文章编号:1004-0609(2013)07-1879-06

Cu-0.36Cr-0.03Zr合金的时效动力学

丁宗业1,贾淑果1, 2,邓 猛1,宋克兴1, 2,刘 平1

(1. 河南科技大学 材料科学与工程学院,洛阳 471023;

2. 河南科技大学 河南省有色金属材料科学与加工技术重点实验室,洛阳 471023)

摘 要:对Cu-0.36Cr-0.03Zr合金进行时效处理,研究时效温度和时间对合金性能和组织的影响,借助高分辨透射电镜观察时效析出相的组织形态,并研究不同温度下该合金的时效析出动力学。结果表明:经过时效处理后,析出相弥散分布,提高了合金的显微硬度和导电率,经500 ℃时效2 h后,合金硬度和导电率分别达到153.9 HV和84.54 %IACS;通过微观分析确定在550 ℃时效2 h后合金中存在Cr和Cu4Zr两种析出相;通过对导电率与析出相体积分数关系的分析,确定合金在不同温度下时效的相变动力学Avrami经验方程和导电率方程,并绘制等温转变动力学曲线。

关键词:Cu-0.36Cr-0.03Zr合金;时效处理;组织;相变动力学方程

中图分类号:TG146.1 文献标志码:A

Aging kinetics of Cu-0.36Cr-0.03Zr alloy

DING Zong-ye1, JIA Shu-guo1, 2, DENG Meng1, SONG Ke-xing1, 2, LIU Ping1

(1.School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Henan Key Laboratory of Advanced Non-ferrous Metals, Henan University of Science and Technology, Luoyang 471023, China)

Abstract: The effects of aging temperature and aging time on the microstructure and properties of Cu-0.36Cr-0.03Zr alloy aged at different temperatures were studied. The morphology of precipitation was observed by means of high resolution transmission electron microscope and the aging kinetics of the alloy was studied. The results show that the precipitates are dispersed and the microhardness and electrical conductivity are enhanced to 153.9 HV and 84.54 %IACS, respectively, due to aging treatment at 500 ℃ for 2 h. There are Cr and Cu4Zr precipitates existing in the alloy aged at 550 ℃ for 2 h through the micro-analysis. The Avrami equation of phase transformation kinetics and the electrical conductivity equation are obtained, while the transformation kinetics curve is drawn through the analysis of the relationship between electrical conductivity and volume fraction of precipitates.

Key words: Cu-0.36Cr-0.03Zr alloy; aging treatment; microstructure; phase transformation kinetics equation

Cu-Cr-Zr合金具有较高的强度、优良的导电和导热性以及较高的再结晶温度,广泛应用于集成电路引线框架、电力机车架空导线及触头材料等领域[1-4]。由于Cr与Zr在析出过程中的交互作用,Cu-Cr-Zr合金较Cu-Cr和Cu-Zr合金更具有潜力,目前,有关该合金时效组织、性能及强化机理的研究较多[5-8],但关于时效动力学的研究报道较少。Cu-Cr-Zr合金的时效过程是从过饱和固溶体中析出溶质原子并形成新相的相变过程,析出相的数量、形状及分布对合金性能影响很大,因此,开展Cu-Cr-Zr合金的时效析出动力学的研究对实际生产具有一定的参考意义[9-13]。

本文作者对固溶态Cu-0.36Cr-0.03Zr合金在400~500 ℃时效0~8 h后的组织与性能进行研究,通过时效过程中合金导电率的变化,依据导电率与析出相转变量的关系,确定该合金在不同时效温度下的Avrami相变动力学方程和导电率方程,并绘制等温转变动力学曲线。

1 实验

试验材料以纯铜、纯铬和Cu-50Zr中间合金为原料,在真空感应炉中进行熔炼,浇铸并锻造成型,合金最终成分(质量分数,%)为Cu-0.36Cr-0.03Zr。合金的固溶(950 ℃,1.5 h)、时效处理在RJX-3-12型氮气保护管式炉中进行,控温精度为±3 ℃。电阻测量在ZY9987型数字式微欧计上进行,测量误差<0.000 2 Ω,每个试样测量次数不少于5次,取其平均值。显微硬度测量使用国产HV1000数字显微硬度计,加载载荷设定为0.98 N,加载时间设定为10 s,每个试样至少测量5次并取其平均值。微观组织在JEM-2100型高分辨透射电镜上进行,试样经电解双喷减薄,电解液体积比为:V(CH3OH):V(HNO3)=3:1,电解液工作温度为-30 ℃。

