文章编号:1004-0609(2015)-03-0589-06

采用FSW与MIG工艺补焊6005A-T6铝合金的接头力学性能

姚俊歌,贺地求,赖瑞林,李 然,王海军

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,

有色金属先进结构材料与制造协同创新中心,长沙 410083)

摘 要:针对6005A-T6铝合金型材搅拌摩擦焊接头缺陷补焊的应用要求,研究搅拌摩擦焊(FSW)补焊和熔化极气体保护焊(MIG)补焊工艺,对两种补焊接头的力学性能进行分析。结果表明:FSW补焊与MIG补焊方法均可以消除FSW接头缺陷,两种补焊接头的强度均达到无缺陷的FSW接头强度的88%以上,FSW补焊接头的平均抗拉强度为216.72 MPa,平均屈服强度为145.5 MPa,略高于MIG补焊接头的平均抗拉强度(206.2 MPa)和平均屈服强度(134.07 MPa)。两种补焊的接头硬度最低值都出现在热影响区,最高值都出现在母材区。

关键词:6005A-T6铝合金;搅拌摩擦焊;熔化极气体保护焊;补焊;力学性能

中图分类号:TG453 文献标志码:A

Mechanical properties of repairing welding joints of 6005A-T6 aluminum alloy prepared by FSW and MIG processes

YAO Jun-ge, HE Di-qiu, LAI Rui-lin, LI Ran, WANG Hai-jun

(Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Centrer,

State Key Laboratory of High Performance Complex Manufacturing, School of Mechanical and

Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: For the repairing welding demands of friction stir welding defects of 6005A-T6 aluminum alloy, the repairing welding processes of friction stir welding (FSW) and metal inert-gas welding (MIG) were investigated. The mechanical properties of the repairing welding joints prepared by FSW and MIG processes were analyzed. The results show that both the repairing welding methods can eliminate the FSW defects and the strength of the repairing welding joints can reach above 88% of the strength of defect-free FSW joints. The tensile strength and the yield strength of the FSW repairing welding joints are 216.72 and 145.5 MPa, which are slightly higher than those of MIG repairing welding joints (206.2 and 134.07 MPa), respectively. The lowest microhardnesses of both the FSW and MIG repairing welding joints appear in the heat-affected zone, and the highest microhardnesses appear in the base metal zone.

Key words: 6005A-T6 aluminum alloy; friction stir welding; metal inert-gas welding; repairing welding; mechanical property

随着列车速度的不断提高,对列车减轻自重以及列车安全性的要求越来越高。6005A铝合金具有比强度高、热导率高、耐腐蚀性强、力学性能优良等特点,是高速列车、轻轨车辆、地铁等列车车体常用的新型材料。当前国内铝合金车体主要以熔化焊为主,而铝合金在熔焊过程中经常会出现气孔、裂纹、夹渣等缺陷,存在较大的残余应力和焊后变形,降低了焊接接头的强度,严重影响了焊件的质量[1-4]。

搅拌摩擦焊是一种固相连接技术,由于焊接温度低于被焊金属的熔点,避免了熔焊中易出现的凝固裂纹、气孔等缺陷,焊接变形小,接头力学性能好,因此,采用FSW技术制造高速列车车体已经成为国际主流趋势[5-10]。

在搅拌摩擦焊焊接过程中,由于FSW本身的产热机制局限和焊接工艺窗口较窄,当工艺参数搭配不当或者操作不当时,易出现沟槽、孔洞、未焊合等缺陷[11-12]。针对这些缺陷,LIU等[13]和姚君山等[14]研究了铝合金FSW焊接缺陷的FSW补焊工艺,发现FSW补焊可以消除FSW沟槽缺陷,对焊缝同一位置进行不大于3次的重复FSW补焊,接头的力学性能不会明显下降。王恩泽[15]、闫忠杰等[16]和张瑜等[17]研究铝合金车体MIG焊接缺陷的MIG补焊工艺,随着MIG补焊次数增加,焊缝热影响区的固溶区和过时效区的宽度增加,接头力学性能逐渐下降。这些学者的研究分别说明了FSW补焊和MIG补焊的可行性,以及FSW焊接缺陷采用FSW补焊工艺,MIG焊接缺陷采用MIG补焊工艺,补焊后接头的性能组织变化。但针对FSW缺陷,分别采用FSW和MIG的方法对同一种材料进行补焊,补焊后的接头力学性能的变化还缺乏深入的研究。

