铝锶中间合金连续挤压过程中的组织演变

来源期刊:中国有色金属学报(英文版)2017年第2期

论文作者:毕胜 运新兵 裴久扬 赵颖 闫志勇 张旭

文章页码:305 - 311

关键词:铝锶中间合金;晶粒细化剂;连续挤压;组织演变

Key words:Al-Sr master alloy; grain refiner; continuous extrusion; microstructure evolution

摘 要:利用X射线衍射仪(XRD)、扫描电镜(SEM)和透射电镜(TEM)对铝锶中间合金连续挤压过程中组织演变进行研究。结果表明:连续挤压工艺可以显著改变铝锶中间合金中Al4Sr相的大小和形态。铸态针状的Al4Sr粒子在镦粗区破碎成小块状,并在粘着区严重破碎;在直角弯曲区大量位错缠结在一起;在扩展区Al4Sr粒子开始长大;最终,产品中Al4Sr粒子的长度约为28 μm。在连续挤压过程中有Al2Sr粒子析出。与卧式挤压产品相比,连续挤压产品中Al4Sr粒子更加细小均匀。

Abstract: The microstructure evolution of Al–Sr master alloy during continuous extrusion was investigated using X-ray diffractometer, scanning electron microscope and transmission electron microscope. Results indicate that the continuous extrusion process could change the Al4Sr particles of the alloy significantly in size and morphology. The as-cast needle-like Al4Sr particles are broken into small blocks in upsetting zone and crushed heavily in adhesion zone. Plenty of dislocations get tangled up in right-angle bending zone. Al4Sr particles grow in the extending zone. Finally, Al4Sr particles in products are approximately 28 μm in length. Al2Sr particles precipitate during the process. Compared with products by horizontal extrusion, Al4Sr particles by continuous extrusion are finer and distribute more evenly.

Trans. Nonferrous Met. Soc. China 27(2017) 305-311

Sheng BI1, Xin-bing YUN1, Jiu-yang PEI1, Ying ZHAO1, Zhi-yong YAN2, Xu ZHANG2

1. Engineering Research Center of Continuous Extrusion, Ministry of Education, Dalian Jiaotong University, Dalian 116028, China;

2. Dalian Konform Technical Company Limited, Dalian 116050, China

Received 2 December 2015; accepted 13 June 2016

Abstract: The microstructure evolution of Al–Sr master alloy during continuous extrusion was investigated using X-ray diffractometer, scanning electron microscope and transmission electron microscope. Results indicate that the continuous extrusion process could change the Al4Sr particles of the alloy significantly in size and morphology. The as-cast needle-like Al4Sr particles are broken into small blocks in upsetting zone and crushed heavily in adhesion zone. Plenty of dislocations get tangled up in right-angle bending zone. Al4Sr particles grow in the extending zone. Finally, Al4Sr particles in products are approximately 28 μm in length. Al2Sr particles precipitate during the process. Compared with products by horizontal extrusion, Al4Sr particles by continuous extrusion are finer and distribute more evenly.

Key words: Al-Sr master alloy; grain refiner; continuous extrusion; microstructure evolution

1 Introduction

Modification plays a leading role in the casting of aluminium by changing the size and morphology of the major phases in aluminium alloy. Al-Sr master alloy, as one of the permanent refiners, possesses several merits including good reproducibility, long effective modification time, no corrosion on equipment and no delitescence of modification. This alloy is widely applied to modifying hypoeutectic and eutectic Al-Si as-cast alloys [1,2]. Al-Sr master alloy rods have a great demand in industrial production, and Al4Sr phases are required to exhibit a homogeneous distribution in rods with a small size. Unfortunately, most of domestic grain refiners fail to meet the demand to produce high- performing Al alloy materials due to their inferior refining effects [3]. Therefore, it is of great significance to seek an economic and effective way to process Al-Sr master alloy with high quality.

