DOI:10.19476/j.ysxb.1004.0609.2017.12.09

不同淬火介质下7055铝合金厚板淬火内应力测试

李亚楠1,张永安1,李锡武1,李志辉1,王国军2,闫宏伟1,金龙兵1,熊柏青1

(1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088;

2. 东北轻合金有限责任公司,哈尔滨 150060)

摘 要:7xxx系铝合金在淬火后会产生较大的残余应力,且淬火介质对淬火残余应力的水平与分布影响显著。通过裂纹柔度法研究不同淬火介质种类、温度和浓度对淬火残余应力的影响规律。结果表明:淬火残余应力符合典型的“外压内拉”分布,淬火残余应力水平随水温升高先缓慢降低后急速降低,随PAG浓度升高先迅速降低后缓慢降低。各淬火介质下应力水平由高到低的顺序依次为5%NaCl+5%KNO3溶液(质量分数)、20 ℃水、5%PAG溶液(体积分数)。在80 ℃水和15%PAG溶液(体积分数)淬火后,残余应力水平降低比例最大均达到60%以上,抑制残余应力效果明显。

关键词:7055铝合金;淬火残余应力;裂纹柔度法;淬火介质

文章编号:1004-0609(2017)-12-2467-06 中图分类号:TG146 文献标志码:A

7055超高强变形铝合金具有高强度、高韧性以及优异的抗应力腐蚀开裂性能和抗疲劳性能,目前已被广泛应用于航空领域[1-2]。在7055铝合金厚板的制备过程中需要通过淬火快速冷却获得过饱和固溶体,从而在随后的时效过程中析出强化提高力学性能[3]。然而,淬火过程中会产生较高的温度梯度从而导致较大淬火残余应力的形成。淬火残余应力的存在使得在后续的机加工过程中发生变形以及降低疲劳和应力腐蚀开裂性能等问题[4]。

淬火参数会影响淬火残余应力的分布与水平,其中一个重要影响因素是淬火介质,包括淬火介质种类、淬火介质温度和淬火介质浓度等。常用的淬火介质有水、PAG溶液、淬火油、盐溶液等,ZHANG等[5]对不同淬火介质种类下的冷却能力和表面残余应力进行研究,发现冷却能力大小依次为盐溶液、水、淬火油,油淬后的残余应力水平最低。最常用的淬火介质是室温水,可以通过调节水温获得不同的冷却速率,从而产生不同水平的淬火残余应力[6]。LIN等[7]对不同水温淬火表面残余应力进行了钻孔法测试,结果表明水温从40 ℃升至80 ℃时7075铝合金厚板残余应力水平降低了30%。PAG由于在水中具有逆溶性,可以有效地抑制高温段的冷却速率,达到降低残余应力水平的目的。申坤等[8]采用钻孔法和X射线衍射法对2A12铝合金表面残余应力进行测试,结果显示PAG溶液淬火后残余应力明显降低。

常用的内应力测试方法有剥层法[9]、裂纹柔度法[10]、应变云图法[11]等。裂纹柔度法由VAIDYANATHAN等[12]在1971年首次提出,之后PRIME等[13]将裂纹柔度法应用于铝合金厚板内部残余应力测试。相比于其他方法,裂纹柔度法具有较高的敏感性和精确度,并且能够获得全厚度上的应力分布[14]。目前,裂纹柔度法多用于预拉伸或预压缩残余应力的测试,而淬火介质对淬火残余应力的影响研究多集中于钻孔法和X射线衍射法等表面残余应力测 试[7]。因此,本文作者采用裂纹柔度法测试不同淬火介质、不同水温以及不同浓度PAG溶液的淬火残余应力,分析淬火介质对残余应力水平与分布的影响规律,为淬火介质的选择提供实验依据。

1 实验

1.1 实验样品

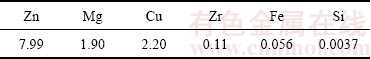

实验材料选择东北轻合金有限责任公司生产的7055铝合金热轧态厚板,合金成分如表1所列。从规格为1000 mm×2400 mm×27 mm(长×宽×厚)的板材截取尺寸为162 mm×81 mm×27 mm的样品8块。其中4块试样用于制备水温为20 ℃、40 ℃、60 ℃和80 ℃的固溶态试样,3块试样用于制备5%、10%和15%PAG(体积分数)的固溶态试样,1块试样用于制备5%NaCl+5%KNO3溶液(质量分数)的固溶态试样,PAG溶液和盐溶液的温度均为20 ℃。

表1 7055铝合金热轧态厚板合金成分(质量分数,%)