本文作者针对FSW接头缺陷,分别采用FSW和MIG方法进行补焊,分析对比了两种补焊接头的力学性能,研究结果为6005A-T6铝合金型材FSW焊接缺陷的补焊工艺选择提供理论依据和实验基础。

1 实验

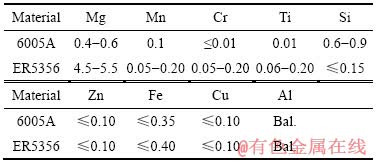

以BSEN755-2为标准的EN 6005A-T6铝合金型材为实验材料,接头为对搭接结构,接头名义厚度为4.3 mm,接缝两侧各设厚0.3 mm、宽5 mm的工艺凸台,如图1所示。MIG补焊实验采用的焊丝为ER5356,焊丝直径1.2 mm。6005A-T6铝合金和焊丝的化学成分如表1所列,6005A-T6型材的力学性能如表2所列。

实验所采用的搅拌摩擦焊机为中南大学自主研发的FSW1609K型焊机,首次FSW及FSW补焊采用的搅拌头为自主研发设计的搅拌头,轴肩直径为12 mm,搅拌针长度为4.6 mm,搅拌针形状为锥形,带螺纹,搅拌针大径为5.4 mm,小径为4.3 mm。 MIG补焊实验采用MIG/MAG-500逆变式脉冲弧焊机。

图1 6005A-T6铝合金接头

Fig. 1 Joint of 6005A-T6 aluminum alloy

表1 6005A铝合金及ER5356焊丝的化学成分(质量分数,%)

Table 1 Chemical compositions of 6005A aluminum alloy and ER5356 welding wires (mass fraction, %)

表2 6005A-T6铝合金的力学性能

Table 2 Mechanical property of 6005A-T6 aluminum alloy

实验先对6005A铝合金型材进行FSW一次焊,对所获得的焊缝进行无损检测,选出FSW无缺陷及有缺陷焊缝,对有缺陷的FSW焊缝进行补焊实验。FSW补焊的工艺参数为:焊速为1200 mm/min,搅拌头转速为2800 r/min,工艺倾角为3°。MIG补焊的工艺参数为:焊接电流为168 A,电弧电压为20.5 V,焊接速度约为60 mm/min,氩气流量为15~20 L/min。

补焊完成后,对无缺陷的FSW补焊和MIG补焊焊缝进行分析实验。将型材沿横截面剖开,铣去筋板,用线切割慢走丝的方式垂直焊缝切取拉伸试样和金相试样。用MTS810拉伸实验机测试试样的拉伸性能。采用15%的NaOH溶液腐蚀金相试样,采用DM2500M金相显微镜观察焊缝显微组织,采用HXD-1000TM/ LCD数字式显微硬度计测试试样的硬度。

2 结果与分析

2.1 补焊接头金相组织

图2(a)所示为FSW补焊后的宏观金相图,通过FSW补焊后,补焊试样呈现“洋葱环”状,轮廓曲线饱满,与底部母材结合良好,接头整体致密性良好。图2(b)所示为MIG补焊后的宏观金相图,接头呈现上宽下窄的敞口“盆”状,热影响区比FSW补焊后的热影响区范围大。