Continuous casting and rolling process are widely used to shape grain refiner rods like Al-Ti-B owing to its energy saving and automotive production, but it could not be used to produce such poor plastic materials like Al-Sr master alloy. Although WANG et al [4] has successfully produced Al-Sr master alloy by continuous casting–extrusion process, this process has low productivity due to its casting speed [5]. Several works have been carried out to investigate Al-Sr master alloy by extrusion process. LIAO et al [6] produced Al-Sr master alloy with a relatively good modification performance by employing “direct reaction–hot extrusion” method. TAVIGHI et al [7] reported the effect of extrusion temperature on the size of Al4Sr particles and found the optimum extrusion temperature for Al-16%Al4Sr (mass fraction) metal matrix composite. On this basis, SHARIFIAN et al [8] analyzed the microstructure and tensile properties of Al matrix composite that contained different amounts of Al4Sr after hot extrusion. However, hot extrusion process is usually combined with semi-continuous casting process in industry, namely semi-continuous casting and extrusion process, to produce grain refiner rods. Semi-continuous casting and extrusion process could not manufacture coiled rods due to the limited product length and a lot of energies are wasted for middle heating in the process.

It was reported that continuous casting and extrusion process could provide good production flexibility and produce rounded and smooth products [9]. The continuous extrusion as the subsequent process is vital to the microstructure and property of products and has several advantages over the other processes mentioned above [10]. In continuous extrusion process, the friction force that acts as useless work in traditional extrusion is ingeniously converted into driving force and heating source during deformation, which saves energy greatly and improves material utilization. Furthermore, severe shear deformation that occurs during the process can contribute to fine microstructure and homogenous distribution of particles [11-13]. This condition is highly favorable to decreasing the size of intermetallic phases in refiners. To the best of our knowledge, however, few studies have been conducted to produce Al-Sr master alloy by continuous extrusion. Hence, the attempt to apply continuous extrusion process to the production of Al-Sr master alloy is meaningful.

Continuous extrusion is a relatively complicated deformation process, during which rolling, upsetting, right-angle bending and extrusion deformation can occur. Since the continuous extrusion deformation process is enclosed, how the microstructure is transformed in the process is unknown. Therefore, observation of the intermetallic phase’s variation in Al-Sr master alloy during the process can be helpful to understand the process penetratingly and provide guidance to optimize the process parameters in industrial production, which is the aim of our present work.

2 Experimental

As-cast Al-10Sr (9%-11%Sr, mass fraction) master alloy with a trapezium section prepared by rotary-wheel continuous casting was the billet for experiment. The cross section area of the billet was 744 mm2. The billet, chamber and die were preheated to 500 °C (773 K), and the extrusion process was carried out on a LLJ400 continuous extrusion machine at a wheel speed of 5 r/min with an extrusion ratio of 5.2:1. Moreover, the extrusion chamber had an extending structure, and double products were extruded from the die once. The products’ diameter was 9.5 mm. The extruded products were cooled to room temperature by using a water cooling device. Samples from the groove and chamber were cut in the longitudinal direction with a wire cutting machine after cooling down. A comparison was made between the products by continuous extrusion and by horizontal extrusion. The products by horizontal extrusion were manufactured by a factory in China.

Microscopic samples were etched in a 0.5% hydrofluoric acid (HF) aqueous solution at 25 °C for 5 s and then examined using a VEGA -TESCAN scanning electron microscope (SEM). Transmission electron microscopy (TEM) was performed using a JEM 2100F microscope. Finally, in order to characterize the phases in the billet, X-ray diffraction (XRD) was accomplished by Empyrean X-ray diffractometer. About eighty particles in each zone were taken to measure the length and width of Al4Sr particles and the average was calculated.