Table 1 Chemical composition of 7055 aluminum alloy hot rolling plate (mass fraction, %)

1.2 实验过程

固溶淬火实验中试样从固溶炉取出后快速转移至淬火槽,整个淬火过程中稳定站立于钢铁支架上,底端接触疏松的铁丝网。淬火过程无任何搅拌,且冷却水量充足,保证淬火过程的一致性。

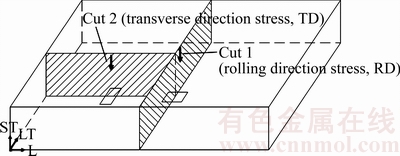

试样裂纹的引入一般通过线切割或者锯切实现,其中线切割具有更高的精度和较小的附加应力[15]。本文作者采用线切割引入裂纹,电极丝选用0.2 mm黄铜丝。应变片型号为BSF120-3AA,电阻栅长度为3 mm。图1所示为应变片粘贴位置及线切割位置示意图,切割1的应变可用于计算轧向(L向)应力分布,切割2的应变可用于计算横向(LT向)应力分布。切割时对试样一端夹持,而另一端无任何约束。在应变片上覆盖一层凡士林以防止冷却液对应变采集产生影响。裂纹的切割从1 mm逐步增加至27 mm,每切割1 mm待应变示数稳定后记录数据。

图1 测试过程与应变片位置

Fig. 1 Test procedure and strain gage locations

2 数据分析

应力分布一般可以通过级数展开方法求解。由于板材的厚度相比于长度与宽度较小,因此板材内沿长度与宽度方向的应力分布可近似为平面应力分布,而应力只随厚度变化而变化。假设应力随厚度z变化的函数关系为 ,则其可表示为一个级数展开式:

,则其可表示为一个级数展开式:

(1)

(1)

式中:Ai为需要求解的待定系数; 为插值函数。由于2阶以上的勒让德多项式能够保证力和力矩的自平衡,因此,插值函数选取勒让德多项式。n为插值函数的阶数。

为插值函数。由于2阶以上的勒让德多项式能够保证力和力矩的自平衡,因此,插值函数选取勒让德多项式。n为插值函数的阶数。

为了确定上式中待定系数Ai,需要获得裂纹深度aj与应变的对应关系Cij,Cij被称为柔度函数。采用叠加原理,应变可通过级数展开表示为

(2)

(2)

最终,采用最小二乘法对式(2)中的应变与测试应变进行拟合。结合式(1)可得出Ai的表达式为

(3)

(3)

柔度函数矩阵Cij可通过断裂力学解析法、体力法以及有限元或其他数值方法求解获得。采用ANSYS有限元分析软件求解柔度函数。考虑到结构对称性,取裂纹一侧的一半试样建模,单元类型选择2D结构单元PLANE182,网格尺寸为1 mm。材料的弹性模量设为72 GPa,泊松比设为0.33。通过依次去除裂纹处的对称边界约束条件模拟实验线切割过程,之后通过节点位移计算图1中应变片处的应变值。最终,根据式(3)由有限元计算的柔度函数Cij和测试应变 求解待定系数Ai。选取8阶多项式进行数据拟合,即2阶至9阶勒让德多项式。

求解待定系数Ai。选取8阶多项式进行数据拟合,即2阶至9阶勒让德多项式。

3 结果与讨论

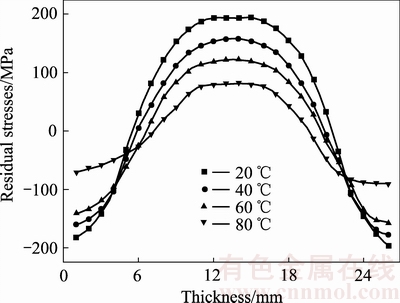

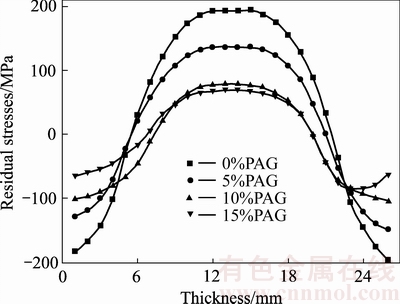

图2和图3所示为不同水温下的淬火残余应力分布图,可以看出测试结果符合典型的淬火残余应力分布规律,即表面为压应力而心部为拉应力。水温20 ℃时轧向最大压应力为-195.8 MPa,最大拉应力为195.4 MPa;横向最大压应力为-200.5 MPa,最大拉应力为154.0 MPa。最大压应力位于试样表层而最大拉应力位于试样厚度中心。