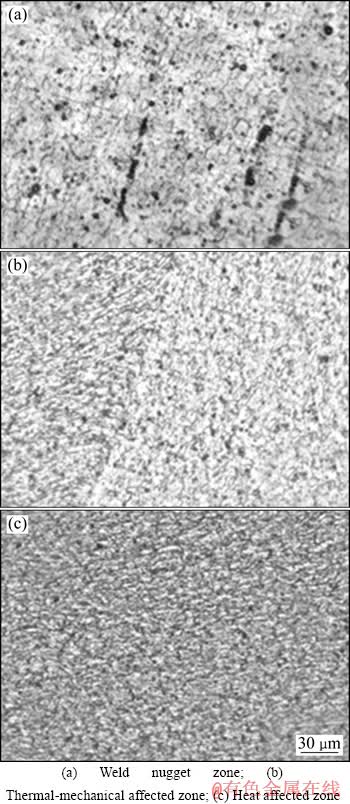

与一次FSW的焊缝组织相似,FSW补焊焊缝组织也分为母材区、热影响区、热机影响区和焊核区,图3所示为FSW补焊接头各区的金相显微照片。观察发现,焊核区为细小的等轴晶粒微观组织,在搅拌头的搅拌和摩擦热的作用下,焊核区发生了塑性变形和连续的动态再结晶,晶粒细化,黑色的强化相Mg2Si组织析出,呈点状均匀分布在焊核区;热机影响区受搅拌和热综合作用,发生不同程度的塑性变形和部分再结晶,形成狭长的晶粒组织;热影响区只受焊接热作用,晶粒长大,形成粗晶微观组织。

图2 FSW和MIG工艺补焊后接头形貌

Fig. 2 Morphologies of joints after different repairing welding processes

图3 FSW补焊接头各区的显微组织

Fig. 3 Microstructures of joints at different zones after FSW repairing welding

MIG补焊焊缝的微观组织为典型的铸态组织。大量的热输入以及焊缝温度急剧下降,使得黑色的强化相Mg2Si长大聚集,呈斑点状分布在基体上,如图4所示。与FSW补焊组织相比,MIG补焊接头的强化相总体数目减少。热影响区组织因受热晶粒长大,呈现粗大的晶粒组织。

图4 MIG补焊接头各区的显微组织

Fig. 4 Microstructures of joints at different zones after MIG repairing welding

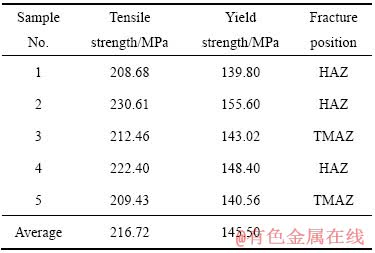

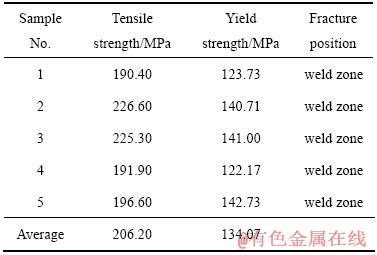

2.2 拉伸性能

拉伸试验按照GB/T 2651-2008 (ISO 4136:2001, IDT)进行,分别从无缺陷的FSW一次焊、FSW补焊和MIG补焊的焊件上各取5个拉伸试样,进行拉伸试验。结果表明:无缺陷的FSW一次焊接头的平均抗拉强度为220 MPa,平均屈服强度为151 MPa;FSW补焊接头的平均抗拉强度为216.72 MPa,平均屈服强度为145.5 MPa,分别是无缺陷FSW一次焊接头强度的98.5%和96.4%;MIG补焊的平均抗拉强度为206.2 MPa,平均屈服强度为134.07 MPa,分别是无缺陷FSW一次焊接头强度的93.7%和88.8%。可见FSW补焊接头的平均抗拉强度和平均屈服强度都略高于MIG补焊接头。分析认为:FSW补焊接头微观组织中的强化相数目相对较多,且在基体上弥散分布得更均匀,强化作用较充分,而MIG补焊的强化相长大聚集,总体数目减少,强化效果相对较差。