3 Results and discussion

3.1 Microstructure of billet

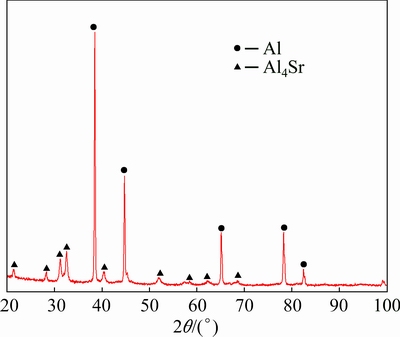

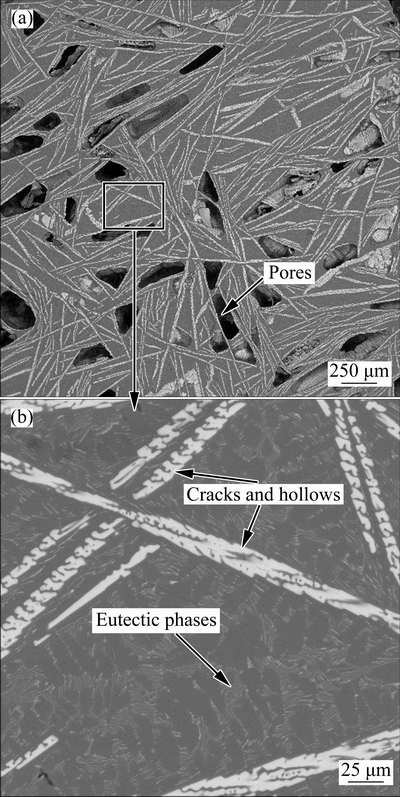

Figure 1 shows the XRD pattern of the as-cast Al-Sr billet. XRD pattern reveals that the billet is composed of α(Al) matrix and Al4Sr intermetallic phases. According to the Al-Sr equilibrium phase diagram, the primary Al4Sr phases form from the liquid at first and the eutectic (Al+Al4Sr) phases appear subsequently because of the eutectic reaction at a temperature of 654 °C during solidification. Therefore, primary Al4Sr phases and eutectic (Al+Al4Sr) phases coexist in the Al-10Sr master alloy at room temperature. Figure 2 shows the microstructures of as-cast Al-Sr master alloy. In Fig. 2(a), the second phases in the Al matrix with long, needle-like morphology are the primary Al4Sr phases. The Al4Sr particles cross each other and have an indiscriminate distribution. The average length of Al4Sr particles by quantitative analysis is 543 μm. This length is 2.5 times longer than that of Al4Sr particles in the billet produced by normal casting (TAVIGHI et al [14] reported that the length of Al4Sr particles in as-cast MMC billet was about 200 μm). Furthermore, many macro large pores exist in the as-cast billet with length in the range of 200-400 μm and width in 50-100 μm. These pores that form during solidification can easily result in inferior mechanical properties and poor plasticity of the as-cast billet. This might be the reason why Al-Sr alloy rods could not be shaped by continuous casting and rolling process. From the enlarged image in Fig. 2(b), most of the Al4Sr particles evidently consist of many relatively large grains with some hollows and cracks inside. Existence of hollows in the Al4Sr phases is associated with lack of Sr atoms in the two tips of one Al4Sr particle growing in the main solidification direction. It can also be seen that the eutectic phases have a lamellar shape and distribute uniformly in the matrix.

Fig. 1 XRD pattern of Al-10Sr billet

Fig. 2 Back-scattered SEM image of billet (a) and enlarged image (b) in marked region in Fig. 2(a)

3.2 Microstructure evolution during continuous extrusion

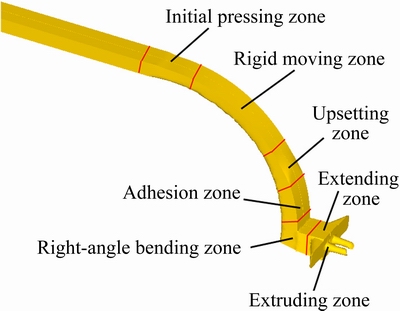

Combined with features of the chamber structure and microstructure variation in different zones [15,16], the plastic deformation zones during continuous extrusion could be divided into initial pressing zone, rigid moving zone, upsetting zone, adhesion zone, right-angle bending zone, extending zone and extruding zone, as shown in Fig. 3.

