生产工艺[4],采用热冷组合铸型(Heating-cooling combined mold,HCCM)水平连铸技术[5]制备具有优良的冷加工性能的黄铜管坯,然后进行大变形量冷轧加工,可显著缩短生产流程,提高成材率和降低成本[6]。梅俊等[7-8]研究HCCM水平连铸BFe10-1-1管坯凝固固液界面位置对管坯表面质量的影响,提出通过调控制备参数控制固液界面处于铸型热型段和冷型段之间的过渡区,在结晶区建立足够大的轴向温度梯度,是连铸生产高表面质量合金管坯的关键,所制备的管坯无需铣面可直接用于冷轧加工。然而,通过开展黄铜管材HCCM水平连铸实验发现,即使将管坯固液界面控制在过渡区,连铸管坯外表面仍出现一种点状缺陷,在后续加工前须进行表面处理,导致工序增加。因此,分析管坯表面点状缺陷的形成原因,提出消除缺陷的方法,对于提升管坯表面质量和减少生产工序具有重要意义。

黄铜的主要合金元素锌元素的熔点较低(约420 ℃),高温条件下易挥发。GIACOBBE[9]研究了锌含量为35.5%(质量分数)的黄铜在610 ℃时的锌元素挥发现象,挥发速率随着黄铜基体锌含量增加和温度升高而增大。因此,连铸过程中高温黄铜管坯的锌元素挥发、石墨铸型(简称“铸型”)与铸坯之间的相互作用对铸坯表面质量具有重要影响,往往造成划伤、裂纹等表面缺陷[10-12]。本文作者针对HCCM水平连铸H62黄铜管坯的情形,通过分析铸型内表面和管坯外表面的形貌和成分,结合连铸过程稳态温度场模拟结果,探讨管坯表面点状缺陷的形成机理,以提出相应的消除措施,为生产应用提供理论指导。

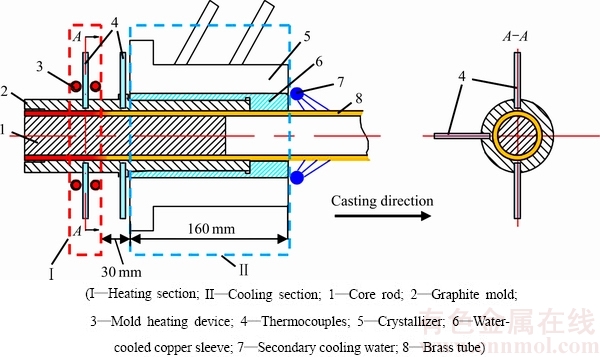

1 实验

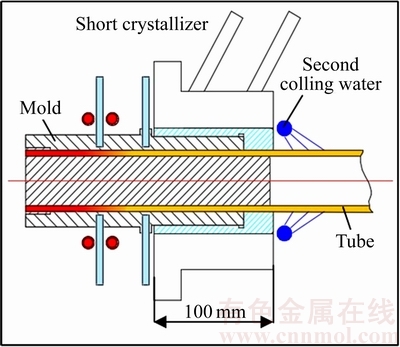

实验材料的化学成分(质量分数,%)为Cu 61.5、Fe 0.05、Pb 0.08、Zn余量。采用实验室自主开发的HCCM水平连铸实验设备进行管坯连铸,连铸工艺原理见文献[5]。实验所使用的结晶器长度为160 mm,组合铸型过渡区(热型段出口与冷型段入口之间的区域)长度为30 mm,所采用的制备参数为熔体温度980 ℃,热型段加热温度980 ℃,冷型段冷却水流量400 L/h,二次冷却水流量400 L/h,连铸速度90 mm/min。连铸管坯的外径为50 mm,壁厚5 mm。实验过程中分别对铸型热型段和近冷型段的上、中、下等6个位置的温度进行实时监测,测温点示意图如图1所示。

图1 HCCM水平连铸铸型测温点示意图

Fig. 1 Schematic diagram of temperature measuring positions of HCCM horizontal continuous casting mold

为了分析管坯表面点状缺陷的形成过程,采用“连铸-急停”实验以保留铸型内表面和管坯外表面在稳定连铸状态下的形貌,即在管坯连铸达到稳定状态且其表面出现点状缺陷时,突然停止拉坯和热型段加热,维持冷却水流量不变使铸型内的管坯快速降温。待实验装置降至室温后,将铸型和管坯保持为一体从实验装置上拆除下来,然后沿铸型轴线进行剖切,观察铸型内表面和对应位置的管坯外表面形貌。采用ZEISS EVO 18 型扫描电镜(SEM)分别对铸型内表面和管坯外表面的微观形貌和成分进行分析。从管坯上切取纵截面金相试样并通过机械打磨和抛光后,使用10 g FeCl3+30 mL HCl+120 mL H2O混合溶液进行浸蚀,采用Nikon ECLIPSE LV150型金相显微镜(OM) 观察显微组织。