表3 FSW补焊接头拉伸试验数据

Table 3 Tensile test data of joints after FSW repairing welding

表4 MIG补焊接头拉伸试验数据

Table 4 Tensile test data of joints after MIG repairing welding

FSW补焊拉伸试样主要断在热影响区和热机影响区,断口与受力方向夹角约为45°,且有少量“颈缩”现象,MIG补焊接头断口主要在焊缝区,部分断口与受力方向夹角约为45°,其余断口基本与受力方向垂直,“颈缩”现象较明显。FSW补焊接头和MIG补焊接头拉伸断口形貌分别如图5所示,两者都有大小不一的韧窝,大韧窝的边缘棱上分布许多小韧窝,属韧性断裂。MIG补焊断口的韧窝相对大而深,表明在拉伸受力的时变形较大。与FSW补焊接头拉伸断口相比,MIG补焊接头拉伸断口的韧窝大小差别较大,分布不均匀。

图5 FSW和MIG补焊拉伸试样断口形貌

Fig. 5 Morphologies of fracture surface of tensile specimen after different repairing welding processes

2.3 显微硬度

补焊接头的显微硬度测试在距焊缝上表面1.5 mm处,以焊缝中心为0位,沿两侧对称取点,间距为1 mm 。图6所示为FSW补焊和MIG补焊接头显微硬度分布。

由图6可见,FSW补焊接头的显微硬度分布呈“W”形,最低值出现在热影响区,约为70 HV,最高值出现在母材区,约为100 HV。分析认为,6005A-T6是时效强化铝合金,热影响区在焊接过程中发生过时效而析出β'相,同时热影响区组织因受热导致晶粒长大、粗化,主要强化相Mg2Si长大聚集,强化效果相对较差,而母材中含有大量β"相,强化效果最好;热机影响区由于搅拌头的搅拌作用,晶粒尺寸较热影响区小,位错密度高,虽然也处于过时效状态,但硬度比热影响区高;焊核区为细小的等轴晶组织,硬度比热影响区和热机影响区的高。

图6 FSW补焊接头和MIG补焊接头的显微硬度分布

Fig. 6 Microhardness distributions of joints after repairing welding processes

MIG补焊的显微硬度分布呈现不规则的“W”形。与FSW补焊接头的硬度分布相似,母材区的硬度值最高,热影响区的硬度值最低,约为60 HV,但比FSW补焊接头热影响区的硬度值略低,分析认为MIG补焊热输入大于FSW补焊热输入,在MIG补焊接头中强化相长大程度较大,以及过时效析出的β'相数目更多,因此,MIG补焊接头热影响区的硬度值略低于FSW补焊接头的热影响区硬度值。

综上所述,FSW补焊和MIG补焊都可以消除FSW焊接缺陷,补焊接头的强度均达到无缺陷FSW接头强度的88%以上,满足补焊工艺要求。MIG补焊热输入大于FSW补焊热输入,使得MIG补焊的热影响区范围较大,晶粒粗大现象较明显,而且MIG补焊接头急速冷却,也使接头出现气孔、裂纹可能性增大,强化相长大聚集,强化效果变差;而FSW补焊通过搅拌头的机械搅拌作用,细化晶粒,接头组织相对均匀致密。由此可见,MIG补焊接头在抗拉强度和屈服强度等力学性能上略低于FSW补焊接头的力学性能。另外,焊接环境的温度、湿度等外界因素对MIG补焊质量影响较大,使MIG补焊接头的性能不稳定。但是MIG补焊通过填充焊丝,可以补焊横截面积较大的缺陷,而FSW补焊只能补焊横截面积较小、不需填充材料的缺陷。因此,对于小孔洞等横截面积较小的缺陷,优先选用FSW补焊,补焊强度高且补焊效率高;对于较大的孔洞、隧道型缺陷以及对补焊后接头的下沉量有较高要求的缺陷,则宜采用MIG填丝补焊。