Fig. 3 Deformation zones during continuous extrusion

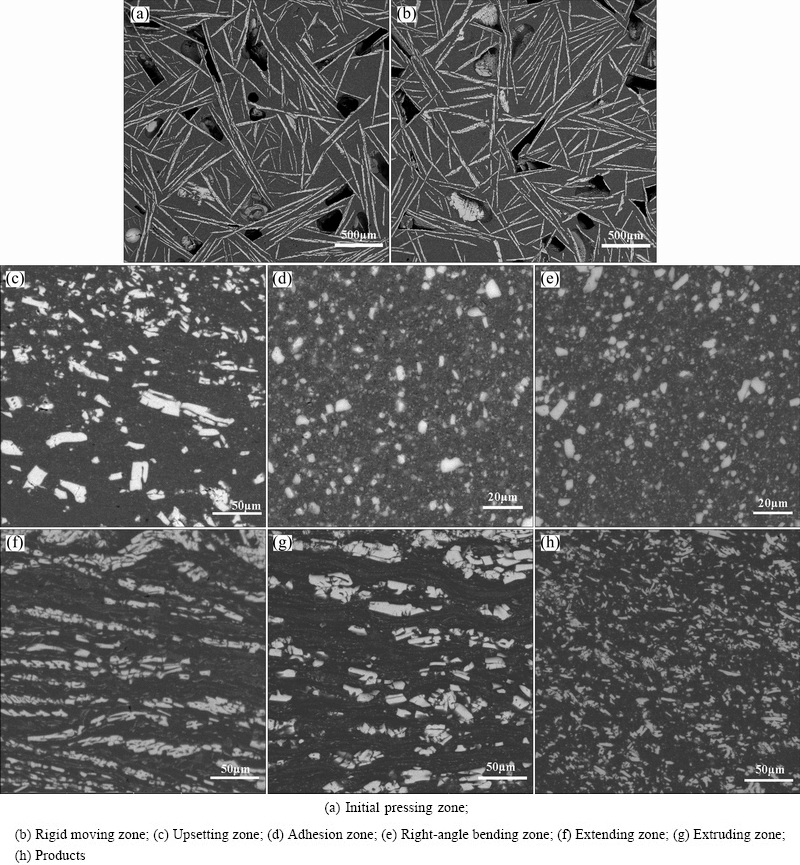

In initial pressing zone (Fig. 4(a)) and rigid moving zone (Fig. 4(b)), the deformation is not large because of the small pressure of the coining roller. The needle-like Al4Sr particles remain unchanged and a small amount of these particles are cracked. The Al4Sr particles seem similar in size and morphology from the two images. Figure 4(c) shows the microstructure of Al-Sr master alloy in upsetting zone. In the upsetting zone, the section size of the metal becomes larger because of the upsetting deformation. Some Al4Sr particles are broken into small blocks and spread along the deformation direction. Notably, the Al4Sr particles have changed significantly in size in upsetting zone compared with the first two zones 10-40 μm. In adhesion zone (Fig. 4(d)), the metal fills up the entire groove space and sticks to the groove’s side surface entirely. The Al4Sr particles morph from a blocky shape to an irregular shape. Moreover, the size of the particles becomes smaller. This might because severe shear deformation has occurred in adhesion zone. Since the size of Al4Sr particles in upsetting zone is not large, it is easy for the particles to decrease further in adhesion zone due to shear deformation. As the extrusion wheel continues to revolve, the metal turns 90° on account of the abutment’s obstruction. The Al4Sr particles in right-angle bending zone (Fig. 4(e)) are almost identical to those in adhesion zone in size and morphology. In extending zone, Al4Sr particles agglomerate together and grow in a stripe shape (Fig. 4(f)). It is the temperature in this zone that leads to the growth of Al4Sr particles. TAVIGHI et al [7] reported that 420 °C was the suitable extrusion temperature for Al-16%Al4Sr metal matrix composite. In this experiment, since the preheated temperatures of the billet and chamber are high (500 °C), the Al4Sr particles are easily to agglomerate and grow in this situation to reduce the interface energy. In extruding zone (Fig. 4(g)), some particles are broken because of the impact of extrusion die. Figure 4(h) shows the microstructure of the products after extrusion. The Al4Sr particles are fine and distribute uniformly in the matrix. The size of these particles is about 30 μm, which means 94% reduction compared with that in the billet of 543 μm.

