600 MW“W”型火焰锅炉的爆管机理

曹小玲1,唐世斌1,彭好义2,蒋绍坚2,符慧林1,彭朝辉3,赵国光3,龙宁晖3,陈忠雄3

(1. 长沙理工大学 能源与动力工程学院,湖南 长沙,410004;

2. 中南大学 能源科学与工程学院,湖南 长沙,410083;

3. 湖南金竹山电厂,湖南 冷水江,417503)

摘要:以某电厂1台超临界600 MW “W”火焰锅炉受热面爆管频繁为背景,对锅炉炉内的燃烧过程进行数值模拟,研究不同负荷、不同煤种和不同配风方式对锅炉爆管的影响。研究结果表明:负荷为450 MW时,温度场明显偏斜,高温火焰冲刷受热面严重,可能会导致受热面的爆管;负荷为300 MW时,火焰中心很低,火焰冲刷冷灰斗严重,可能导致冷灰斗受热面爆管;不同煤种有不同的火焰中心,这可能引起炉内燃烧震荡,导致受热面因温度梯度过大而爆管;不同配风方式导致火焰中心偏离,这也是造成受热面爆管的重要因素。

关键词:“W”型火焰锅炉;爆管;温度场;数值模拟

中图分类号:TK224 文献标志码:A 文章编号:1672-7207(2013)08-3533-06

Mechanism of pipe expansion in a 600 MW W-shape flame boiler

CAO Xiaoling1, TANG Shibin1, PENG Haoyi2, JIANG Shaojian2,

FU Huilin1, PENG Chaohui3, ZHAO Guoguang3, LONG Ninghui3, CHEN Zhongxiong3

(1. School of Energy and Power Engineering, Changsha University of Science and Technology, Changsha 410004, China;

2. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

3. Hunan Jinzhushan Power Plant, Lengshuijiang 417503, China)

Abstract: Because a 600 MW supercritical W-shape flame boiler of a power plant has a problem of frequent pipe expansion, numerical simulation of the boiler on combustion process was conducted to study the effect of pipe expansion with different loads, coals and air distributions. The results show that the temperature field is significantly skewed and the temperature flame sweeps over heating surface seriously in 450 MW, which may lead to the pipe explosion of the heating surface. The flame center is low and flame washes cold ash hopper seriously in 300 MW, which may lead to pipe explosion of the cold ash hopper heating surface. The different coals have different flame centers, which may cause combustion shock and make the heating surface have a large temperature gradient to pipe expansion. Different air distributions also affect the flame center, which may cause pipe expansion.

Key words: W-shape flame boiler; pipe expansion; temperature field; numerical simulation

“W”型火焰锅炉是我国燃用低挥发分无烟煤的主要炉型,而超临界“W”型火焰锅炉能高效地节约能源,是未来发展的方向之一,但我国目前运行的超临界“W”型火焰锅炉普遍存在受热面爆管频繁、局部温度过高、火焰偏烧和NOx排放量过高等问题[1-3],这不但影响锅炉的经济性和使用寿命,严重时还影响锅炉的安全运行。随着计算机技术的发展,数值模拟计算成为研究炉内燃烧过程的一种有效的手段,数值模拟可以详细反映炉内燃烧过程[4-10],且模拟结果准确性较高[11-14],还能得到许多运行现场不能得到的数据和结论。湖南某电厂的600 MW超临界“W”型火焰锅炉在运行中出现受热面爆管频繁,目前爆管机理尚不清楚,为此本文作者以此锅炉出现的问题为背景,采用数值模拟方法对锅炉炉内燃烧过程进行模拟,研究不同负荷、不同煤种和不同配风方式对炉膛温度场的影响规律,以期获得锅炉爆管的机理,为锅炉运行中避免受热面爆管提供理论指导依据。

1 研究背景

湖南某电厂的600 MW超临界机组无烟煤“W”型火焰锅炉为北京巴威公司按美国巴威公司“W”型火焰及超临界系列锅炉技术标准,结合实际工程燃用的设计、校核煤质特性和自然条件,进行性能、结构优化设计的超临界参数“W”型火焰锅炉。但是,实际现场运行中常出现受热面爆管频繁的问题,严重威胁着机组的安全和稳定运行。图1所示为该锅炉某次爆管的图片,经现场初步分析认为,受热面变形和爆管的原因可能是锅炉内外壁温差过大或者是横向水冷壁变形不一,从而造成水冷壁撕裂等。可见锅炉内温度场的均匀性等是爆管的最重要影响因素之一。为此,本文作者就影响温度场的各种主要因素:即负荷、煤种和配风方式等对锅炉爆管的机理进行研究,以期获得相关锅炉受热面爆管的机理,从而对锅炉的受热面爆管提出运行改进措施,并指导锅炉安全运行。