3 结论

1) FSW补焊和MIG补焊都可以消除FSW焊接缺陷,MIG补焊的热影响区范围大于FSW补焊的热影响区范围。

2) FSW补焊接头的平均抗拉强度和屈服强度分别为216.72和145.5 MPa;MIG补焊接头的平均抗拉强度和屈服强度分别为206.2和134.07 MPa,两种补焊接头的强度均达到无缺陷的FSW接头强度的88%以上,FSW补焊接头的平均抗拉强度和屈服强度比MIG补焊接头的强度略高。

3) FSW补焊接头和MIG补焊接头的显微硬度分布均呈“W”型,最低值都出现在热影响区,最高值出现在母材区。

4) FSW补焊接头的综合力学性能略高于MIG补焊接头的综合力学性能,且比MIG补焊接头更稳定。FSW工艺较适合补焊横截面积相对较小的缺陷,MIG工艺则可以补焊横截面积较大的缺陷。

REFERENCES

[1] 董 鹏, 孙大千, 李洪梅, 宫文彪, 刘 杰. 6005A-T6铝合金搅拌摩擦焊接头组织与力学性能特征[J]. 材料工程, 2012(4): 27-31.

DONG Peng, SUN Da-qian, LI Hong-mei, GONG Wen-biao, LIU Jie. Microstructural and mechanical characteristics of friction stir welded 6005A-T6 aluminum alloy[J]. Journal of Materials Engineering, 2012(4): 27-31.

[2] 刘 艳, 王 淮, 宫文彪, 王振吉. 6005A铝合金搅拌摩擦焊接头疲劳性能的研究[J]. 长春工业大学学报, 2009, 30(1): 12-17.

LIU Yan, WANG Huai, GONG Wen-biao, WANG Zhen-ji. Fatigue performance research of stir welding joint of 6005A alloy[J]. Journal of Changchun University of Technology, 2009, 30(1): 12-17.

[3] 李鹏伟, 张明铭, 杨志勇, 齐芃芃, 黄 明, 刘景刚. 温度对6005A铝合金焊接接头组织与性能的影响[J]. 轻合金加工技术, 2013, 41(9): 45-48.

LI Peng-wei, ZHANG Ming-ming, YANG Zhi-yong, QI Peng-peng, HUANG Ming, LIU Jing-gang. Effects of temperature on microstructure and properties of 6005A aluminum alloy welding joint[J]. Light Alloy Fabrication Technology, 2013, 41(9): 45-48.

[4] 葛怀普, 金文涛. 铝合金车体用6005A-T6焊接气孔的防止[J]. 金属加工, 2012(14): 62-64.

GE Huai-pu, JIN Wen-tao. Methods to prevent welding porosity of 6005A-T6 aluminum alloy for vehicle body[J]. Metal Working, 2012(14): 62-64.

[5] SIMAR A, BRECHET Y, DE MEESTER B, DENQUIN A, PARDOEN T. Microstructure, local and global mechanical properties of friction stir welds in aluminum alloy 6005A-T6[J]. Materials Science and Engineering A, 2008, 486(1): 85-95.

[6] 周鹏展, 钟 掘, 贺地求. 7A52铝合金厚板搅拌摩擦焊[J]. 中国有色金属学报, 2006, 16(6): 964-970.

ZHOU Peng-zhan, ZHONG Jue, HE Di-qiu. Friction stir welding on thick plate of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 964-970.

[7] 陈荣康, 孙春方, 戴 瑛. 6005A铝合金型材搅拌摩擦焊接头疲劳性能研究[J]. 力学季刊, 2012, 33(3): 443-448.

CHEN Rong-kang, SUN Chun-fang, DAI Ying. Fatigue property of friction stir welded extruded aluminum alloy 6005A[J]. Chinese Quarterly of Mechanics, 2012, 33(3): 443-448.

[8] 王希靖, 达朝炳, 李 晶, 张忠科. 搅拌摩擦焊缝中的洋葱环形成分析[J]. 中国有色金属学报, 2006, 16(10): 1672-1678.

WANG Xi-jing, DA Chao-bing, LI Jing, ZHANG Zhong-ke. Analysis of formation of onion rings in friction stir welding[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(10): 1672-1678.