2 结果与分析

2.1 时效对Cu-Cr-Zr合金性能的影响

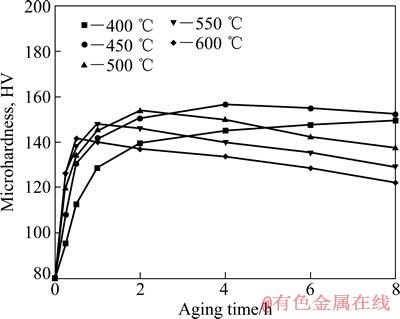

经950 ℃固溶1.5 h后的Cu-0.36Cr- 0.03Zr合金处于过饱和状态,进行时效处理后,过饱和固溶体分解,合金性能发生显著变化。图1和2所示分别为Cu-0.36Cr-0.03Zr合金的显微硬度和导电率在不同时效温度下随时间的变化曲线。从图1可看出,在时效初期,合金显微硬度迅速提高,随时间延长,增加趋势减缓。在450 ℃以下时效,原子扩散能力较低,溶质原子析出速度较慢,析出相较稳定,合金显微硬度呈一直上升趋势。当温度达到450 ℃时,合金显微硬度随时间延长出现峰值后呈下降趋势,温度越高,达到峰值所需时间越短且峰值越低。这是由于在时效初期,固溶体过饱和度较大,析出相析出动力较大,且析出速度较快,合金显微硬度迅速达到峰值,但又由于温度较高,析出相长大趋势增加,且与基体共格关系遭到破坏,合金显微硬度降低。随时效温度升高,原子扩散能力增强,析出速度增加,达到峰值所需时间就越短,同时部分溶质原子发生固溶,析出相越易聚集长大,峰值就越低。

图1 合金显微硬度随时效时间的变化曲线

Fig. 1 Curves of microhardness of alloys versus aging time

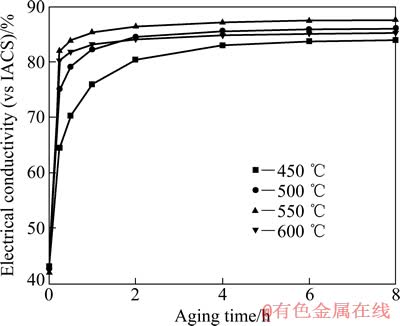

图2 合金导电率随时效时间的变化曲线

Fig. 2 Curves of electrical conductivity of alloys versus aging time

从图2可看出,在时效初期,导电率迅速增加,随时间延长,导电率保持在一个较高的水平。合金的导电性能受固溶元素影响很大,Cu-0.36Cr-0.03Zr合金固溶处理后,固溶元素含量多,固溶体发生弹性畸变程度较大,对电子的散射能力较强,导电率很低。由于时效初期基体过饱和度大,析出相析出动力大,析出速度快,导电率增幅越大。根据固溶体复相导电理论,合金导电率受基体固溶度影响,随时间延长第二相析出速度变慢,导电率增幅趋缓。当时效温度达到600℃时,部分溶质原子发生固溶,导电率下降。

2.2 合金显微组织及析出相分析

图3所示为Cu-0.36Cr-0.03Zr合金在450 ℃不同时效时间下的析出相形貌。时效温度和时间对合金析出相的数量、形状及分布有重大影响,在450 ℃时效2 h时,固溶体过饱和度较大,析出相析出动力较大,析出速度较快,但析出相数量较少,析出相与基体存在共格关系,还有花瓣状畸变衬度,如图3(a)所示。随时间延长,析出速度减缓,析出相数量增加,当时效时间达到8 h时,析出相不稳定,部分发生聚集长大,使合金硬度降低,如图3(b)所示。