图1 受热面爆管示意图

Fig. 1 Schematic illustrations of pipe expansion of heating surface

2 模拟对象

本文模拟的对象为湖南某电厂的600 MW超临界锅炉。锅炉为超临界参数、垂直炉膛、一次中间再热、平衡通风、固态排渣、全钢构架、露天布置的Ⅱ型锅炉,锅炉配有带循环泵的内置式启动系统。

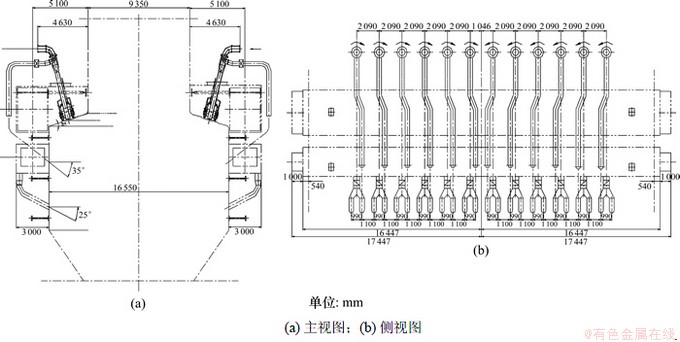

制粉系统为双进双出磨煤机正压直吹系统,锅炉采用“W”火焰燃烧方式,锅炉配A,B,C,D,E和F共6台磨煤机,并配置浓缩型EI-XCL低NOx双调风旋流燃烧器。燃烧器布置在炉膛的前后拱上,并垂直于前后拱,前后拱与水平面成15°,每排各有12只燃烧器,分别与6台磨煤机相连,燃用煤质见表1。本锅炉采用开式大风箱,在锅炉的前后拱上、下部各有1个的开式大风箱,二次风进入上部风箱,分级风进入下部风箱,内、外二次风分别经燃烧器的内、外二次风调风套筒调风后喷入炉内;每台锅炉共24个乏气喷口,前后墙各12个,布置在燃烧器的下部,与燃烧器一一对应,并与水平成35°;在乏气管路上设有电动快关插板门,当某个燃烧器需要停运时,需将该燃烧器对应的乏气管道上电动快关门关闭;每个燃烧器下部均设有分级风管,风管上装有电动风门,每个分级风管分成 2个支管,每台锅炉共有48个分级风喷口,前后墙各24个;分级风从风箱底部引出,分级风喷口与水平方向成 25°倾角引入炉膛。燃烧风箱图如图2所示。

表1 煤的工业分析与元素分析(质量分数)

Table 1 Coal industrial and elemental analysis %

图2 燃烧风箱

Fig. 2 Combustion wind-box

3 数学模型及工况条件

3.1 数学模型

煤粉燃烧过程是一种具有化学反应的湍流反应流动过程,包含流体的流动、传热与传质、组分间的化学反应以及它们之间的相互耦合作用。煤粉燃烧过程包括为挥发分的析出与反应、焦炭的异相气化反应、辐射传热、颗粒运动和湍流流动等过程。本文所研究锅炉模型及网格划分如图3所示。运用gambit软件对锅炉模型划分为六面体网格和适应性四面体网格的混合型网格,并对流动复杂区域进行加密,最终生成的网格总数为94万个。使用Realizable k-ε模型模拟湍流气相流动;采用标量守恒的混合分数-概率密度函数模拟挥发分燃烧;PDF模型的简化形式采用β函数分布;采用P1辐射模型计算炉内辐射换热;采用单步竞争反应速率模型模拟煤粉挥发分的析出;采用动力/扩散控制反应速率模型模拟焦炭颗粒表面燃烧;采用Rosin-Rammler分布描述固相颗粒分布特征;采用拉格朗日离散相模型考虑颗粒相和气相间的相互作用,并采用随机轨道模型追踪颗粒运动轨迹并同时考虑湍流脉动对焦炭运动的影响。

3.2 计算工况

以现场实际运行的额定负荷为基础进行模拟,分析影响“W”型火焰锅炉燃烧特性的因素,并利用现场实测数据验证其计算结果的准确性。在实际工况下,过量空气系数α=1.2;其他工况则为锅炉实际运行可能出现的非设计工况。表2所示为总模拟工况。