图2 不同水温下淬火残余应力分布(轧向)

Fig. 2 Quenching residual stress distributions with various water temperatures (rolling direction)

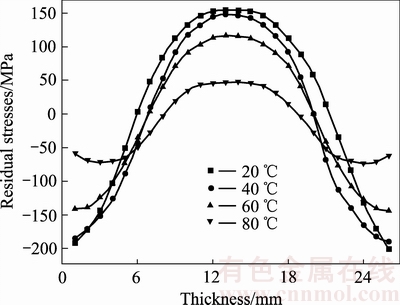

图3 不同水温下淬火残余应力分布(横向)

Fig. 3 Quenching residual stress distributions with various water temperatures (transverse direction)

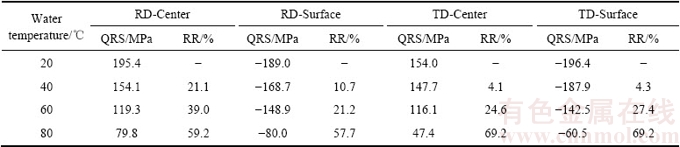

随着水温升高淬火残余应力水平逐渐降低,但应力分布趋势基本相同。由于两表面残余应力水平略有差异,因此以两者平均值作为表面残余应力水平。表2列出了各水温下的表面残余应力与心部残余应力水平及相比于20 ℃的降低比例R(Reduction ratios, 式(4))。可以看出,随着水温的升高在60 ℃之前降低比

例缓慢增加,在60 ℃之后降低比例迅速增加。在 80 ℃水温时,降低比例最大达到69.2%,应力消减效果明显。

(4)

(4)

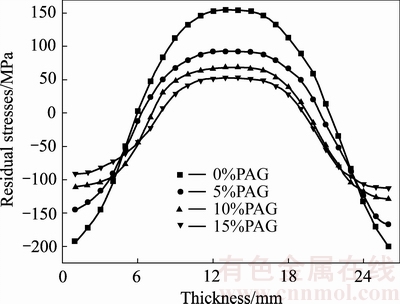

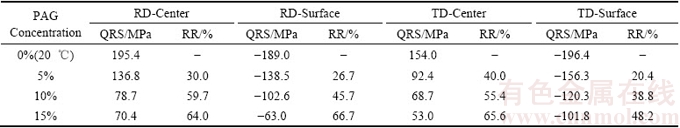

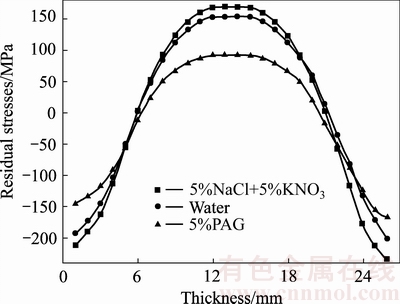

图4和图5所示为不同PAG浓度下的淬火残余应力分布图,随着PAG浓度的升高淬火残余应力水平逐渐降低,其中0%PAG溶液即20 ℃水。表3列出了不同PAG浓度下的应力水平及降低比例,可以看出降低比例随着PAG浓度的增大呈先迅速增大后缓慢增大的趋势,当PAG浓度为15%时,降低比例最大为66.7%。

在淬火过程中,试样周围的淬火液温度升到PAG溶液的浊点后,PAG聚合物就会从溶液中脱溶形成细小的液珠。由于PAG聚合物润湿性较好,当液珠接触到试样的高温表面就会粘附上去形成PAG膜,一定程度上降低表面冷却速率,达到抑制淬火残余应力的目的。通过控制PAG浓度可以控制脱溶PAG膜的覆盖率和厚度等,从而获得不同程度的冷却速率抑制效果。抑制效果随PAG浓度增大的响应程度先明显后逐渐不明显。

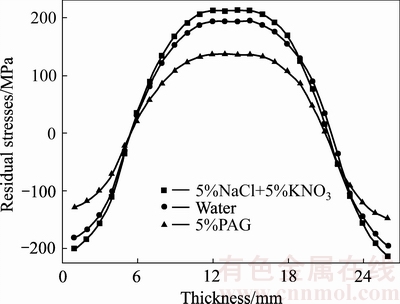

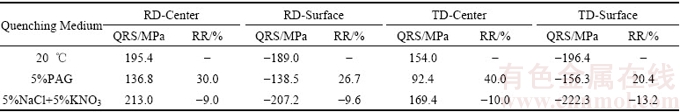

图6和图7所示为不同淬火介质种类下淬火残余应力水平图,由图可知各淬火介质下应力水平大小依次为:5%NaCl+5%KNO3溶液、20 ℃水、5%PAG溶液,相应的冷却能力顺序也是如此。表4所列为不同淬火介质下的应力水平及降低比例,相比于20 ℃水,5%NaCl+5%KNO3溶液下的淬火残余应力上升了10.0%左右。