为了揭示点状缺陷的形成机理,需要分析HCCM 水平连铸过程中管坯和铸型的稳态温度场。为此采用ProCAST铸造模拟软件,建立了包含管坯、铸型、芯棒和水冷铜套在内的三维几何模型,对管坯连铸的稳态温度场进行模拟计算。根据H62黄铜合金的化学成分,使用ProCAST 软件自带的材料数据库对合金的热力学数据(密度、热导率和固、液相线温度等)进行计算并应用于数值模拟。数值模拟的传热界面条件和边界条件设置参考文献[13]。

2 结果及讨论

2.1 连铸管坯内外表面形貌特征及成分

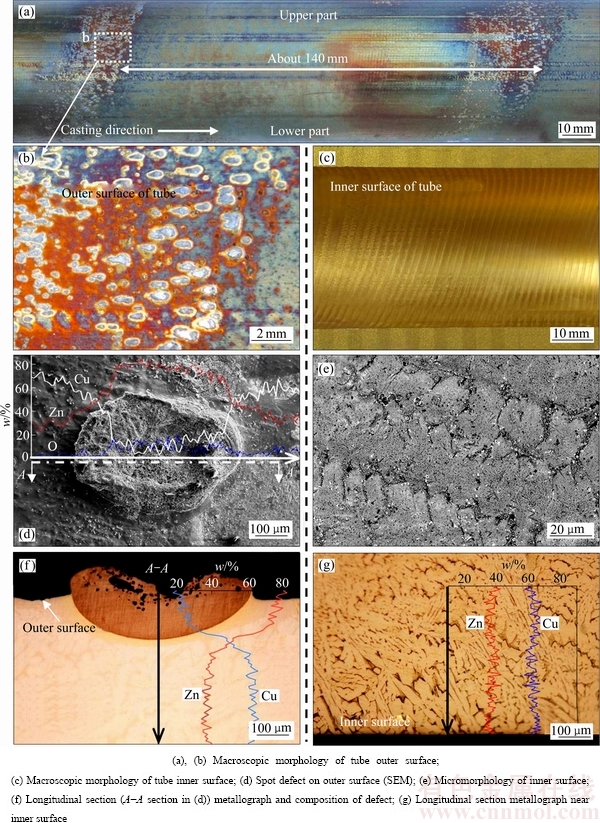

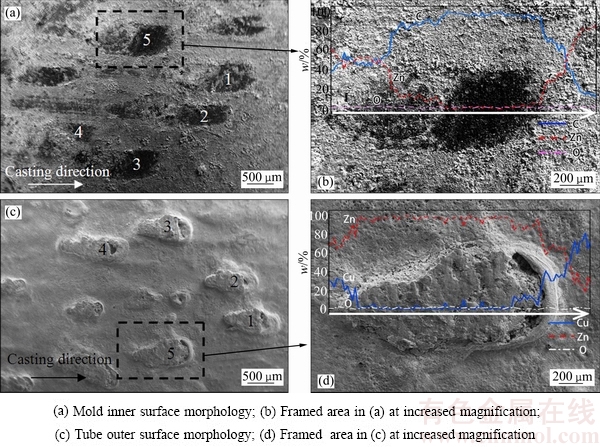

HCCM水平连铸管坯的外表面和内表面形貌如图2所示。从图2(a)和(b)可以看出,管坯外表面存在一种中心部位为灰色颗粒、周围为黄色圆斑的点状缺陷。点状缺陷的出现沿连铸方向呈现出周期性,周期长度约为140 mm,管坯上部的缺陷数量明显多于管坯下部的。采用扫描电镜(SEM-EDS)观察点状缺陷的微观形貌并对其成分进行线扫描分析,其结果如图 2(d)和(f)所示。由图2(d)中的线扫描结果可知,点状缺陷的锌含量(质量分数)可达80%,显著高于管坯基体锌含量(约38%)。从点状缺陷的纵截面金相和成分分布(图2(f))可以看出,一层厚度约为100 μm的富锌物质(锌含量为70%~80%)嵌入了管坯表面。富锌物质与管坯基体之间存在一层厚度约为20 μm过渡层,其成分处于富锌物质与管坯基体之间。相比于管坯外表面,管坯内表面较为光滑,且未观察到上述点状缺陷,如图2(c)所示。管坯内表面的微观形貌也较平整,可观察到整齐排列的枝晶形貌,未发现明显凸起(见图2(e));同时,近管坯内表面的凝固组织和成分较均匀,锌含量没有发生明显变化(见图2(g))。