图3 锅炉模型及网格划分

Fig. 3 Generated grids in boiler model

表2 风量计算工况

Table 2 Calculation conditions of wind kg/s

4 模拟结果及分析

4.1 模型的准确性验证

为了验证所模拟的模型的准确性,使用热电偶分别对4个测试点(高度分别为7.54,9.10,13.30和17.80 m)的烟气温度进行测量。测量时,将热电偶置于窥视孔处。将炉膛内实际测试点处的烟气温度与相应位置的温度模拟结果进行对比,结果如表3所示。

表3 实际测量温度值与模拟计算温度比较

Table 3 Comparison of measurement temperature and simulation temperature

经对比分析,4个测试点处温度的实际测量值和模拟计算值相对误差都在7.50%以内;模拟计算值比实际测量值结果要稍大,但二者还是处于同一数量级上。总的来说,温度模拟计算结果是比较准确的。

4.2 负荷变化对温度场的影响

负荷是随时变化的,当负荷降到一定程度时,需停运燃烧器。为了满足调峰的需要和负荷要求,本文对称停运燃烧器及不对称停运燃烧器对炉内燃烧过程的影响进行分析。

图4所示为不同负荷(600,450和300 MW)时炉膛中心截面处的温度场分布,其中,图4(a)所示为实际工况(即工况1,负荷为600 MW)在炉膛中心截面处温度场分布。从图4(a)可以看出:温度整体上都呈“W”型分布,对称性较好,但温度场稍向后墙偏斜;下炉膛中心区域温度仅为1 900 K左右,而下炉膛中心两侧区域火焰温度达到2 200 K,为温度最高区域;温度在下炉膛呈两侧高中间低的分布特点,这是由喷入煤粉浓度和氧量决定的,在“W”型火焰锅炉中,这对无烟煤的着火及稳定燃烧十分有利;在上炉膛,左、右两侧水冷壁的吸热温度呈中间高两侧低的分布趋势;沿炉高方向,温度先升高,温度在主燃烧区域达到最高,进入上炉膛后,由于水冷壁吸热,温度逐渐降低。

图4(b)所示为工况2(负荷为450 MW)在炉膛中心截面处温度场分布。由于停运了1台磨煤机,炉内温度场分布极不对称,在下炉膛,后墙火焰成为主导火焰,高温火焰对冷灰斗处的受热面冲击严重;在上下炉膛“缩颈”处,高温火焰对前墙折角处水冷壁冲刷严重,可能造成水冷壁的爆管和结渣,这是前、后拱上的煤粉没有在下炉膛中心区域得到有效碰撞所致;此外,后拱气流直接冲刷前墙冷灰斗,可能造成冷灰斗的爆管与结渣,也导致从前拱送入煤粉在炉内停留时间减少,飞灰中含碳量上升,也会使过热器减温水量增加,容易引起过热器超温爆管,不但影响锅炉运行的经济性,也威胁到锅炉的安全运行。

图4 不同负荷时炉膛中心截面处的温度场分布

Fig. 4 Furnace center section temperature fields distribution of different loads

图4(c)所示为工况3(负荷为300 MW)在炉膛中心截面处温度场分布。从图4(c)可见:温度场也呈现明显的“W”形状;由于停运了2台磨煤机,前、后拱上燃烧器一一对应停运,炉内温度场对称性较好。与工况1的温度场相比,高温区域明显减少,火焰中心明显下移,这可能造成高温火焰直接冲刷冷灰斗,导致冷灰斗处受热面爆管;此外,也可能导致煤粉直接冲向冷灰斗不能折转向上,影响锅炉运行的经济效果。

4.3 不同负荷和不同配风方式对水平截面平均温度的影响

图5所示为工况1、工况2和工况3(负荷分别为600,450和300 MW)下沿炉膛高度方向上水平截面的平均温度分布变化曲线。从图5可以看出:随着高度的变化,3种工况的炉膛水平截面平均温度总体上都呈先变高后变低再升高再变低的变化趋势。对比图5中3种工况截面平均温度可以看出:工况1、工况3和工况2在冷灰斗区域截面平均温度依次升高,但相差不大。这主要是由于工况1中拱上气流转向比工况3的早,整体火焰中心较高;而工况2中由于拱上燃烧器不对称停运,燃烧器开启的一侧气流阻力小,下冲距离最大,煤粉下冲距离大,火焰中心最低。在上炉膛区域,由于工况1、工况2和工况3的燃煤量及风量依次减少,所以,上炉膛截面平均温度依次降低。在实际运行过程中,由于调峰需要,锅炉负荷变化频繁,可能导致炉内局部受热面因温度梯度过大而爆管。