Fig. 4 Back-scattered SEM images of Al–Sr master alloy in different zones during continuous extrusion

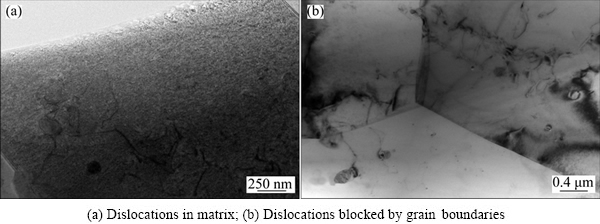

Fig. 5 Bright field TEM images of Al–Sr master alloy in upsetting zone

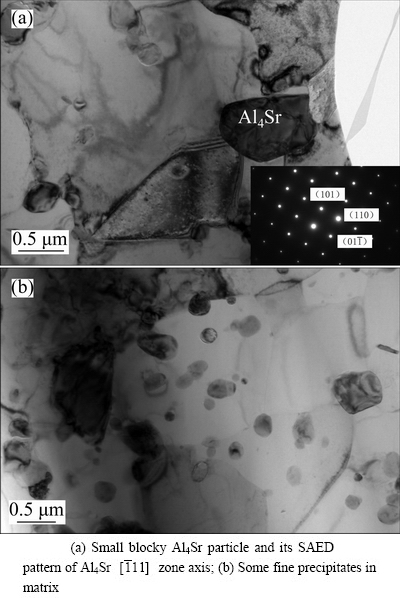

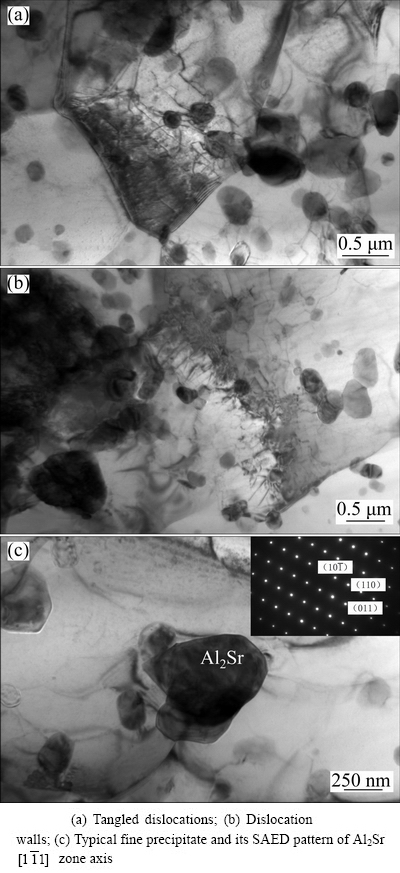

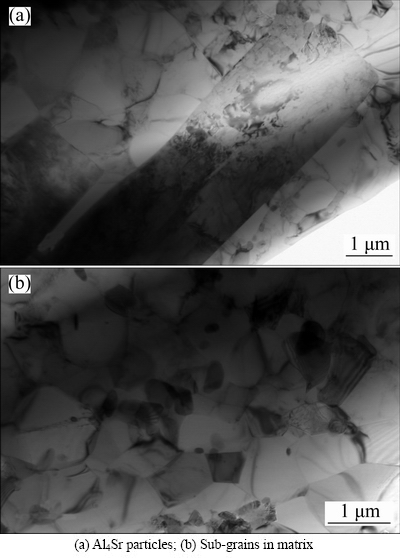

Figure 5 shows the bright field TEM images of Al–Sr master alloy in upsetting zone. In upsetting zone, due to the upsetting deformation, a small amount of dislocations form in the matrix (Fig. 5(a)) and some are blocked by grain boundaries (Fig. 5(b)). Since aluminium is a kind of metal with high stacking fault energy and narrow extended dislocations, the dislocations can cross slip easily. Furthermore, dislocations are easy to climb at an elevated temperature. Therefore, dislocation density in upsetting zone is low. Figure 6 shows the bright field TEM images of Al-Sr master alloy in adhesion zone. Al4Sr particles are broken further in adhesion zone. As shown in Fig. 6(a), a small Al4Sr particle, about 1 μm in size, is crushed heavily due to severe shear deformation. Figure 6(b) shows some fine particles precipitate on sub-grain or grain boundaries and some precipitate in grain interior. TEM images of Al-Sr master alloy in right-angle bending zone are shown in Fig. 7. A large amount of dislocations are tangled with some fine dotted precipitates in grain interior (Fig. 7(a)) and dislocation walls with high density of dislocations are observed in Fig. 7(b). Sharply increased dislocation density illustrates that right-angle bending deformation is a severe plastic deformation during continuous extrusion. Precipitates are chaotic and distribute unevenly in grain interior. The precipitates, identified by SAED pattern, are Al2Sr particles (Fig. 7(c)). WANG et al [17] reported that AlSr particles precipitated when melt-spun Al-10Sr had been isothermally annealed at 873 K for 90 min. It is possible that Al2Sr particles precipitate in adhesion zone based on Wang’s experiment results. Though the temperature in adhesion zone may be lower than 873 K and the duration is shorter than 90 min, Al2Sr particles are easier to form than AlSr particles because two Al atoms need only one Sr atom in Al2Sr particles (Sr atoms account for