由图2(f)的线扫描结果可知,点状缺陷处呈现出表面锌含量较高而内部锌含量较低的现象。具有铸锭表面溶质含量高于铸锭内部这一成分分布特征的现象还包括反偏析[14-16]和偏析瘤[17-18]。合金凝固过程中体积收缩使枝晶间产生负压,该负压将铸锭心部未凝固的富溶质熔体吸至铸锭表面,产生表面溶质含量高于心部的反偏析现象[19-20]。而偏析瘤是由于铸锭凝固收缩形成气隙导致凝壳温度回升,枝晶间富溶质的低熔点物质发生重熔并在金属液静压力作用下挤出铸锭表面,使铸锭表面溶质含量高于内部[21]。上述两种机理均可能使铸锭表面溶质含量高于其内部,却无法解释本研究中连铸黄铜管坯外表面点状缺陷的相关特征。首先,根据反偏析和偏析瘤的形成机理,管坯内外表面的锌含量均会高于内部,然而管坯内表面成分均匀,锌含量未出现明显增加(图2(g))。其次,水平连铸过程中,管坯下部金属液静压力大于上部,根据偏析瘤形成机理,管坯下部的富溶质熔体更容易被挤出管坯表面,形成更多的偏析瘤缺陷,这与本研究中管坯上部缺陷数量多于下部的现象不符。第三,上述两种机理均无法解释点状缺陷的出现呈现周期性变化这一特征(图2(a))。

图2 管坯内外表面的宏观和微观形貌及成分

Fig. 2 Morphologies and composition of as-cast tube surface

为了分析点状缺陷的形成原因,采用SEM观察了大量点状缺陷的微观形貌,发现它们共同的特点是外形呈椭圆形,长轴与连铸方向平行,在管坯表面呈凸起状并略带倾斜,倾斜方向与连铸方向相反(图2(d)),这可能是由于其在形成过程中受到铸型内表面的摩擦作用而发生倾斜。因此,为了进一步揭示这种缺陷的形成机理,需要对连铸过程中铸型内表面和管坯外表面的相互作用进行分析。

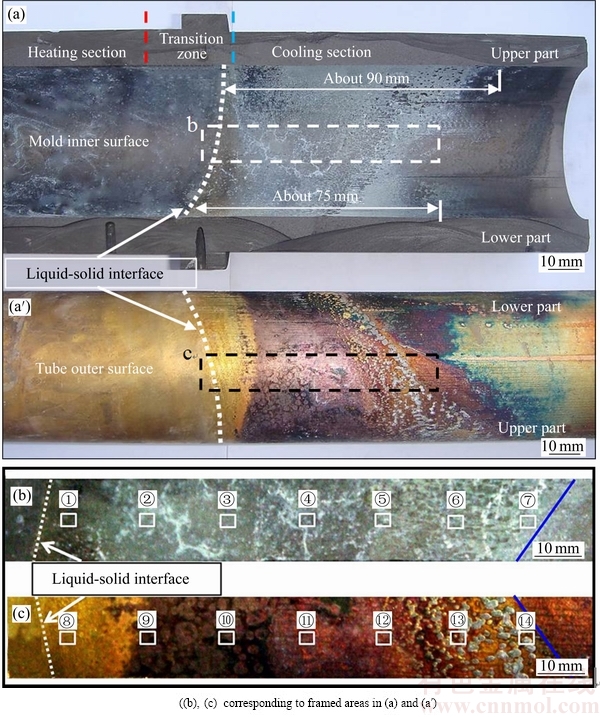

2.2 铸型内表面与管坯外表面的形貌及成分

采用“连铸-急停”实验获得连铸稳定状态下铸型内表面和对应位置的管坯外表面的形貌,如图3(a)所示。从铸型内表面划痕初始位置(见图3(a))和管坯外表面出现节纹的位置(见图3(a′)),可确定管坯凝固时固液界面位于热型段和冷型段之间的过渡区。从固液界面处沿连铸方向,铸型内表面的灰白色附着物逐渐增加,铸型上部和下部附着物分布范围分别为距固液界面90 mm和75 mm,铸型上部附着物数量明显多于铸型下部。从图3(a)和(a′)中虚线方框所示区域切取铸型和对应位置管坯的块状试样,并在试样表面各选取7个对应的区域进行微观形貌观察和成分分析,如图3(b)和(c)所示。

图3 铸型内表面和对应位置的管坯外表面宏观照片

Fig. 3 Macroscopic morphologies of mold inner surface(a) and corresponding tube outer surface(a′), selected areas on mold inner surface for micromorphology observation(b) and selected areas on tube outer surface for micromorphology observation(c)

图4所示为对应于图3(b)铸型内表面各区域的微观形貌和成分分布。从图4中可以看出,沿管坯连铸方向,铸型内表面附着物颗粒数量显著增加,附着物锌含量也逐渐增加,由①处的58.1%增加至⑦处的80.3%,表明铸型内表面附着物主要为富锌物质。此外,从位置⑤开始,铸型内表面出现附着物被摩擦的痕迹,导致相应区域富锌物质数量明显减少,而未被摩擦的区域存在较多的富锌物质,如图4中⑤、⑥和⑦所示。