图5 炉膛高度方向上不同负荷水平截面平均温度分布

Fig. 5 Average temperature of horizontal section of different loads in furnace height

4.4 相同配风情况下煤种不同对温度场的影响

在锅炉运行过程中,燃用煤种经常变动频繁。煤种是影响燃烧的一个重要因素,计算时保持配风方式不变,只改变煤种。

图6所示为工况4和工况5下沿炉宽方向不同截面温度场分布。从图6可见:其温度场分布与工况1的温度场分布基本相同,但也有细微差别;工况4下炉膛火焰充满度明显比工况1的低;在上炉膛燃烧区域,工况4的火焰细而长,这是因为3种煤的挥发分质量分数相差无几,但是煤种2的灰分质量分数最高,氧扩散率小,着火慢且燃烬时间长;工况5在上炉膛温度比工况1和工况4的高,而下炉膛温度稍低于工况1的温度,这是由于煤种3的灰分质量分数最低,氧扩散率大,着火快,煤粉没有下冲到理想的深度就已燃烬,使得火焰中心上移,下炉膛温度要比工况1的低,而上炉膛温度则比工况1的高。所以,煤种变化可导致炉内火焰中心随之改变。

图6 不同煤种时炉膛中心截面处的温度场分布

Fig. 6 Furnace center section temperature fields distribution of different coals

4.5 相同配风方式情况下煤种不同对水平截面平均温度的影响

图7所示为沿炉膛高度方向上不同煤种时水平截面平均温度分布曲线。从图7可以看出:3种工况下沿炉膛高度方向分布趋势基本相同,总体上都呈先变高后变低再升高再变低的变化趋势。

图7 不同煤种时沿炉膛高度方向上水平截面平均温度分布

Fig. 7 Average temperature of horizontal section of different coals in furnace height

对比3种工况可知:工况1的截面平均温度总体上要比工况4的高,尤其是在下炉膛区域,温度最大相差达到150 K左右;而工况5相对于工况1和工况4而言,下炉膛温度低,上炉膛温度高;在工况5中,下炉膛温度过低可导致燃烧不稳,严重时可导致锅炉熄火,而上炉膛温度较高会使过热器超温,导致减温水量增加,影响锅炉运行的安全性和经济性。对于“W”型火焰锅炉,下炉膛火焰区域温度对于锅炉的稳定着火有着非常重要的作用,可以看出工况1稳定燃烧能力要稍比工况4和和工况5的强。由此可知:煤种变化对炉内燃烧过程影响巨大,在实际运行过程中,煤种不可能保持单一,有时甚至偏离较远,这有可能导致炉内燃烧脉动,使得炉内温度梯度增加或局部温度偏高,造成受热面爆管。

5 结论

(1) 锅炉在运行过程中,由于磨煤机停运,炉内速度场、温度场对称性较差,火焰冲刷后前墙水冷壁严重,可能导致受热面爆管。

(2) 当前、后拱上燃烧器对称停运时,炉内速度场、温度场对称较好,但火焰中心降低,高温火焰直接冲刷冷灰斗受热面,可能导致其爆管。

(3) 当煤种不同时,炉内速度场分布与实际工况速度场基本相同,温度场分布也基本相同,但火焰中心会随煤种的变化而变化。而在实际运行过程中,燃用煤种不可能保持单一,有时甚至偏离很大,这样可能导致炉内燃烧出现脉动,可引起受热面爆管。

参考文献:

[1] 王为术, 毕勤成, 朱晓静. 直流锅炉水冷壁热敏感性的研究[J]. 动力工程, 2009, 29(6): 522-527.

WANG Weishu, BI Qincheng, ZHU Xiaojing. Study on thermal sensitivity of waterwall in once-through boiler[J]. Journal of Power Engineering, 2009, 29(6): 522-527.

[2] 付文华. “W”型火焰锅炉屏过爆管原因分析及对策[J]. 电力学报, 2010, 25(6): 504-506.

FU Wenhua. The analysis and countermeasures for the pipe explosion of w type flame boiler platens[J]. Journal of Electric Power, 2010, 25(6): 504-506.

[3] 王为术, 朱晓静, 毕勤成, 等. 超临界 W 型火焰锅炉垂直水冷壁低质量流速条件下热敏感性研究[J]. 中国电机工程学报, 2010, 30(20): 15-21.

WANG Weishu, ZHU Xiaojing, BI Qincheng, et al. Study on thermal sensitivity characteristics of vertical membrane water wall in supercritical pressure w shaped flame boiler[J]. Proceedings of the CSEE, 2010, 30(20): 15-21.