a relatively small proportion of the Al-10Sr master alloy ). Moreover, in terms of the crystal structure, Al4Sr, Al2Sr and AlSr phases are tetragonal, orthorhombic and cubic, respectively. Al2Sr phases are easier to form than AlSr phases because of the low symmetry. Figure 8 shows the bright field TEM images of Al-Sr master alloy in extending zone. In extending zone, the grain boundaries become clear with a low dislocation density. Al4Sr particles grow in a rectangular shape (Fig. 8(a)). From Fig. 8(b), it can be seen that the grains are divided into sub-grains by many dislocation cells in the matrix.

Fig. 6 Bright field TEM images of Al–Sr master alloy in adhesion zone

Fig. 6 Bright field TEM images of Al–Sr master alloy in adhesion zone

Fig. 7 Bright field TEM images of Al–Sr master alloy in right- angle bending zone

3.3 Size variations of Al4Sr particles during continuous extrusion

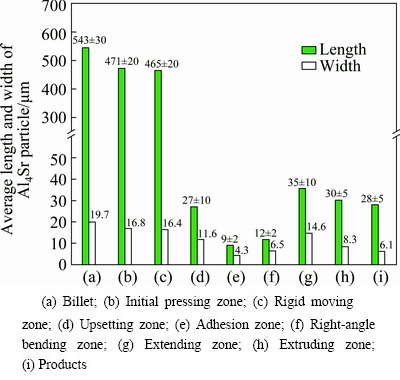

Al-Sr master alloy is a refiner and modifier [18], but Al4Sr particles cannot directly influence the refinement unless free Sr can be obtained by the dissolution of Al4Sr particles [19]. Therefore, fine Al4Sr particles indicate rapid release of Sr and better refining effects of Al-Sr master alloy. Figure 9 demonstrates the variations of average length and width of Al4Sr particles in different zones during continuous extrusion. As shown in Fig. 9, obviously, the length of Al4Sr particles is strongly influenced by continuous extrusion process. The Al4Sr particles slightly reduce in length from 543 to 465 μm in initial pressing zone and rigid moving zone. With the extrusion wheel running, the shear deformation of the metal exacerbates constantly so that a substantial decline of Al4Sr particles in length from 465 to 27 μm appears in upsetting zone. Al4Sr particles are similar in adhesion zone and right-angle zone, with the size of 9-12 μm. Al4Sr particles increase in length from 12 to 35 μm in extending zone but decrease after extrusion of the die. Finally, the length of Al4Sr particles is approximately 28 μm. Similarity could be seen between the changes in both the width and the length of Al4Sr particles during continuous extrusion. It also indicates that the process has a little influence on the width of Al4Sr particles.