[9] 朱向东, 刘力琼, 蒲宏佐. 铝合金搅拌摩擦焊工艺研究及在城轨车辆上的应用[J]. 机车车辆工艺, 2011(5): 1-5.

ZHU Xiang-dong, LIU Li-qiong, PU Hong-zuo. Research of FSW techniques for aluminum alloys and the application to mass transit vehicles[J]. Locomotive & Rolling Stock Technology, 2011(5): 1-5.

[10] 刘 杰, 杨景宏, 韩凤武, 宫文彪. 厚板铝合金搅拌摩擦焊匙孔补焊接头组织与性能[J]. 材料工程, 2012(7): 29-33.

LIU Jie, YANG Jing-hong, HAN Feng-wu, GONG Wen-biao. Microstructures and properties of thickness aluminum alloy eleocellarium repairing welding joint by friction stir welding[J]. Journal of Materials Engineering, 2012(7): 29-33.

[11] 宋友宝, 杨新岐, 崔 雷, 申志康, 候晓鹏. 异种高强铝合金搅拌摩擦焊搭接接头的缺陷和拉伸性能[J]. 中国有色金属学报, 2014, 24(5): 1167-1174.

SONG You-bao, YANG Xin-qin, CUI Lei, SHEN Zhi-kang, HOU Xiao-peng. Defects and tensile properties of friction stir welded joints for dissimilar high-strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1167-1174.

[12] 李 博, 沈以赴, 胡伟叶. 伸缩式搅拌头厚板搅拌摩擦焊缺陷及其补焊工艺[J]. 中国有色金属学报, 2012, 22(1): 62-71.

LI Bo, CHEN Yi-fu, HU Wei-ye. Friction stir welded defects and repairing weld process of thick aluminum plates with telescopic stir-pin[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 62-71.

[13] LIU Hui-jie, ZHANG Hui-jie. Repair welding process of friction stir welding groove defect[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 563-567.

[14] 姚君山, 张春杰, 魏 薇. 搅拌摩擦焊接头隧道类缺陷等强补焊工艺[J]. 宇航材料工艺, 2012, 42(1): 73-81.

YAO Jun-shan, ZHANG Chun-jie, WEI Wei. Repair welding technique for tunnel defects of FSW joints[J]. Aerospace Materials & Technology, 2012, 42(1): 73-81.

[15] 王恩泽. 6082-T6铝合金MIG焊接头微观组织及力学性能研究[D]. 长春: 吉林大学, 2013.

WANG En-ze. Study on microstructures and mechanical properties of MIG welded 6082-T6 aluminum alloy[D]. Changchun: Jilin University, 2013.

[16] 闫忠杰, 陈书翔, 尚 哲, 刘雪松, 方洪渊. A7N01铝合金接头焊接的补焊性能分析[J]. 焊接学报, 2014, 35(5): 51-54.

YAN Zhong-jie, CHEN Shu-xiang, SHANG Zhe, LIU Xue-song, FANG Hong-yuan. Properties analysis of A7N01 aluminum alloy repair welding joints[J]. Transactions of the China Welding Institution, 2014, 35(5): 51-54.

[17] 张 瑜, 王玉玺, 陈书翔, 田爱琴, 史春元. 重复补焊热循环对铝合金焊接接头拉伸断裂特性的影响[J]. 焊接技术, 2014, 43(6): 64-67.

ZHANG Yu, WAGN Yu-xi, CHEN Shu-xiang, TIAN Ai-qin, SHI Chun-yuan. Influence of repeated repair weldingthermalcycle on the tensile and fracture properties for aluminum alloy joints[J]. Welding Technology, 2014, 43(6): 64-67.

(编辑 王 超)

基金项目:国家重点基础研究发展计划(2014CB046605)

收稿日期:2014-05-28;修订日期:2014-11-01

通信作者:贺地求,教授,博士;电话:13974973948;E-mail:hdqzzp@163.com