由于锌元素易挥发,可以认为铸型内表面的富锌物质主要来源于连铸过程中高温黄铜管坯挥发的锌元素。根据锌含量为35.5%的黄铜在610 ℃时锌挥发速率可达8 μg/(cm2·min),且挥发速率随着黄铜基体锌含量增加和温度升高而增大[9],可对管坯连铸过程中挥发的锌元素质量进行估算。在本文实验条件下,外径50 mm的黄铜管坯凝固后温度高于610 ℃的长度约为40 mm (由下文温度场模拟结果获得)。若按8 μg/(cm2·min)的挥发速率进行估算,可得1 min内该高温段管坯的锌元素挥发量约为0.5 mg。在较高的温度(>610 ℃)和较高的锌含量(约38.0%条件下,管坯的锌挥发速率更大,因此,1 min内,管坯实际的锌元素挥发量将显著大于0.5 mg。随着连铸的进行,高温管坯不断挥发出锌元素并在铸型内表面附着形成大量的富锌物质(见图4)。

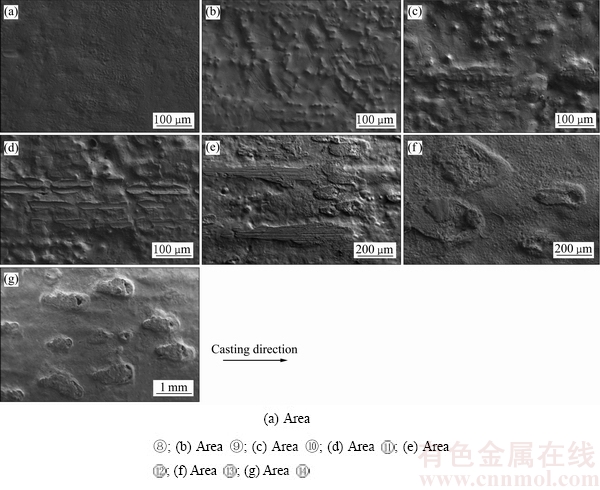

图5所示为对应于图3(c)管坯外表面各区域的微观形貌。从图5中可以看出,沿着连铸方向,管坯外表面的粗糙程度逐渐增加。在位置 和

和 处,管坯表面凸起部分出现被摩擦的痕迹,位置

处,管坯表面凸起部分出现被摩擦的痕迹,位置 和

和 处则出现了椭圆状凸起,各凸起的长轴方向与连铸方向相同,且呈与连铸方向相反的倾斜趋势,其形貌与上文中叙述的点状缺陷相似。

处则出现了椭圆状凸起,各凸起的长轴方向与连铸方向相同,且呈与连铸方向相反的倾斜趋势,其形貌与上文中叙述的点状缺陷相似。

选取管坯表面出现凸起的位置进行取样并制备纵截面金相试样,凸起处的纵截面微观组织如图6所示。从图6中可以看出,块状物质嵌入管坯表面,并与管坯基体之间存在一过渡层。对图6中黑色箭头所示范围进行线扫描分析,发现该块状物质和过渡层的成分与点状缺陷的成分相似(见图2(f))。此外,观察图6还可以发现,嵌入管坯表面的块状物质具有不对称的几何结构特点,沿与连铸相反的方向嵌入较深,相应过渡层也较厚,如图6中白色箭头所示。

为了更直观地体现管坯与铸型之间相互作用,选取管坯外表面点状缺陷密集区域和对应位置的铸型内表面进行形貌观察和成分分析,其结果如图7所示。

图4 铸型内表面微观形貌及成分分布

Fig. 4 Micromorphologies and composition of mold inner surface at different areas

图5 管坯外表面不同区域的微观形貌

Fig. 5 Micromorphologies of tube outer surface in different areas (corresponding to Fig. 3(c))

图6 管坯表面凸起处的纵截面显微组织

Fig. 6 Longitudinal section microstructure and composition profile of bulge on tube surface

从图7可以看出,管坯外表面点状缺陷凸起区域与铸型内表面富锌物质较少区域一一对应(见图7(a)和(c)),未出现点状缺陷的管坯表面所对应的铸型表面仍覆盖着一层富锌物质。通过对铸型内表面和管坯外表面进行成分线扫描后发现,与点状缺陷对应区域的铸型内表面主要为C元素(w(Zn)<10%),而其周围区域仍主要为Zn元素(w(Zn)>50%)(见图7(b))。管坯表面点状缺陷中心部位锌含量大于90%,而其周围仍保持基体的成分(w(Zn)约38%)(见图7(d))。

上述结果表明,管坯表面的富锌物质是在连铸过程中铸型内表面的富锌物质与管坯外表面产生接触而转移至管坯表面的。由于连铸过程中处于铸型内部的管坯仍具有较高温度,转移至管坯表面的富锌物质可能与管坯基体间发生高温扩散反应。因此,为了进一步揭示点状缺陷的形成机理,需要对连铸过程中管坯和铸型的温度场进行分析。由于连铸过程中的温度分布不易直接测量,本研究采用数值模拟方法对管坯连铸稳态温度场进行模拟计算。