图3 合金在450 ℃不同时效时间下的析出相形貌

Fig. 3 Precipitation morphologies of alloys aged at 450 ℃ for different times

图4 合金在550 ℃时效2 h后的析出相形貌及电子衍射花样标定

Fig. 4 Precipitation morphologies and indexing of diffraction patterns of precipitates of alloys aged at 550 ℃ for 2 h

图4所示为Cu-0.36Cr-0.03Zr合金在550 ℃时效2 h后的析出相形貌及电子衍射花样标定。对比图4(a)和(b)可知,时效温度越高,原子扩散速度越高,析出速度越快,析出相数量越多,但越不稳定,易发生聚集长大。BATRA等[14]和刘平等[15]研究了Cu-Cr-Zr系合金,认为时效前期存在Hesuler相CrCu2(ZrMg),后分解为稳定的Cr相和Cu-Zr化合物。本文作者对合金在550 ℃时效2 h后的析出相进行选区电子衍射,通过对衍射花样标定,确定析出相为Cr相和Cu4Zr相(如图4(c)和(d)所示)。

2.3 合金时效析出动力学分析

Cu-0.36Cr-0.03Zr合金在一定温度下时效时,过饱和的溶质原子Cr和Zr从基体中析出并形成第二相,析出相数量越多,合金的导电率就越高。此时析出相体积分数f与转变时间t遵循相变动力学Avrami经验方程:

(1)

(1)

式中:b和n为常数。b取决于相变温度、原始相成分和晶粒大小等因素;n取决于类型和形核位置。由式(1)可知,f与t存在指数型曲线关系,可认为合金导电率与时间也存在指数型曲线关系,导电率σ与体积分数f存在以下线性关系:

(2)

(2)

当转变开始时,合金初始导电率为σ0,析出相体积分数f=0,σ=σ0; 当转变终了时,σ=σmax,析出相体积分数f=1,则A=σmax-σ0,将固溶态Cu-0.36Cr-0.03Zr合金在450~600 ℃时效8 h后的导电率设为最大值σmax,因此可根据合金在不同时效温度下各时刻的导电率计算出相应的体积分数f (见表1)。

为确定Avrami经验方程中的常数b和n,将式(1)移项后两边取对数可得:

(3)

(3)

根据不同温度各时刻下的导电率与析出相体积分数可绘制出lg{ln[1/(1-f)]}-lgt图(见图5(a))。

得到常数b和n,可试算出Cu-0.36Cr-0.03Zr合金在不同温度下的相变动力学方程:

f450℃=1-exp(-0.159t0.565 1)

f500℃=1-exp(-0.454t0.410 4)

f550℃=1-exp(-1.054t0.242 4)

f600℃=1-exp(-1.133t0.220 7) (4)

根据式(4)可绘制出合金在不同温度下析出相的等温转变动力学S曲线,如图5(b)所示。根据式(2)和(4)可得到Cu-0.36Cr-0.03Zr合金在不同温度下等温时效的导电率方程:

σ450 ℃=43.040+41.113[1-exp(-0.159 0t0.566 10)]

σ500 ℃=42.289+43.828[1-exp(-0.454 0t0.410 38)]

σ550 ℃=42.002+45.963[1-exp(-1.054 2t0.242 43)]

σ600 ℃=42.150+43.585[1-exp(-1.133 0t0.220 74)] (5)

其曲线如图6所示,与图2相比较,两者误差较小且较好地反映导电率的变化情况,可认为导电率同析出相的转变比率存在线性关系。

表1 合金在不同温度下的导电率与析出相的体积分数

Table 1 Electrical conductivity (σ) and precipitates volume fraction (f) of alloys aged at different temperatures

图5 不同温度时效时的转变比率与转变时间的关系和相变动力学S曲线

Fig. 5 Relationship between transformation ratio and aging time (a) and S-curves of transformation kinetics at different temperatures (b)

图6 合金在不同温度下时效计算所得导电率曲线

Fig. 6 Electrical conductivity of alloys aged at different temperatures by calculation