Fig. 8 Bright field TEM images of Al-Sr master alloy in extending zone

Fig. 9 Average length and width of Al4Sr particles in different zones

3.4 Comparison with products by horizontal extrusion

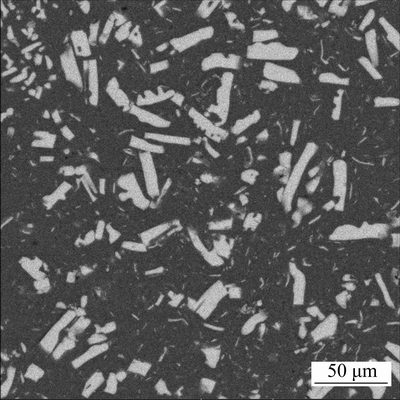

The performance of Al-Sr grain refiner depends to a large extent on the size and distribution of Al4Sr particles. Figure 10 shows the microstructure of Al-10Sr rod products by horizontal extrusion. Al4Sr particles are different in morphology by two processes. Al4Sr particles in products by horizontal extrusion are in a blocky shape while those by continuous extrusion are in a strip-like shape (Fig. 4(h)). Al4Sr particles by continuous extrusion are finer and distribute more evenly. The average length of Al4Sr particles by horizontal extrusion is about 78 μm while that of Al4Sr particles by continuous extrusion is only 28 μm.

Fig. 10 Back-scattered SEM image of Al-10Sr rod products by horizontal extrusion

4 Conclusions

1) Long needle-like Al4Sr particles are broken into small blocks in upsetting zone during the continuous extrusion of Al-Sr master alloy. These particles are crushed heavily in adhesion zone. Al4Sr particles begin to grow in extending zone and decrease further in extruding zone.

2) Al2Sr particles precipitate during continuous extrusion. Dislocations form and are blocked by grain boundaries in upsetting zone. Plenty of dislocations get tangled up and dislocation walls form in right-angle bending zone. Grain boundaries become clear and grains are divided into sub-grains by dislocation cells in extending zone.

3) The continuous extrusion process could change the Al4Sr particles significantly in size and morphology. Al4Sr particles have changed in length from 543 to 28 μm. Compared with products by horizontal extrusion, Al4Sr particles in products by continuous extrusion are finer and distribute more evenly.

References

[1] CENG Ren-ju, PAN Fu-sheng, WANG Wei-qing. Development status of preparation and application of Al-Sr master alloy [J]. Light Alloy Fabrication Technology, 2006, 34(7): 5-11. (in Chinese)

[2] SHIN S S, KIM E S, YEOM G Y, LEE J C. Modification effect of Sr on the microstructures and mechanical properties of Al-10.5Si-2.0Cu recycled alloy for die casting [J]. Materials Science and Engineering A, 2012, 532: 151-157.

[3] LI Xiao-min. Brief analysis of Al-Ti-B grain refiner market [J]. World Nonferrous Metal, 2012(8): 56-57. (in Chinese)

[4] WANG Zhen-qing, LIU Xiang-fa, BIAN Xiu-fang. The comparison of three production processes of Al-Ti-B master alloy rod [J]. Foundry, 2000, 49(4): 231-233. (in Chinese)

[5] WANG Shun-cheng, CHEN Yan-bo, WEN Jing-lin. Study on continuous extrusion process for producing Al-Sr master alloy rod [J]. Light Alloy Fabrication Technology, 2003, 31(3): 19-22. (in Chinese)

[6] LIAO Cheng-wei, CHEN Jian-chun, LI Yang, TU Rui, PAN Chun-xu. Morphologies of Al4Sr intermetallic phase and its modification property upon A356 alloys [J]. Journal of Materials Science & Technology, 2012, 28(6): 524-530.

[7] TAVIGHI K, EMAMY M, EMAMI A R. Effects of extrusion temperature on the microstructure and tensile properties of Al-16wt% Al4Sr metal matrix composite [J]. Materials & Design, 2013, 46: 598-604.

[8] SHARIFIAN K, EMAMY M, TAVIGHI K, VAZIRI YEGANEH S E. Microstructures and tensile properties of hot-extruded al matrix composites containing different amounts of Al4Sr [J]. Metallurgical and Materials Transactions A, 2014, 45(12): 5344-5350.