2.3 点状缺陷形成机理

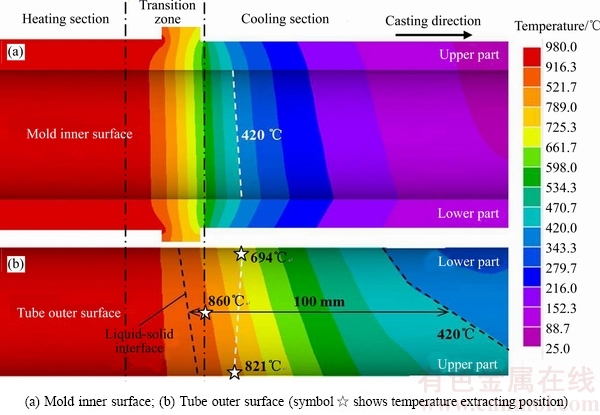

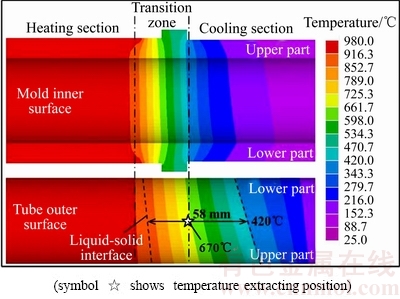

采用ProCAST 铸造模拟软件对管坯连铸过程的稳态温度场进行模拟,模拟计算获得的铸型内表面及管坯外表面温度分布如图8所示。从模拟结果中提取与实际6个测温点对应位置节点处的温度,并与管坯达到连铸稳定状态时6个测温点的实测温度进行对比,如表1所列。从表1中可以看出,模拟获得的温度与实测温度之间的偏差小于5%,表明模拟温度场与管坯连铸实际温度场吻合较好。

从图8(b)中可以看出,管坯凝固固液界面位于过渡区近冷型入口处,与实验确定的固液界面位置相近(见图3(a)),表明通过模拟获得的管坯温度与管坯实际温度较为接近。管坯进入冷型后温度约为860 ℃(见图8(b)),沿连铸方向温度缓慢降低,直至接近铸型出口管坯的温度仍高于纯锌的熔点420 ℃。对比图8中铸型内表面和管坯外表面的温度场可以发现,进入冷型段后管坯温度显著高于铸型温度,铸型内表面温度降至420 ℃时,相对应位置的管坯外表面仍处于较高温度(694~821 ℃) (见图8(b))。因此,在高温管坯热辐射的作用下,挥发的锌元素可能仍以液滴的形式附着于铸型内表面。由于富锌液滴的锌含量显著高于管坯基体,当铸型内表面上的锌液滴与高温管坯表面接触时,锌元素向管坯基体进行快速扩散,使管坯表面接触点处的锌含量增加。

图7 点状缺陷密集区域铸型和管坯表面形貌及成分对比

Fig. 7 Comparison of morphology and composition profile of mold inner surface with tube outer surface with dense spot defects

图8 管坯连铸稳态温度场

Fig. 8 Simulated steady-state temperature field during continuous casting

表1 铸型实测温度与模拟温度对比

Table 1 Comparison of simulated temperature and measured temperature of mold

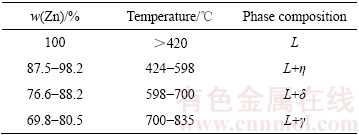

根据铜锌二元相图[22]可得不同锌含量的铜锌合金在不同温度下的组成相,如表2所列。从表2可以看出,当管坯表面与锌含量大于90%的富锌物质接触时(见图7(d)),由于扩散反应,管坯表面锌含量增加,熔点下降。如果管坯温度大于425 ℃,接触点处可能形成L+ε相,使管坯表面出现液相。当管坯温度升高,富锌物质与高温管坯接触还可能形成L+δ或L+γ相,同样会造成管坯表面出现液相或固液两相共存。

根据上述分析可以进一步解释管坯表面点状缺陷的形成原因,点状缺陷形成过程示意图如图9所示。

表2 不同锌含量铜锌合金在不同温度下的组成相

Table 2 Phase composition of Cu-Zn alloy with different zinc contents at different temperatures

合金凝固收缩使铸型与管坯之间产生气隙,同时,在凝固界面附近管坯发生高温脱锌,挥发的锌元素在铸型内表面遇冷凝结为锌液滴(见图9(a))。随着连铸过程的进行,铸型内表面附着的锌液滴数量增加,并发生长大,当锌液滴尺寸达到气隙宽度时将与管坯外表面发生接触(见图9(b))。在管坯的高温作用下,锌液滴中的锌元素向合金基体进行快速扩散,使基体的锌含量上升,熔点下降,在管坯外表面局部区域产生熔蚀作用而形成点状富锌区(见图9(c))。管坯沿连铸方向移动时,铸型内表面上的锌液滴不断与已形成的点状富锌区发生合并,使该富锌区体积增大。同时,该富锌区中的锌元素不断向管坯基体中进行扩散,使富锌区的深度增加。当接触点处的温度低于富锌区合金的固相线温度时,固液相共存的富锌区完全凝固而形成点状缺陷。