[4] 申春梅, 孙锐, 吴少华. 1 GW单炉膛双切圆炉内煤粉燃烧过程的数值模拟[J]. 中国电机工程学报, 2006, 26(15): 51-57.

SHEN Chunmei, SUN Rui, WU Shaohua. Numerical simulation of pulverized coal combustion in a 1 GW dual circle tangential firing single chamber boiler[J]. Proceedings of the CSEE, 2006, 26(15): 51-57.

[5] 潘维, 池作和, 斯东波. 200 MW四角切圆燃烧锅炉改造工况数值模拟[J]. 中国电机工程学报, 2005, 25(8): 110-115.

PAN Wei, CHI Zuohe, SI Dongbo, et al. Numerical simulation of combustion process in a 200 MW tangentially fired furnace to study furnace reconstruction[J]. Proceedings of the CSEE, 2005, 25(8): 110-115.

[6] 刘泰生, 周武, 叶恩清. 燃尽风对炉内流动和燃烧过程影响的数值模拟[J]. 动力工程, 2006, 26(1): 116-120.

LIU Taisheng, ZHOU Wu, YE Enqing. Numerical simulation of the effect of over-fire air on flow and combustion in furnaces[J]. Journal of Power Engineering, 2006, 26(1): 116-120.

[7] 方庆艳, 周怀春, 汪华剑, 等. 3种型号W火焰锅炉结渣特性的数值模拟[J]. 动力工程, 2008, 28(5): 657-663.

FANG Qingyan, ZHOU Huaichun, WANG Huajian, et al. Numerical simulations of the slagging characteristics in three types of W-flame boiler[J]. Journal of Power Engineering, 2008, 28(5): 657-663.

[8] Luis I D, Cristobal C, Antonio C. Modeling of pulverized coal boilers: Review and validation of on-line simulation techniques[J]. Progress in Energy and Combustion Science, 2005, 25(10): 1516-1533.

[9] 李芳芹, 魏敦崧, 马京程, 等. 燃煤锅炉空气分级燃烧降低 NOx排放的数值模拟[J]. 燃料化学学报, 2004, 32(5): 537-541.

LI Fangqin, WEI Dunsong, MA Jingcheng, et al. Numerical simulation of low-NOx emission in a coal-fired utility boiler with staged-air combustion[J]. Journal of Fuel Chemistry and Technology, 2004, 32(5): 537-541.

[10] 周武, 庄正宁, 刘泰生, 等. 切向燃烧锅炉炉膛结渣问题的研究[J]. 中国电机工程学报, 2005, 25(4): 131-135.

ZHOU Wu, ZHUANG Zhengning, LIU Taisheng, et al. Study on slagging problem in the furnace of a tangential fired boiler[J]. Proceedings of the CSEE, 2005, 25(4): 131-135.

[11] 庞力平, 孙保民, Salcudean M E. 电站锅炉受热面高温积灰的数值模拟[J]. 中国电机工程学报, 2004, 24(10): 219-223.

PANG Liping, SUN Baomin, Salcudean M E. Using CFD to simulate heater fouling in a utility boiler[J]. Proceedings of the CSEE, 2004, 24(10): 219-223.

[12] YIN Chungen, Caillat S, Harison J L, et al. Investigation of the flow, Combustion, heat-transfer and emissions from a 609 MW utility tangentially fired pulverized coal boiler[J]. Fuel, 2002, 81(8): 997-1006.

[13] Pallarés J, Arauzo I, Williams A. Integration of CFD codes and advanced combustion models for quantitative burnout determination[J]. Fuel, 2007, 86(15): 2283-2290.

[14] 湛志钢, 方庆艳. W火焰锅炉结渣特性的数值模拟研究[J]. 电站系统工程, 2006, 22(1): 30-32.

ZHAN Zhigang, FANG Qingyan. Numerical simulation on the characteristics of slagging in a W-flame boiler[J]. Power System Engineering, 2006, 22(1): 30-32.

(编辑 陈灿华)

收稿日期:2012-10-12;修回日期:2013-01-21

基金项目:国家自然科学基金资助项目(51276023);国家自然科学基金国际(地区)合作与交流项目(51310105026);教育部归国留学基金资助项目(2011-508)

通信作者:曹小玲(1974-),男,湖南郴州人,博士,副教授,硕士研究生导师,从事燃烧理论与低劣煤的高效稳燃技术;电话:15973111541;E-mail:xiaolingcao3258@gmail.com