[9] GAO Ze-sheng. Supply industry of aluminium grain refiners in the world (1) [J]. Light Material, 1999(9): 50-53. (in Chinese)

[10] ZHANG Xiao-yuan, ZHANG Hui, KONG Xiang-xin, FU Ding-fa. Microstructure and properties of Al-0.70 Fe-0.24 Cu alloy conductor prepared by horizontal continuous casting and subsequent continuous extrusion forming [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1763-1769.

[11] FENG Hui, JIANG Hai-chang, YAN De-sheng, RONG Li-jian. Effect of continuous extrusion on the microstructure and mechanical properties of a CuCrZr alloy [J]. Materials Science and Engineering: A, 2013, 582: 219-224.

[12] ZHANG Hui, YAN Qi-qi, LI Luo-xing. Microstructures and tensile properties of AZ31 magnesium alloy by continuous extrusion forming process [J]. Materials Science and Engineering A, 2008, 486(1): 295-299.

[13] JI Xian-kun, ZHANG Hui, LUO Song, JIANG Fu-lin, FU Ding-fa. Microstructures and properties of Al-Mg-Si alloy overhead conductor by horizontal continuous casting and continuous extrusion forming process [J]. Materials Science and Engineering A, 2016, 649: 128-134.

[14] TAVIGHI K, EMAMY M, TANHAEE Z, VAZIRI YEGANEH S E. Effects of Zn addition on the microstructure and tensile properties of hot-extruded Al-16wt% Al4Sr in-situ composite [J]. Materials Science and Engineering A, 2014, 606: 92-100.

[15] WANG Jun, YUN Xin-bing, LI Bing, FAN Zhi-xin, SONG Bao-yun. Microstructure evolution of copper during continuous extrusion process [J]. Nonferrous Metals: Extractive Metallurgy, 2011(5): 38-41. (in Chinese)

[16] YUAN Yuan, DAI Cheng, LI Zhou, YANG Guang, LIU Yue, XIAO Zhu. Microstructure evolution of Cu-0.2 Mg alloy during continuous extrusion process [J]. Journal of Materials Research, 2015, 30(18): 2783-2791.

[17] WANG Yan, LIU Guo-dong, BIAN Xiu-fang, SUN Yue, ZHANG Zhong-hua. Transient spinodal decomposition during annealing of rapidly solidified Al-10Sr alloy [J]. Journal of University of Science and Technology Beijing, 2003, 10(1): 58-60.

[18] REN Jun, TAO Qin-gui, MA Ying. Development and situation of refinement mechanism and grain refinement of Al-Ti-B alloy [J]. Foundry Technology, 2007, 28(1): 69-73. (in Chinese)

[19] EMAMY M, OLIAYEE M, TAVIGHI K. Microstructures and tensile properties of Al/2024-Al4Sr composite after hot extrusion and T6 heat treatment [J]. Materials Science and Engineering A, 2015, 625: 303-310.

毕 胜1,运新兵1,裴久扬1,赵 颖1,闫志勇2,张 旭2

1. 大连交通大学 连续挤压教育部工程研究中心,大连 116028;

2. 大连康丰科技有限公司,大连 116050

摘 要:利用X射线衍射仪(XRD)、扫描电镜(SEM)和透射电镜(TEM)对铝锶中间合金连续挤压过程中组织演变进行研究。结果表明:连续挤压工艺可以显著改变铝锶中间合金中Al4Sr相的大小和形态。铸态针状的Al4Sr粒子在镦粗区破碎成小块状,并在粘着区严重破碎;在直角弯曲区大量位错缠结在一起;在扩展区Al4Sr粒子开始长大;最终,产品中Al4Sr粒子的长度约为28 μm。在连续挤压过程中有Al2Sr粒子析出。与卧式挤压产品相比,连续挤压产品中Al4Sr粒子更加细小均匀。

关键词:铝锶中间合金;晶粒细化剂;连续挤压;组织演变

(Edited by Yun-bin HE)

Foundation item: Project (51175055) supported by the National Natural Science Foundation of China; Project (LR2015011) supported by Program for Liaoning Excellent Talents in University, China

Corresponding author: Xin-bing YUN; Tel: +86-411-84109416; E-mail: yunxb@djtu.edu.cn

DOI: 10.1016/S1003-6326(17)60035-9