在点状缺陷形成过程中,当锌液滴不断附着到管坯外表面时,由于摩擦作用,管坯表面的点状富锌区沿着与连铸相反的方向倾斜,进而形成具有倾斜特征的点状缺陷,如图2(d)和图7(d)所示。点状缺陷在与连铸相反方向一侧嵌入较深(见图6和9(d)),是由于该侧在高温下作用时间较长,锌元素扩散距离较大。当铸型内表面上的锌液滴逐渐被管坯带走,后续凝固的管坯外表面不易与铸型内表面锌液滴发生接触,该阶段管坯表面不会形成点状缺陷。随着连铸进行,高温管坯挥发的锌元素持续在铸型内表面附着,使铸型内表面的锌液滴的数量和尺寸增加(见图9(d))。当管坯外表面再次与锌液滴接触时,点状缺陷重新形成,导致管坯表面点状缺陷的出现呈周期性现象(见图2(a))。

水平连铸过程中,由于重力作用,管坯下部与铸型紧密接触,管坯上部与铸型之间产生较大的气隙,导致管坯上部传热效率较低,管坯温度较高[23],易挥发出更多的锌元素,使铸型上部附着更多的锌液滴,且由于管坯上部高温扩散反应更显著,致使管坯上部产生的点状缺陷数量明显多于管坯下部(见图2(a))。

另一方面,管坯受到冷型的冷却作用,其温度低于内部的芯棒,管坯内表面挥发出来的锌元素主要由低温的管坯连续带出而不会在高温的芯棒表面附着,因而芯棒表面不会形成锌液滴而向管坯内表面转移的现象,即管坯内表面不产生点状缺陷,可以获得光滑无缺陷的内表面,如图2(c)所示。

由点状缺陷形成机理可知,铸型冷型段内表面附着的锌液滴长大至足够大的尺寸时才可能与管坯外表面接触,而锌液滴的尺寸和数量主要受管坯锌元素挥发速率的影响,管坯温度越高,锌元素挥发速率越大,形成的锌液滴数量越多。在冷型段内管坯与锌液滴接触时的温度越高,锌元素向合金基体扩散的速率越大,产生的点状缺陷尺寸越大。因此,冷型段内管坯的温度是影响点状缺陷形成的重要因素。降低冷型段内管坯的温度以减少锌元素挥发,避免大量锌液滴聚集、长大,并抑制锌元素向管坯基体快速扩散,是消除管坯表面点状缺陷的有效措施。

图9 管坯表面点状缺陷形成过程示意图

Fig. 9 Schematic diagram of formation process of spot defect on tube outer surface

2.4 消除点状缺陷的措施

根据前述分析,可以认为通过增强冷型段的一次冷却能力和二次冷却水的冷却能力,降低冷型段内管坯温度,是减少点状缺陷的重要措施。但由于管坯凝固收缩形成气隙后,冷型对管坯的一次冷却作用存在界限。因此,本文作者主要考虑采用增强二次冷却水的冷却作用的方法控制冷型段内管坯温度。

由图8所示的管坯连铸温度场可知,在结晶器的长度160 mm的条件下,管坯进入冷型段时的温度约为860 ℃,管坯锌元素挥发速率较大,使铸型内表面聚集较多的锌液滴,且较高的温度使锌元素向管坯基体扩散反应加快,进而形成数量较多和尺寸较大的点状缺陷。图10所示为结晶长度变化示意图。保持其他制备条件不变,将结晶器长度缩短至100 mm时,管坯连铸温度场如图11所示。从图11可以看出,管坯进入冷型段时的温度降低至670 ℃,且管坯高温区显著缩短,管坯凝固固液界面与420 ℃等温线之间的距离由长结晶器时的100 mm(见图8(b))缩短至58 mm (见图11)。结果表明,缩短结晶器长度使二次冷却水与管坯凝固固液界面之间的距离缩短,通过强制喷水冷却可使冷型段内已凝固管坯的温度快速降低,有利于降低管坯锌元素挥发速率,进而减少铸型内表面富集锌液滴的数量,同时可以抑制转移至管坯表面的锌液滴向管坯基体快速扩散,以减少或消除管坯表面点状缺陷。

图10 结晶器长度变化示意图

Fig. 10 Schematic diagram of crystallizer length

图11 短结晶器连铸的稳态温度场

Fig. 11 Steady-state temperature field of mold and tube under short crystallizer condition

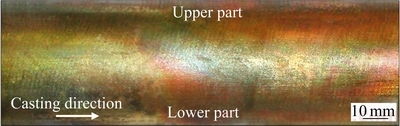

为此,本文作者采用长度为100 mm的结晶器进行管坯连铸,保持其它连铸条件不变(组合铸型过渡区长度30 mm,熔体温度980 ℃,热型段加热温度980 ℃,冷型段冷却水流量400 L/h,二次冷却水流量400 L/h,连铸速度90 mm/min),所制备的管坯的外表面宏观形貌如图12所示。由图12中可见,管坯外表面光滑,未观察到明显的点状缺陷,表明通过控制使冷型段内管坯温度快速降低,可以有效消除管坯外表面的点状缺陷,同时也证明了本研究提出的连铸黄铜管坯表面点状缺陷形成机理的合理性。上述点状缺陷的形成机理和控制方法可应用于指导其他牌号黄铜合金连铸坯的表面质量控制,对于提高水平连铸黄铜合金表面质量具有重要意义。