表2 不同温度下应力水平及降低比例(负号代表压应力)

Table 2 Quenching residual stresses (QRS) and reduction ratios (RR) with various water temperatures (minus sign means compressive stress)

图4 不同PAG浓度下淬火残余应力分布(轧向)

Fig. 4 Quenching residual stress distributions with various PAG concentrations (rolling direction)

图5 不同PAG浓度下淬火残余应力分布(横向)

Fig. 5 Quenching residual stress distributions with various PAG concentrations (transverse direction)

表3 不同PAG浓度下应力水平及降低比例(负号代表压应力)

Table 3 Quenching residual stresses (QRS) and reduction ratios (RR) with various PAG concentrations (minus sign means compressive stress)

图6 不同淬火介质下淬火残余应力分布(轧向)

Fig. 6 Quenching residual stress distributions with various quenching mediums (rolling direction)

图7 不同淬火介质下淬火残余应力分布(横向)

Fig. 7 Quenching residual stress distributions with various quenching mediums (transverse direction)

表4 不同淬火介质下应力水平及降低比例(负号代表压应力)

Table 4 Quenching residual stresses (QRS) and reduction ratios (RR) with various quenching mediums (minus sign means compressive stress)

一般来说淬火过程可以分为3个阶段:蒸汽膜阶段、核态沸腾阶段和对流阶段[16]。盐溶液与水作为淬火介质的主要区别体现为:高温试样进入水中会迅速气化周围介质,在表面形成一层蒸汽膜,降低试样冷却速率,而盐水介质在形成蒸汽膜的同时还会析出盐晶体导致蒸汽膜不断地破裂,形成气泡,提高冷却能力。当试样冷却至核态沸腾区,表面形成气泡时同样会析出盐晶体促进气泡形核,提高冷却能力。因此盐水的冷却能力高于室温水的,从而导致更高的淬火残余应力水平。

4 结论

1) 随着水温升高淬火残余应力水平逐渐降低,但应力分布趋势相同。在60 ℃之前降低比例缓慢增加,在60 ℃之后降低比例迅速增加。在80 ℃水温时,降低比例最大达到69.2%。

2) 随着PAG浓度升高淬火残余应力水平逐渐降低,降低比例呈先迅速增大后缓慢增大的趋势。当PAG浓度为15%时,降低比例最大为66.7%。

3) 各淬火介质下应力水平由大到小依次为:5%NaCl+5%KNO3溶液、20 ℃水、5%PAG溶液。相比于20 ℃水,10%NaCl+KNO3溶液下的淬火残余应力上升了约10.0%。

REFERENCES

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminum alloys[J]. Materials and Design, 2014, 56(4): 862-871.

[2] 冯 迪, 张新明, 邓运来, 刘胜胆, 吴泽政, 郭奕文. 预时效温度及回归加热速率对 7055 铝合金组织及性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1141-1150.

FENG Di, ZHANG Xin ming, DENG Yun lai, LIU Sheng dan, WU Ze zheng, GUO Yi wen. Effect of pre ageing temperature and retrogression heating rate on microstructure and properties of 7055 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1141-1150.

[3] ZHENG Y L, LI C B, LIU S D, DENG Y L, ZHANG X M. Effect of homogenization time on quench sensitivity of 7085 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2275-2281.

[4] ROBINSON J S, TANNER D A, TRUMAN C E. 50th anniversary article: The origin and management of residual stress in heat-treatable aluminium alloys[J]. Strain, 2014, 50(3): 185-207.

[5] ZHANG Z H, WANG W P, FU H D, XIE J X. Effect of quench cooling rate on residual stress, microstructure and mechanical property of an Fe–6.5Si alloy[J]. Materials Science and Engineering A, 2011, 530(11): 519-524.

[6] KOPUN R, SKERGET L, HRIBERSEK M, ZHANG D S, STAUDER B, GREIF D. Numerical simulation of immersion quenching process for cast aluminum part at different pool temperatures[J]. Applied Thermal Engineering, 2014, 65(1/2): 74-84.

[7] LIN G Y, ZHANG H, ZHU W, PENG D S, LIANG X, ZHOU H Z. Residual stress in quenched 7075 aluminum alloy thick plates[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(3): 641-644.