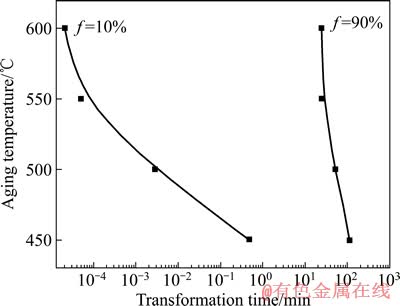

Cu-0.36Cr-0.03Zr合金在不同温度下等温时效时,若将析出相的转变比率10%和90%分别定义为合金转变开始和终了时间,由式(6)可计算出不同温度下时效析出的转变开始时间和终了时间。

(6)

(6)

根据式(6)计算值可绘制出合金的等温转变动力学TTT曲线(见图7)。

图7 合金等温转变动力学(TTT)曲线

Fig. 7 Curves of isothermal transformation of alloy

从图7可看出,Cu-0.36Cr-0.03Zr合金在600 ℃时效析出相开始析出所用时间最短,转变终了所用时间也最短,与实验结果相一致。因此,可用析出相体积转变比率与时间的相变动力学Avrami经验方程来研究Cu-0.36Cr-0.03Zr合金的时效析出动力学。

3 结论

1) Cu-0.36Cr-0.03Zr合金经过时效处理,显微硬度和电导率显著提高,在500 ℃时效2 h后合金硬度和电导率分别达到153.9 HV和84.54 %IACS;通过微观分析确定在550 ℃时效2 h后合金中存在Cr和Cu4Zr两种析出相。

2) 根据Cu-0.36Cr-0.03Zr合金时效过程中导电率的变化规律,利用析出相转变比率与时间的关系,推导出不同温度下合金的相变动力学Avrami经验方程和导电率方程。

3) 由Cu-0.36Cr-0.03Zr合金等温转变动力学曲线可知,该合金在600 ℃时效时析出相开始析出所用时间最短,转变终了所用时间也最短。

REFERENCES

[1] 刘 平, 康布熙, 曹兴国, 黄金亮, 殷 标, 顾海澄. 快速凝固Cu-Cr-Zr-Mg合金的时效析出与再结晶[J]. 中国有色金属学报, 1999, 9(2): 241-246.

LIU Ping, KANG Bu-xi, CAO Xing-guo, HUANG Jin-liang, YIN Biao, GU Hai-cheng. Aging precipitation and recrystallization of rapidly solidified Cu-Cr-Zr-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 241-246.

[2] 贾淑果, 刘 平, 田保红, 郑茂盛, 周根树, 娄花芬. 高强高导Cu-0.1Ag-0.11Cr合金的强化机制[J]. 中国有色金属学报, 2004, 14(7): 1144-1148.

JIA Shu-guo, LIU Ping, TIAN Bao-hong, ZHENG Mao-sheng, ZHOU Gen-shi, LOU Hua-fen. Strengthening mechanism in high-strength and high-conductivity Cu-0.1Ag-0.11Cr alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1144-1148.

[3] 贾淑果, 刘 平, 宋克兴, 陈讲彪, 陈小红, 田保红, 任凤章. Cu-Cr-Zr原位复合材料的组织与性能[J]. 中国有色金属学报, 2010, 20(7): 1334-1338.

JIA Shu-guo, LIU Ping, SONG Ke-xing, CHEN Jiang-biao, CHEN Xiao-hong, TIAN Bao-hong, REN Feng-zhang. Microstructures and properties of Cu-Cr-Zr in-situ composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1334-1338.

[4] XIA Cheng-dong, ZHANG Wan, KANG Zhan-yuan, JIA Yan-lin, WU Yi-feng, ZHANG Rui, XU Gen-ying, WANG Ming-pu. High strength and high electrical conductivity Cu-Cr system alloys manufactrured by hot rolling-quenching process and thermomechanical treatments[J]. Materials Science and Engineering A, 2012, 538: 295-301.

[5] LIU P, KANG B X, CAO X G. Aging precipitation and recrystallization of rapidly solidified Cu-Cr-Zr-Mg alloy[J]. Materials Science and Engineering A, 1999, 265: 262-267.