图12 短结晶器连铸管坯的外表面宏观形貌

Fig. 12 Macroscopic morphology of outer surface of tube produced by HCCM horizontal continuous casting with short crystallizer

3 结论

1) HCCM水平连铸H62黄铜管坯外表面出现的点状缺陷主要为富锌低熔点物质,锌含量达80%。点状缺陷的出现沿连铸方向呈现出周期性的特点,管坯上部点状缺陷数量明显多于管坯下部。

2) 连铸过程中,凝固界面附近挥发的锌在铸型内表面形成的锌液滴与高温管坯外表面接触后发生熔蚀作用,使管坯外表面局部区域形成点状固液共存区,凝固后形成了管坯表面点状缺陷。

3) 通过缩短结晶器长度,增强二次冷却水的冷却作用,使冷型段内管坯温度快速降低,以减少管坯锌元素挥发及铸型内表面锌液滴数量,同时抑制转移至管坯表面的锌液滴向管坯基体的快速扩散,可有效消除点状缺陷。

REFERENCES

[1] TROSTMANN A, MORIN O. Optimized copper alloy tubing configuration for a multi-stage flash distiller[J]. Desalination and Water Treatment, 2010, 22(1/3): 299-310.

[2] KAZDAL Z H. Failure analysis of cooling water pipes used in the condensation system of a gas turbine[J]. Materials Characterization, 2008, 59(2): 167-172.

[3] 雷玉霞, 林高用, 周玉雄, 王 宏, 张胜华.两种生产工艺对 H65 黄铜管组织与性能的影响[J]. 材料科学与工程学报, 2012, 30(3): 413-418.

LEI Yu-xia, LIN Gao-yong, ZHOU Yu-xiong, WANG Hong, ZHANG Sheng-hua. Influences of two kinds of manufactureing processes on structures and properties of H65 brass tube[J]. Journal of Materials Science & Engineering, 2012, 30(3): 413-418.

[4] 谢建新, 刘新华, 刘雪峰, 梅 俊. 一种黄铜管材的短流程高效生产方法. 中国专利: ZL201110210692.9[P]. 2012-08-21.

XIE Jian-xin, LIU Xin-hua, LIU Xue-feng, MEI Jun. Compact process for high efficiency fabrication of brass tube. Patent No. ZL201110210692.9[P]. 2012-08-21.

[5] MEI Jun, LIU Xin-hua, XIE Jian-xin. Microstructure and mechanical properties of BFe10 cupronickel alloy tubes fabricated by a horizontal continuous casting with heating- cooling combined mold technology[J]. International Journal of Minerals, Metallurgy, and Materials, 2012, 19(4): 339-347.

[6] MO Yong-da, JIANG Yan-bin, LIU Xin-hua, XIE Jian-xin. Effects of microstructure on the deformation behavior, mechanical properties and residual stress of cold-rolled HAl77-2 aluminum brass tube[J]. Journal of Materials Processing Technology, 2016, 235: 75-84.

[7] MEI Jun, LIU Xin-hua, JIANG Yan-bin, XIE Jian-xin. Liquid- solid interface control of BFe10-1-1 cupronickel alloy tubes during HCCM horizontal continuous casting and its effect on the microstructure and properties[J]. International Journal of Minerals, Metallurgy, and Materials, 2013, 20(8): 748-758.

[8] 梅 俊, 刘新华, 姜雁斌, 谢建新. 轴向取向组织BFe10-1-1管材冷轧加工过程中组织、织构与力学性能的变化[J]. 中国有色金属学报, 2012, 22(9): 2529-2538.

MEI Jun, LIU Xin-hua, JIANG Yan-bin, XIE Jian-xin. Evolution of microstructure, texture and mechanical properties of BFe10-1-1 tube with microstructure along axial orientation during cold-rolling[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2529-2538.

[9] GIACOBBE F W. Thermodynamic dezincification behavior of brass during annealing[J]. Journal of Alloys and Compounds, 1993, 202(1): 243-250.

[10] 陈 琴, 陈 平, 贺永东, 孙武林.Φ165 mm HA177-2铝黄铜铸锭生产试验[J]. 上海有色金属, 2009, 30(1): 27-30.

CHEN Qin, CHEN Ping, HE Yong-dong, SUN Wu-lin. Experimental production of Φ165 mm cast ingot of HAl 77-2 brass[J]. Shanghai Nonferrous Metals, 2009, 30(1): 27-30.

[11] 韩淑敏, 刘 刚. 水平连铸-冷轧法生产H65黄铜带工艺研究[J]. 有色金属加工, 2007, 36(3): 21-26.