[8] 申 坤, 许 东. PAG淬火介质冷却速率对2A12合金性能的影响[J]. 热处理技术与装备, 2012, 33(5): 43-47.

SHEN Kun, XU Dong. Influences of cooling rate of PAG quenching medium on properties of 2A12 alloy[J]. Heat Treatment Technology and Equipment, 2012, 33(5): 43-47.

[9] 廖 凯, 吴运新, 龚 海, 张舒原. 积分法在铝合金厚板残余应力计算中的应用[J]. 中国有色金属学报, 2009, 19(6): 1006-1011.

LIAO Kai, WU Yun-xin, GONG Hai, ZHANG Shu-yuan. Application of integral method on residual stress calculation along depth in aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1006-1011.

[10] 唐志涛, 刘战强, 艾 兴, 万 熠. 基于裂纹柔度法的铝合金预拉伸板内部残余应力测试[J]. 中国有色金属学报, 2007, 17(9): 1404-1409.

TANG Zhi-tao, LIU Zhan-qiang, AI Xing, WAN Yi. Measuring residual stresses depth profile in pre-stretched aluminum alloy plate using crack compliance method[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(9): 1404-1409.

[11] ZHANG Z, YANG Y F, LI L, CHEN B, TIAN H. Assessment of residual stress of 7050-T7452 aluminum alloy forging using the contour method[J]. Materials Science & Engineering A, 2015, 644: 61-68.

[12] VAIDYANATHAN S, FINNIE I. Determination of residual stresses from stress intensity factor measurements[J]. Journal of Basic Engineering, 1971, 93: 242-246.

[13] PRIME M B, STEINZIG M L. Beyond the streetlight effect: a united future for relaxation and diffraction methods for residual stress measurement[J]. Advanced Materials Research, 2014, 996(996): 234-242.

[14] WANG Q C, KE Y L, XING H Y, WENG Z Y, YANG F E. Evaluation of residual stress relief of aluminum alloy 7050 by using crack compliance method[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(5): 1190-1193.

[15] 宋 寒, 杨吟飞, 陈 波, 郑晓伟. 7055-T7751铝合金预拉伸板内部残余应力分布评估[J]. 机械制造与自动化, 2016, 45(1): 18-21.

SONG Han, YANG Yin-fei, CHEN Bo, ZHENG Xiao-wei. Evaluation of residual stress in depth profile of 7055-T7751 pre-stretched aluminum alloy plate[J]. Machine Building & Automation, 2016, 45(1): 18-21.

[16] XIAO B W, WANG Q G, JADHAV P, LI K Y. An experimental study of heat transfer in aluminum castings during water quenching[J]. Journal of Materials Processing Technology, 2010, 210(14): 2023-2028.

Quenching residual stress of 7055 aluminum alloy thick plate with various quenching mediums

LI Ya-nan1, ZHANG Yong-an1, LI Xi-wu1, LI Zhi-hui1, WANG Guo-jun2, YAN Hong-wei1, JIN Long-bin1, XIONG Bai-qing1

(1. State Key Laboratory of Nonferrous Metals and Processes, General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Northeast Light Alloy Co., Ltd., Harbin 150060, China)

Abstract: Large residual stress produces after quenching in 7xxx series aluminum alloy and quenching medium influences the quenching residual stress obviously. In this work, the effects of quenching medium type, temperature, concentration on quenching residual stress were studied by using the crack compliance method. The results show that the quenching residual stress with typical distribution decreases slowly at first and then decreases rapidly with water temperature rising, while decreases rapidly at first and then decreases slowly with the increasing of PAG concentration. The stress level of each quenching medium from high to low is as follows: 5%NaCl+5%KNO3 solution (mass fraction), 20 ℃ water, 5%PAG solution (volume fraction). After quenching at 80 ℃ water or 15%PAG solution (volume fraction), the reduction ratio of residual stress level is above 60%, thus the reduction of quenching residual stress is obvious.

Key words: 7055 aluminum alloy; quenching residual stress; crack compliance method; quenching medium

Foundation item: Project(2012CB619504) supported by the National Basic Research Development Program of China; Project(51274046) supported by the National Natural Science Foundation of China

Received date: 2016-08-15; Accepted date: 2017-03-08

Corresponding author: ZHANG Yong-an; Tel: +86-10-82241172; E-mail: zhangyagrinm@126.com

(编辑 王 超)

基金项目:国家重点基础研究发展计划资助项目(2012CB619504);国家自然科学基金资助项目(51274046)

收稿日期:2016-08-15;修订日期:2017-03-08

通信作者:张永安,教授,博士;电话:010-82241172;E-mail: zhangyagrinm@126.com