[6] HUANG F X, MA J S. Analysis of phases in a Cu-Cr-Zr alloy[J]. Scripta Materialia, 2003, 48: 97-102.

[7] BATRA I S, DEY G K, KULKAMI U D, BANERJEE S. Precipitation in a Cu-Cr-Zr alloy[J]. Materials Science and Engineering A, 2002, 356: 32-36.

[8] 王俊峰, 贾淑果, 陈少华, 刘 平, 宋克兴, 刘红勋. 固溶态Cu-Ni-Si合金时效过程的相变动力学[J]. 中国有色金属学报, 2012, 22(10): 2862-2867.

WANG Jun-feng, JIA Shu-guo, CHEN Shao-hua, LIU Ping, SONG Ke-xing, LIU Hong-xun. Kinetics of phase transformation of solution-treated Cu-Ni-Si alloy during aging treatment[J]. The Chinese Journal of Nonferrous Metals, 2012,22(10): 2862-2867.

[9] 张 毅, 刘 平, 田保红, 贾淑果, 刘 勇. Cu-2.0Ni-0.5Si合金时效析出动力学研究[J]. 功能材料, 2010, 41(10): 1827-1830.

ZHANG Yi, LIU Ping, TIAN Bao-hong, JIA Shu-guo, LIU Yong. Study on aging kinetics of Cu-2.0Ni-0.5Si alloy[J]. Journal of Functional Materials, 2010, 41(10): 1827-1830.

[10] 雷静果, 刘 平, 赵冬梅, 井晓天, 郅 晓. Cu-Ni-Si合金时效早期动力学研究[J]. 功能材料, 2005, 36(3): 368-370.

LEI Jing-guo, LIU Ping, ZHAO Dong-mei, JING Xiao-tian, ZHI Xiao. Study on early aging stage kinetics in Cu-Ni-Si alloy[J]. Journal of Functional Materials, 2005, 36(3): 368-370.

[11] 雷静果, 刘 平, 赵冬梅, 康布熙, 田保红. 用导电率研究Cu-Ni-Si-Cr合金时效早期相变动力学[J]. 材料热处理学报, 2003, 24(4): 22-26.

LEI Jing-guo, LIU Ping, ZHAO Dong-mei, KANG Bu-xi, TIAN Bao-hong. Study on the transformation kinetics of early stage aging of Cu-Ni-Si-Cr alloy by measuring the electric conductivity[J]. Transactions of Materials and Heat Treatment, 2003, 24(4): 22-26.

[12] 王俊峰, 贾淑果, 陈少华, 刘 平, 宋克兴. 热轧态Cu-Ni-Si-Mg合金的时效动力学[J]. 材料热处理学报, 2012, 33(7): 33-36.

WANG Jun-feng, JIA Shu-guo, CHEN Shao-hua, LIU Ping, SONG Ke-xing. Aging kinetics of Cu-Ni-Si-Mg alloy[J]. Transactions of Materials and Heat Treatment, 2012, 33(7): 33-36.

[13] SU Juan-hua, LIU Ping, LI He-jun, REN Feng-zhang, DONG Qi-ming. Phase transformation in Cu-Cr-Zr-Mg alloy[J]. Materials Letters, 2007, 61: 4963-4966.

[14] BATRA I S, DEY G K, KUIKAR N I, BANERJEE S. Microstructure and properties of a Cu-Cr-Zr alloy[J]. Journal of Nuclear Materials, 2001, 299: 91-100.

[15] 刘 平, 赵冬梅, 田保红. 高性能铜合金及其加工技术[M]. 北京: 冶金工业出版社, 2005.

LIU Ping, ZHAO Dong-mei, TIAN Bao-hong. High-performance copper alloy and processing technology[M]. Beijing: Metallurgical Industry Press, 2005.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50571035);河南省高校科技创新团队支持计划资助项目(2012IRTSTHN008);河南省高等学校青年骨干教师资助计划资助项目(09003047);河南科技大学科研创新培育基金资助项目(2010CZ0008)

收稿日期:2012-09-07;修订日期:2013-03-17

通信作者:贾淑果,教授,博士;电话:0379-64229405;E-mail:sgjia@mail.haust.edu.cn