HAN Shu-min, LIU Gang. Study on horizontal continuous casting-cold rolling process of H65 strip[J]. Nonferrous Metals Processing, 2007, 36(3): 21-26.

[12] 刘 刚, 韩淑敏, 白常厚. H65黄铜水平连铸工艺研究[J]. 金属世界, 2007(2): 10-13.

LIU Gang, HAN Shu-min, BAI Chang-hou. The study of process to manufacture H65 brass strip by horizontal casting[J]. Metal World, 2007(2): 10-13.

[13] 梅 俊, 刘新华, 谢建新. BFe10白铜管材热冷组合铸型水平连铸凝固温度场模拟[J]. 中国有色金属学报, 2012, 22(5): 1430-1439.

MEI Jun, LIU Xin-hua, XIE Jian-xin. Solidification temperature field simulation of BFe10 cupronickel tube during heating-cooling combined mold continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1430-1439.

[14] KATO H, CAHOON J R. Inverse segregation in directionally solidified Al-Cu-Ti alloys with equiaxed grains[J]. Metallurgical & Materials Transactions A, 1985, 16(16): 579-587.

[15] CHANG S, STEFANESCU D M. A model for inverse segregation: The case of directionally solidified Al-Cu alloys[J]. Acta Materialia, 1996, 44(6): 2227-2235.

[16] LUO Ji-hui, LIU Xue-feng, SHI Lai-xin, CHENG Chang-fei. Experimental and numerical simulation of surface segregation in two-phase zone continuous casting Cu-Sn alloy[J]. Materials Science Forum, 2016, 850: 610-617.

[17] THEVIK H J, MO A, RUSTEN T. A mathematical model for surface segregation in aluminum direct chill casting[J]. Metallurgical & Materials Transactions B, 1999, 30(1): 135-142.

[18] HAUG E, MO A R, THEVIK H J. Macrosegregation near a cast surface caused by exudation and solidification shrinkage[J]. International Journal of Heat and Mass Transfer, 1995, 38(9): 1553-1563.

[19] MINAKAWA S, SAMARASEKERA I V, WEINBERG F. Inverse segregation[J]. Metallurgical Transactions B, 1985, 16(3): 595-604.

[20] FLEMINGS M C. Solidification processing[J]. Metallurgical & Materials Transactions A, 1974, 5(10): 2121-2134.

[21] KAEMPFFER F, WEINBERG F. Macrosegregation in a copper alloy directionally cast with exudation of liquid[J]. Metallurgical & Materials Transactions B, 1971, 2(9): 2477-2483.

[22] BAKER H. ASM handbook: Alloy phase diagrams (Vol.3)[M]. Ohio: ASM International, Materials Park, 1992.

[23] MAHMOUDI J. Horizontal continuous casting of copper-based alloys[J]. International Journal of Cast Metals Research, 2013, 18(6): 355-369.

Formation mechanism and control of spot defect on surface of brass tube fabricated by HCCM horizontal continuous casting

MO Yong-da1, JIANG Yan-bin1, 2, LIU Xin-hua1, 2, XIE Jian-xin1, 2

(1. Key Laboratory for Advanced Materials Processing, Ministry of Education, University of Science and Technology Beijing, Beijing 100083, China;

2. Beijing Laboratory of Metallic Materials and Processing for Modern Transportation, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The characteristic and formation mechanism of spot defect on the outer surface of H62 (UNS C27400) brass tube fabricated by HCCM horizontal continuous casting were studied, and an effective method for eliminating the defect was proposed. The results show that the spot defect on the tube outer surface is main zinc-rich low-melting-point substance, whose zinc content (mass fraction) reaches 80%. The spot defects are periodically formed along the casting direction and the number of the defects on the upper part of the tube is much more than that on the lower part. During casting, the volatilized zinc attaches to the graphite mold inner surface and forms zinc droplets which causes an erosion effect on the tube surface when the zinc droplets contact with the tube, leading to the formation of the zinc-rich spot defect on the tube surface. A method of rapidly lowering the temperature of the solidified tube in the cold mold, which can reduce the zinc volatilization and the number of the zinc droplets on the inner surface of the mold, is proposed to eliminate the spot defects effectively.

Key words: HCCM horizontal continuous casting; brass tube; zinc-rich substance; surface defect; formation mechanism

Foundation item: Projects(2016YFB0301301, 2016YFB0301404) supported by the National Key Research and Development Program of China

Received date: 2016-08-15; Accepted date: 2016-12-26

Corresponding author: XIE Jian-xin; Tel: +86-10 62332254; E mail: jxxie@mater.ustb.edu.cn

(编辑 李艳红)

基金项目:国家重点研发计划资助项目(2016YFB0301301,2016YFB0301404)

收稿日期:2016-08-15;修订日期:2016-12-26

通信作者:谢建新,教授,博士;电话:010 62332254;E mail: jxxie@mater.ustb.edu.cn